MC 1,5/ 2-G-3,81 P26 THRR24

-

PCB header

1103274

PCB headers, nominal cross section: 1.5 mm2, color: black, nominal current: 8 A, rated voltage (III/2): 160 V, contact surface: Sn, contact connection type: Pin, number of rows: 1, number of positions: 2, product range: MC 1,5/..-G-THR, pitch: 3.81 mm, mounting: THR soldering / wave soldering, pin layout: Linear pinning, solder pin [P]: 2.6 mm, number of solder pins per potential: 1, plug-in system: COMBICON MC 1,5, Pin connector pattern alignment: Standard, locking: without, mounting method: without, type of packaging: 24 mm wide tape, For user information and design recommendations for through-hole reflow technology, go to: Downloads

Product details

| Product family | MC 1,5/..-G-THR |

| Product line | COMBICON Connectors S |

| Number of positions | 2 |

| Pitch | 3.81 mm |

| Number of rows | 1 |

| Pin layout | Linear pinning |

| Solder pins per potential | 1 |

| Properties | |

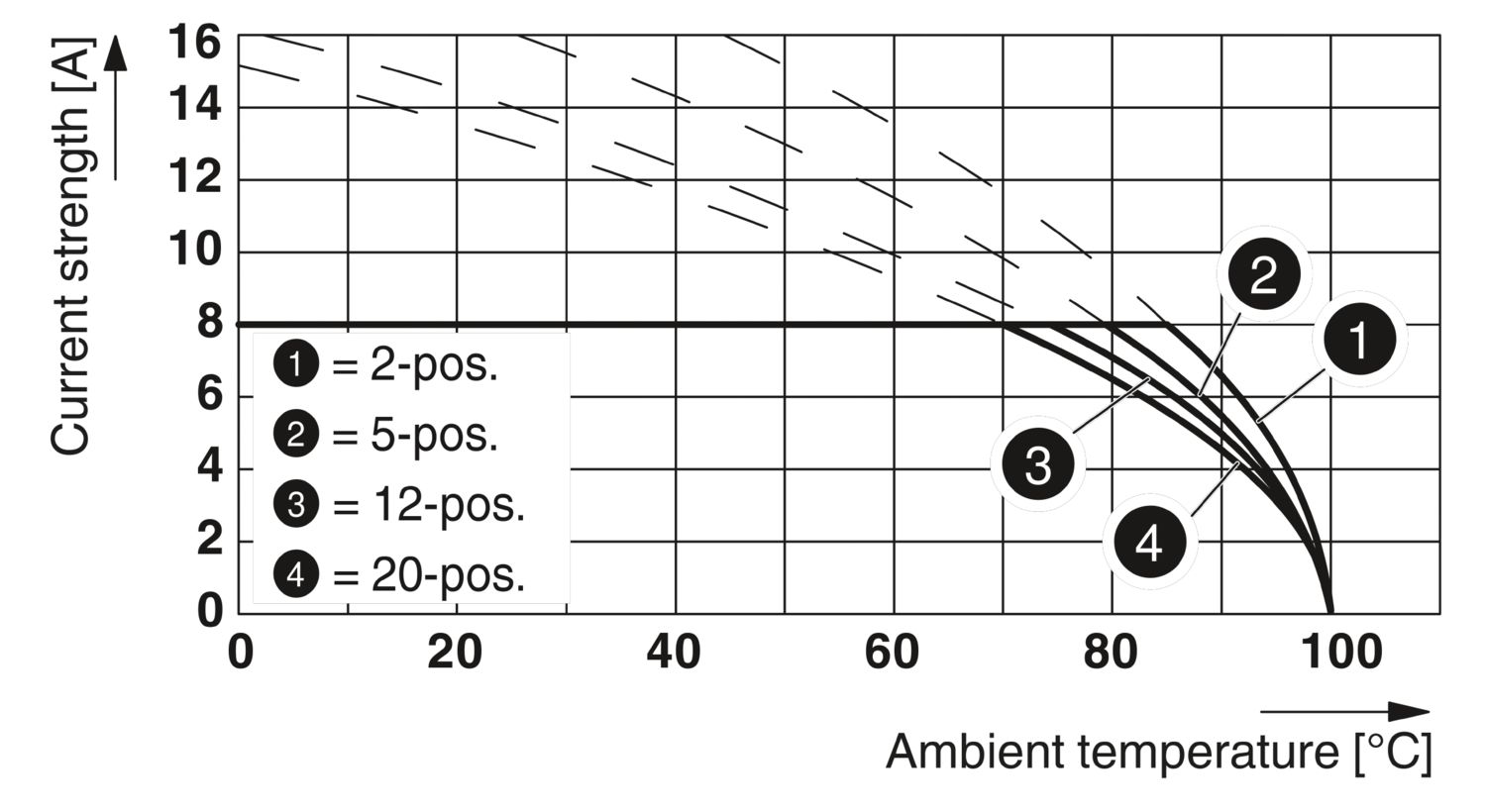

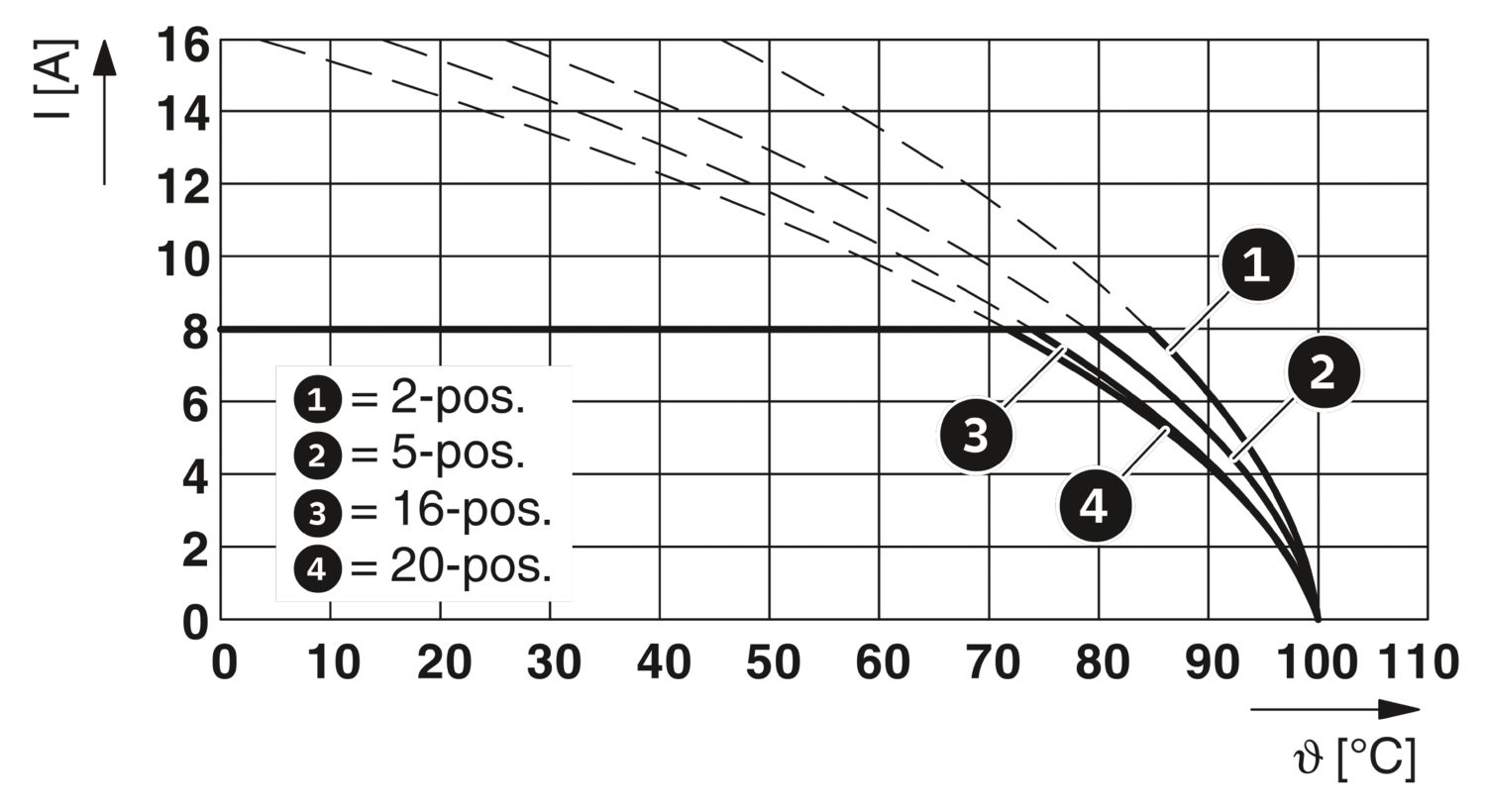

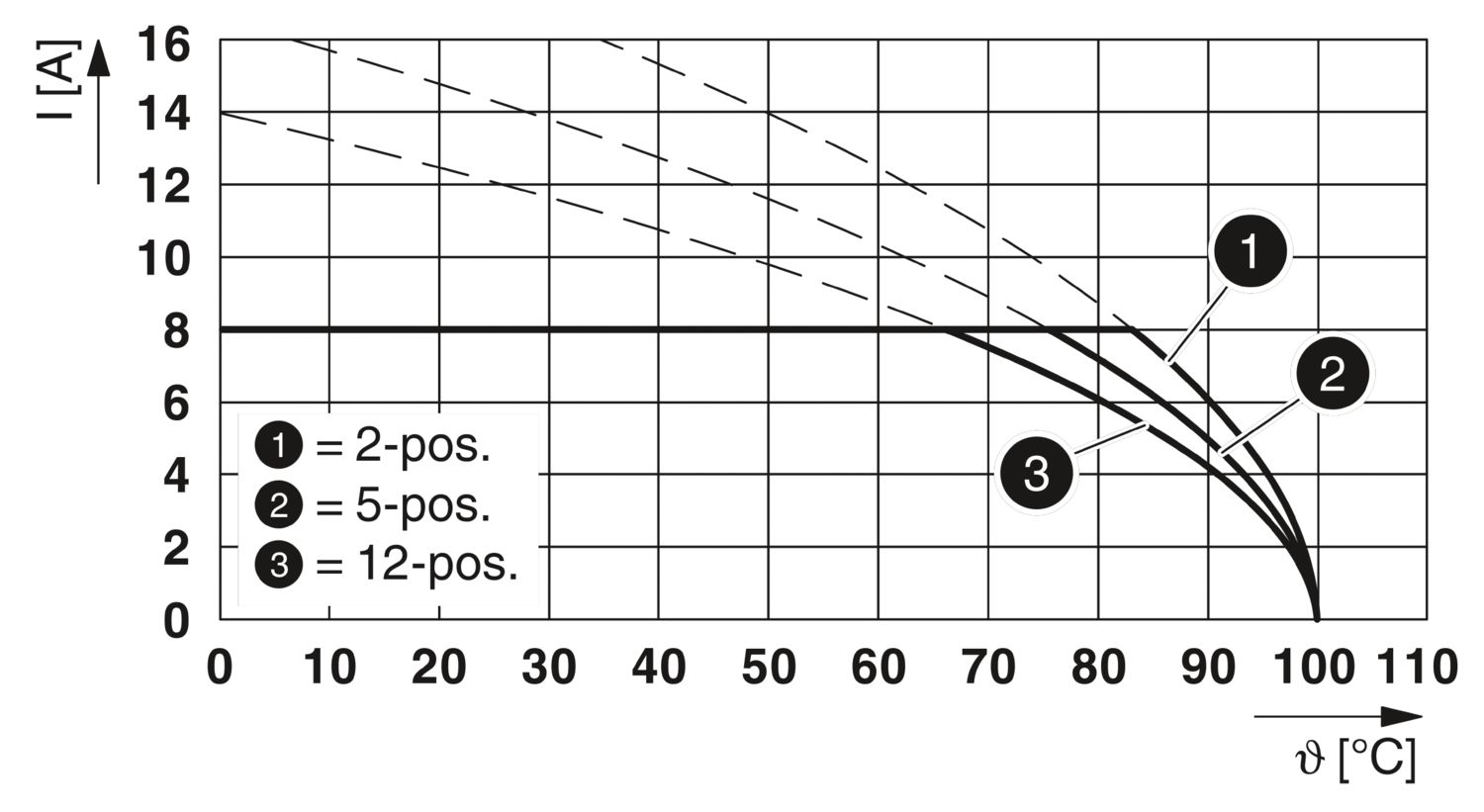

| Nominal current IN | 8 A |

| Nominal voltage UN | 160 V |

| Contact resistance | 1.4 mΩ |

| Rated voltage (III/3) | 160 V |

| Rated surge voltage (III/3) | 2.5 kV |

| Rated voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| Rated voltage (II/2) | 250 V |

| Rated surge voltage (II/2) | 2.5 kV |

| Mounting type | THR soldering / wave soldering |

| Pin layout | Linear pinning |

| Processing notes | |

| Process | Reflow/wave soldering |

| Moisture Sensitive Level | MSL 1 |

| Classification temperature Tc | 260 °C |

| Solder cycles in the reflow | 3 |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | Tin-plated |

| Metal surface contact area (top layer) | Tin (3 - 5 µm Sn) |

| Metal surface contact area (middle layer) | Nickel (1.3 - 3 µm Ni) |

| Metal surface soldering area (top layer) | Tin (3 - 5 µm Sn) |

| Metal surface soldering area (middle layer) | Nickel (1.3 - 3 µm Ni) |

| Material data - housing | |

| Color (Housing) | black (9005) |

| Insulating material | LCP |

| Insulating material group | IIIa |

| CTI according to IEC 60112 | 175 |

| Flammability rating according to UL 94 | V0 |

| General | In accordance with IEC 61984, COMBICON connectors have no switching power (COC). During designated use, they must not be plugged in or disconnected when carrying voltage or under load. |

