OPC UA OPC UA already serves as a manufacturer-independent, Ethernet-based communication standard in many systems. With OPC UA FX (Field eXchange), this standard is now being developed further for direct field communication and will enable uniform communication from the field to the cloud in the future. OPC UA FX is therefore one of the key communication protocols for Industry 4.0 and the IoT.

What does OPC UA mean?

“Open Platform Communications Unified Architecture” (OPC UA for short) is a platform-independent communication standard that was published by the OPC Foundation in 2008. The standard is internationally standardized in IEC 62541 and is supported worldwide by automation suppliers for hardware and software.

OPC UA not only describes a communication protocol, but also the semantics of the transmitted objects. This standardizes access to all systems in industrial environments and enables manufacturer-independent data exchange between machines.

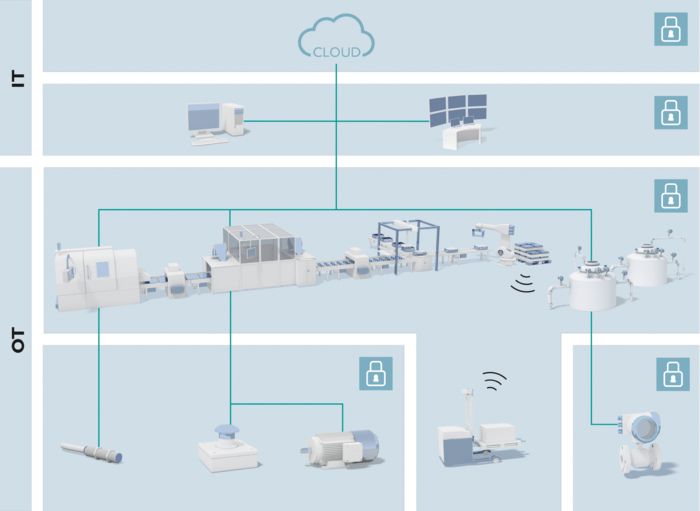

OPC UA FX: Uniform communication from the field to the cloud

OPC UA FX (Field eXchange)

OPC UA FX is an OPC UA specification that is being developed in the “Field Level Communications Initiative”. This means that the standard, which was previously only used on higher-level communication layers, can now be used right through to field level. This enables the cross-manufacturer exchange of process and configuration data between automation components at field level.

To do this, OPC UA FX extends the existing protocol with various application profiles for factory and process automation, e.g., I/O, safety, or motion. Furthermore, standardized device models are defined for the uniform configuration and diagnostics of devices in the network. The conformity tests necessary for a high degree of compatibility are also described. Taken together, this will enable the widespread connection of field devices to the cloud in the future, thereby permitting the consistent connection of IT and OT.

The key features of OPC UA

Communication mechanisms

For a long time, the topic of OPC UA took the form of client/server technology. However, this approach is limited, especially in cloud scenarios. That’s why OPC UA 2018 was extended to include connectionless communication via the OPC UA PubSub specification. Client/server and PubSub use the information from the same namespace. Both approaches can be used simultaneously in a network as well as in a device.

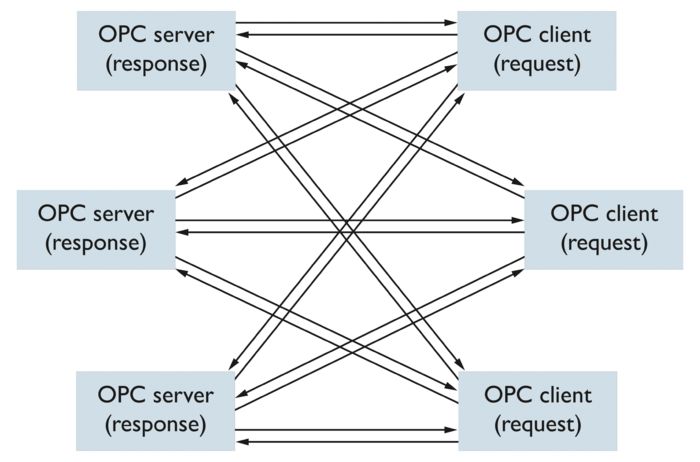

In the case of client/server communication, a client requests information and receives a response from a server.

