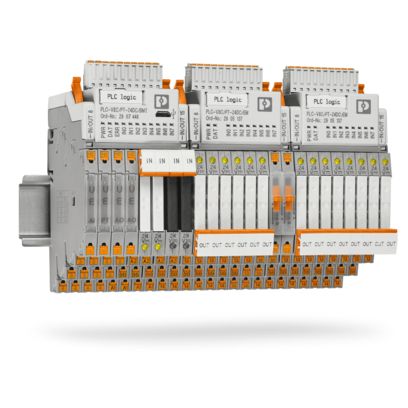

PLC logic basic module, Generation 2, with 16 I/Os, for plug-in connection to eight digital or analog PLC-INTERFACE terminal blocks, can be extended to 48 I/Os, real-time clock, micro USB female connector, accommodates memory module and Bluetooth adapter, Push-in connection