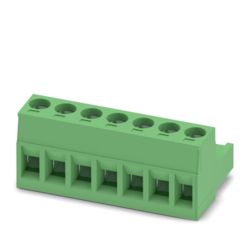

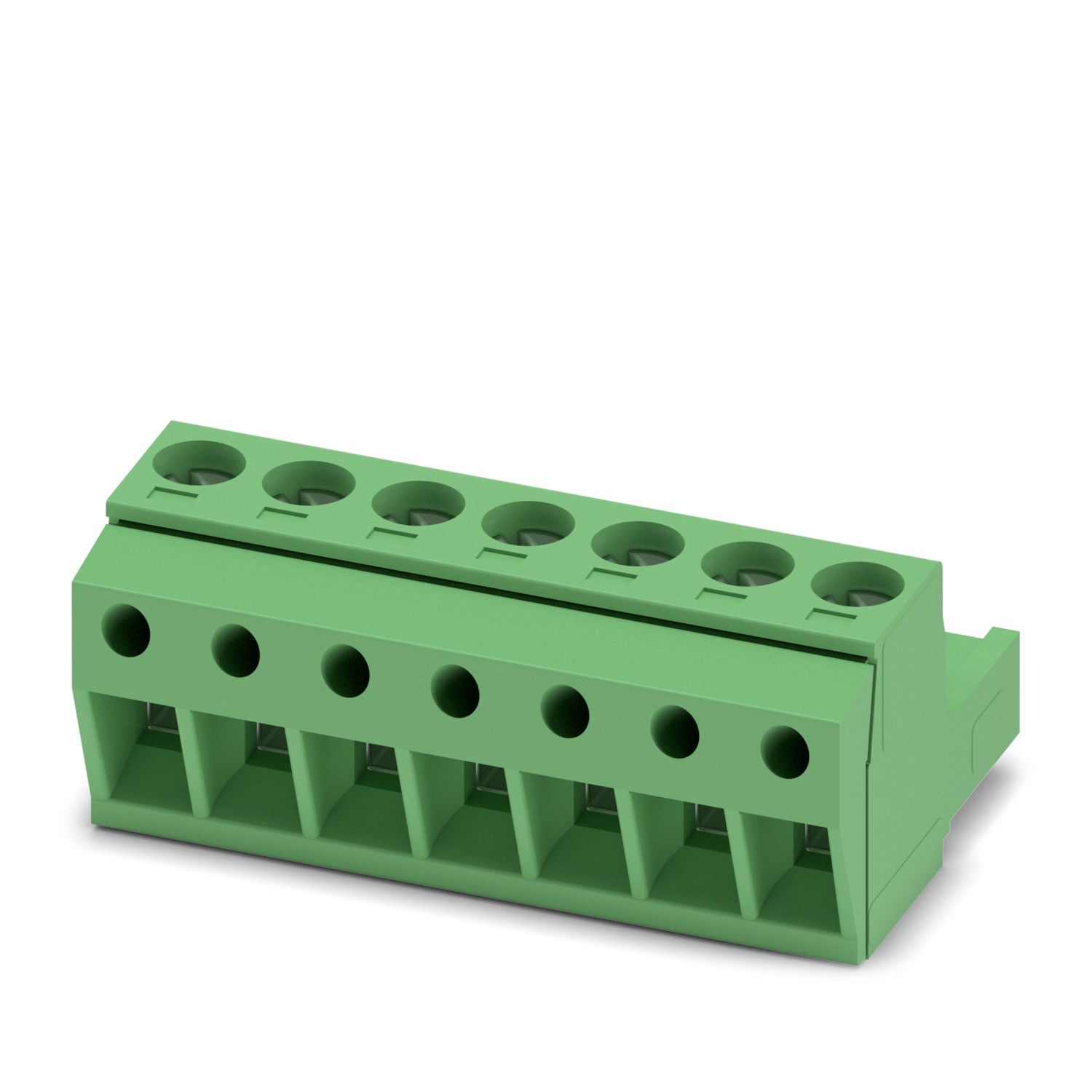

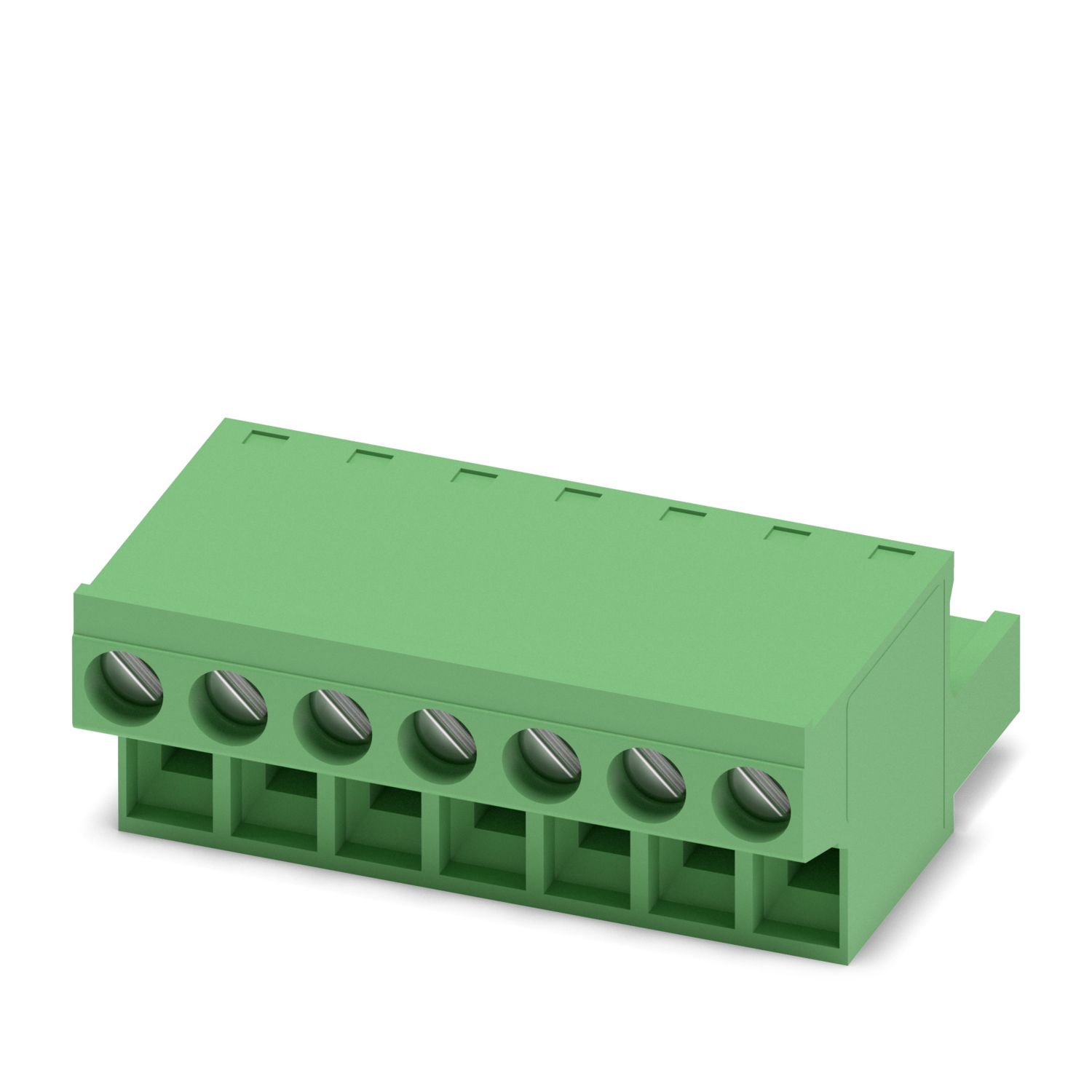

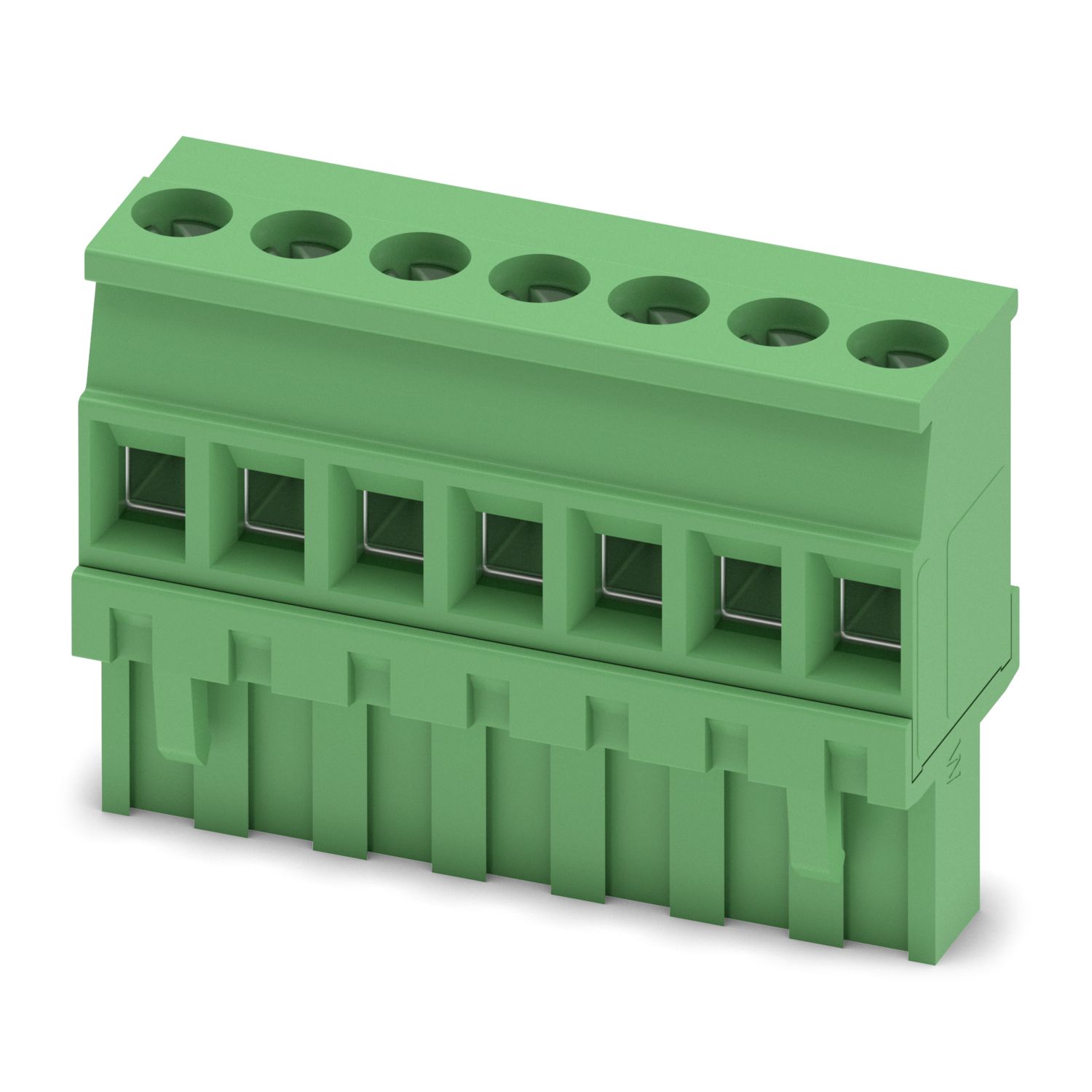

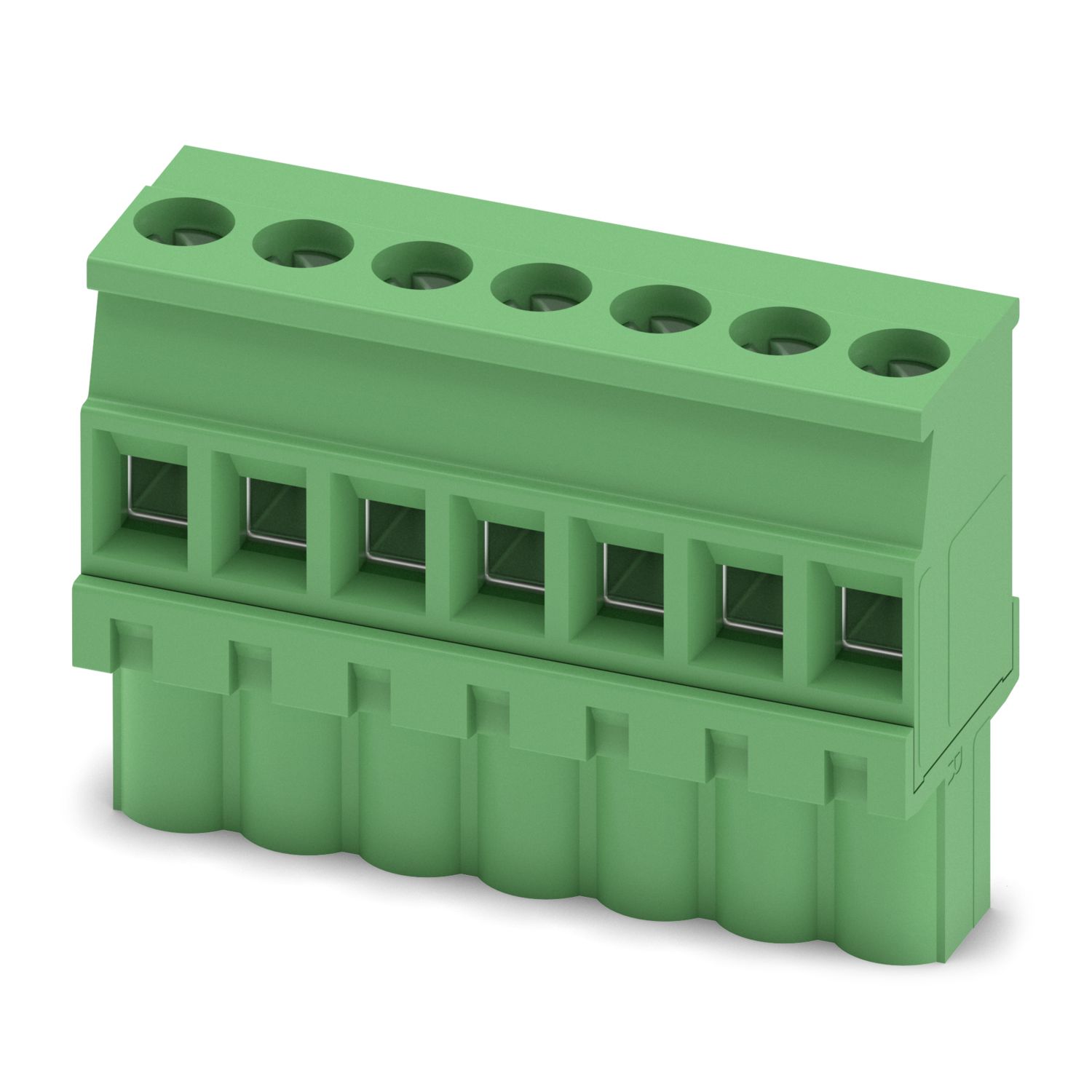

