Functional safety for group switch-off in three-phase motors Functional safety is a particularly important topic in machine building and plant engineering. It prevents exposing personnel to hazards as well as damage to systems and machines. Groups of three-phase motors are frequently used in various real-world applications. Simple realization of solutions with functional safety is essential here for safe and cost-effective operation.

Application

Easy group switch-off and high system availability

- Reliable and simple group switch-off to protect your personnel and your machines and systems

- High system availability, thanks to 10 times longer service life with hybrid technology

- Safe shutdown with integrated safety function up to SIL 3 and PL e

Our solution

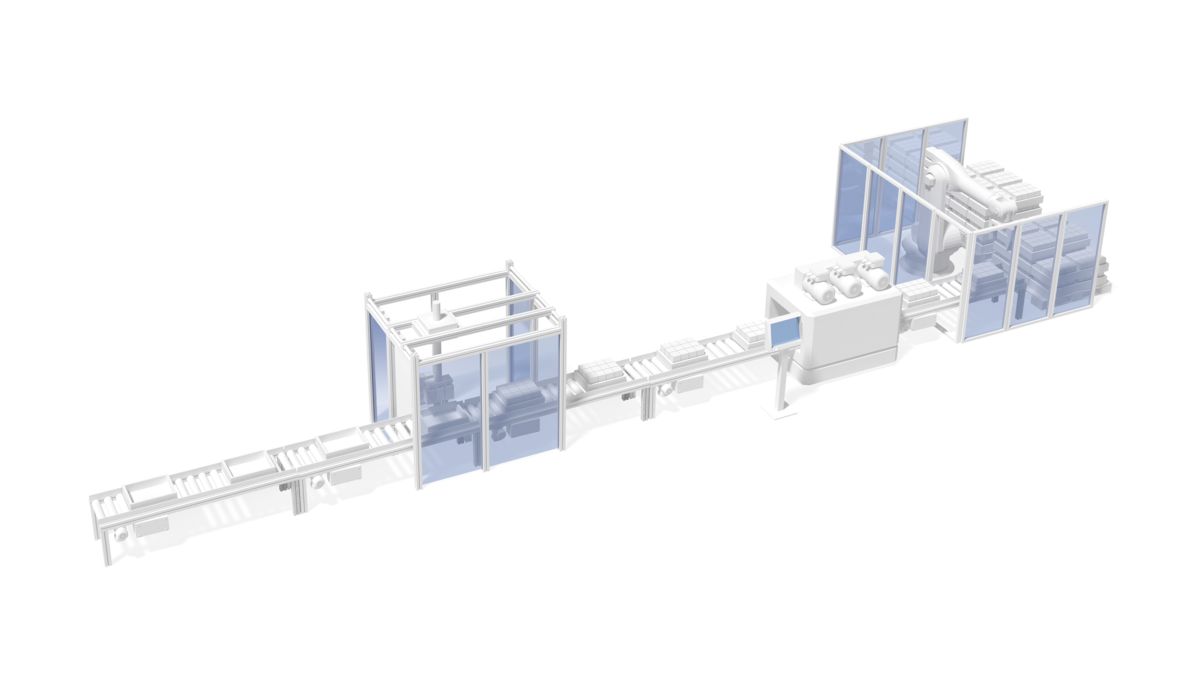

Functional safety for three-phase motors: Application illustration

Simplicity in functional safety

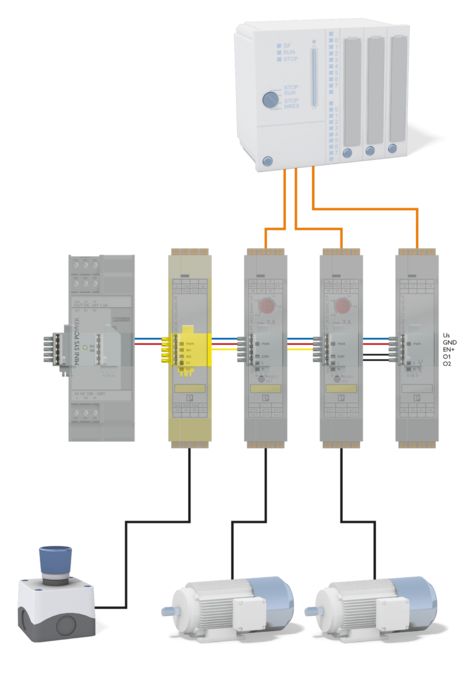

Using the DIN rail connector, you can perform an emergency stop group switch-off of all the downstream hybrid motor starters without the need for additional wiring.

In addition, all modules can be supplied from the system power supply. The optional response module makes it possible to easily monitor the motor status.

Longer service life with the CONTACTRON hybrid technology

The service life of the CONTACTRON hybrid motor starter is ten times higher than with conventional switching devices, which provides a significant advantage at high switching frequencies. This extends maintenance intervals and increases system availability.

Intelligent switching and safe shutdown of motor groups

Easy integration of safety technology in machine building

A high value is placed on safety technology in machine building. It prevents operating personnel from being put at risk or the machine from becoming damaged.

The EN ISO 13849-1 standard, which is designed to meet the Machinery Directive, has led not only to increased requirements for the implementation of safety functions, but also to new opportunities for you as a machine builder.