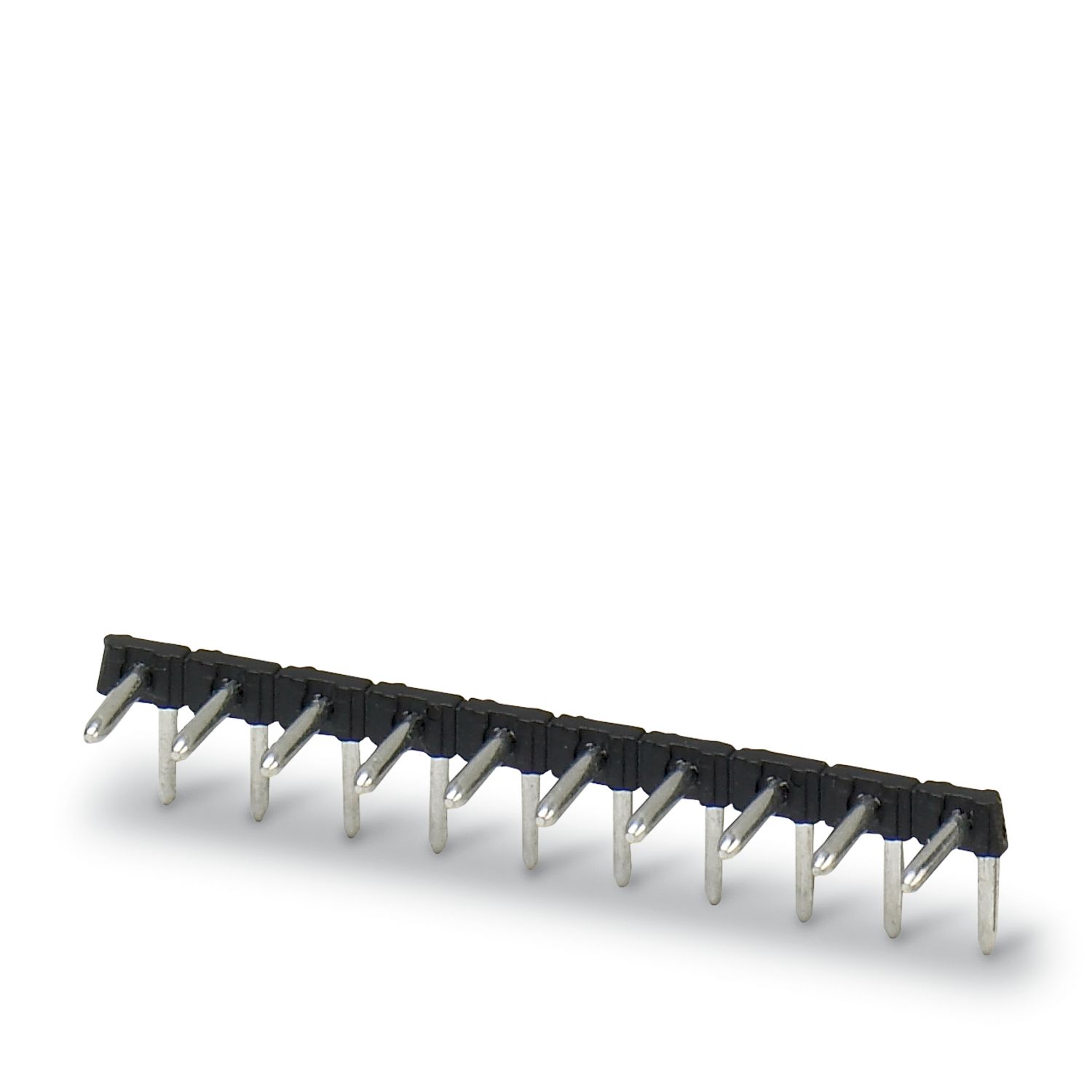

product line COMBICON Connectors S

cross section 1.5 mm2

connection method Screw connection with tension sleeve

screw head form Slotted Phillips recess

type of packaging packed in cardboard

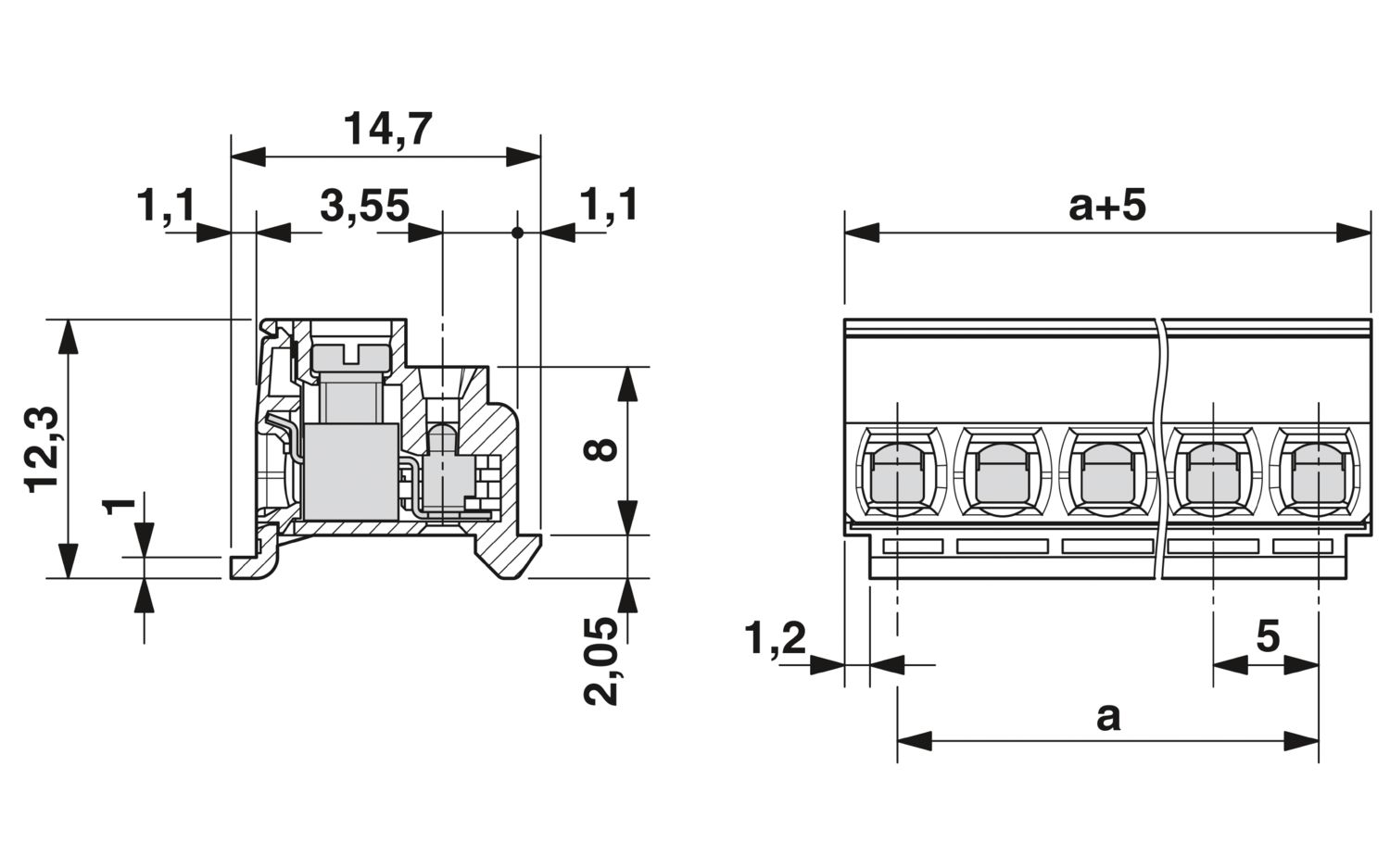