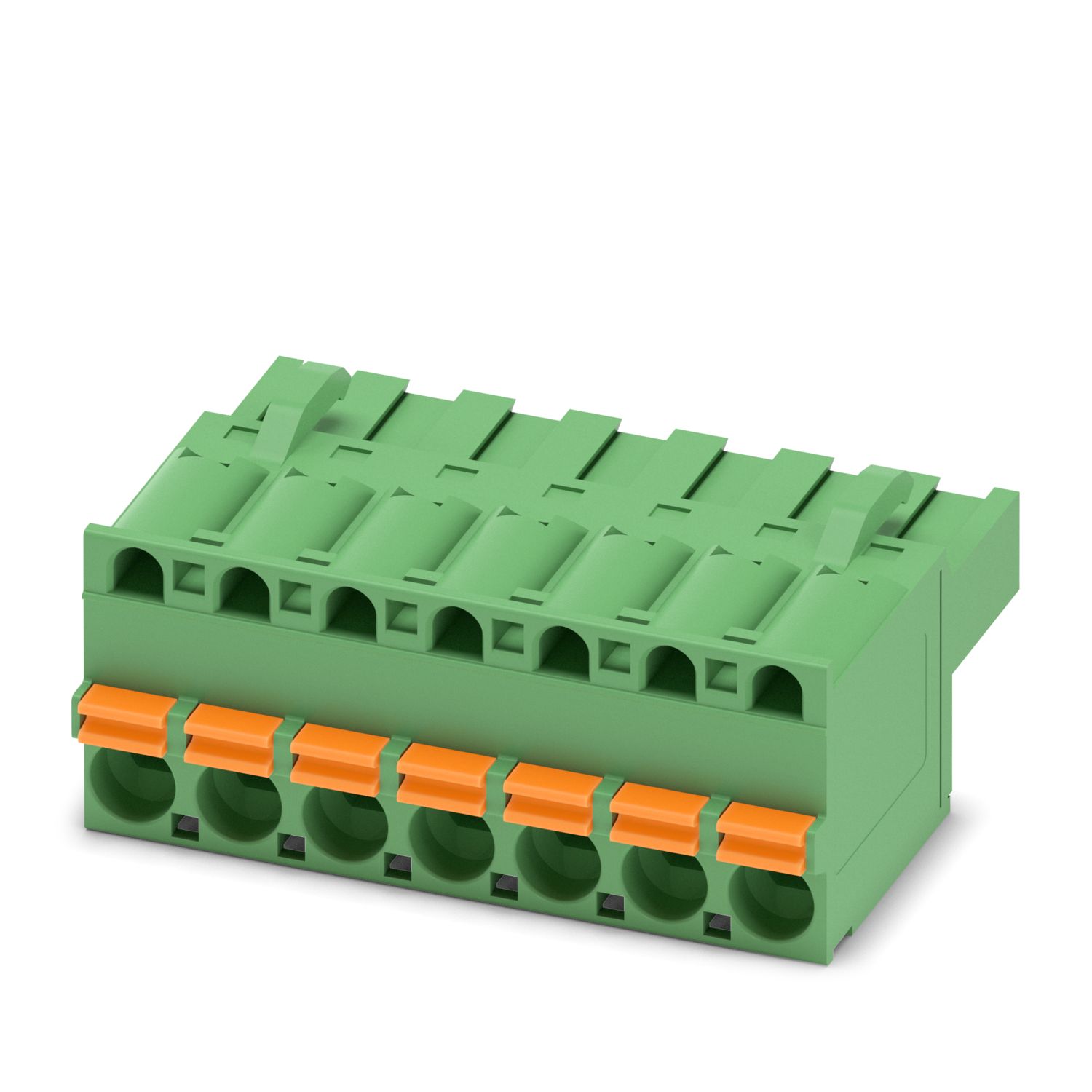

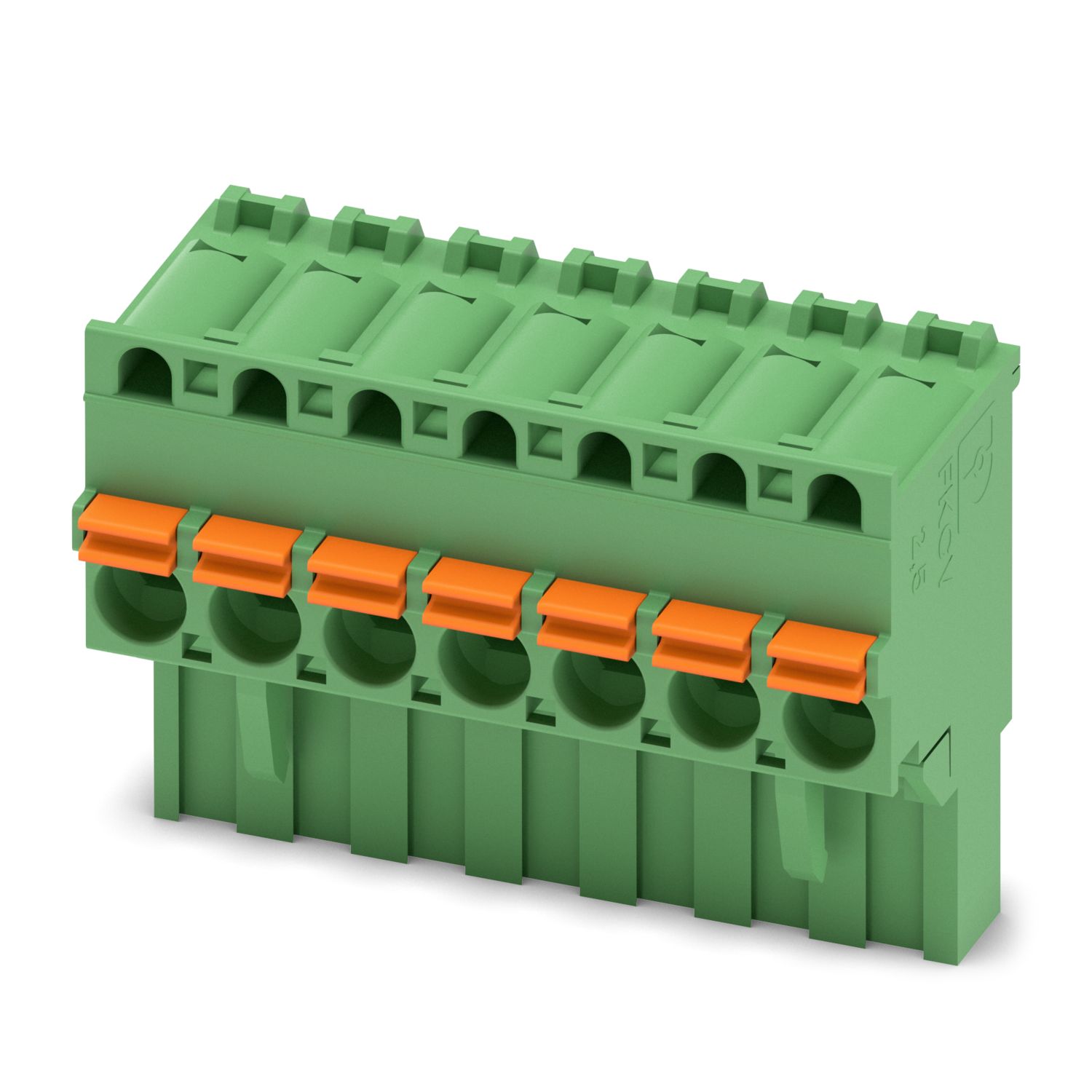

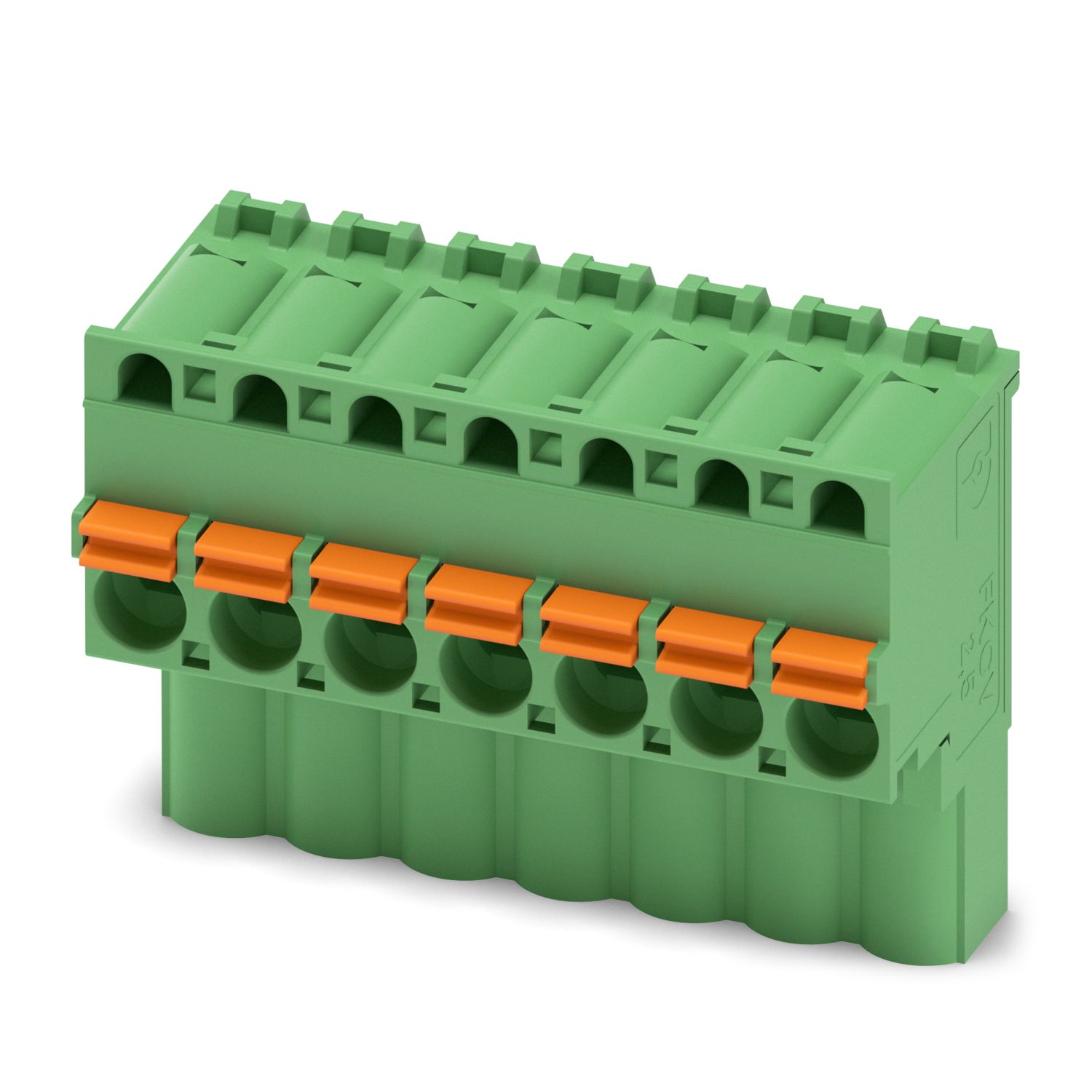

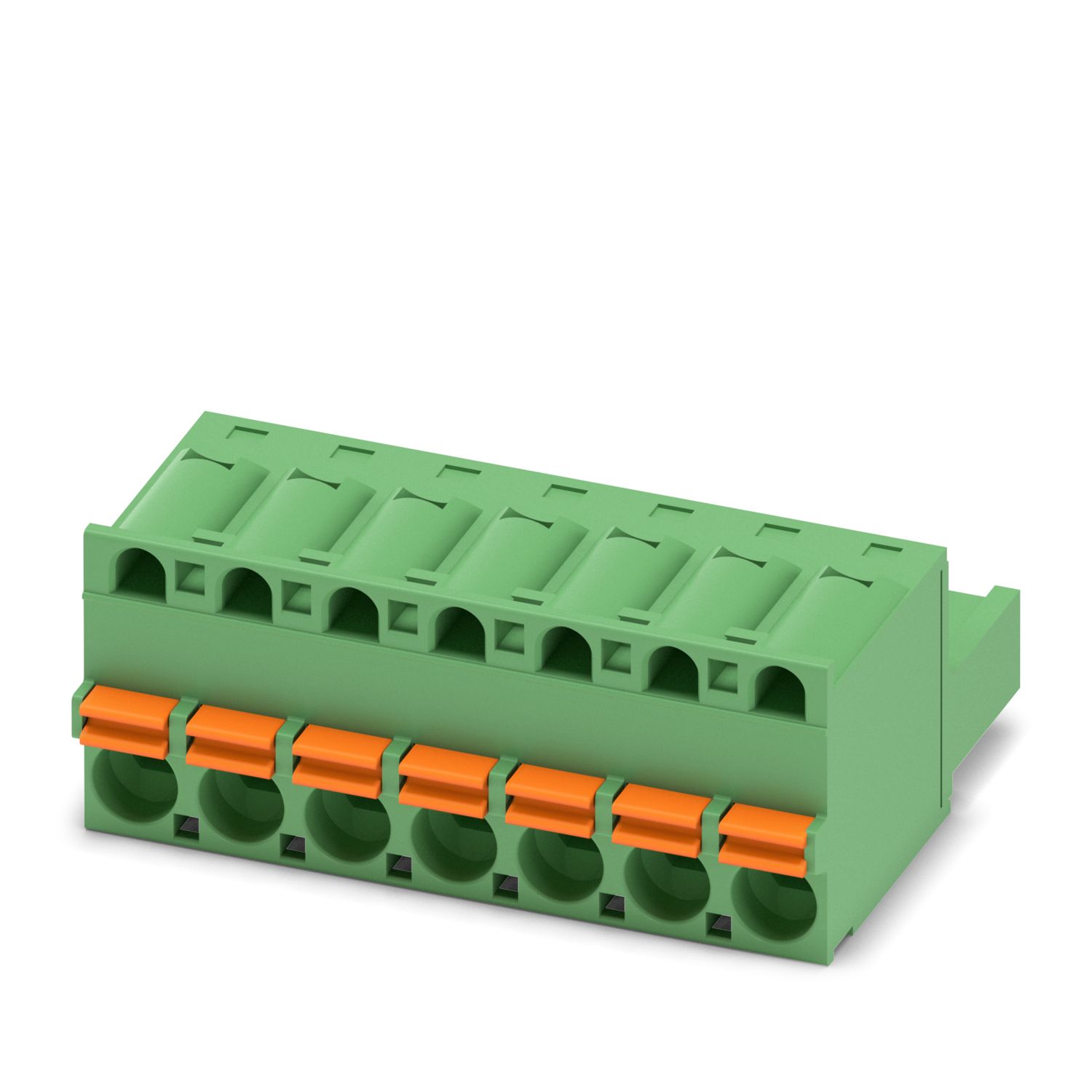

