Switching signals reliably – in the tightest of spaces Relay systems from Phoenix Contact form a powerful and reliable interface between control and system peripherals.

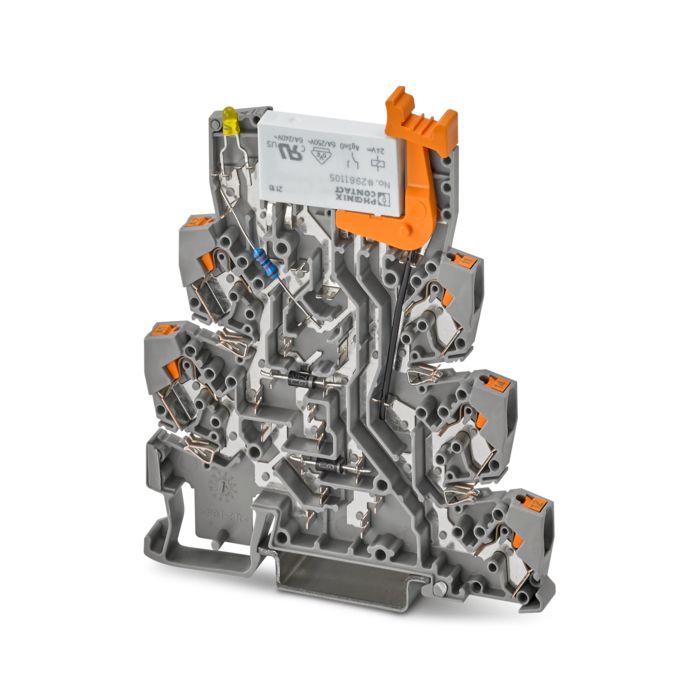

The lead-frame technology in the PLC-INTERFACE relay series provides the solid foundation for reliably switching, isolating, and amplifying signals. In addition, electromechanical and solid-state relays are used – this combination proves itself day after day in millions of switching operations and in relay switching.

Innovation, passion, and pioneering spirit

In 1996, Phoenix Contact set a milestone in relay technology: Lead-frame technology was integrated for the first time into relay modules with an overall width of 6.2 mm. To date, this is unique on the market.

Lead-frame technology Your advantages:

Lead-frame technology enables:

- Pressed-in electronic components such as diodes, RC combinations, and LEDs for integrated functional and protective circuits directly in the relay base

- Optimized thermal management reduces localized heating and extends the service life of electronics components

- Proven technology for highly compact relay systems

- Sustainable construction with easily separable construction elements

- Easy wiring with Push-in and screw connection technology

Relay trends

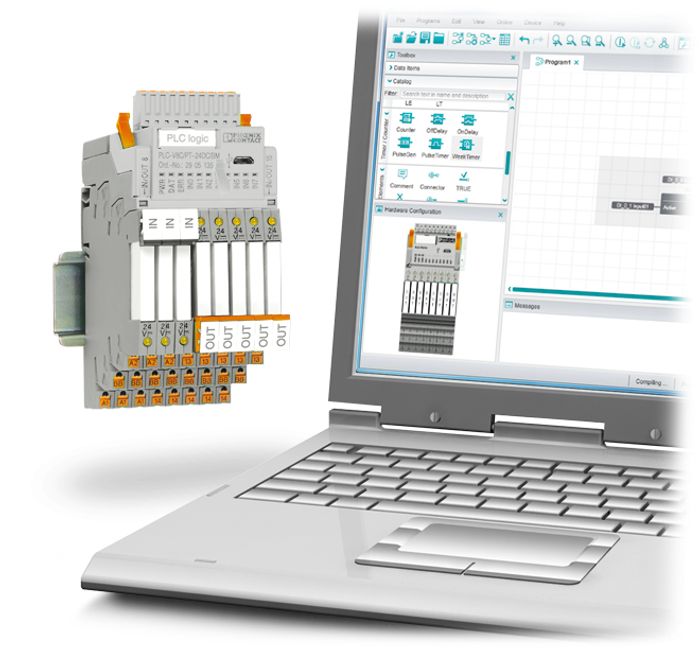

Digitalization and networking combined with space savings and optimized switching behavior for high availability: These are trends that Phoenix Contact already provides as standard with the PLC-INTERFACE modular relay series. The product portfolio is intended for special applications as well as all common applications in all industries.

- Highly compact relay systems with easy handling and integrated functions through to error-free connection to controllers via system cabling

- Electromechanical and solid-state relays are combined to form hybrid switching devices

- Force-guided relays for high reliability

- DC relays with high switching currents as required for LED lighting and charging units

- Simple extension of the PLC relay series up to the PLC logic module with integration into networks

- Digitalization of relays as well as configuration and access via app

Production of PLC relay modules with lead-frame technology Quality down to the smallest detail

It is only when you keep sight of every little detail that you can be sure of the quality. We produce items that later form the basis for high-quality components in our own plastic, and metal production facilities.

It goes without saying that every product undergoes a 100% inspection.

Phoenix Contact relies on in-house experience and expertise in a range of contexts. Innovative product ideas are continuously being implemented in the design and development departments.