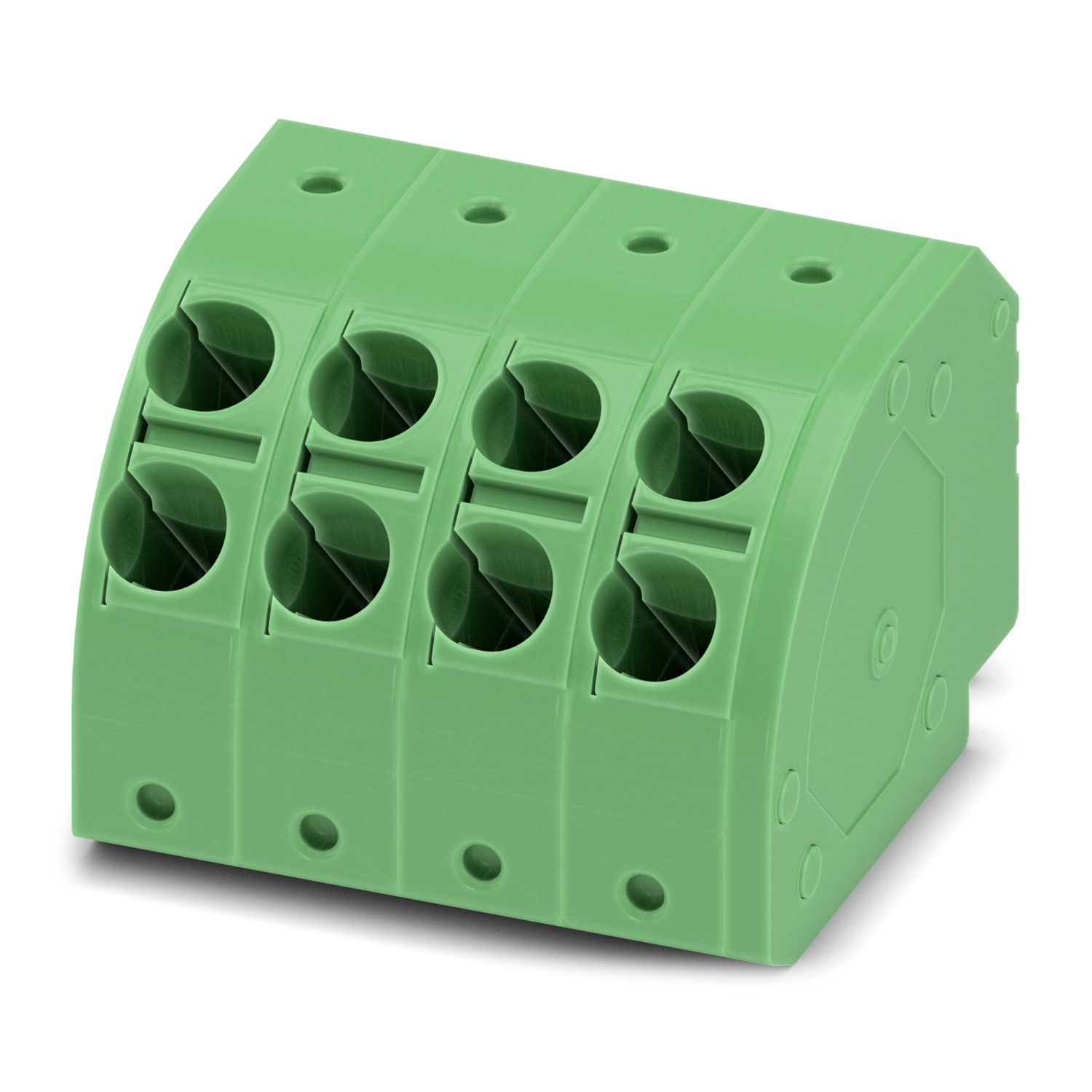

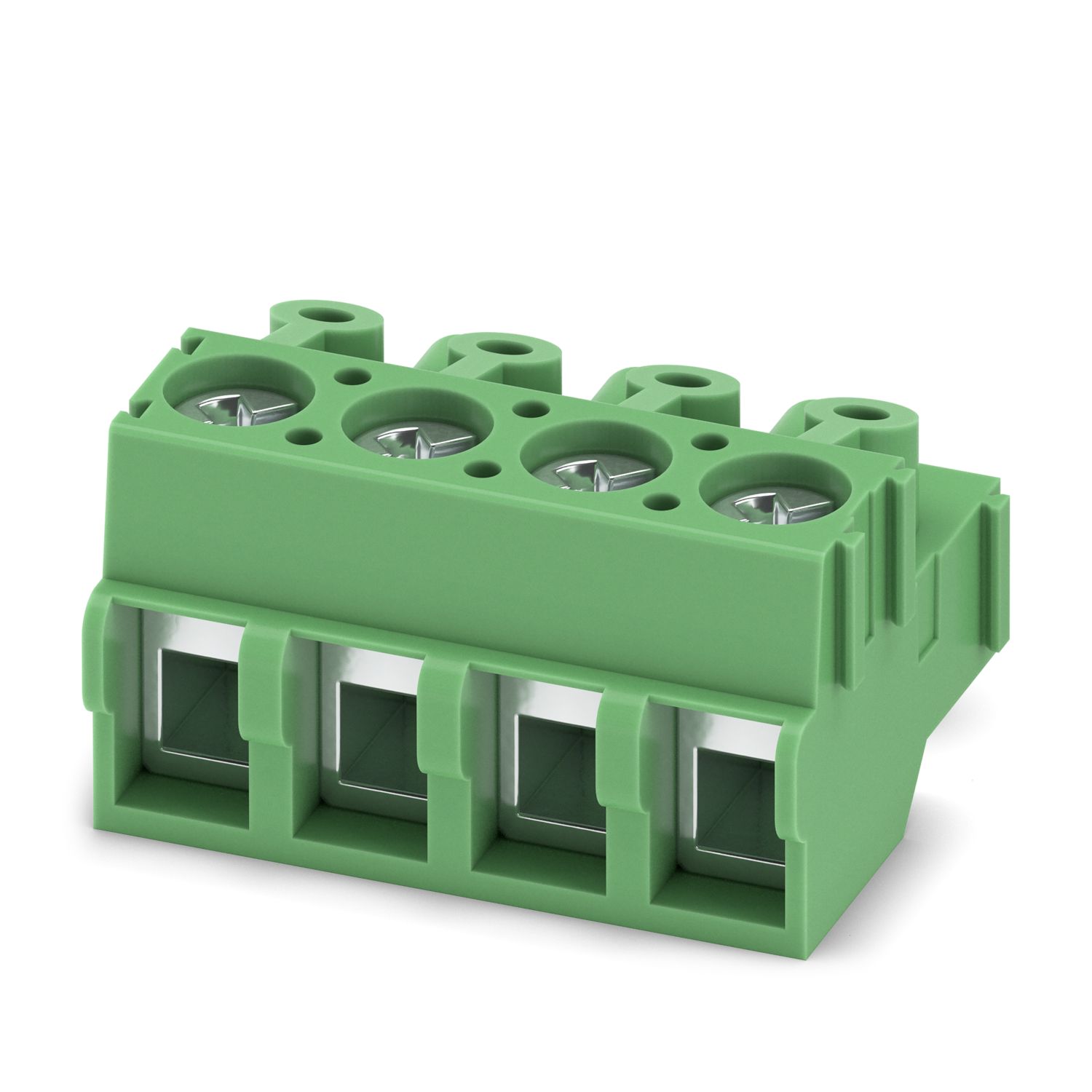

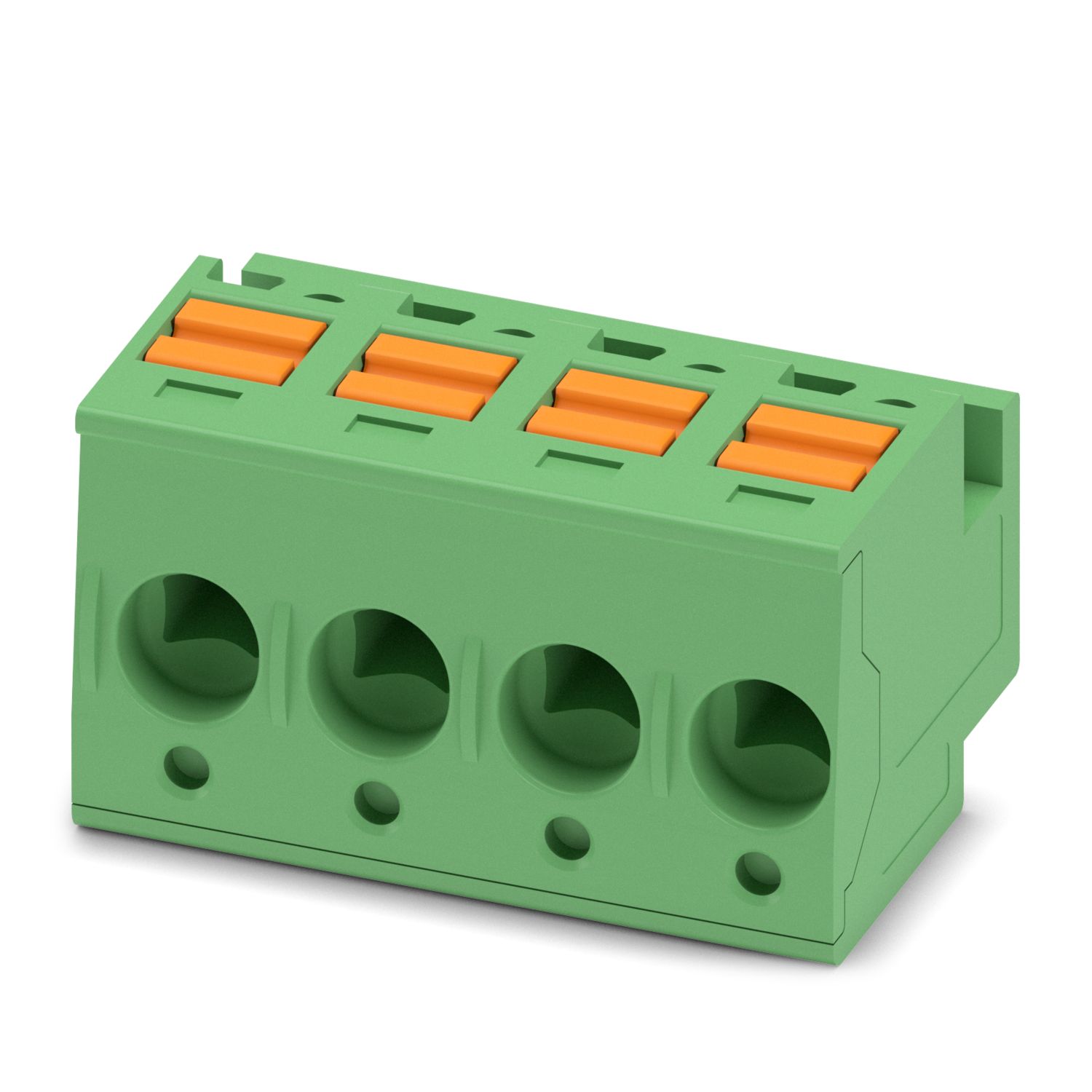

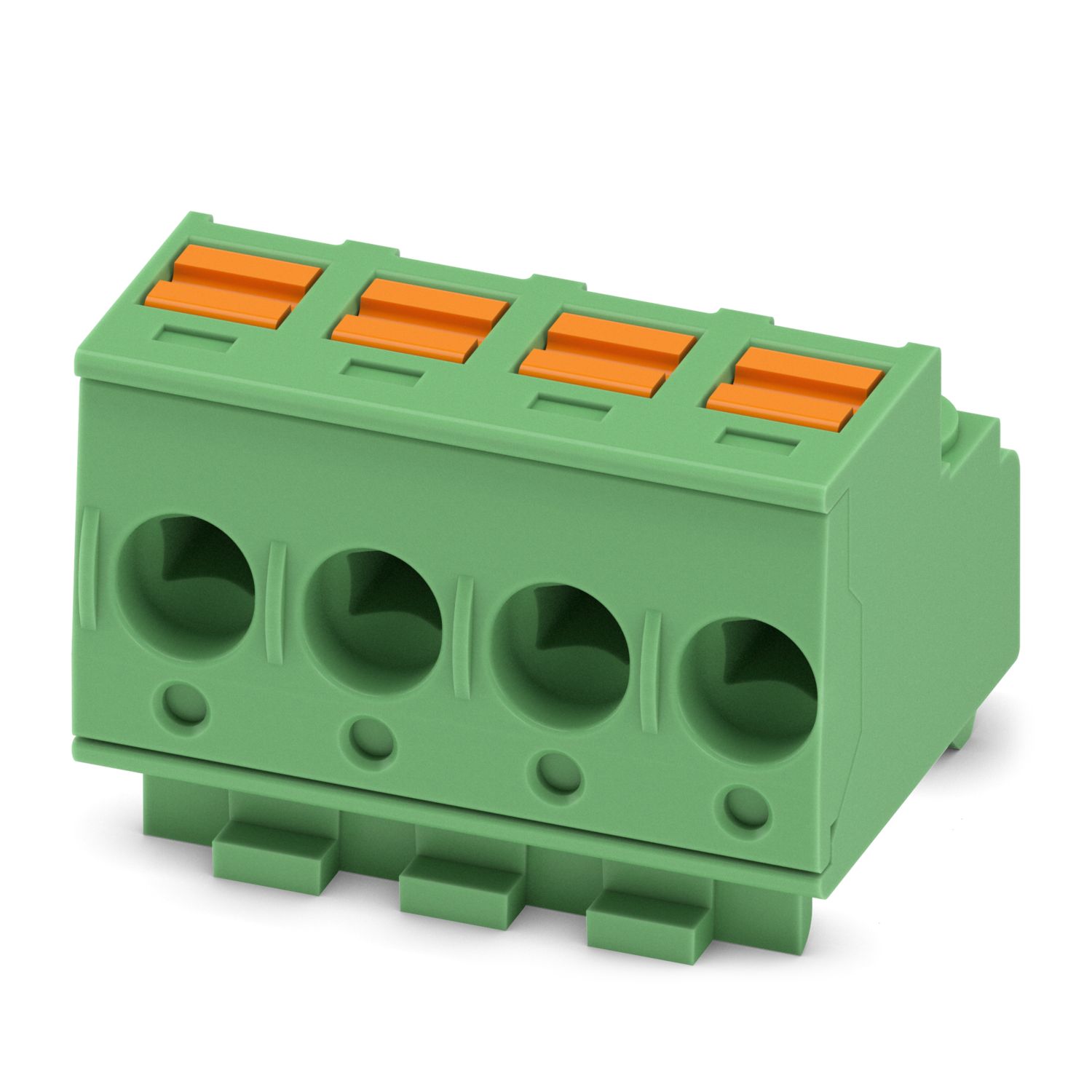