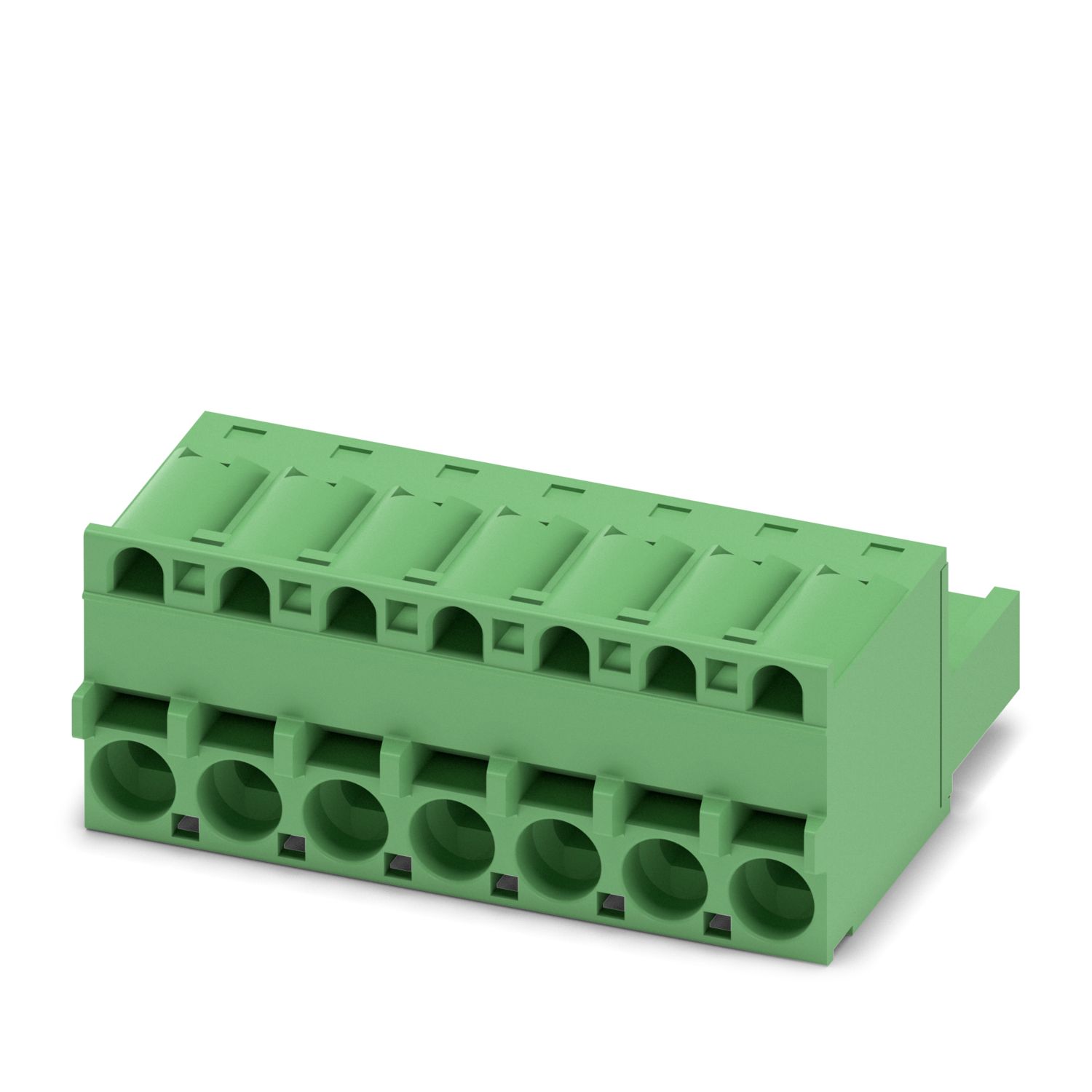

product line COMBICON Connectors M

cross section 2.5 mm2

mounting type Wave soldering

type of packaging packed in cardboard

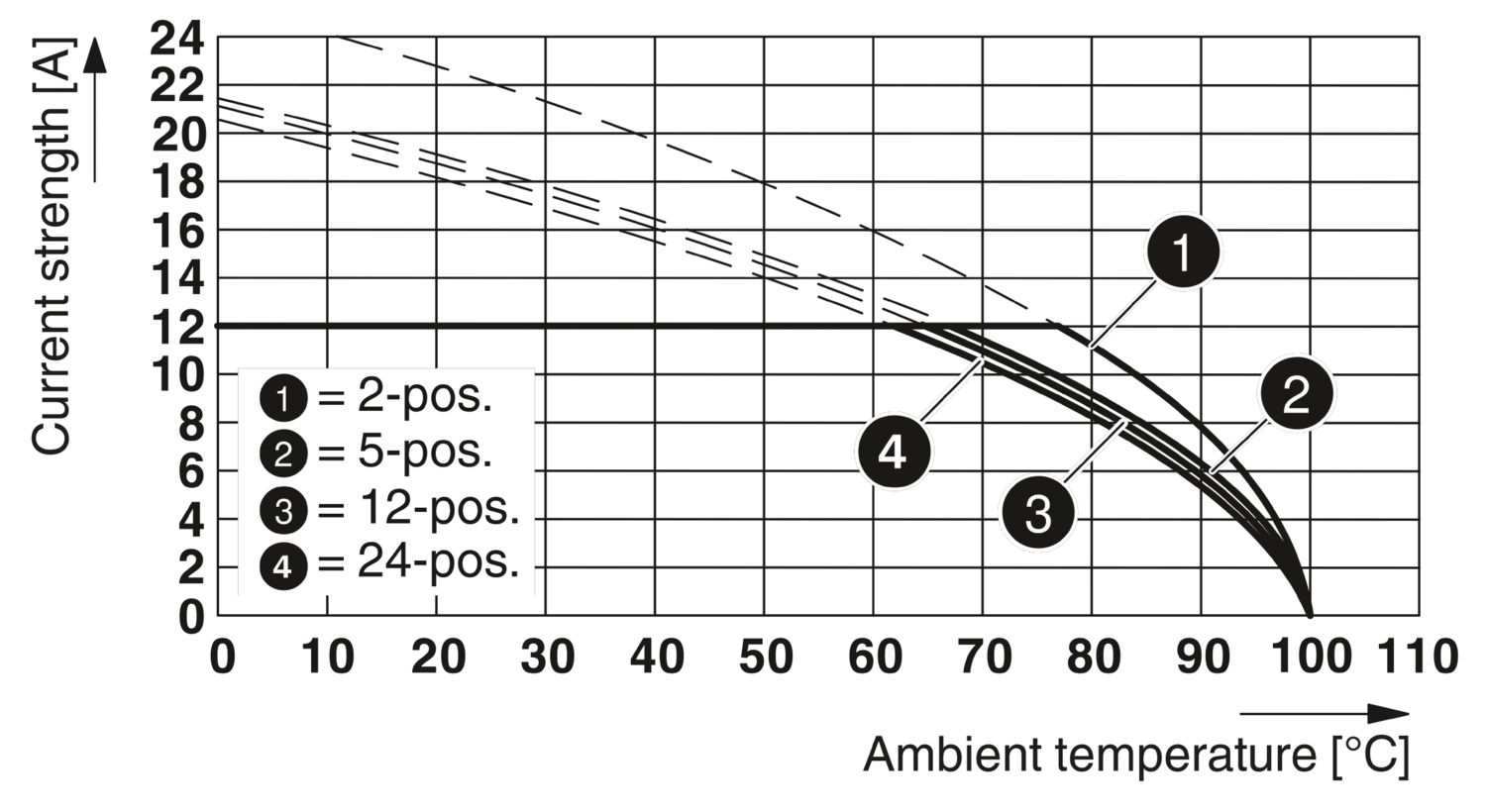

