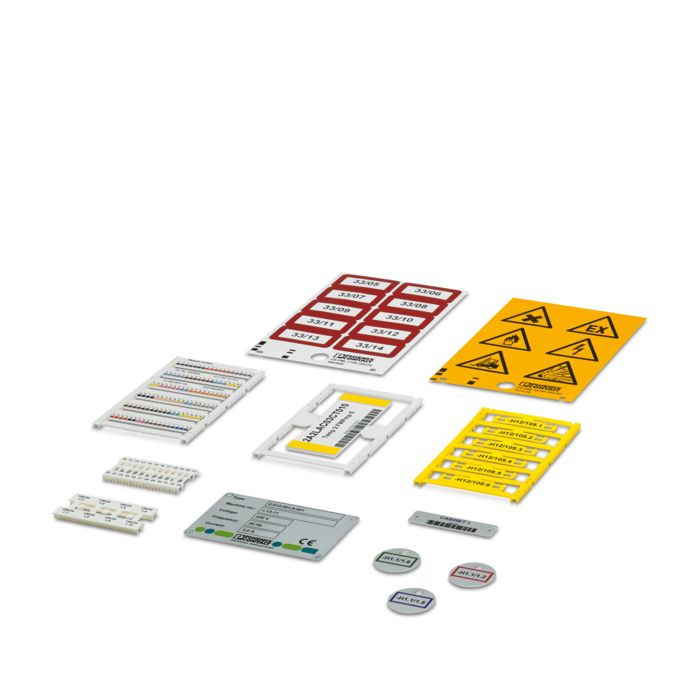

Marking material for industrial identification The right material for every printing process – Digital printing can be used to mark a wide range of materials. Ready-to-use card materials made from plastic, plastic and metal labels, and sleeve materials are all widely used.

Marking material

Material properties

In order to produce an optimum print image, the process parameters for marking must be tailored to the relevant material properties.

The surface quality is a deciding factor here. It must be appropriate for the printing process and print medium.

To this end, different surface refinement techniques are used so that the quality of markings on a range of materials can still be guaranteed.

Overview of marking materials

Today, all branches of industry are under increasing cost pressure. For this reason, companies are always looking for new ways to save money. This also applies to marking – clear and permanent marking saves time and money.

Metal

The biggest advantages of metal labels are their resistance and durability. Unlike the majority of plastics, metal materials can be used even in the harshest ambient conditions. This means that these materials are increasingly used in industrial environments, for example as rating plates in machine, controller, and systems manufacturing.

Phoenix Contact offers marking material made from metal for conductor and cable marking, for snapping into carriers, as well as materials with a self-adhesive film that is also suitable for rough surfaces.

Polyamide (PA)

Even at high operating temperatures, polyamide has excellent electrical, mechanical, chemical, and thermal properties. Brief peak temperatures of up to +200°C are permitted as a result of heat aging stabilization.

Polyamide absorbs moisture from its surroundings, on average 2.8%. This moisture is not crystallization water in the plastic itself, but chemically bonded H2O groups in the molecular structure. This makes the plastic flexible and resistant to breakage, even at temperatures as low as -60°C.

Flammability rating V2 to V0 (in accordance with UL 94)

Free from silicone and halogen

Temperature range: From -60°C to +125°C

Polycarbonate (PC)

Polycarbonate is characterized by its high mechanical strength and chemical resistance. Other properties of this material include rigidity, dimensional stability, and good heat distortion resistance. Polycarbonate is used to manufacture particularly smooth and stable marking materials.

Low moisture absorption

Free from silicone and halogen

Temperature range: From -40°C to +125°C

Polyvinyl chloride (PVC)

PVC has a long service life. It is characterized in particular by its outstanding mechanical strength and high chemical resistance. PVC is unaffected by oxygen and ozone. The material is resistant to corrosive salt solutions and most acids.

Free from silicone

Temperature range: From -30°C to +80°C

Polyester

Polyester is resistant to chemicals. It is ideally suited to printing, shaping, and punching. Polyester is resistant to UV radiation and absorbs little moisture.

Free from silicone and halogen

Temperature range: From -40°C to +150°C (depending on composition)

Polyethylene (PE)

Polyethylene is a thermoplastic material which is highly resistant to acids, lyes, and other solvents. PE absorbs hardly any moisture and has high durability and breaking elongation.

Free from silicone and halogen

Temperature range: -40°C to +80°C

Polyolefins

Polyolefins are semi-crystalline thermoplastics, which can be easily processed as extrusion profiles (shrink sleeves). They are characterized by good chemical resistance.

Free from silicone

Temperature range: -55°C to +125°C