product line COMBICON Connectors M

cross section 1.5 mm2

mounting type THR soldering / wave soldering

type of packaging packed in cardboard

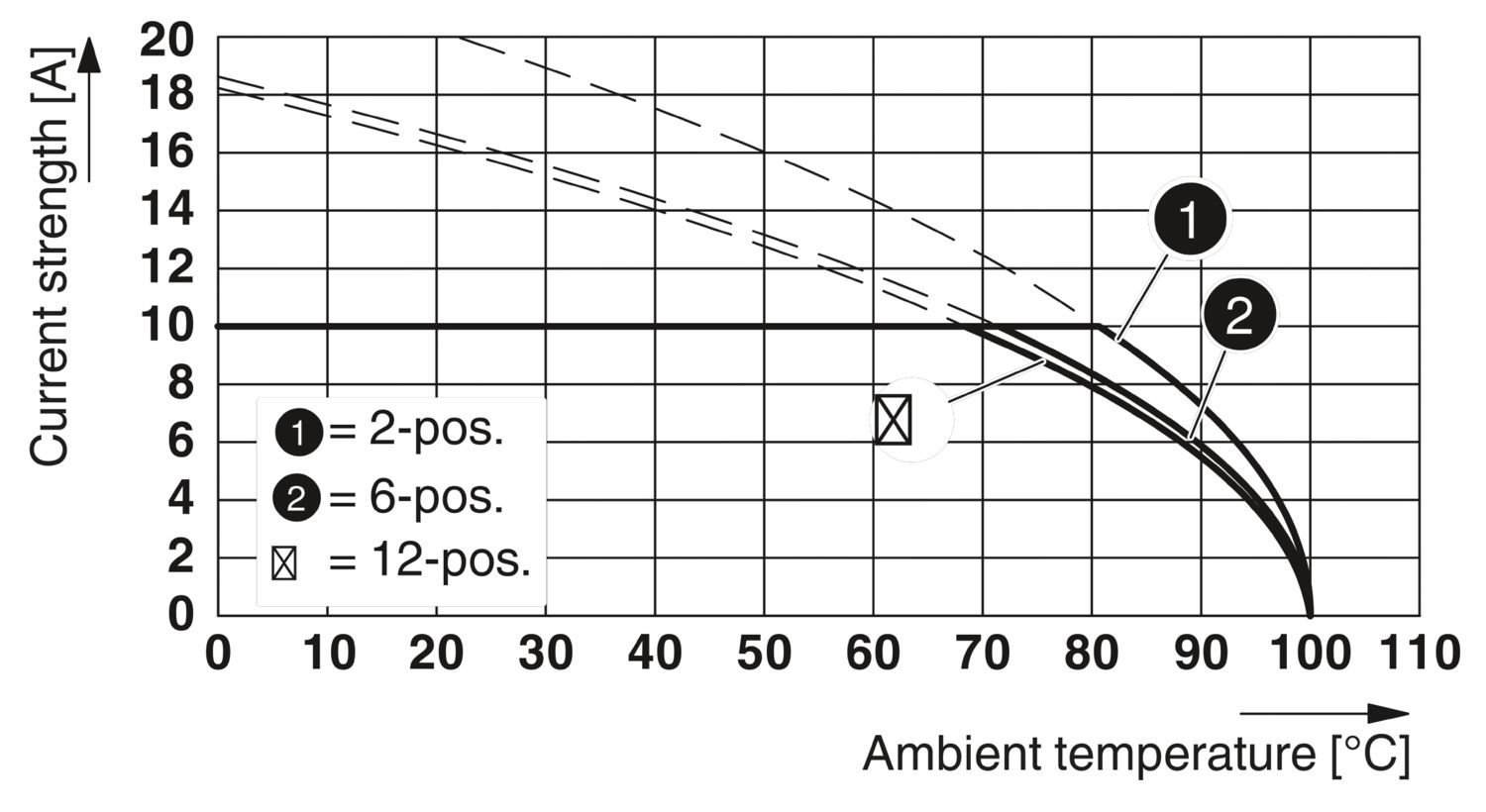

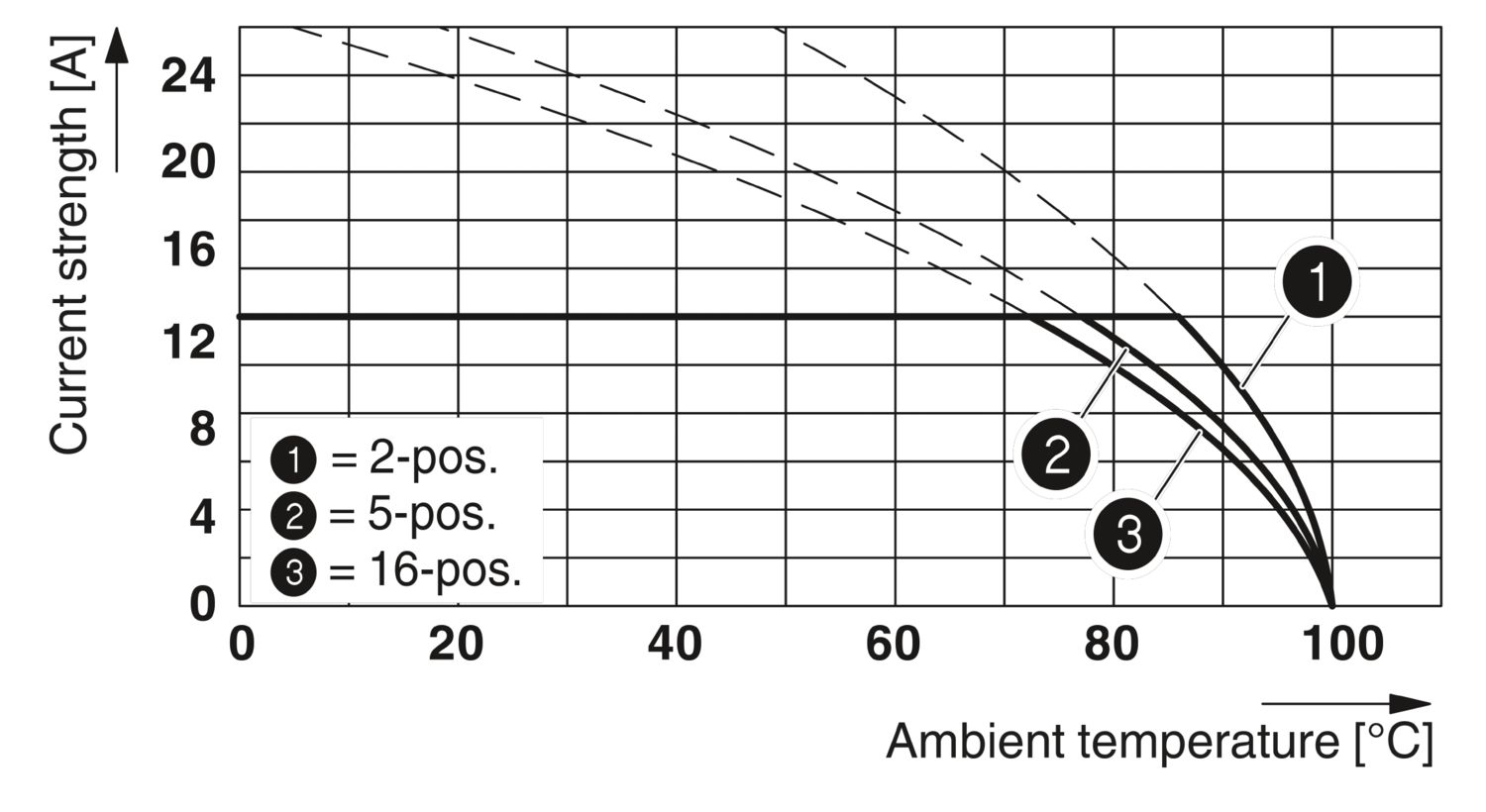

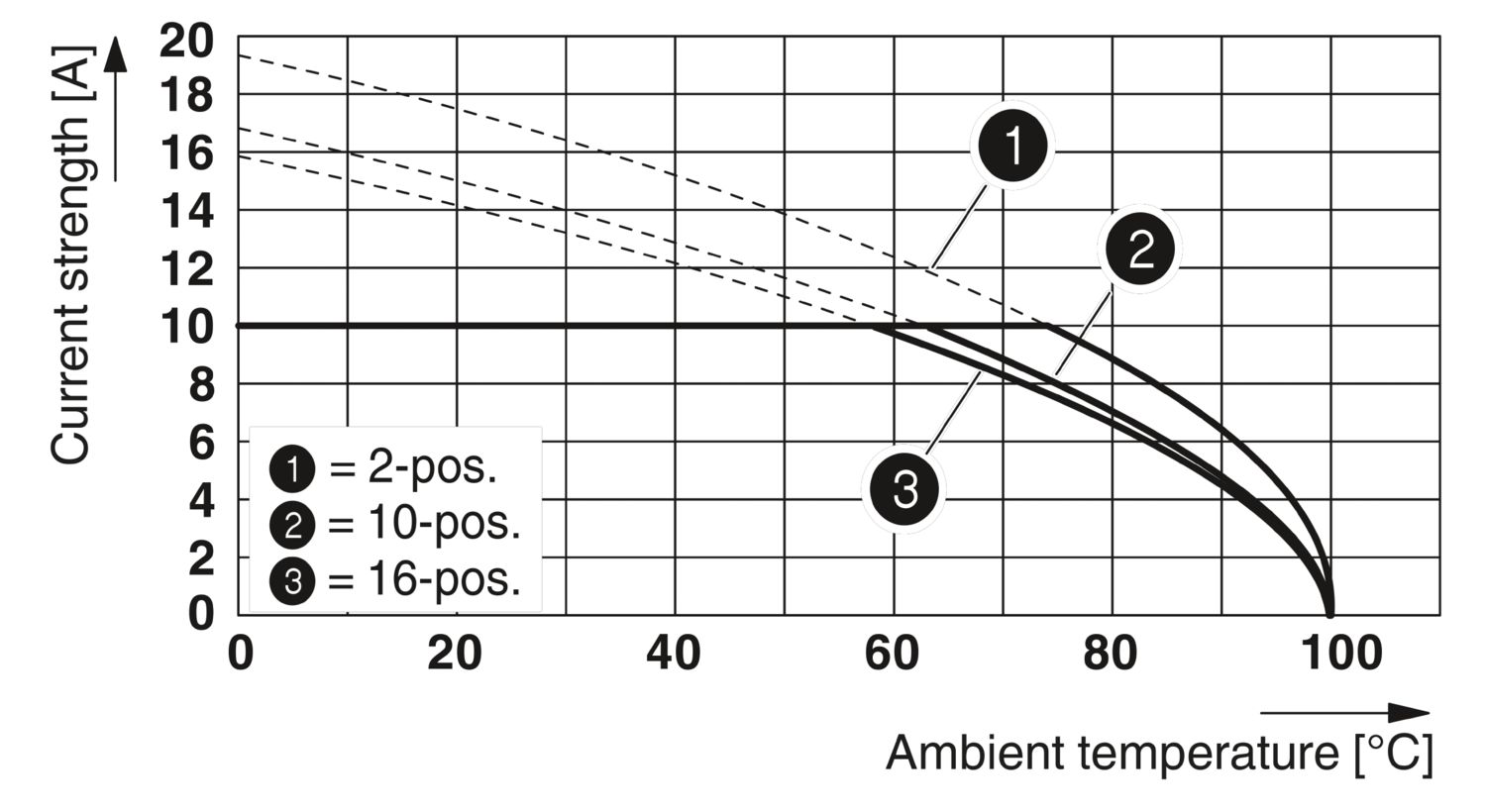

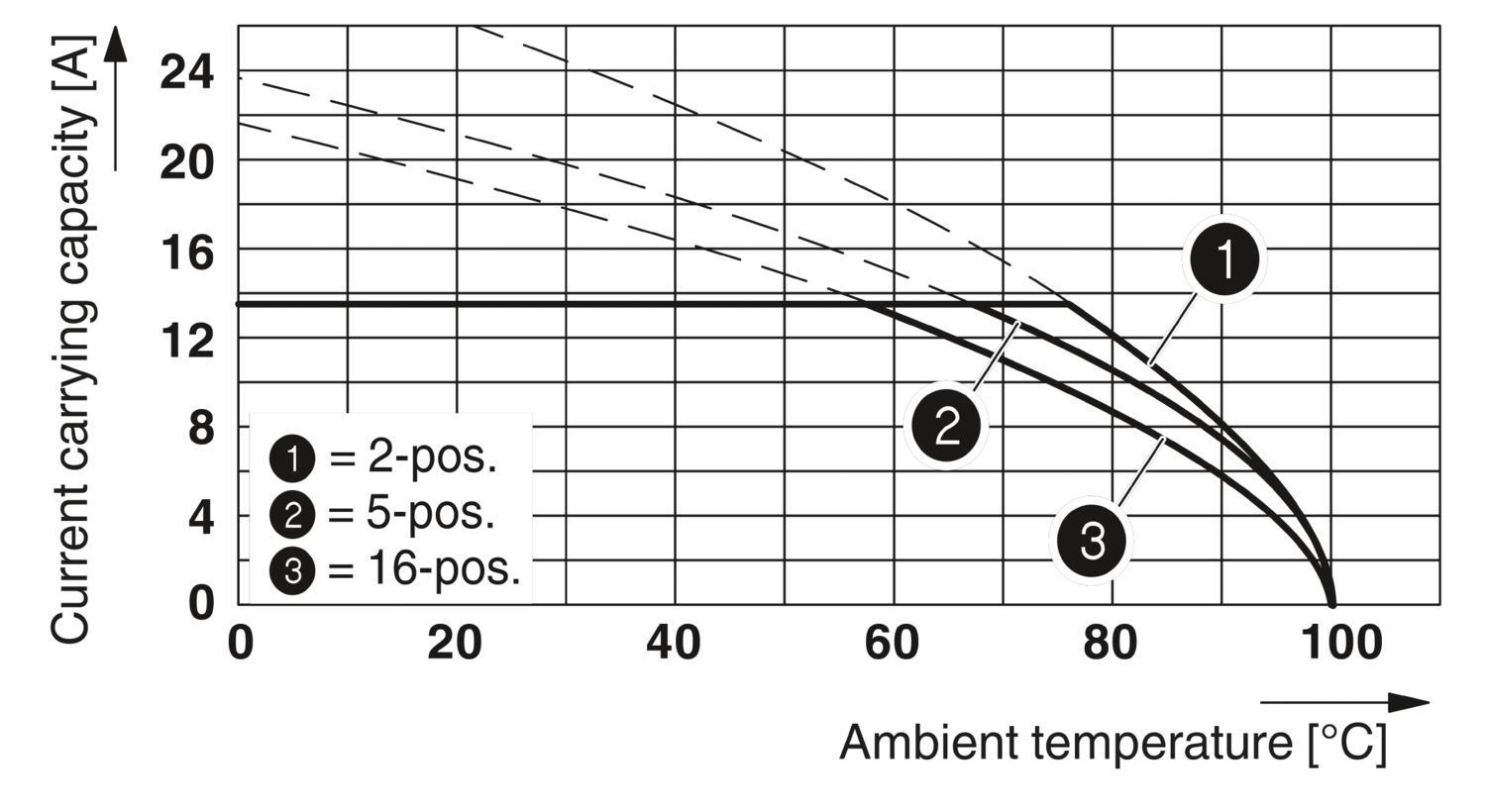

