Automatic tools and printing systems can be positioned on the surface of the worktop. Accessories such as sockets, storage shelves, or containers for storing excess materials can be attached directly to the system worktop when necessary.

The clipx WIRE assist worker assistance system enables efficient conductor processing. The software-supported system guides users through the process of semi-automated conductor processing, automatically controls the relevant output devices, and provides the necessary information based on CAE data.

Software dongle, for activating the clipx WIRE assist 1.x software license, USB version

Device carrier arm right, with clamping lever and device carrier rail, for accommodating up to 2 device carriers and additional storage units on the AS-WORKBENCH-F ...

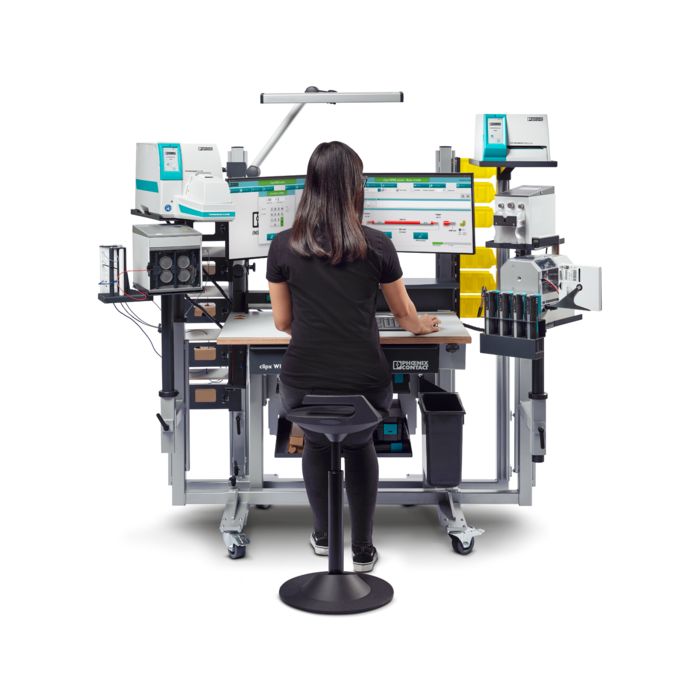

Mobile workbench, electrical height adjustment, modular extension with holder systems, device carriers, and shelves for automatic tools, printers, hand tools, and accessories, basis for the clipx WIRE assist and further workshop applications.

Storage shelf for materials or tools with suspension unit for attaching to the AS-WORKBENCH-F ...

Device carrier with locking ring for the height and angle-adjustable positioning of automatic tools on the AS-WORKBENCH-F ...

Wire guide for attaching to the device carrier for the automatic cutting tool for guiding a maximum of 16 conductors for the AS-WORKBENCH-F ...

Device carrier arm left-hand, with clamping lever and device carrier rail, for accommodating up to 2 device carriers and additional storage units on the AS-WORKBENCH-F ...

Device carrier with locking ring for the height and angle-adjustable positioning of automatic tools or printers on the AS-WORKBENCH-F ...

Height and angle-adjustable monitor holder including swivel arm for an AS-WORKBENCH-F 90 screen

Wire roll holder with clamping lever for height-adjustable fastening to the device carrier rail for the AS-WORKBENCH-F ...

In industrial control cabinet building, processes still feature a large number of manual steps. There is still considerable potential in particular in wire preparation and processing. These time-consuming activities account for more than half of the time spent on control cabinet building. The clipx WIRE assist worker assistance system from Phoenix Contact is a “tool” for exploiting this potential as far as possible in terms of economy and efficiency.

Software-supported conductor preparation

The necessary wiring information for the software-supported completion of the processes is exported from standard CAE programs. The information is fed into the clipx WIRE assist system. In addition, an integrated editor function also allows data to be compiled manually.

Based on this data, the clipx Wire assist software guides the worker through the semi-automated conductor finishing process. At the same time, the system’s devices are controlled directly and the necessary information for further processing and wiring is visually enhanced and automatically displayed on the monitor in an easy-to-follow format.

Ergonomic workstation design

The height-adjustable clipx WIRE assist workbench is designed to satisfy ergonomic requirements. One advantage of this is the ability to switch between sitting and standing while working and the system can also be adapted to the physical height of the worker and/or to the activity to be completed. Ideal positioning of the printing systems and automatic tools in the working area reduces the reaching distance, which is another ergonomic benefit.

The worker assistance system is mounted on four industrial-grade castors with brakes, making it very mobile. This means that the system can be used where the work needs to be performed, thus reducing unnecessary legwork.

Worker assistance system based on lean principles

The system concept is based on lean principles such as the 5S principle.

These principles help to eliminate disorder and optimize organization.

Short search-and-retrieve times are achieved through the use of multi-layer hard foam inserts in which each tool and aid has a predefined recess. Here, the tools that are used more frequently can be accessed easily and the tools used less often are positioned further away.

Automatic tools and printing systems can be positioned on the surface of the worktop. Accessories such as sockets, storage shelves, or containers for storing excess materials can be attached directly to the system worktop when necessary.

To save space, automatic tools and printing systems can be attached directly to the worktop of the worker assistance system using the appropriate accessories. Guides are attached to the support arms and columns to hold additional accessories.

The devices can be positioned extremely flexibly in terms of height and orientation, and their positioning can be tailored to personal needs as well as the requirements of the task at hand.

With the help of the wire guide system, a wide range of different wires can be stocked and provided directly at the automatic cutting device or the cutting machine.