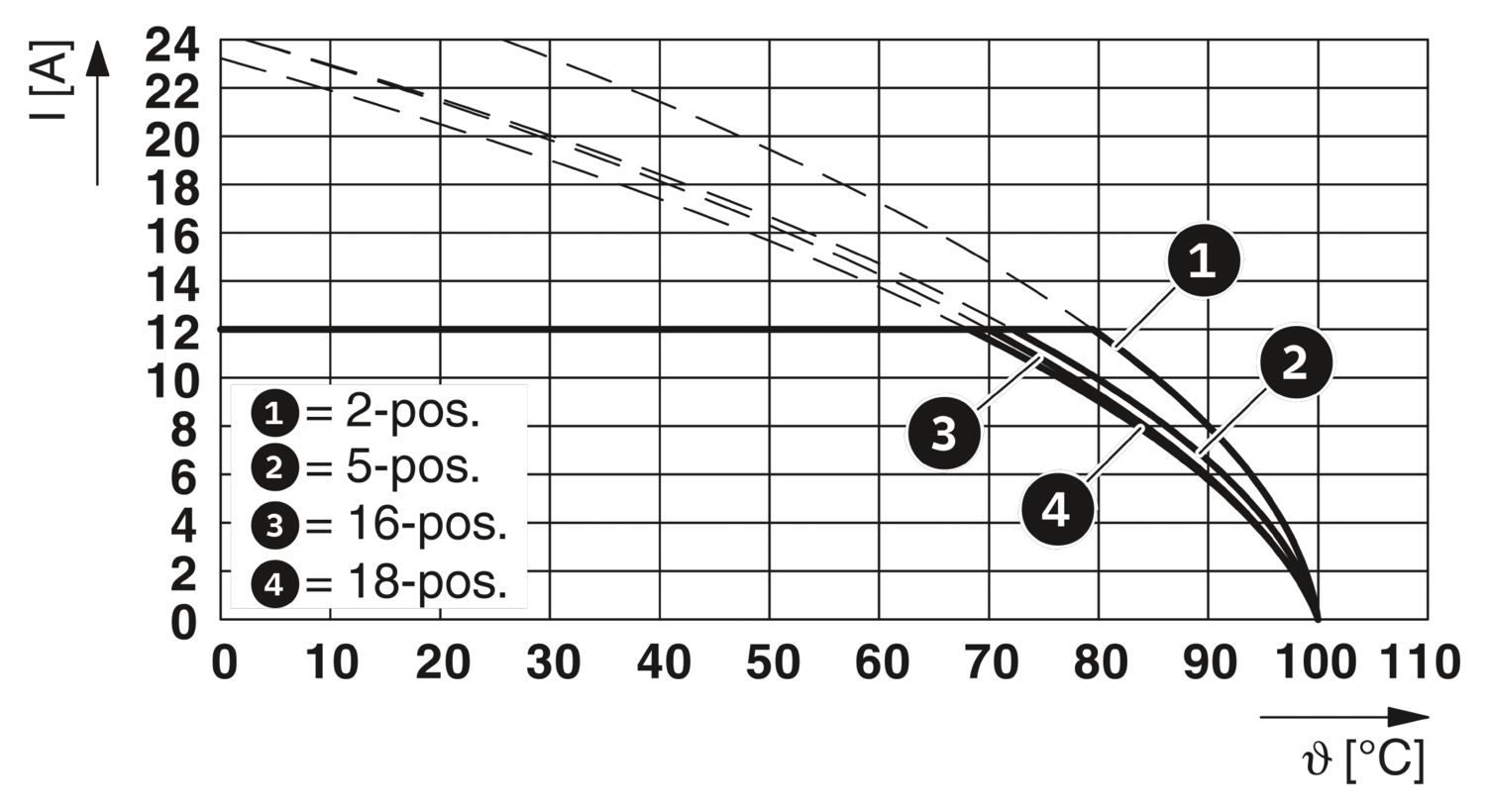

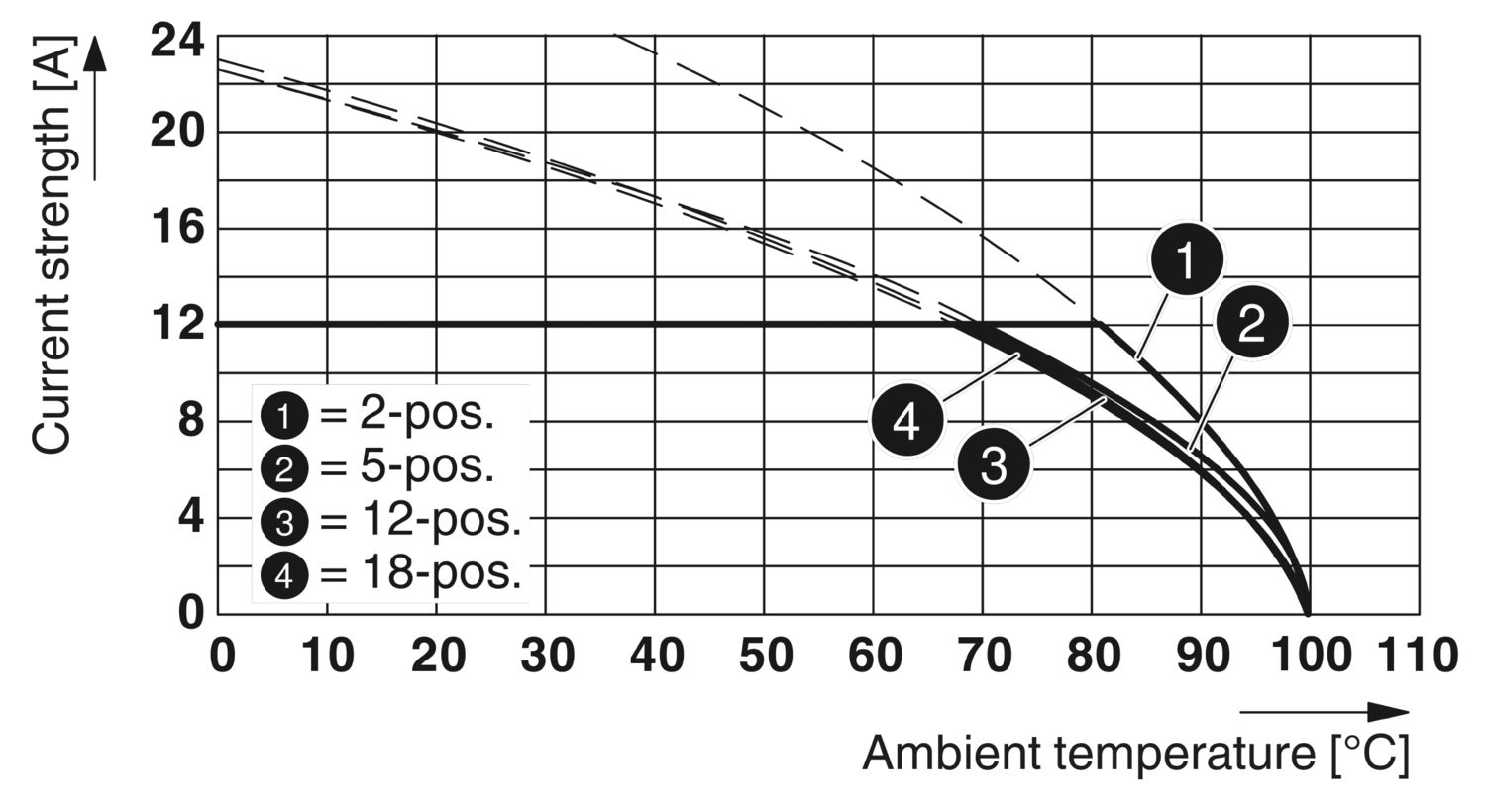

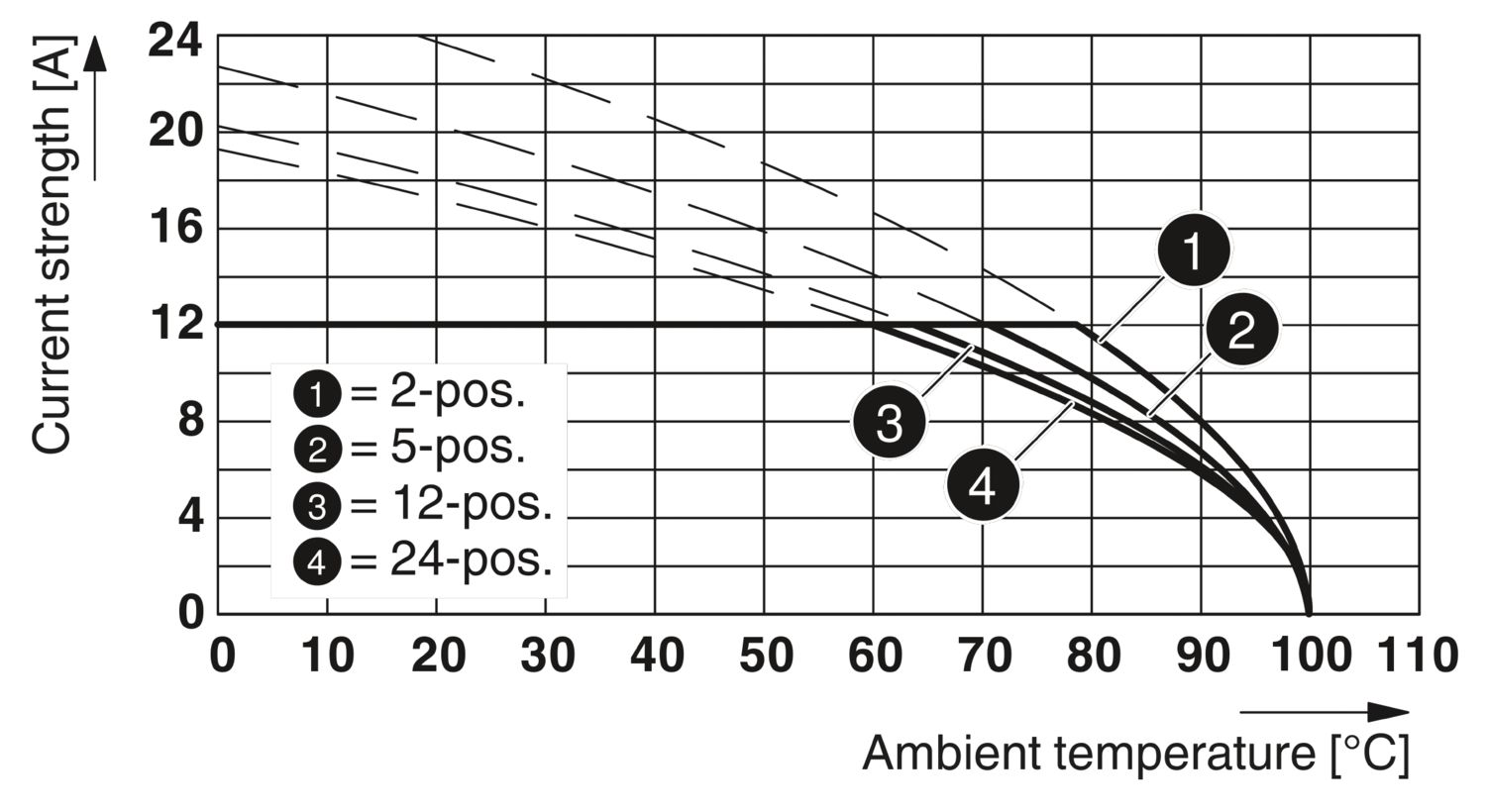

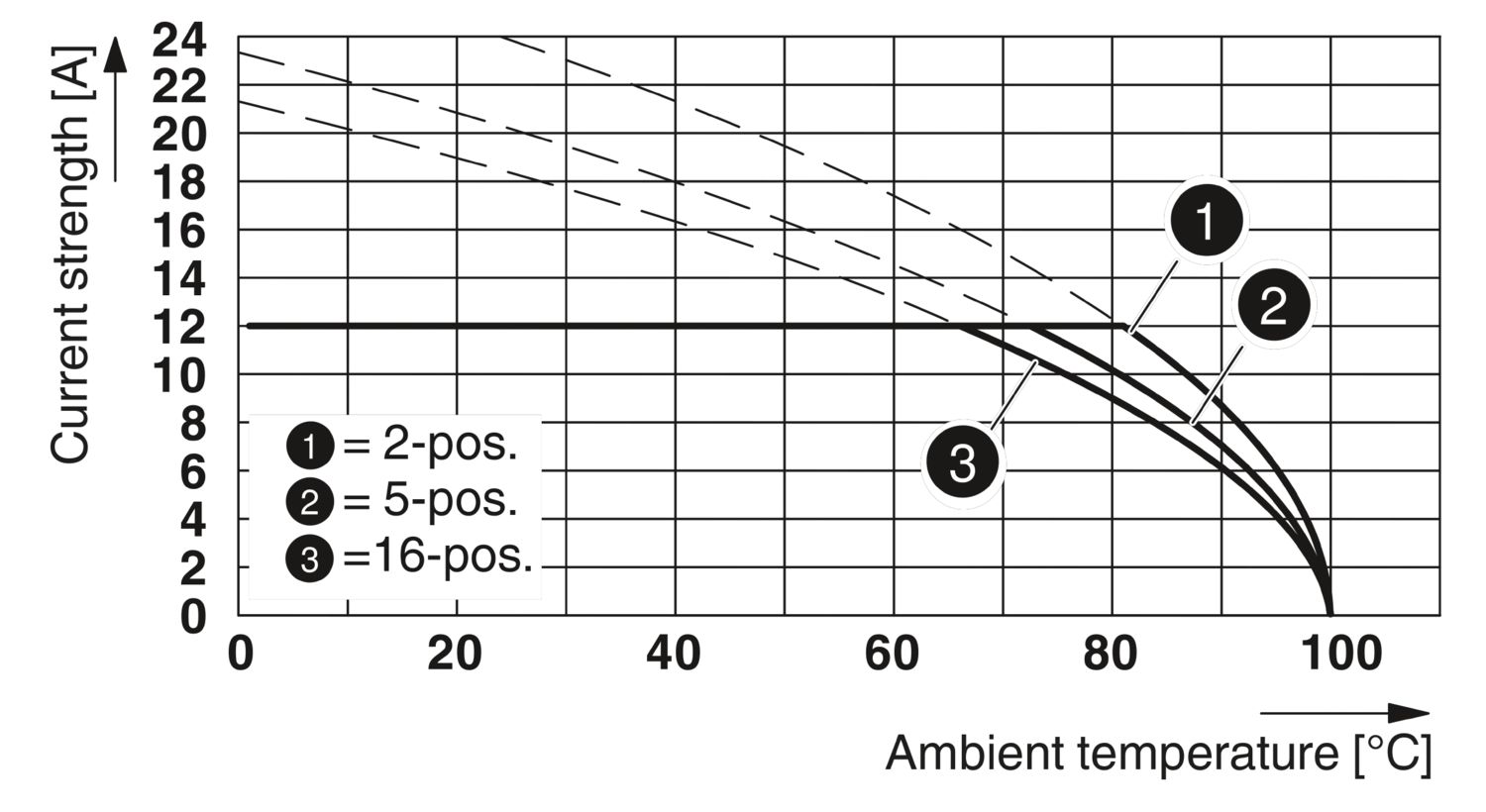

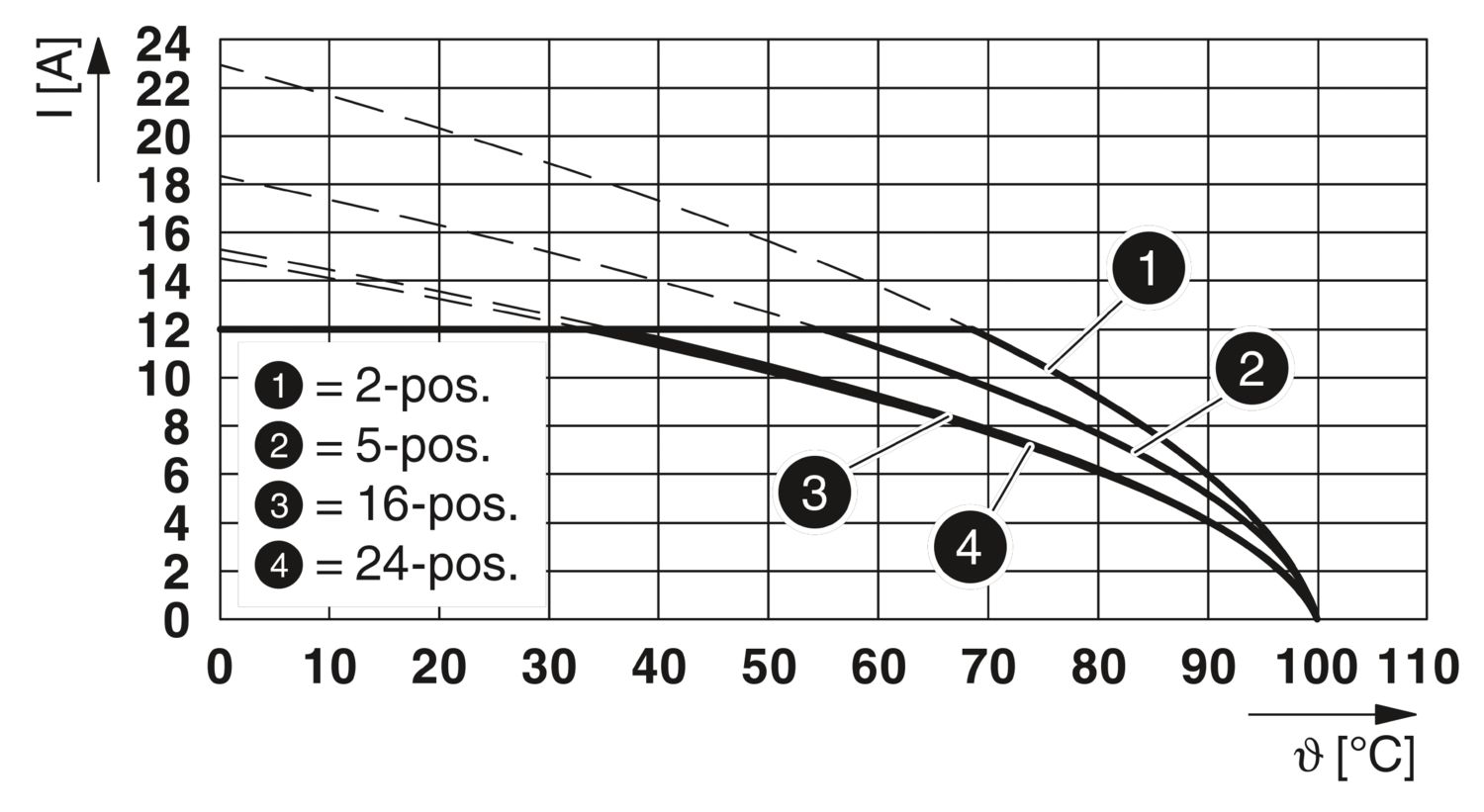

