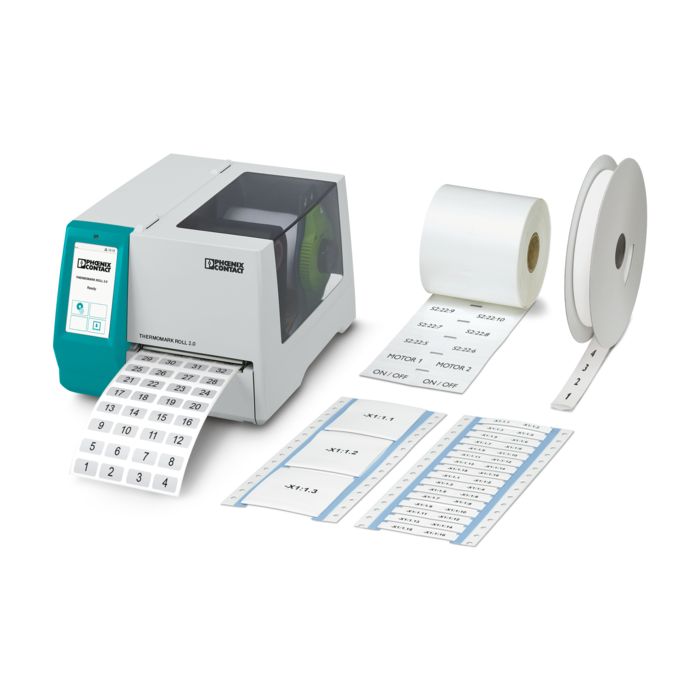

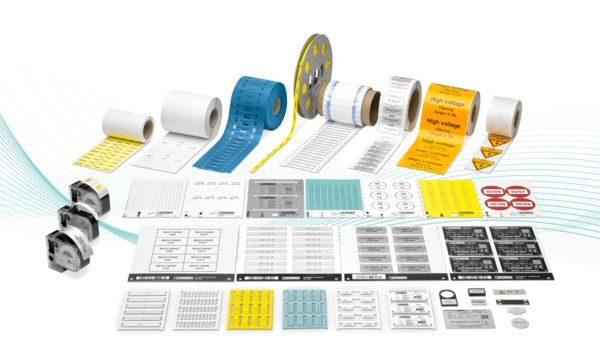

The THERMOMARK ROLL 2.0 thermal transfer printer prints markers in roll and continuous format for applications in terminal marking, wire and cable marking, and equipment and plant marking. Create high-quality printed labels, insert labels, and shrink and marking sleeves in prepunched or continuous format.