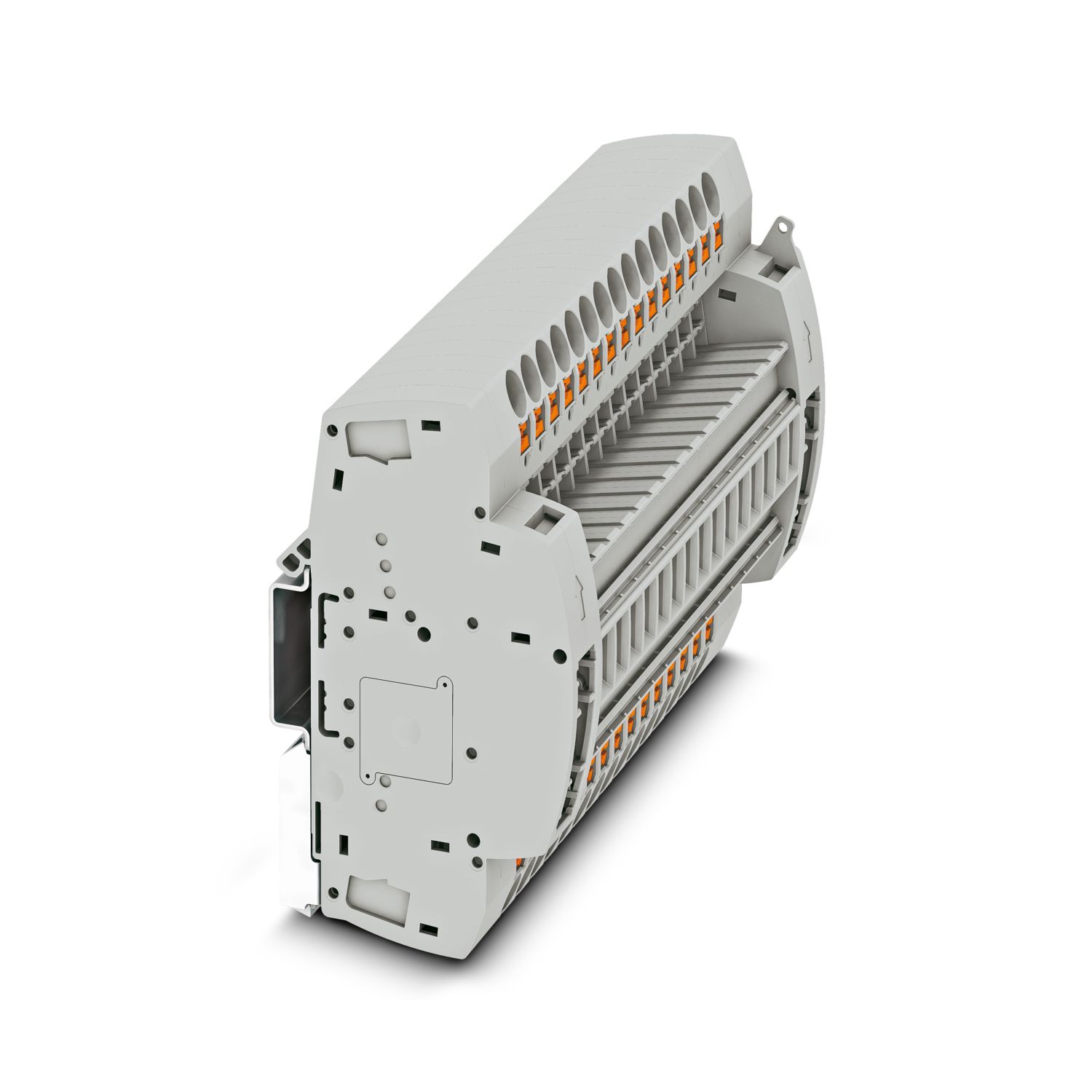

PTRE 6-2/15

-

Test terminal strip

3069864

Test terminal strip, nom. voltage: 400 V, number of connections: 30, number of positions: 15, connection method: Push-in connection, Rated cross section: 6 mm2, 1 level, cross section: 0.5 mm2 - 10 mm2, mounting type: NS 35/7,5, NS 35/7,5, color: gray

Product details

| Number of positions | 15 |

| Pitch | 8.2 mm |

| Number of connections | 30 |

| Number of rows | 1 |

| Potentials | 15 |

| Insulation characteristics | |

| Overvoltage category | III |

| Rated surge voltage | 4 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

| Test surge voltage | 5 kV |

| Number of connections per level | 30 |

| Nominal cross section | 6 mm² |

| 1 level | |

| Connection method | Push-in connection |

| Stripping length | 12 mm |

| Internal cylindrical gage | A5 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.5 mm² ... 10 mm² |

| Cross section AWG | 20 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.5 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] | 20 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 6 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Maximum load current | 30 A (with 6 mm² conductor cross-section) |

| Nominal voltage | 400 V AC/DC |

| Nominal cross section | 6 mm² |

| 1 level Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 1 mm² ... 10 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 1 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 1 mm² ... 6 mm² |

| Width | 154.9 mm |

| Height | 99.7 mm |

| Depth | 56.5 mm |

| Depth on NS 35/7,5 | 61.8 mm |

| Depth on NS 35/15 | 69.3 mm |

| Pitch | 8.2 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Mechanical data | |

| Open side panel | No |

| Ambient conditions | |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/7,5 |

| Item number | 3069864 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Sales key | NULL |