OPC UA with client/server communication

OPC UA with client/server communication is widely used in automation. In this proven communication mechanism, each OPC UA client receives access to the data of the OPC UA server via point-to-point communication. The OPC UA server thus forms the basis of OPC communication by processing the client’s requests and then sending back a response. The OPC client is therefore the logical counterpart to the OPC server that establishes the communication sessions. In general, client/server communication can reach its limits when the network contains many devices.

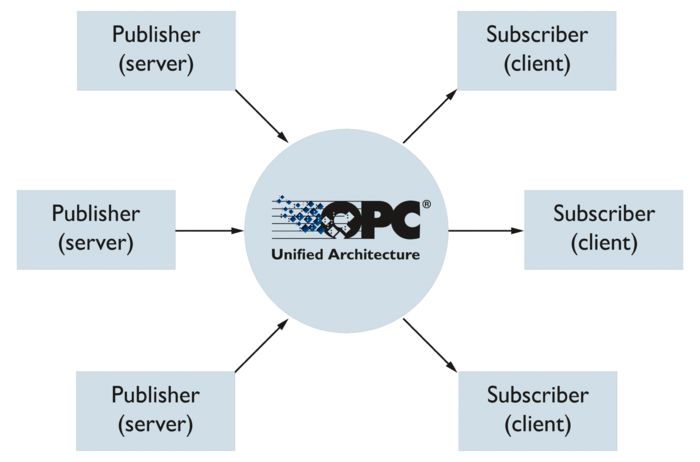

In the case of PubSub communication, a server sends its data to the network (Publish). Each client can receive this data (Subscribe).

OPC UA with PubSub communication

In the case of OPC UA with the PubSub model, communication is connectionless and unconfirmed. PubSub stands for Publish and Subscribe, because the server can send its data to the network (Publish), so that every client can receive this data (Subscribe). In order to be able to encrypt and decrypt the data, both communication partners must have the same security credentials. Either one publisher provides data that is received by any number of subscribers in the network, or many publishers send information to one subscriber. This makes OPC UA PubSub particularly suitable for direct IoT communication or for fast cyclic processes at field level.

OPC UA PubSub and TSN enable real-time-capable communication at control and device level.

OPC UA and Time-Sensitive Networking

In combination with Time-Sensitive Networking (TSN), OPC UA PubSub enables real-time-capable communication at control and device level. OPC UA PubSub meets the requirement of time-critical applications with high synchronism, determinism, and convergence. Time synchronization and data prioritization ensure that IT and OT communication do not influence each other in TSN-enabled networks.

OPC UA includes basic mechanisms for secure use of the architecture.

OPC UA and cybersecurity

As a central component of networking, OPC UA has numerous cybersecurity mechanisms built in. A special security layer defines the authentication of services and devices as well as the encryption, signing, and authentication of data via tokens, certificates, or the user and password. The roles and necessary security credentials can be managed centrally and distributed in a standardized way.

Our involvement in the OPC Foundation The standard for the future

In order to obtain a uniform, cross-manufacturer communication standard, Phoenix Contact and other companies support the OPC Foundation in its efforts to standardize OPC UA through to field level. As one of the driving forces behind this initiative, Phoenix Contact is an active member of various working groups within the OPC Foundation, and is thus helping to define the future standard for all devices in OT – from sensors and actuators through to controllers.

Other new communication technologies Consistent communication through to the field

New communication standards such as OPC UA, TSN, SPE, and 5G are currently being created by various committees and in standardization projects. However, these new technologies should not be considered independent of each other – rather, they will form the communication of the future together.

As a technology leader with more than 30 years of experience in industrial communication technology, Phoenix Contact is actively involved in all of the key standardization committees. In these committees, we are helping to shape the new, cross-manufacturer communication standard for automation.

Find out more about the new standards on our webpages.