Case studies Find out how our product solutions have helped customers overcome challenges.

Energy

Automation of a hydrogen energy storage solution from Endua

Endua required a reliable, scalable, and precise control and safety system for its hydrogen-powered energy storage systems. With a control solution based on PLCnext Control, including a safety system, Endua can increase its operational efficiency, save costs, and ensure a safe working environment.

Saving money and improving sustainability through energy monitoring

Phoenix Contact has installed energy-monitoring systems on three of the machines in its U.S. headquarters. Employees can use this data to make better decisions, which will improve operations, save money, and reduce energy usage.

Roaming HMI gives Lucky Peak technicians data when and where they need it

As part of a larger digitalization project, Lucky Peak worked with Phoenix Contact to develop a secure wireless network for their roaming human-machine interface (HMI) system. With the roaming HMI solution, the Lucky Peak staff has real-time visibility into all remote assets, ultimately making the plant more efficient, collaborative, and safe.

Building technology

How Infinity Panel Solutions keeps critical facilities running

Infinity Panel Solutions builds its panels to industrial standards to ensure reliability. Phoenix Contact components not only save them time and money, but meet the highest standards.

Thermodynamics at scale: How Energy IQ redefined comfort and efficiency in Times Square

Energy IQ created a building automation system to help the Marriott Marquis maximize energy efficiency. The hotel’s cogeneration plant relies on Phoenix Contact automation technology to ensure the speed, security, and reliability needed in a complex, dynamic environment.

Water purifying technology saves lives around the world

New Life International (NLI) developed a water purification system that provides clean water and later modified that system to produce medical-grade hypochlorous antiseptics. To automate these processes so they are available to more people in need, NLI relies on automation technology from Phoenix Contact.

Smart Ethernet Box reduces commissioning time for Power over Ethernet surveillance systems

When designing Power over Ethernet (PoE) control panels for surveillance systems, Accurate Controls spent significant time engineering and building the panels. Switching to the Smart Ethernet Box has greatly reduced Accurate Controls’ building and commissioning time.

Connectivity

Partners in sustainable production: SEL and Phoenix Contact share common values

Schweitzer Engineering Laboratories (SEL) has committed to keeping production close to its North American customer base. Like SEL, Phoenix Contact also prioritizes local manufacturing to better serve customers and improve sustainability. Through this trusting partnership,Phoenix Contact will develop new connector technologies to help SEL enhance grid resilience.

Vari-Lite lights up the entertainment world

When designing the latest generation of its RigSwitch+, Vari-Lite needed a flexible electronics housing solution that would make it easy to customize. The BC Housing from Phoenix Contact was easy to adapt, had numerous accessories available, and was available with custom printing.

Track your energy usage and maximize savings

With Phoenix Contact's PTSA terminal blocks, Elevation has reduced installation time and improved the overall quality of its Curb Energy Monitoring devices.

Lever terminal blocks solve design challenge and reduce costs

A water sterilizer company asked RLC Electronic Systems to design a new controller that would be easier to install. A previous version had lever-style terminal blocks that bumped into the enclosure wall. Phoenix Contact’s LPTA 2.5 terminal blocks eliminated this problem and reduced connectivity costs by about 30 percent.

ECI Cables finds the right tools for growth

Phoenix Contact introduced ECI Cables to a variety of hand tools and machines that make it easy to process large jobs.

Data centers

Wired for what matters

When choosing a partner, Custom Controls of Arizona looks for a company that shares its values of quality, integrity, and teamwork. Custom Controls of Arizona has trusted Phoenix Contact as a partner for more than 20 years.

Lighting control system slashes installation and commissioning time at hyperscale data center

NICOR developed the Illumination Management System (IMS), a low-voltage control system, for normal and emergency luminaires within a facility. The combination of NICOR’s custom coding and Phoenix Contact’s PLC hardware and DALI lighting control solution ensure simple user management for easy commissioning and control.

Factory automation

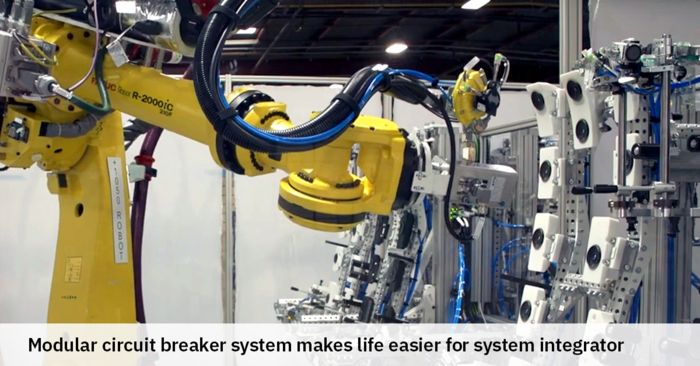

Modular circuit breaker system makes life easier for system integrator

In the past, ATN Hoelzel sometimes spent up to a day and a half wiring the I/O for its circuit breaker system. By switching to the Phoenix Contact CAPAROC electronic circuit breaker system, ATN saved significant time and space.

Making their mark: NSRW brings printing in-house to improve efficiency

NSRW brought labeling in-house with the Phoenix Contact TOPMARK NEO. The NEO and other Phoenix Contact products have helped improve efficiency and reduce delivery times.

Anomaly detection at automotive press shop: Efficient and resource-saving production

An international auto manufacturer used the Phoenix Contact Digital Factory now strategy to detect errors early in its pressing process. This approach minimizes downtime and ensures consistent product quality.

Audi uses PLCnext Technology for the sustainable production of electric cars

Phoenix Contact has supported Audi’s transition to greater sustainability by providing key technologies for electrification,networking, and automation, including PLCnext Technology.

Cobot makes manufacturing safer and more efficient at Phoenix Contact

Phoenix Contact added a cobot to its manufacturing floor. The new "coworker" improves the efficiency of packing boxes,while freeing workers to focus on more important tasks.

Infrastructure

Electronic monitoring system with plug-in timer modules

Geopraevent AG relies on Plug-in timer modules from the RIFLINE Complete family to create redundancy in its alarm systems.

Networking

Cleaner cabinets, quicker installation, and improved network reliability

System Concepts PLUS needed to redesign a control cabinet for a customer that manufactures floor materials. Phoenix Contact delivered a diverse range of competitively priced products, which reduced installation time and improved network reliability.

IIoT

Automation maximizes court time and profits for gymnasiums

Litania worked with Springfield Electric to develop the Powr-Touch 6, an intuitive system that lets a gym employee control multiple systems at one time. Thanks to reliable Phoenix Contact products, such as PLCnext Technology, the Powr-Touch 6 helps gym operators maximize court usage.

Agriculture

Creating organic fertilizer with cutting-edge plasma technology

Radom Corporation has found a unique way to create nitric acid by utilizing a microwave plasma process using only electricity,water, and air. Radom selected PLCnext Technology, which offers programming in high-level languages and can communicate with all the required industrial protocols.