Digital oil field Benefit from the capabilities of the digital oil field for optimizing your production operations. Find out more in the white paper about our robust all-in-one solution for monitoring your production sites reliably and cost-effectively, even over long distances.

The challenge

Optimization of production operations

In many onshore oilfields, data acquisition is done by employees who go out into the oilfields and write down information such as flow rate, pressure, and temperature on their clipboards. These notes are later manually merged into Excel spreadsheets. In times of low crude oil prices, reducing costs and increasing efficiency – in particular on the upstream side – are of crucial importance. One way to do this is to digitalize oilfields. This enables data acquisition on oil rigs and consolidating the data from complete oil fields. Alongside monitoring, you can also use this approach to control equipment and systems in the oil field, such as emergency switch-off units and injection pumps.

The solution

Automation increases quality and efficiency

The step from continuous data acquisition to higher automation is not a huge one. In the oil gathering centers, for example, it is possible to set the contractually agreed API grade (American Petroleum Institute grade) by controlling the pumps and control valves in the supplying pipelines. Separators for the separation of water can also be operated and monitored automatically. Controlling water or gas injection systems prevents a decrease in oil delivery pressure during the oil recovery process.

Open, digital solutions to increase competitiveness

Future-proof technologies play a central role in converting long-standing production sites into a digital oilfield.We are actively involved in helping to shape open, flexible solutions such as NAMUR Open Architecture (NOA) and Open Process Automation (OPA). In particular, our open Linux-based PLCnext Technology control platform enables state-of-the-art automation tailored to the requirements and potentials of Industry 4.0. Global oilfield operators are already taking advantage of the Open Process Automation (OPA) concept. A Distributed Control Node (DCN) enables the extension of existing systems, which allows the implementation of OT services, such as advanced control or process optimization.

From condition diagnostics to increased overall plant effectiveness

In addition to process data, we enable you to record and evaluate status information provided by digital field devices and intelligent pumps and compressors. Based on this, various Industry 4.0 use cases can be realized, such as the transition from reactive or preventive maintenance to predictive maintenance. As a result, you save resources and replacement parts. You also get an increase in equipment availability and reduced downtimes.

Real-time diagnostics and the resulting Industry 4.0 applications, which are based on the integration of different data silos, enable processes to be improved in the sense of operational excellence. Derive trends by visualizing and contextualizing the data. You can also optimize business performance metrics such as overall asset effectiveness.

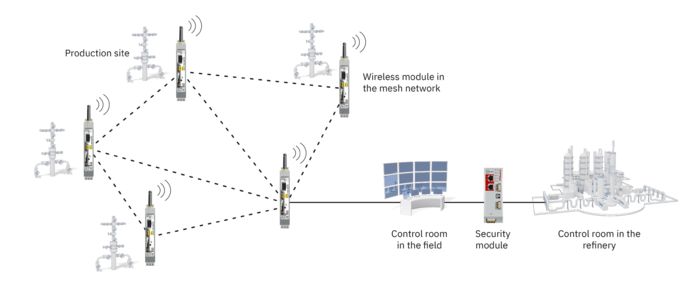

Wireless measurement data transmission

Production sites often constitute an extensive and widely branched network. For reliable data transmission over many kilometers, you will find communication solutions based on various wireless technologies as well as Ethernet communication over existing 2-wire cables by using SHDSL technology.

In wireless technology, both 4G and 5G solutions and the specialized wireless solution Radioline are used. This also allows fast setup of mesh networks, directly on the device using a thumbwheel or USB stick. In the event of a fault, failure of a wireless module is compensated immediately.

Utilizing advantages of the digital oilfield

- Reliable and cost-efficient monitoring and diagnostics of oil and gas production sites over large distances

- Secure communication due to encryption technology suitable for many transmission paths

- Efficient and cost-saving maintenance with concepts for mobile or distributed system access

Contact person

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.