Shield connection in the field Would you like to find out more about our shielded connectors and cables? If so, just contact us!

Totally protected shielding

Advanced Shielding Technology

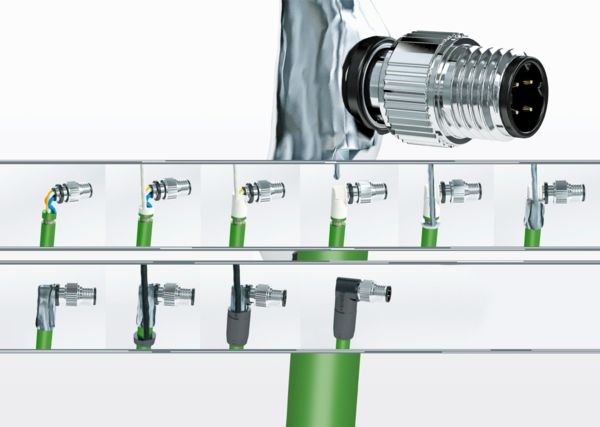

Advanced Shielding Technology from Phoenix Contact is the innovative shielding concept for sensor/actuator cabling. The large-area, material-bonding 360° shield connection is unique on the market and optimizes the current design of M8 and M12 connectors. Liquid metal that completely encloses the cable shielding during the manufacturing process guarantees a totally protected shield connection and thus enables the reliable and interference-free transmission of data, signals, and power in future factory automation.

Manufacturing processes with pre and metal-molding

Seamless shielding concept

Advanced Shielding Technology means totally protected shielding. Even when exposed to extreme environmental influences, such as high mechanical load or lightning strikes, the 360° shield connection protects your data, signal, and power transmission.

The pre-molding and metal molding performed during the innovative automated production process for assembled M8 and M12 connectors with Advanced Shielding Technology improves shielding performance.

The pre-molding of the base plate attached to the cable with polyamide provides exceptional mechanical stability in applications involving axial loads. The protected and reliable 360° shield connection is achieved thanks to tin which was developed specifically to meet the electrical and mechanical demands.

The large-area, complete bonding between the braided shield and connector also guarantees total EMC protection, optimum heat dissipation, and resistance to overvoltages and current peaks.

Advantages of Advanced Shielding Technology

Your advantages

- Reliable even when subjected to high levels of mechanical strain, such as shock and vibrations

- Resistant to transient overvoltages caused by the switching processes of inductive loads

- Minimal generation of heat and secure current flow in the event of a short circuit

- Future-proof transmission of high data volumes and continuously increasing transmission rates in environments subject to high levels of electromagnetic interference

- Robust even when exposed to extreme environmental influences such as a lightning strike

Reliable in the field

Safeguard the operation of your systems: We provide you with comprehensive solutions for the connection of sensors and actuators. Whether for standard applications, cabling in complex industries, or special applications.

Shielded sensor/actuator cabling

Shielded sensor/actuator cabling

In systems that are particularly susceptible to interference or subject to severe interference, it may be necessary to shield all signal lines, connectors, devices, and control cabinets. Sensor/actuator cables are particularly susceptible here, as they are distributed over a large area of a production plant and therefore inevitably have to be led past sources of interference. One example of this is a robot-operated welding unit in the automotive industry. High welding currents that are switched on and off at short intervals generate a combination of different and very severe types of interference. To ensure interference-free operation in this type of environment, signal lines, sensors/actuators, and indeed the cabling for the necessary sensor/actuator boxes should always be shielded. This is because it is precisely these components that are connected to controllers that are particularly susceptible to interference.

M12 connectors with Push-Lock connection

Shielded M12 connectors designed for assembly

M12 connectors designed for assembly with Push-Lock connection deliver easy, tool-free assembly of rigid, pre-treated conductors. The clamping chambers are opened and closed easily via a lever. This means that users have both hands free to insert the conductor, and installation is greatly simplified. The long-term stability and vibration-resistance of the PE and shield connection ensure the safe, reliable operation of your system.

Compatible insertion, flexible combination

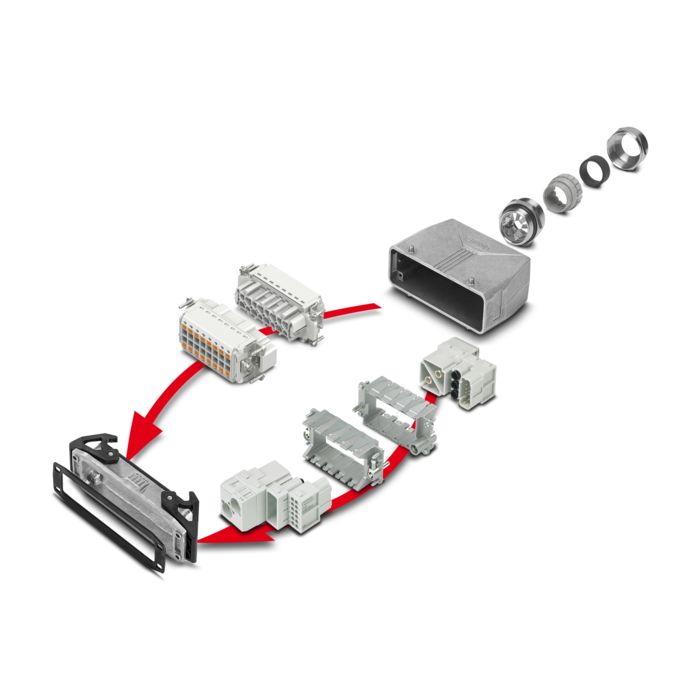

HEAVYCON heavy-duty connectors protect your interfaces and also ensure the reliable transmission of power, data, and signals even under harsh conditions.

All metal housings are EMC-ready, thanks to conductive surfaces and seals. They are resistant to vibrations, high mechanical stress, and are sealed up to IP69K degree of protection.

Reliable protection from the field to the inside of the control cabinet with HEAVYCON industrial connectors

Shielded, heavy-duty connectors

The measures considered thus far for shield connection using shield clamps are only suitable for discharging interference that is “collected” on the installation route. The control cabinet with the shield connection point is located in an area with low or zero interference. If a shielded cable is to be led into a control cabinet or device that is itself subject to severe interference, a different approach is needed. In this case, it is not just the cables, but the entire control cabinet that needs to be shielded. Just as with cables and lines, the aim here is to achieve the most sealed, closed coverage possible. The starting point for this is a metal housing or a control cabinet developed specifically for EMC applications. Of course, cable entries and connectors must not create new gaps in the otherwise-closed shielding system. This is why appropriate connectors have been developed for shielded cables, which connect the closed cable shielding to the control cabinet panel or the device via their housing. This makes both the construction and the connection of the connector more complicated. However, both pay off later when interference-free system operation is achieved.

Shielded, HEAVYCON heavy-duty connector

Construction of a shielded, heavy-duty connector

The housing is a crucial component of a shielded connector. The metal housings of our heavy-duty industrial connectors are made from high-quality and corrosion-resistant die-cast aluminum. With their conductive surfaces and seals, they provide reliable EMC protection. The cable shielding is connected to the housing using cable glands made from nickel-plated brass. The EMC inserts of the cable glands are positioned above the cable shield during installation. As a result, the contact springs establish a secure connection between the connector and cable shield. With this construction, the connector creates an uninterrupted and fully enclosed transition between the cable shielding and the shielded housing.