| Product key | BE6112 |

| GTIN | 4046356962308 |

| Weight per piece (including packing) | 462.9 g |

| Weight per piece (excluding packing) | 462.9 g |

| Customs tariff number | 85369010 |

| Country of origin | US |

ECLASS

| ECLASS-13.0 | 27250304 |

ETIM

| ETIM 9.0 | EC002555 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

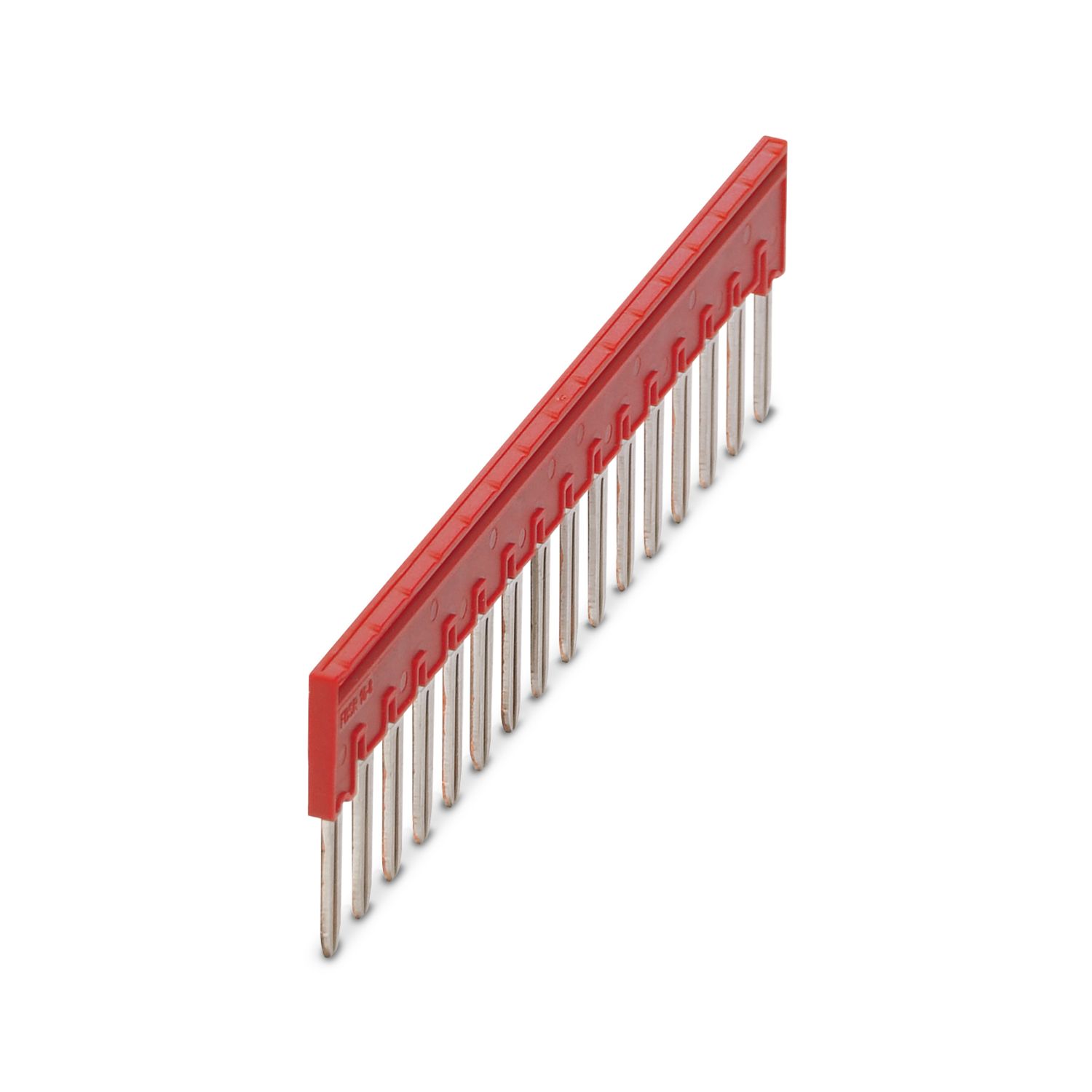

-

-

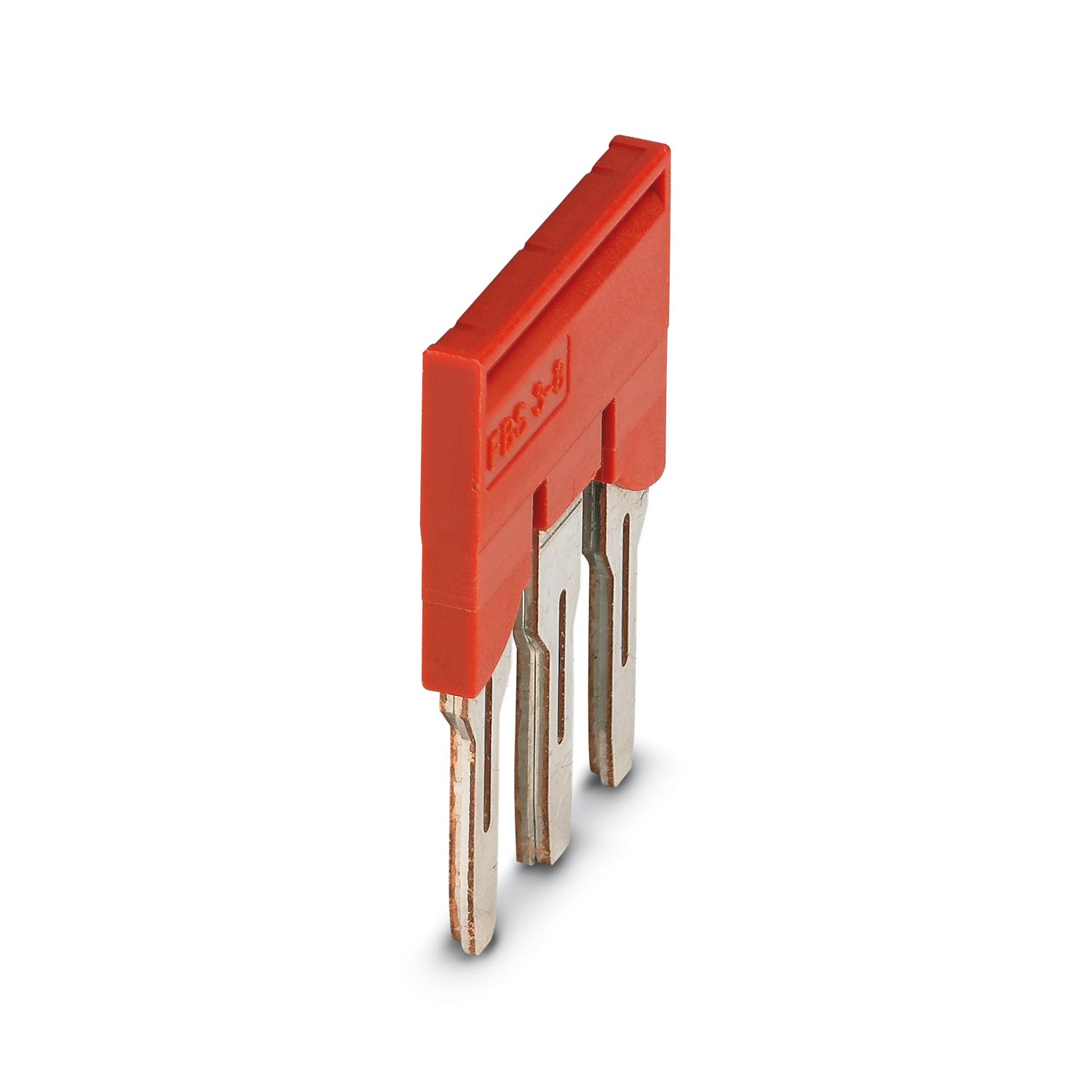

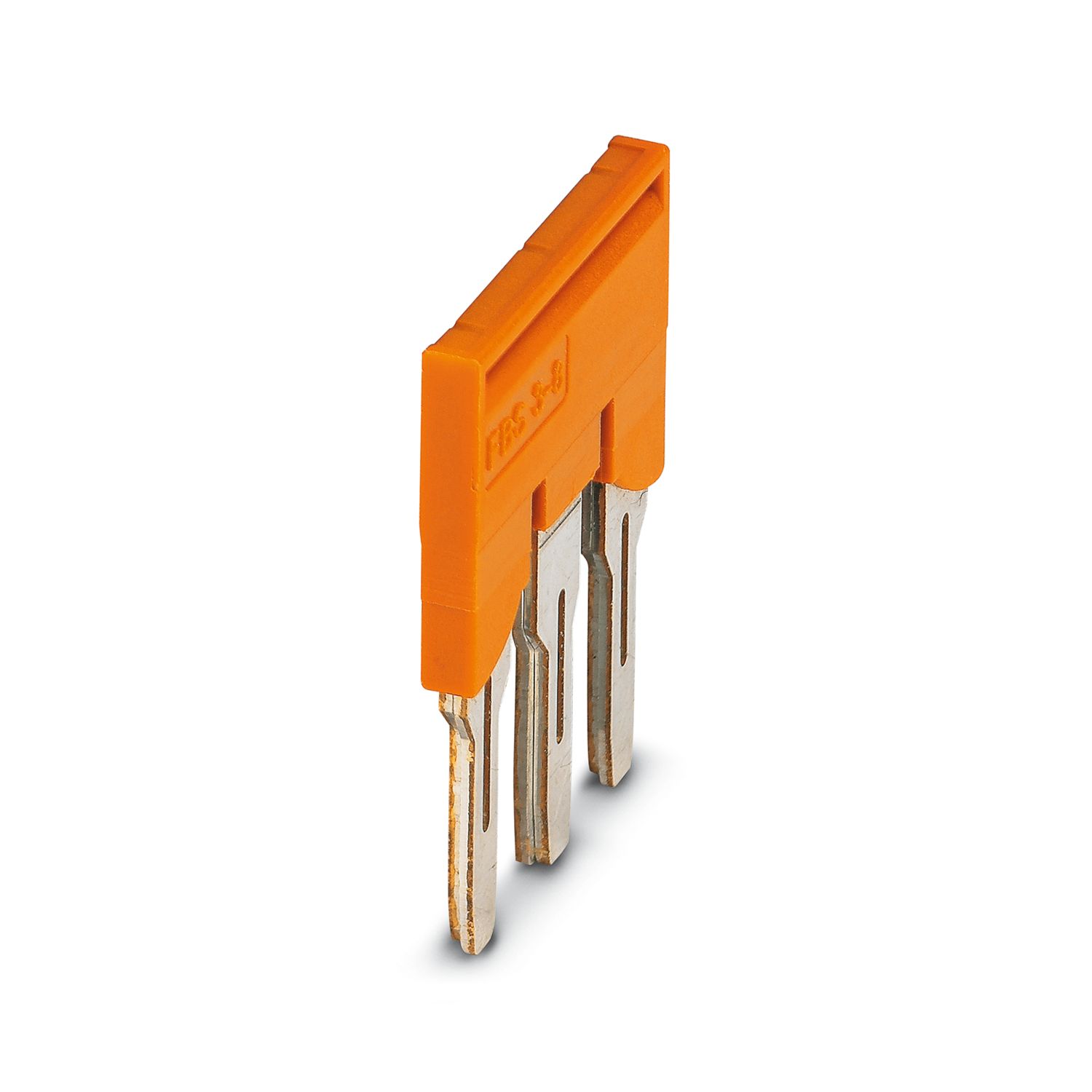

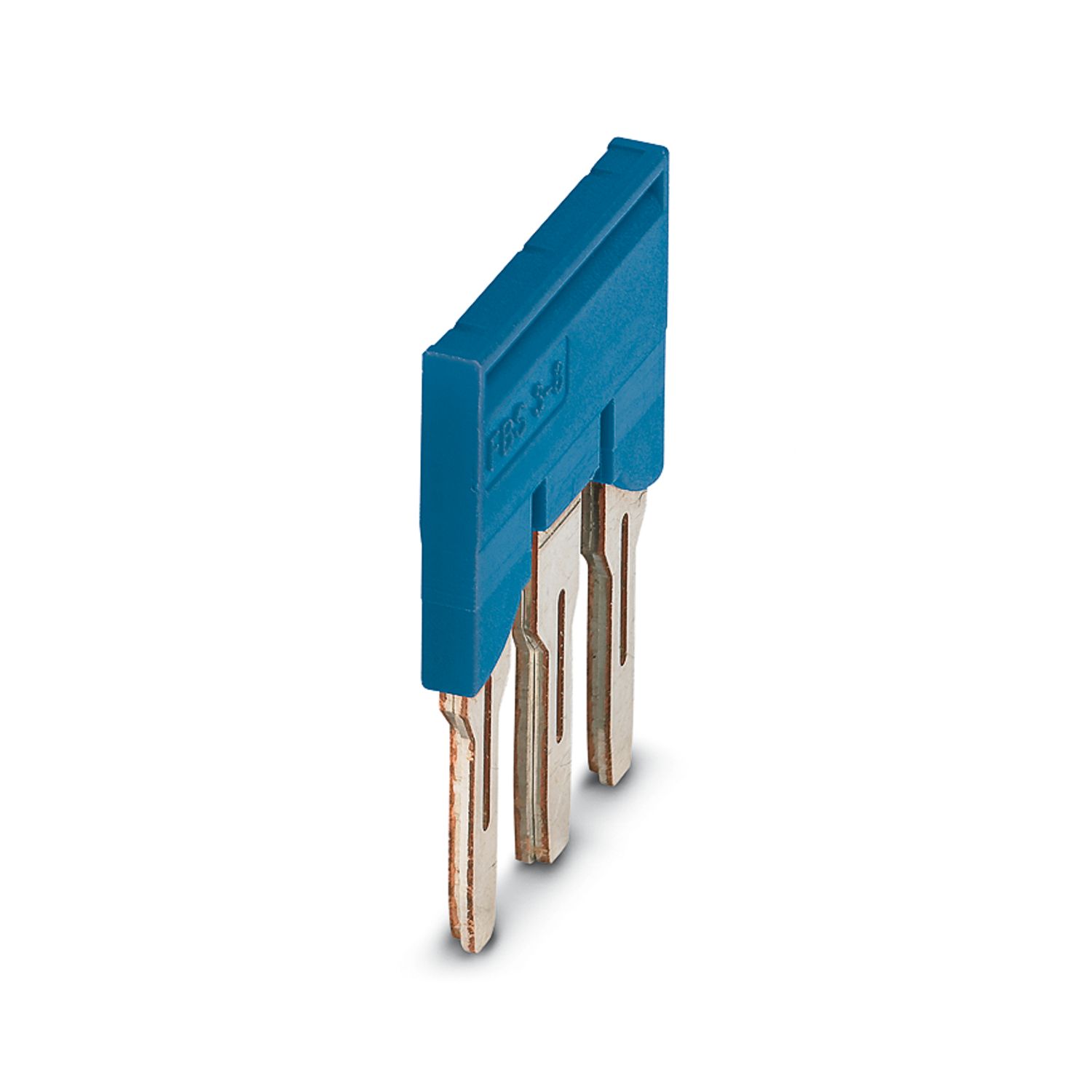

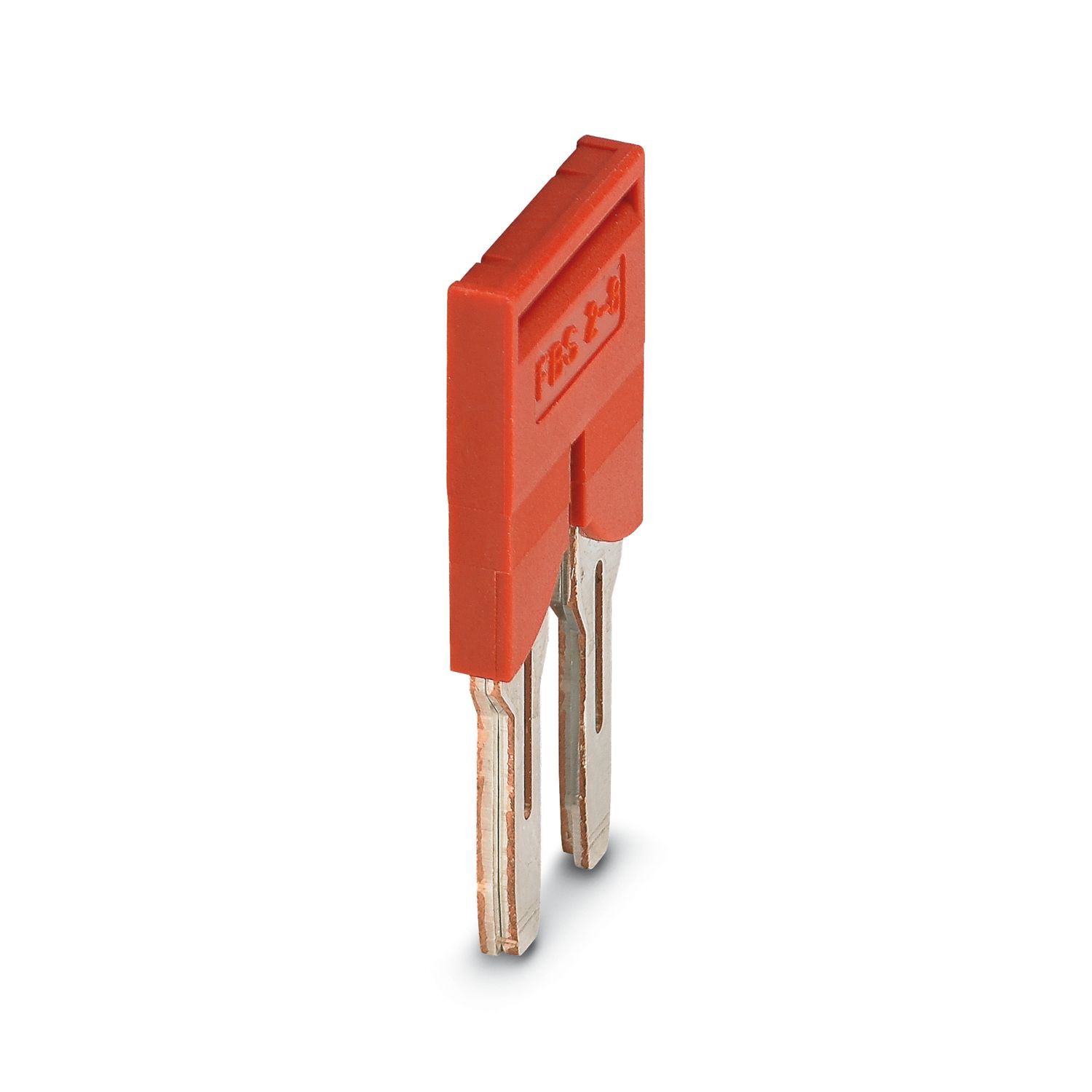

FBS 3-8 - Plug-in bridge 3030297

-

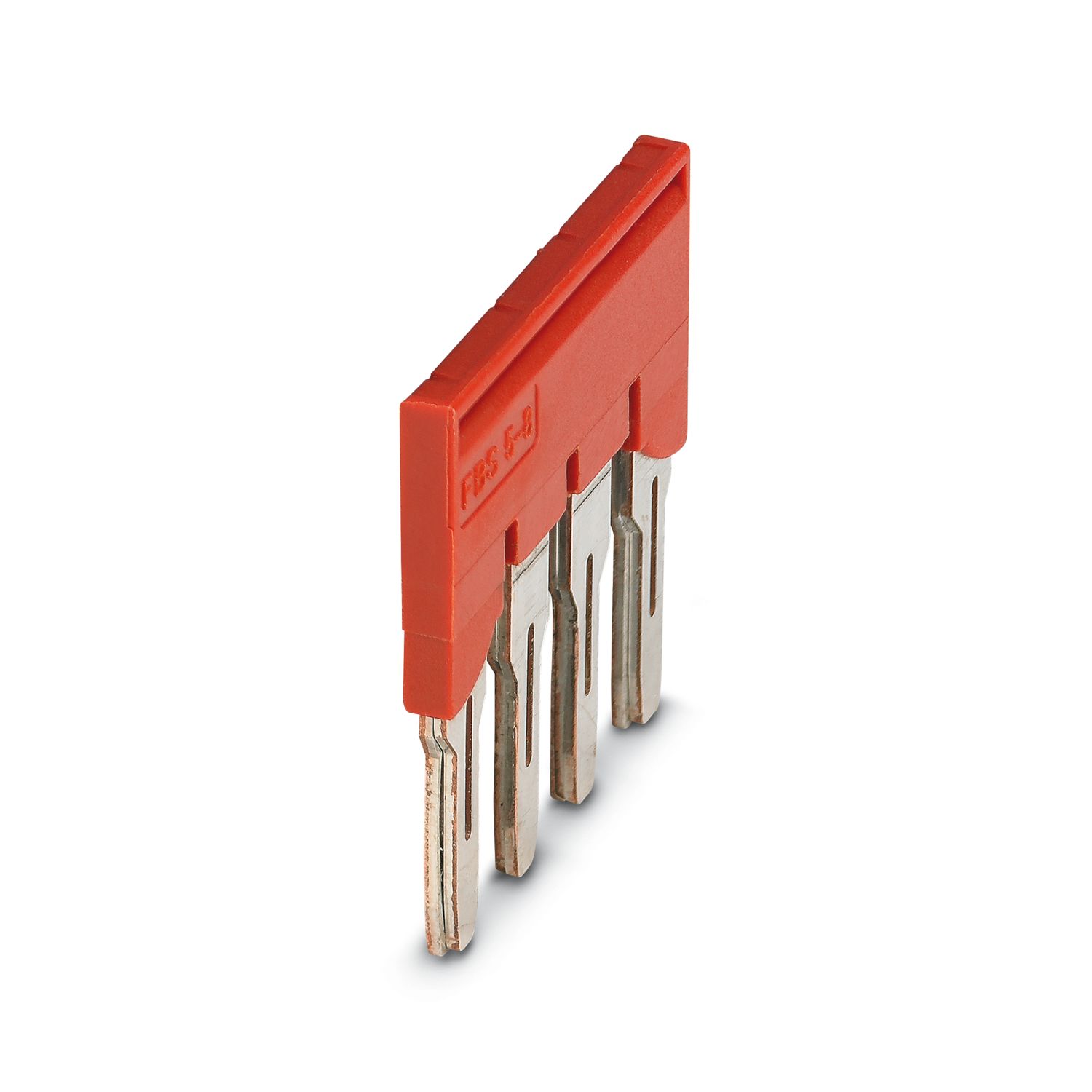