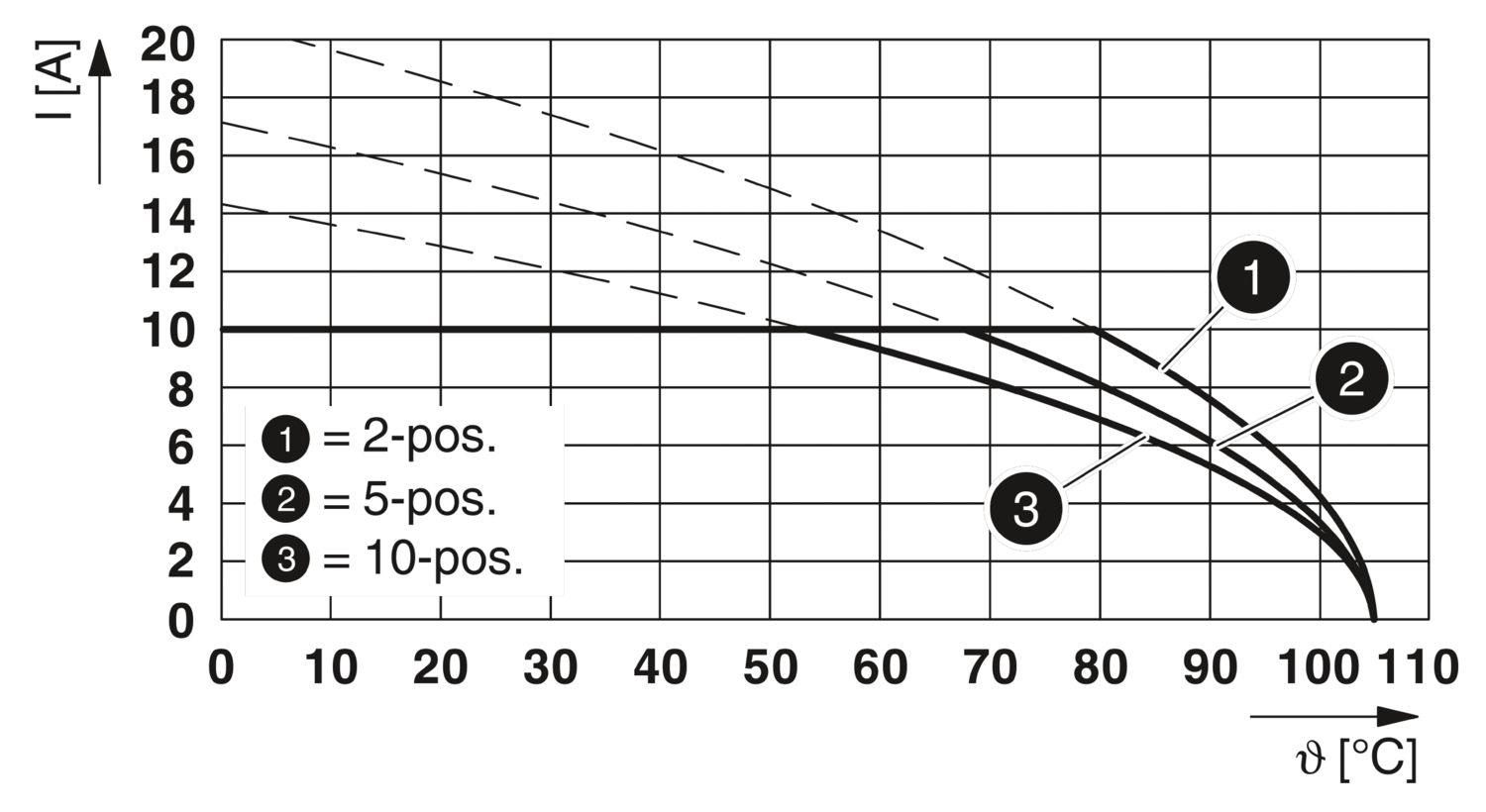

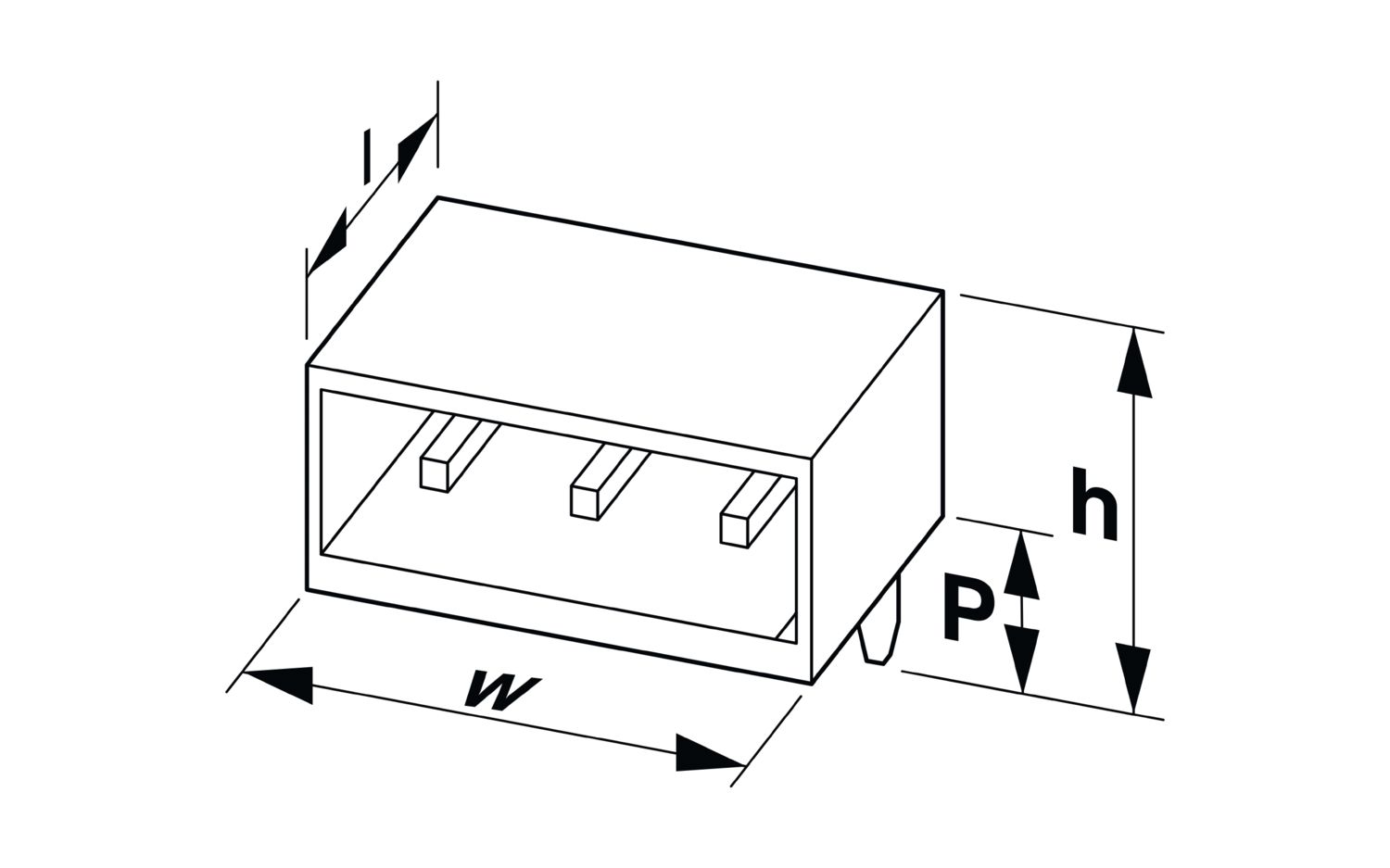

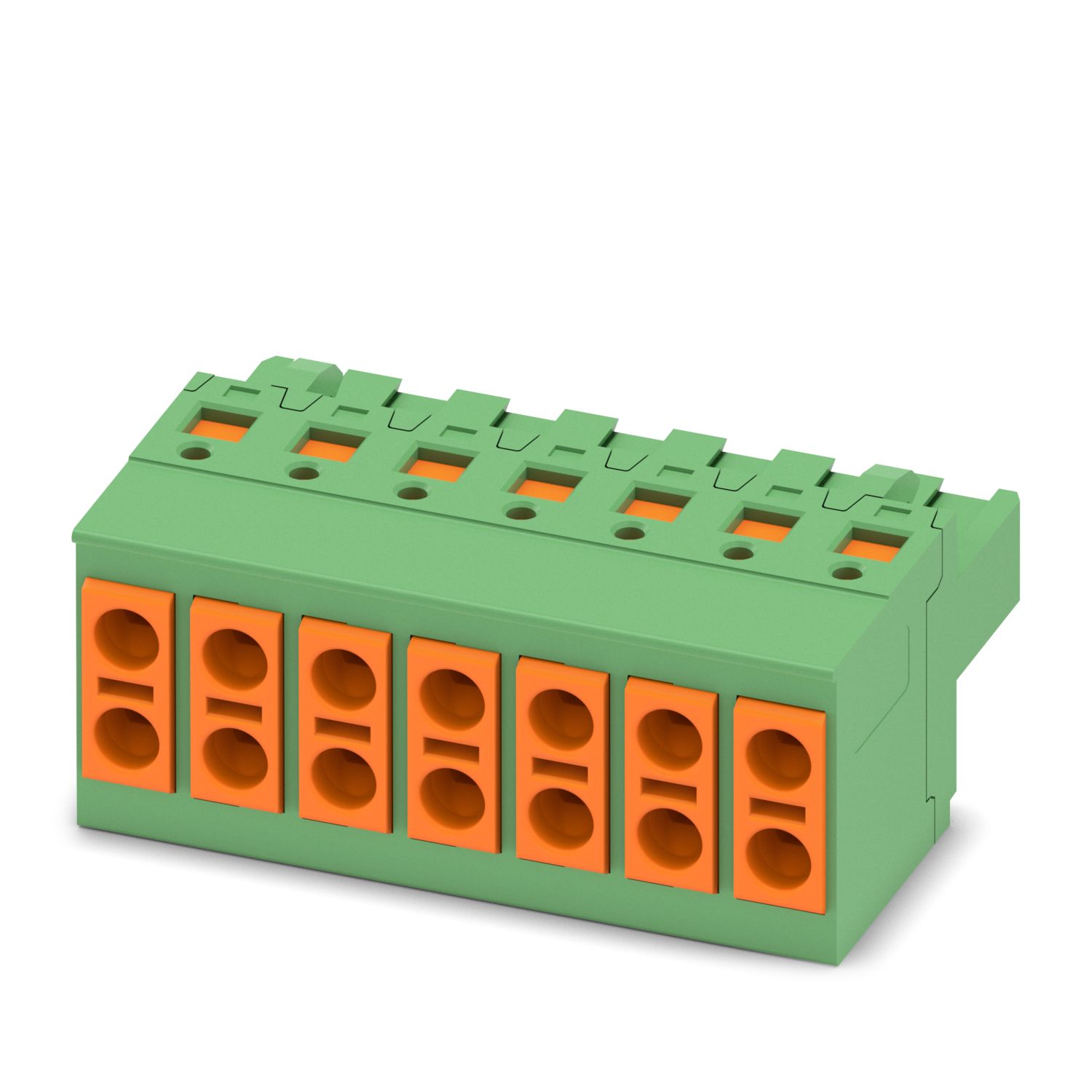

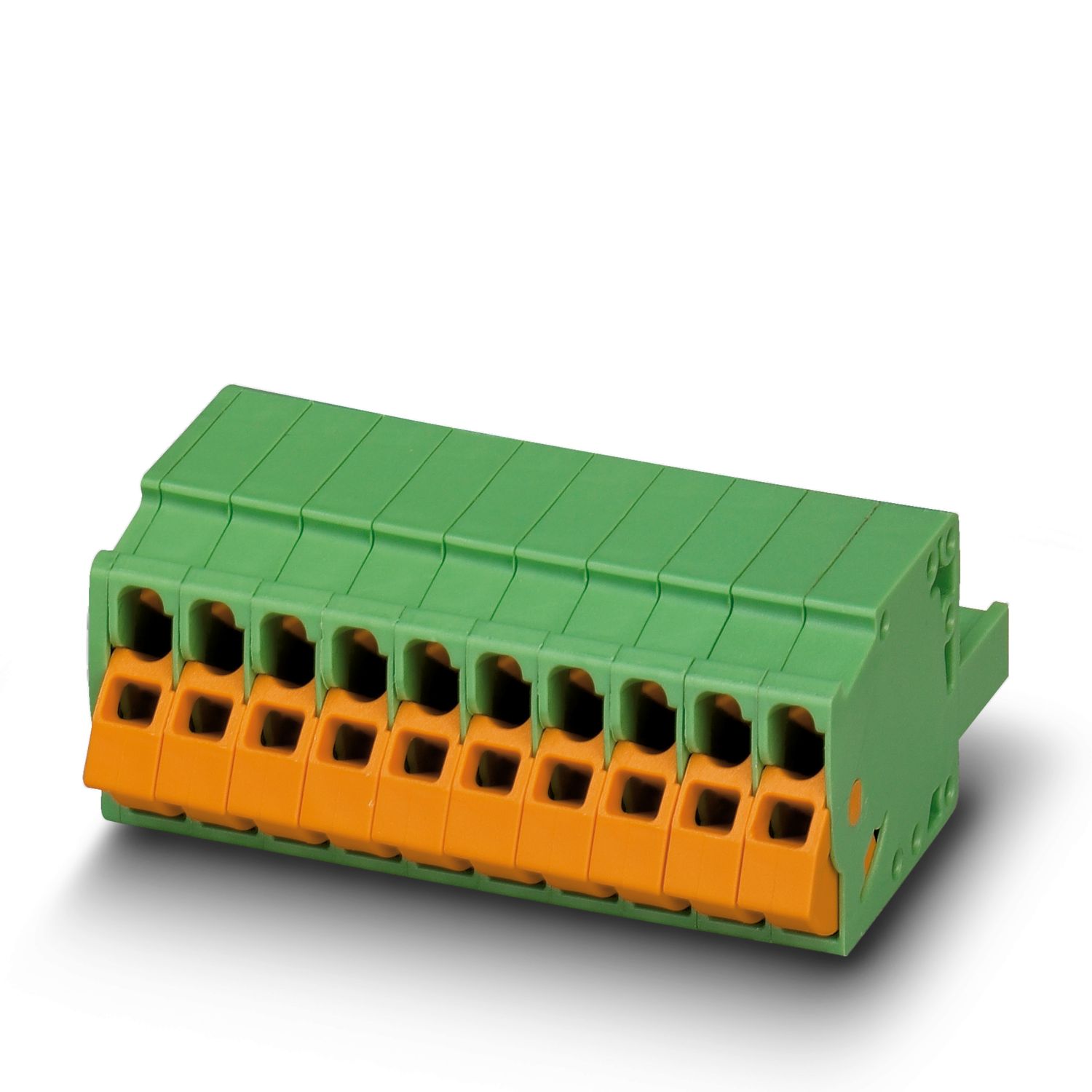

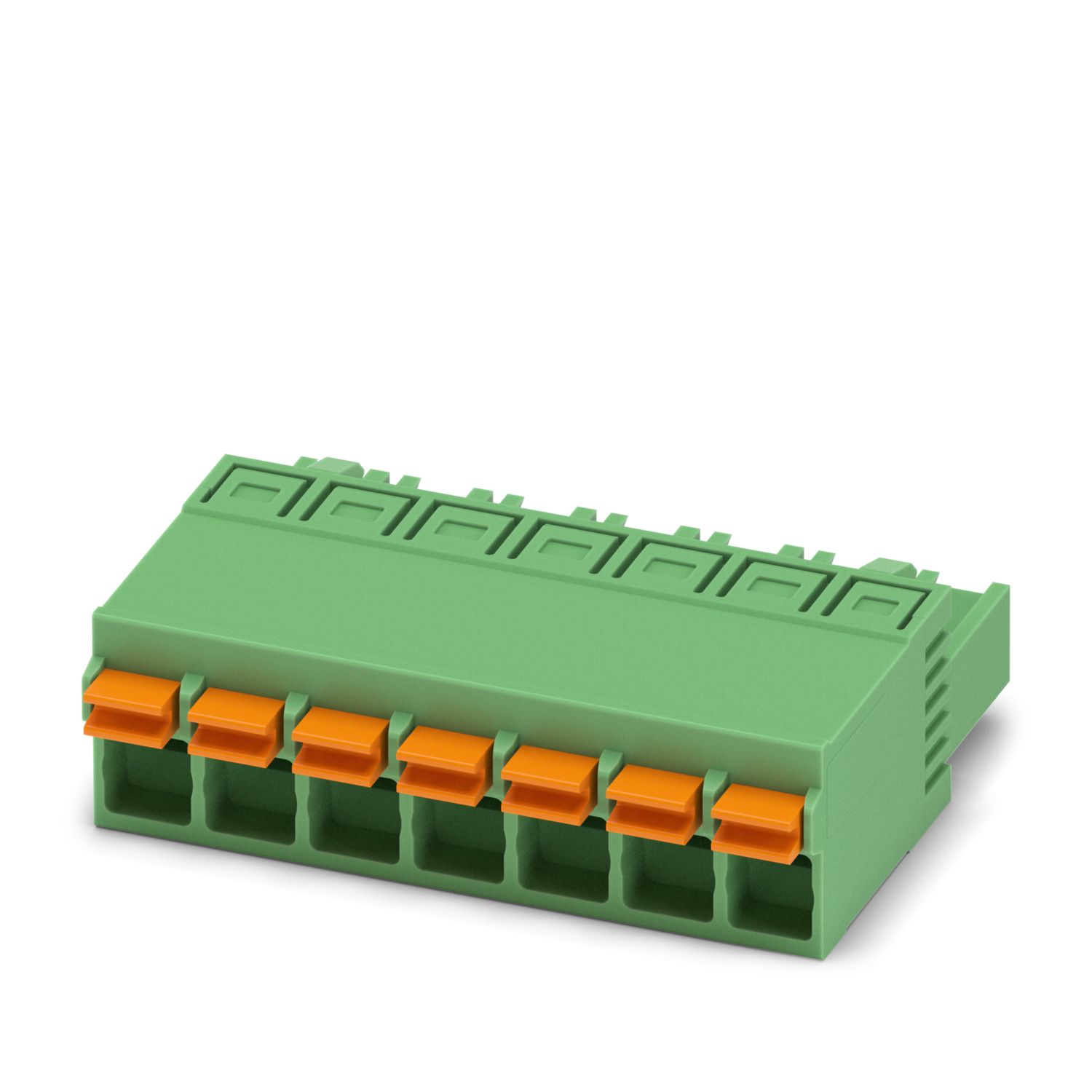

