Solder connection Solder connection is a globally proven standard connection technology for various litz wires.

Your advantages

- Quick connection due to the simple process

- Ideal for connecting litz wires on site

- Easy mounting, no special tools required

The solder connection in detail

The soldering process produces a material-to-material bond between a base material and a metallic filler material (solder). The process is very simple, because only the solder and a soldering iron are needed.

Wave soldering is the traditional mounting method for all push-through components on the PCB. The method is described in detail in standards; for lead-free processes, the process requirements have been redefined.

The trend toward SMD components (surface mount devices) continues unabated. Production on SMT lines is an alternative due to the use of cost-effective, fully automated processes with regard to solder paste printing, component assembly, and soldering.

Our portfolio with solder connection

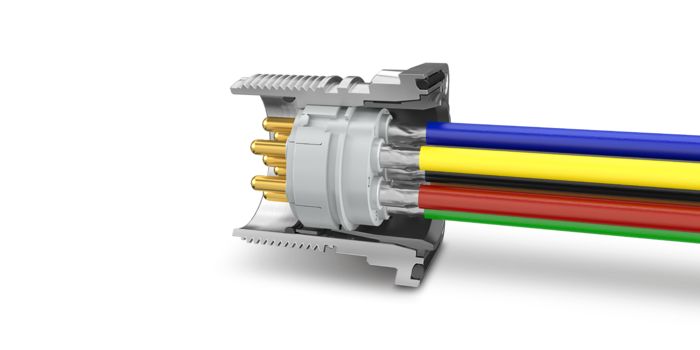

M23 circular connectors

M23 circular connectors with solder connection are suitable for litz-wire connection on site, also in the case of repairs. The connectors are suitable for signal transmission for voltages up to 48 V AC and for currents up to 20 A. Cable, coupling, and device connectors are available for front and rear mounting.

As a version with solder-in connection, device connectors can be soldered directly onto a PCB. The M23 signal connectors are available as male or female versions with numbers of positions from 6 to 19.

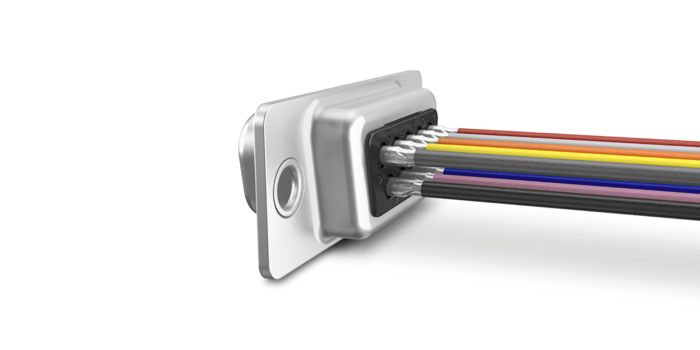

D-SUB connectors

D-SUB connectors with solder cup are suitable for conductors up to 0.5 mm². The connectors are available in 3 shell sizes with numbers of positions from 9 to 25 and enable a very compact conductor connection in a small space.