FBS 4-8 - Plug-in bridge 3030307

-

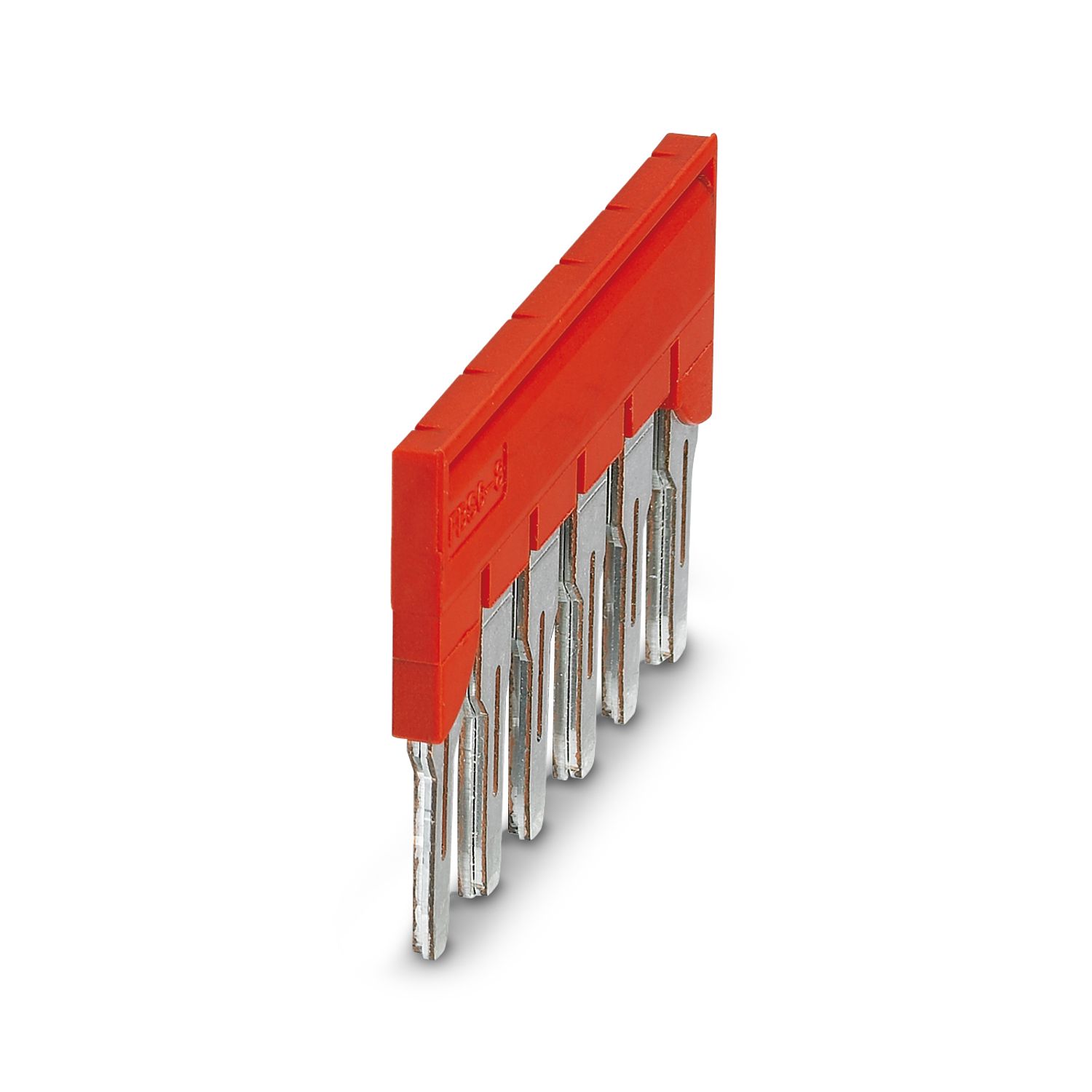

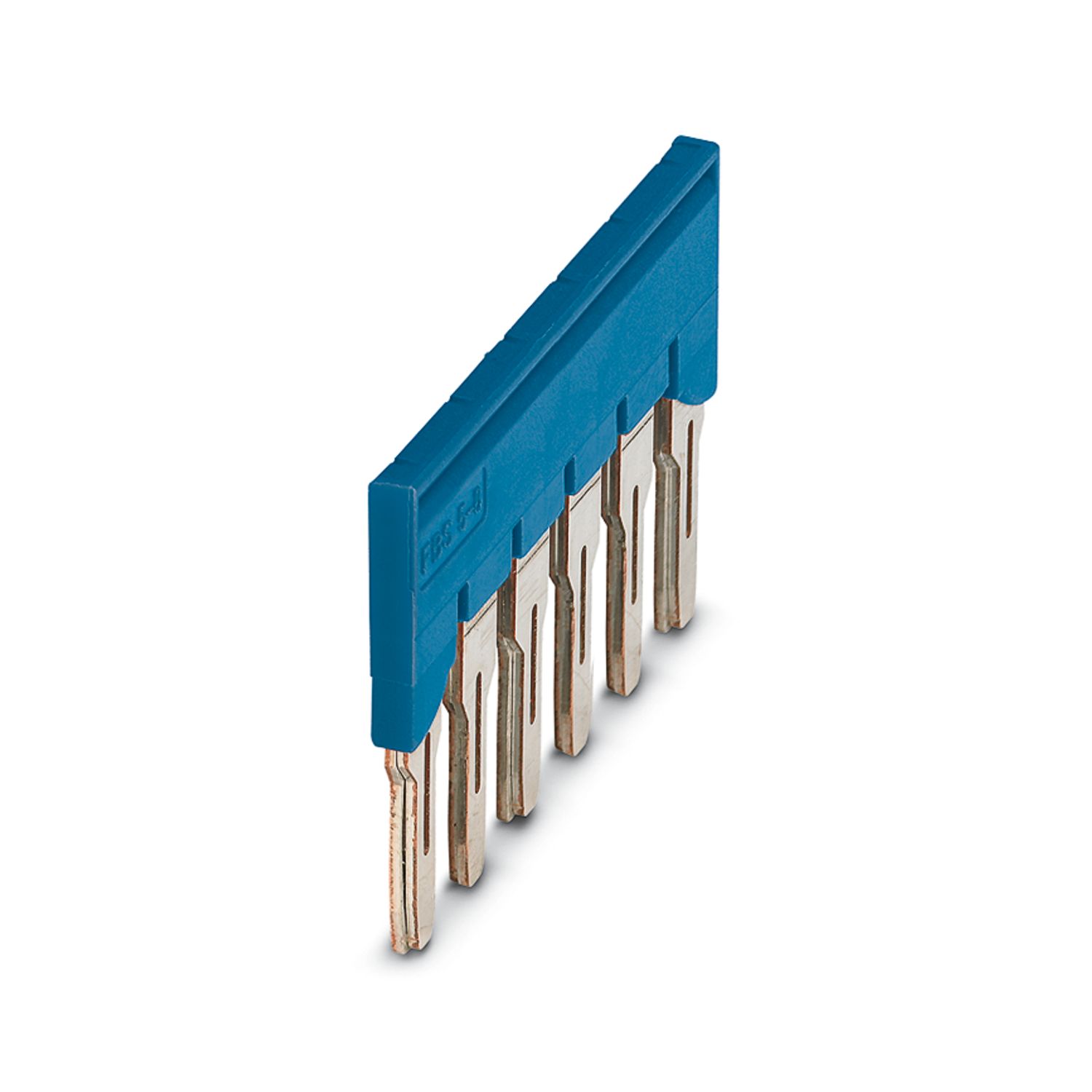

FBS 5-8 - Plug-in bridge 3030310

-

FBS 6-8 - Plug-in bridge 3032470

-

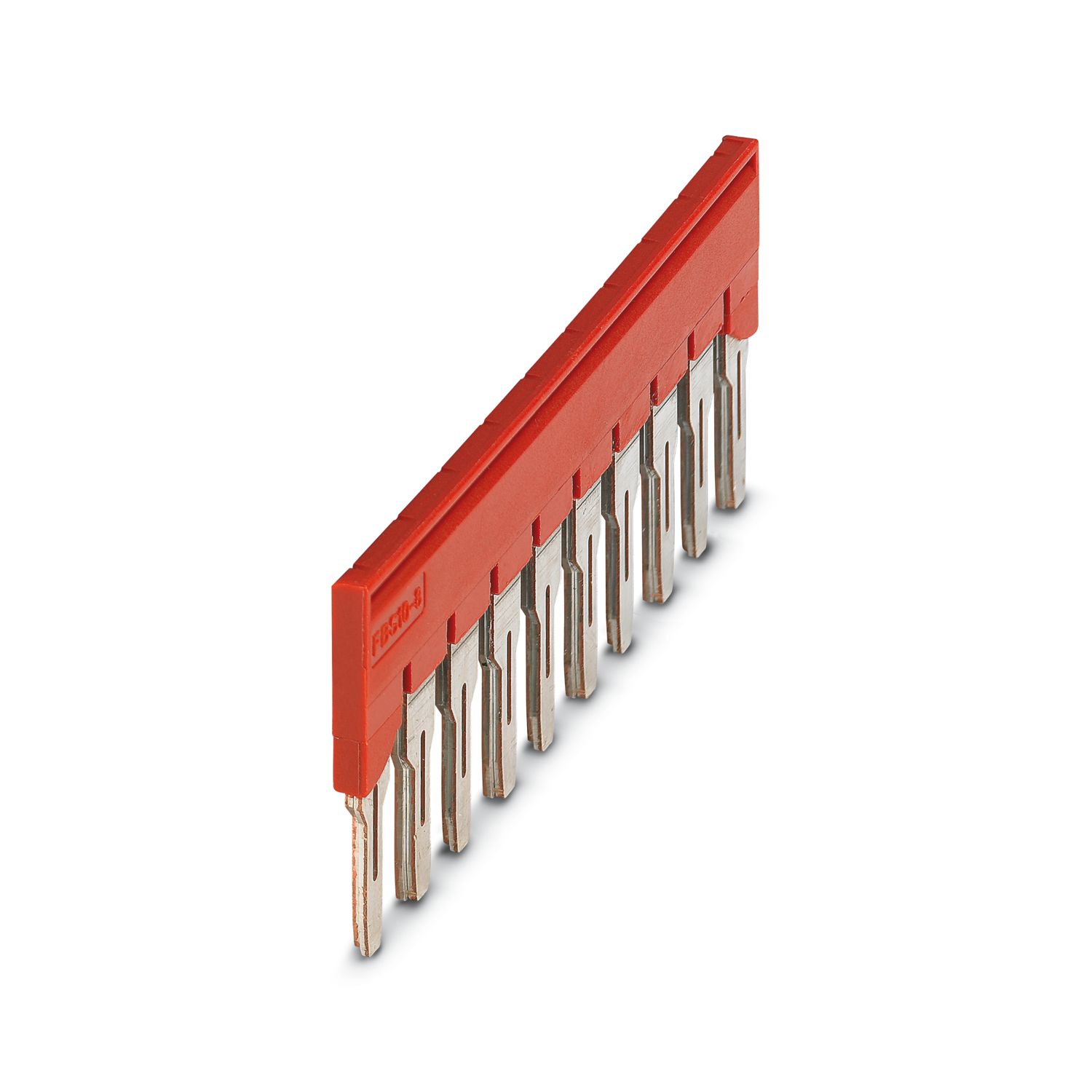

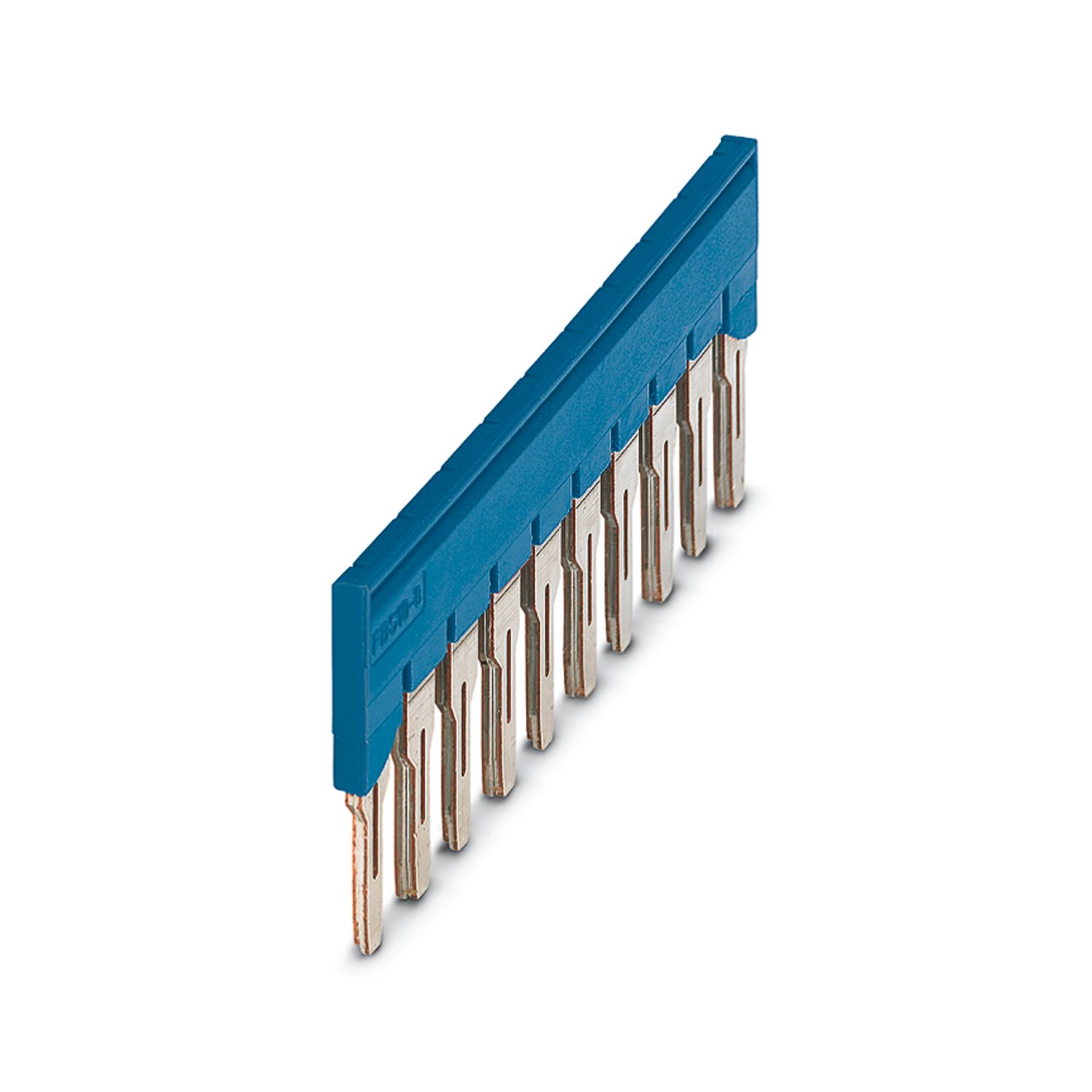

FBS 10-8 - Plug-in bridge 3030323

-

FBSR 16-8 - Plug-in bridge 3033816

-

FBS 1/3-8 - Plug-in bridge 3032363

-

FBS 1/4-8 - Plug-in bridge 3032376

-

FBS 1/3/5-8 - Plug-in bridge 3032389

-

FBS 1/4/7/10-8 - Plug-in bridge 3032402

-

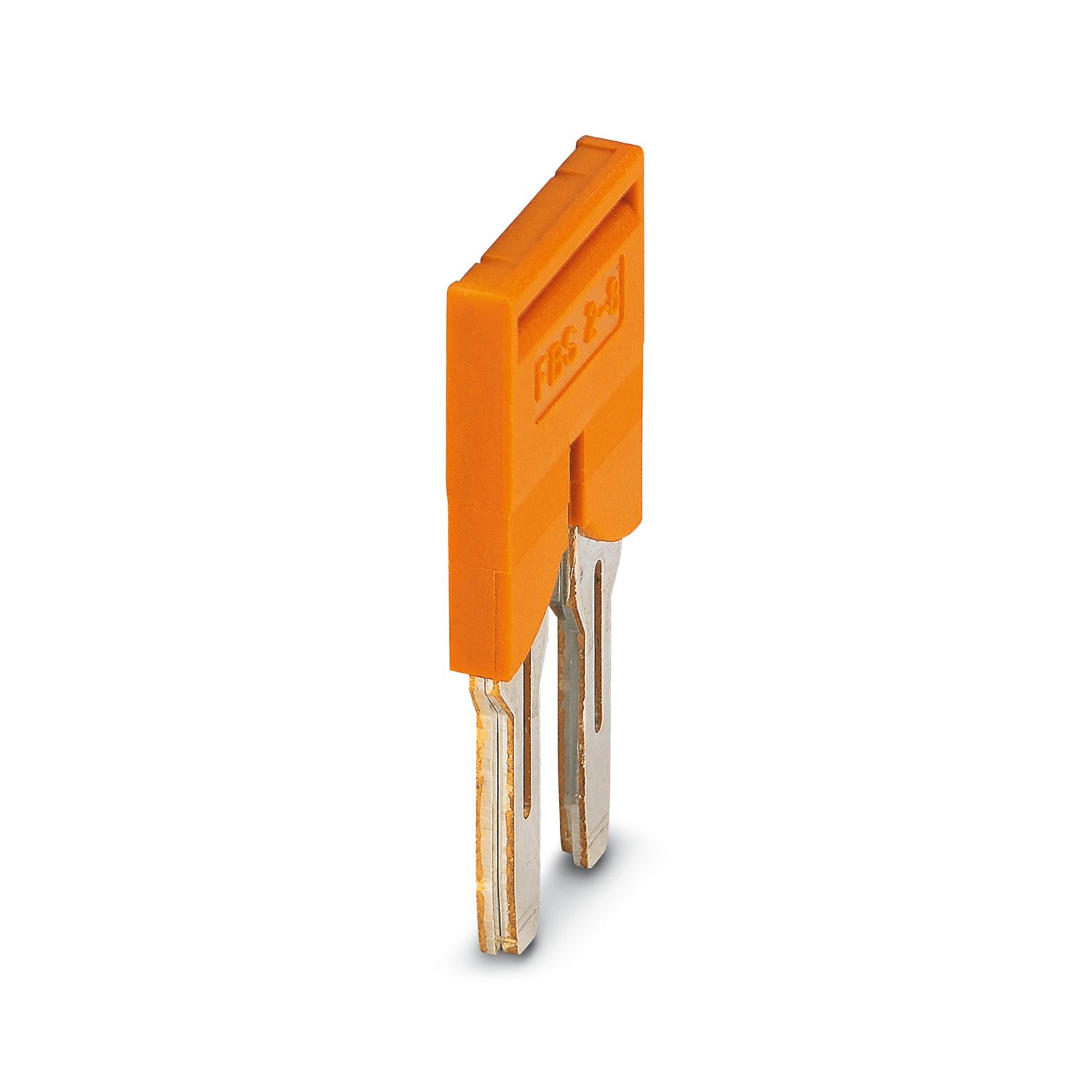

FBS 2-8 CT - Plug-in bridge 3033830

-

FBS 3-8 CT - Plug-in bridge 3033831

-