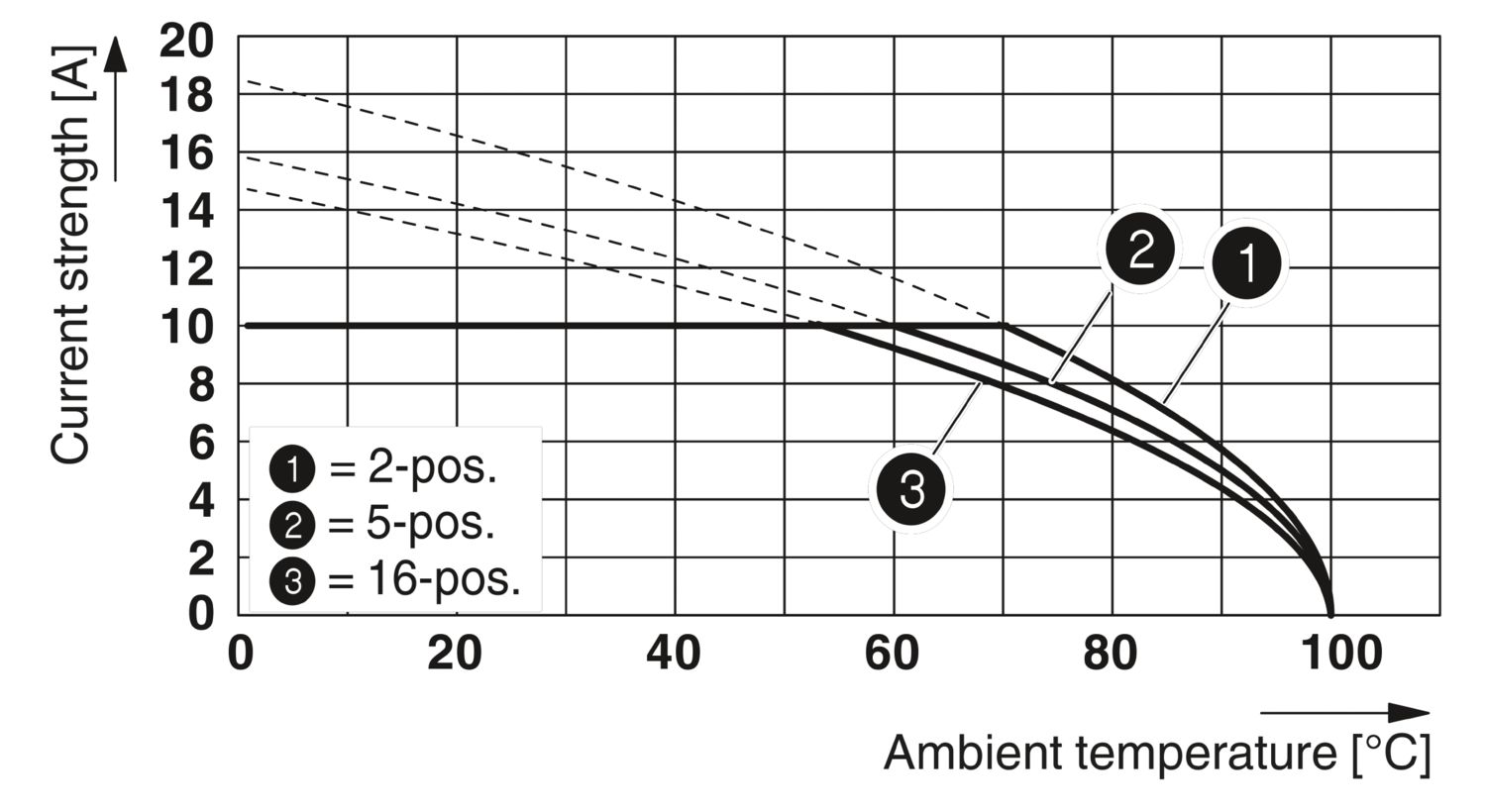

PCB connector, nominal cross section: 1.5 mm2, color: green, nominal current: 10 A, rated voltage (III/2): 400 V, contact surface: Sn, contact connection type: Socket, number of potentials: 2, number of rows: 1, number of positions: 2, number of connections: 2, product range: PT 1,5/..-PH CLIP, pitch: 5 mm, connection method: Screw connection with tension sleeve, screw head form: H1L Slotted Phillips recess, conductor/PCB connection direction: 0 °, plug-in system: COMBICON PST 1,3, locking: without, mounting method: without, type of packaging: packed in cardboard