Valve monitoring Easily transmit valve position information to your control system wirelessly and in real time.

The challenge

Monitoring manual valves

Manual valves come in high numbers in process plants. They meter and control liquids, air, or gases. Depending on the production step, manual valves have to be set to the correct position by plant personnel, especially in existing installations. Using checklists, employees go round the expansive plants and prepare for the startup, flushing, or cleaning of the production plant. Incorrect operation can result in production stoppages or major accidents. The open/close position of manual valves can be monitored easily to prevent such incorrect operation.

The solution

Collect data from the Ex area using the intrinsically safe I/O system

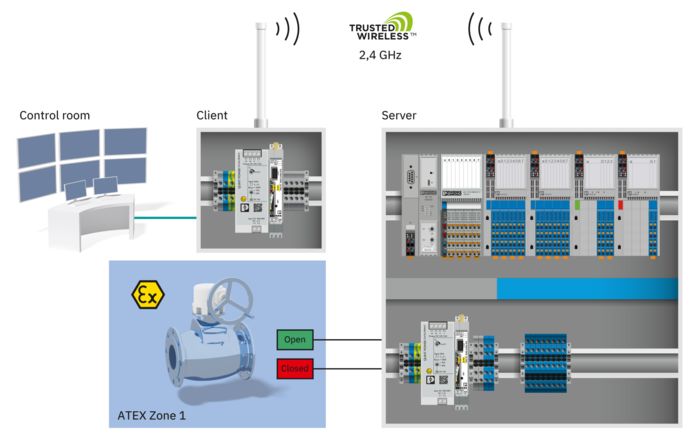

The example architecture shows a valve monitoring system based on decentral substations for acquiring the signals in zone 0 or 1. The structure of a local substation (server station) consists of the power supply, the wireless module, and the intrinsically safe input modules. The number of I/O modules is defined by the application. The system is modular. Extension via the local bus is possible.

Improved intervention options

Retrofitting NAMUR limit switches and the transmission of I/O information to the control system make it possible to use software interlocks. Benefit from our preassembled control box. This gives you a continuous overview of the valve positions in the control room and, at the same time, optimum sensor diagnostics, including the cabling.

Extend the solution with various types of signals. These include, for example, temperatures, pressure values, and flow rates.

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.