FBS 4-8 CT - Plug-in bridge 3033832

-

FBS 10-8 CT - Plug-in bridge 3033833

-

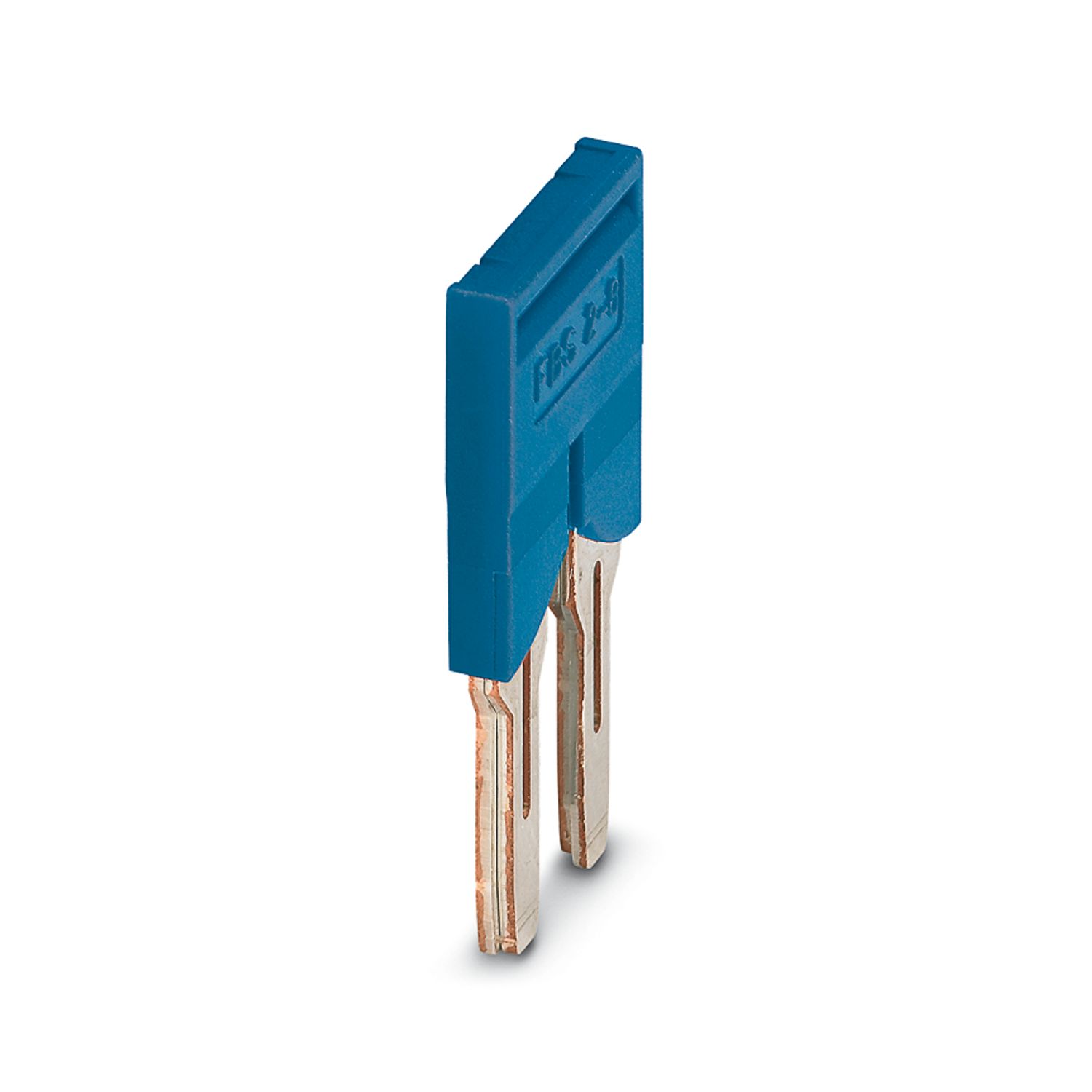

FBS 2-8 BU - Plug-in bridge 3032567

-

FBS 3-8 BU - Plug-in bridge 3032570

-

FBS 4-8 BU - Plug-in bridge 3032583

-

FBS 5-8 BU - Plug-in bridge 3032596

-

FBS 6-8 BU - Plug-in bridge 3032677

-

FBS 10-8 BU - Plug-in bridge 3032606

-

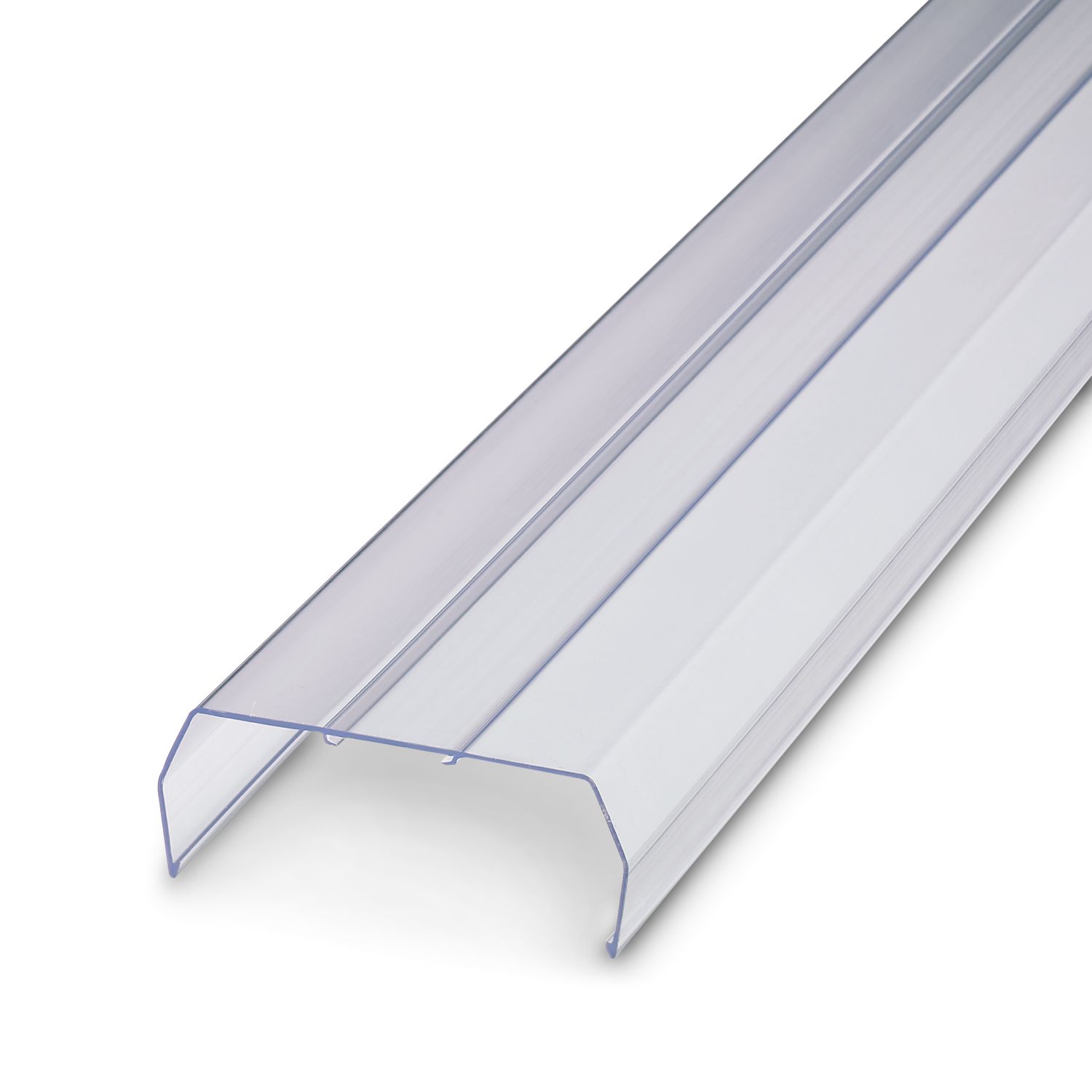

AP-ME METER - Cover profile 3034361

-

APH-ME - Cover profile carrier 3034374

-

APT-ME - Cover profile carrier 3034358

-

PC-UTWE-TRI - Coding profile 3069897

-

FTP-2/2 SERVICE - Test plug 3069464

-

FTP-2/3 SERVICE - Test plug 3069465

