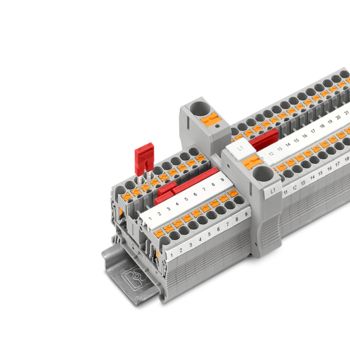

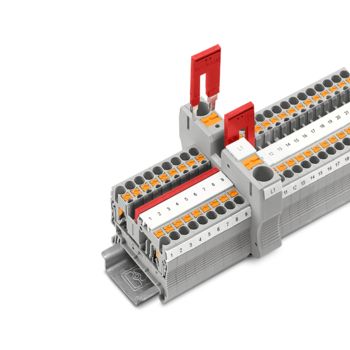

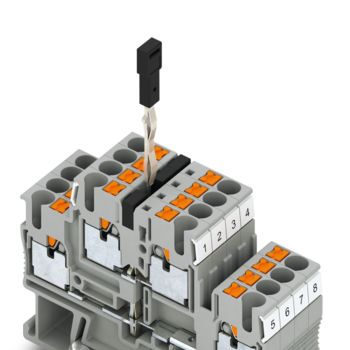

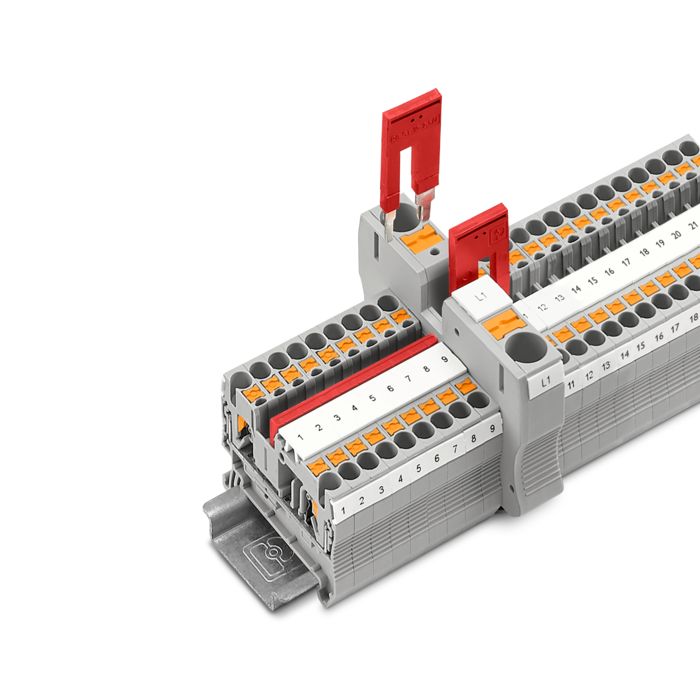

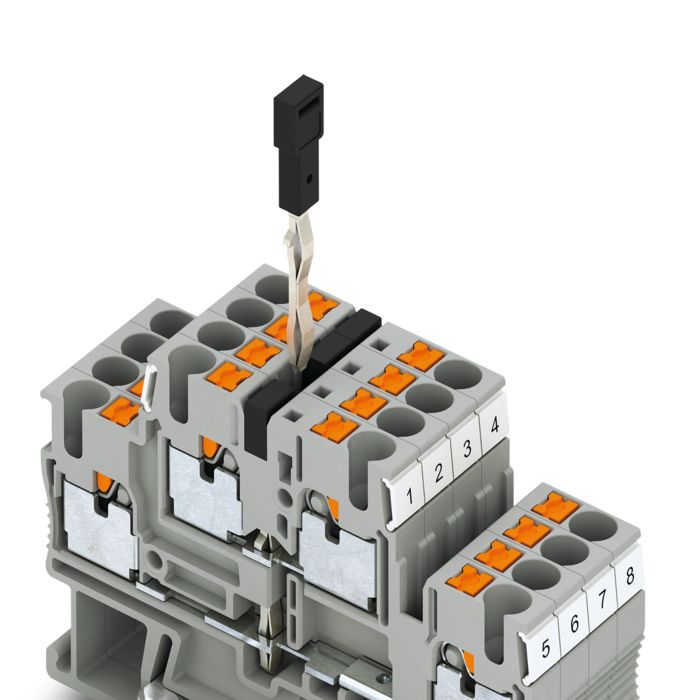

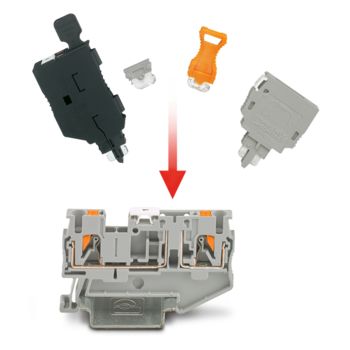

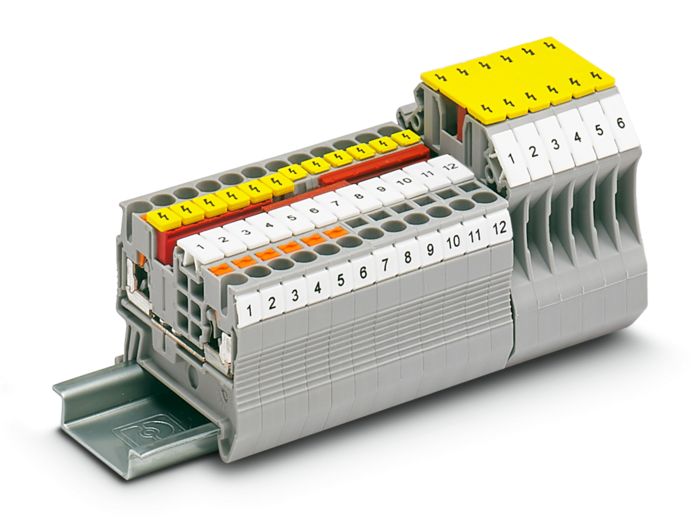

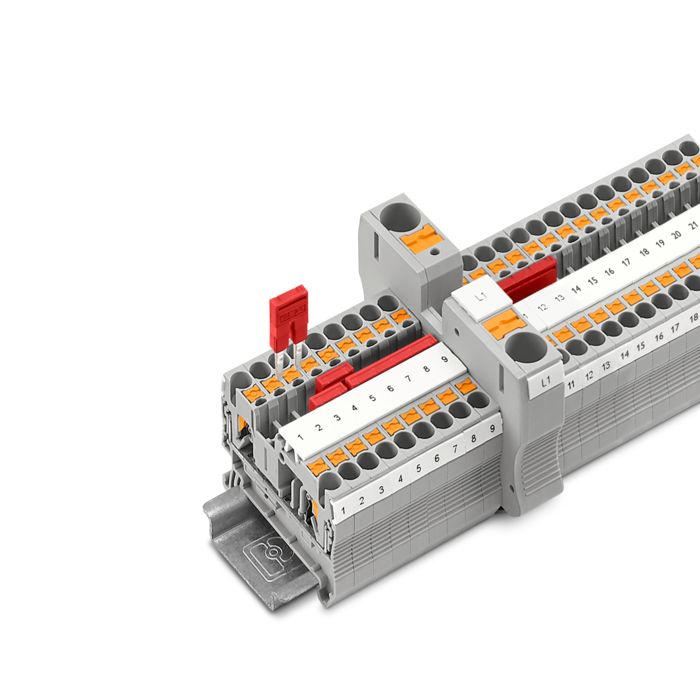

The standard FBS plug-in bridges are used for easy potential distribution between terminal blocks with the same nominal cross-section. The plug-in bridges are available with up to 50 contact tabs, enabling you to connect up to 50 potentials together. If you require shorter plug-in bridges, you can either opt for shorter plug-in bridges or you can shorten the plug-in bridge using a cutting tool (CUTFOX 18). For non-adjacent bridges, individual contact tabs can also be removed. The CUTFOX-FBS, for example, is suitable for this.