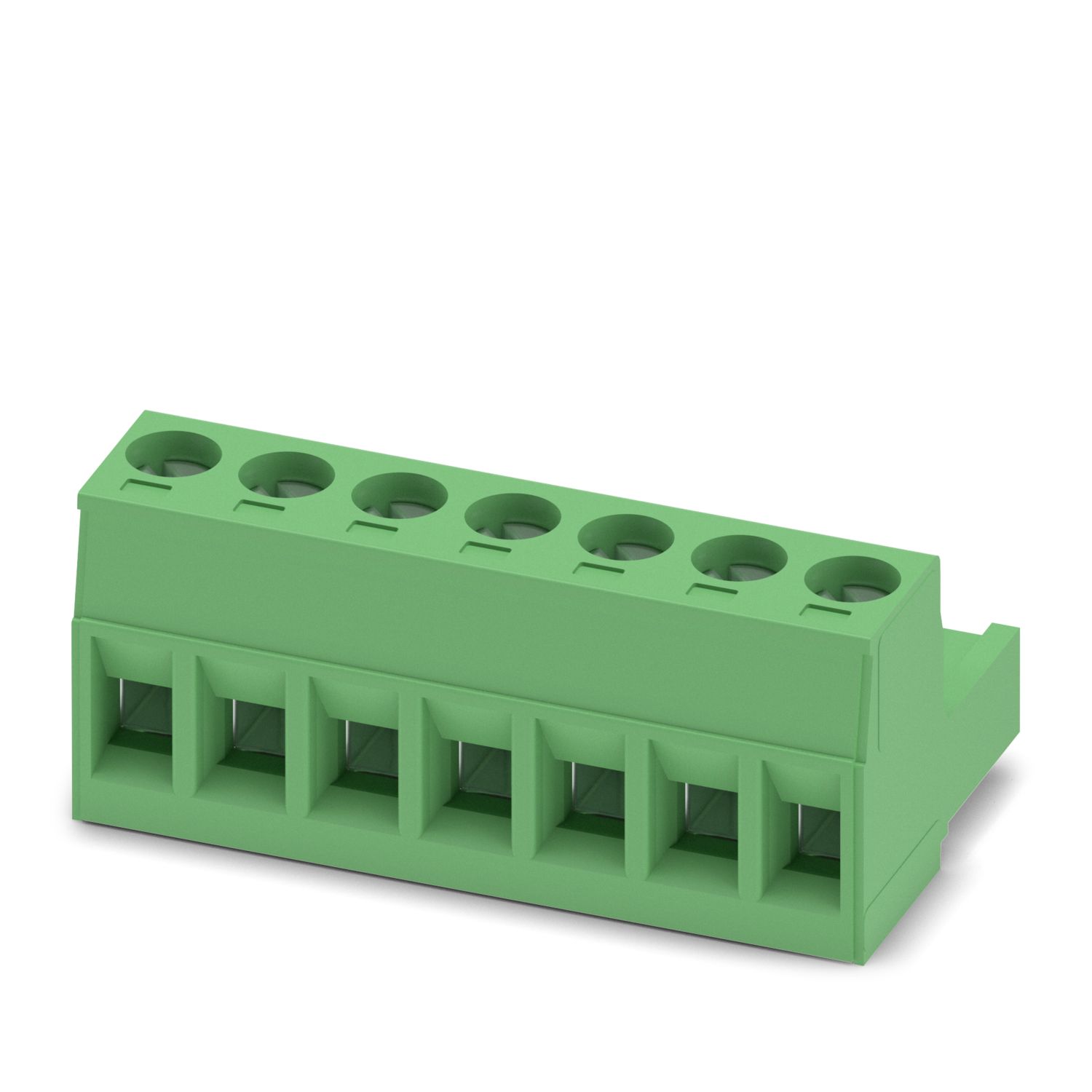

PCB headers, nominal cross section: 2.5 mm2, color: green, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Pin, number of potentials: 7, number of rows: 1, number of positions: 7, number of connections: 7, product range: MSTBA 2,5/..-G, pitch: 5 mm, mounting: Wave soldering, pin layout: Linear pinning, solder pin [P]: 3.23 mm, number of solder pins per potential: 1, plug-in system: COMBICON MSTB 2,5, Pin connector pattern alignment: Standard, locking: without, mounting method: without, type of packaging: packed in cardboard