-

FTP-2/1 SERVICE 0R1 - Test plug 3069466

-

FTP-2/4 SERVICE - Test plug 3069468

-

FTP-2/1 SERVICE - Test plug 3069469

-

PAI-4-N GY - Test adapter 3032871

-

PAI-4-FIX BU - Test adapter 3032729

-

PAI-4-FIX OG - Test adapter 3034455

-

PAI-4-FIX YE - Test adapter 3032745

-

PAI-4-FIX RD - Test adapter 3032732

-

PAI-4-FIX GN - Test adapter 3032758

-

PAI-4-FIX BK - Test adapter 3032774

-

PAI-4-FIX GY - Test adapter 3032790

-

PAI-4-FIX VT - Test adapter 3032761

-

PAI-4-FIX BN - Test adapter 3032787

-

PAI-4-FIX WH - Test adapter 3032797

-

PAIS-4-FIX GY - Test adapter 3032791

-

PAIS-4-FIX BK - Test adapter 3032792

-

PAIS-4-FIX RD - Test adapter 3032793

-

PAIS-4-FIX BU - Test adapter 3032798

-

PAIS-4-FIX YE - Test adapter 3032799

-

PAIS-4-FIX GN - Test adapter 3032801

-

PAIS-4-FIX VT - Test adapter 3032802

-

PSBJ-URTK 6 FARBLOS - Test plug strip 3026450

-

PSBJ-URTK 6 RD - Test plug strip 3026719

-

PSBJ-URTK 6 BU - Test plug strip 3026434

-

PSBJ-URTK 6 YE - Test plug strip 3026405

-

PSBJ-URTK 6 GN - Test plug strip 3026418

-

PSBJ-URTK 6 VT - Test plug strip 3026421

-

PSBJ-URTK 6 GY - Test plug strip 3026612

-

PSBJ-URTK 6 BK - Test plug strip 3026447

-

PSBJ-URTK 6 BN - Test plug strip 3026971

-

PSBJ-URTK 6 WH - Test plug strip 3026448