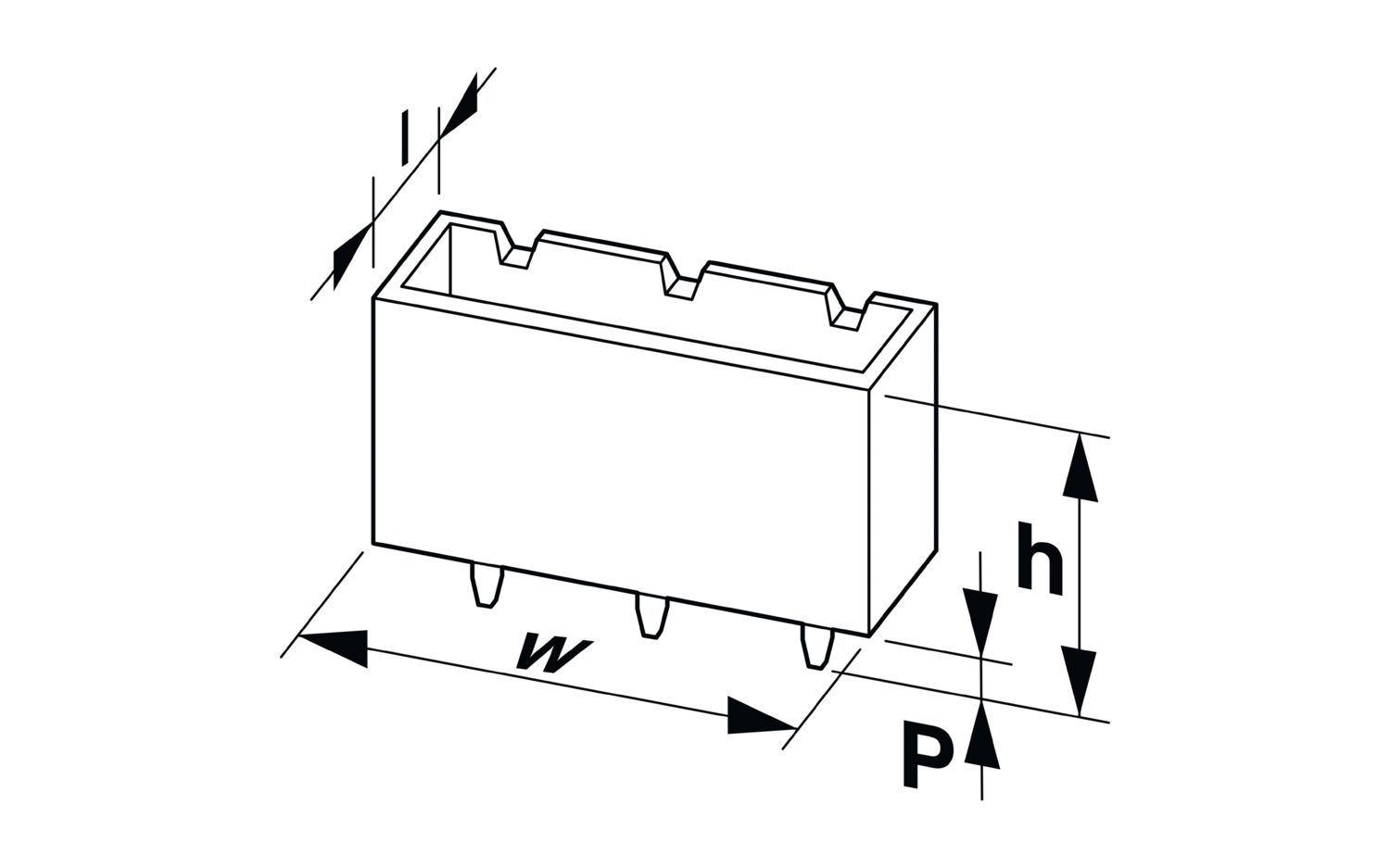

Pin strip, nominal cross section: 1.5 mm2, color: black, nominal current: 12 A (depends on the plug used), rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Pin, number of potentials: 4, number of rows: 1, number of positions: 4, number of connections: 4, product range: PST 1,3/..-V, pitch: 5 mm, mounting: THR soldering / wave soldering, pin layout: Linear pinning, solder pin [P]: 3.5 mm, plug-in system: COMBICON PST 1,3, locking: without, mounting method: without, type of packaging: packed in cardboard, The maximum current depends on the plug used. The lower of the two current values apply for plug and pin strip. The pin strip is made of highly temperature resistant plastic and is thus suitable for the reflow process.