-

ZB 8:UNBEDRUCKT - Zack marker strip 1052002

-

ZB 8 CUS - Zack marker strip 0825011

-

UC-TM 8 - Marker for terminal blocks 0818072

-

UC-TM 8 CUS - Marker for terminal blocks 0824597

-

UCT-TM 8 - Marker for terminal blocks 0828740

-

UCT-TM 8 CUS - Marker for terminal blocks 0829616

-

ZB 8,LGS:FORTL.ZAHLEN - Zack marker strip 1052015

-

ZB 8,QR:FORTL.ZAHLEN - Zack marker strip 1052028

-

ZB 8,LGS:L1-N,PE - Marker for terminal blocks 1052413

-

TMT (EX9,5)R - Marker for terminal blocks 0828295

-

US-TM 100 - Marker for terminal blocks 0829255

-

SZF 2-0,8X4,0 - Screwdriver 1204520

-

FTPR-2/15 - Test plug 3001693

-

FTP-2/15 - Test plug 3001717

-

FBP-2/15 - Blind plug 3069886

Your advantages

Space saving, thanks to compact, modular test terminal strips

Cost-effective, thanks to the tailored, modular design and use of standardized CLIPLINE complete accessories

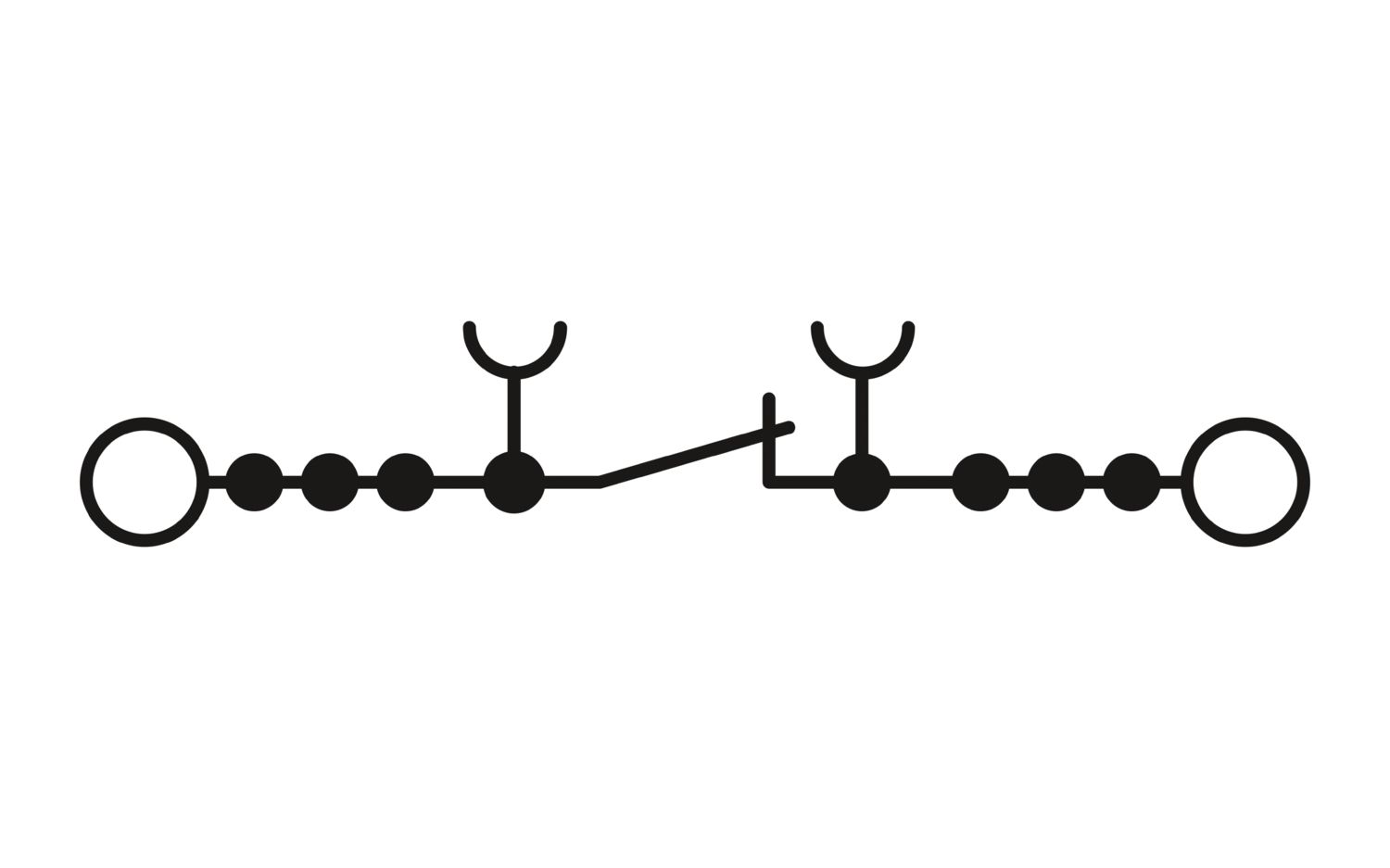

The integrated, robust switch contact is designed for the most stringent demands, and the use of high-quality materials ensures the transmission of signal currents, even after multiple actuations

Maximum safety with leading and automatic transformer short circuit

PHOENIX CONTACT

586 Fulling Mill Road, Middletown, PA 17057