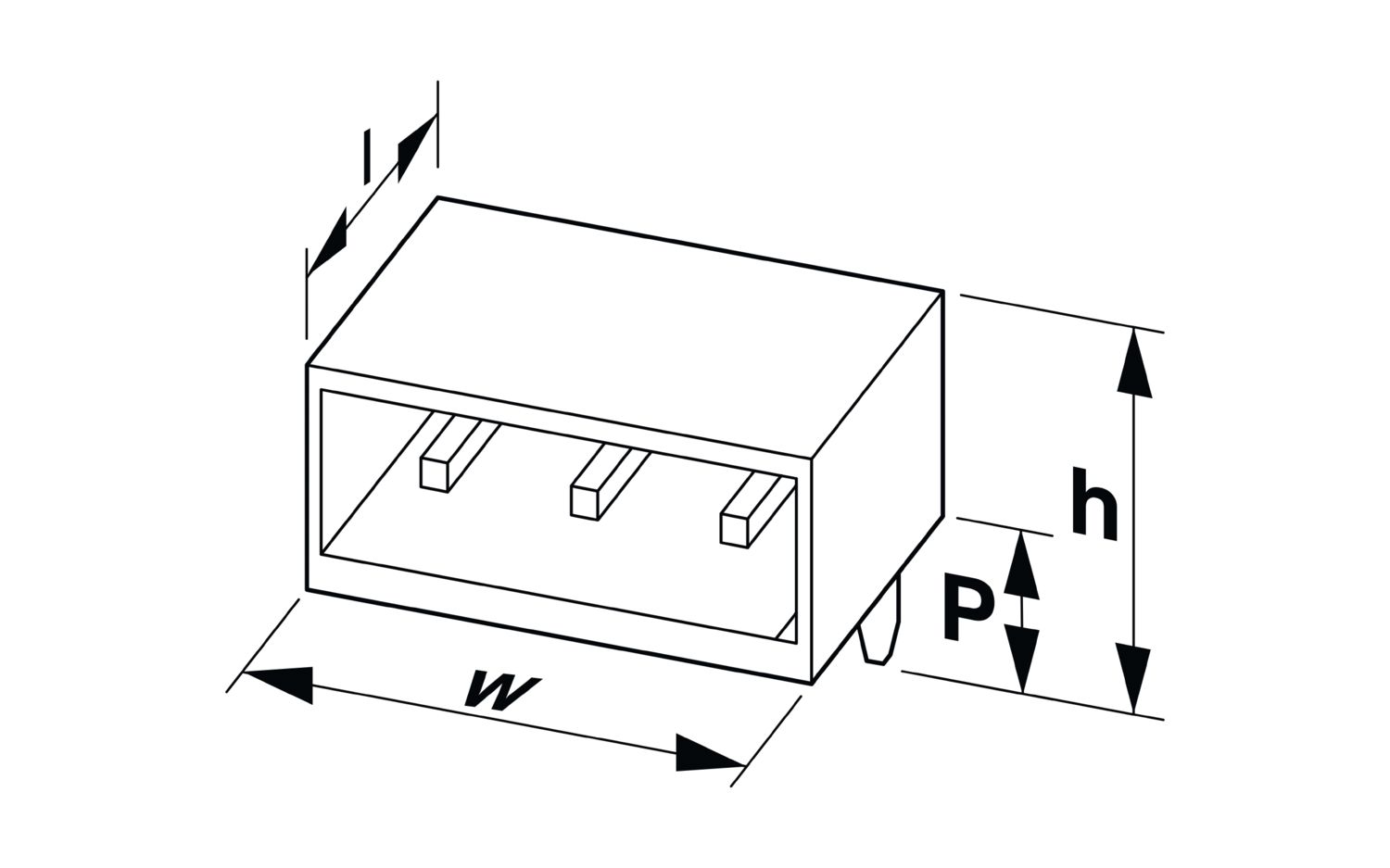

| Dimensional drawing |

|

| Pitch | 3.81 mm |

| Width [w] | 9.01 mm |

| Height [h] | 9.5 mm |

| Length [l] | 9.2 mm |

| Installed height | 6.9 mm |

| Solder pin length [P] | 2.6 mm |

| Pin dimensions | 0.8 x 0.8 mm |

| PCB design | |

| Hole diameter | 1.4 mm |

| Visual inspection | |

| Specification | IEC 60512-1-1:2002-02 |

| Result | Test passed |

| Dimension check | |

| Specification | IEC 60512-1-2:2002-02 |

| Result | Test passed |

| Resistance of inscriptions | |

| Specification | IEC 60068-2-70:1995-12 |

| Result | Test passed |

| Polarization and coding | |

| Specification | IEC 60512-13-5:2006-02 |

| Result | Test passed |

| Contact holder in insert | |

| Specification | IEC 60512-15-1:2008-05 |

| Contact holder in insert Requirements >20 N |

Test passed |

| Insertion and withdrawal forces | |

| Result | Test passed |

| No. of cycles | 25 |

| Insertion strength per pos. approx. | 8 N |

| Withdraw strength per pos. approx. | 6 N |

| Thermal test | Test group C | |

| Specification | IEC 60512-5-1:2002-02 |

| Tested number of positions | 20 |

| Insulation resistance | |

| Specification | IEC 60512-3-1:2002-02 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | IIIa |

| Comparative tracking index (IEC 60112) | CTI 175 |

| Rated insulation voltage (III/3) | 160 V |

| Rated surge voltage (III/3) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/3) | 1.5 mm |

| minimum creepage distance (III/3) | 2.5 mm |

| Rated insulation voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/2) | 1.5 mm |

| minimum creepage distance (III/2) | 1.6 mm |

| Rated insulation voltage (II/2) | 250 V |

| Rated surge voltage (II/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (II/2) | 1.5 mm |

| minimum creepage distance (II/2) | 2.5 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Durability test | |

| Specification | IEC 60512-9-1:2010-03 |

| Impulse withstand voltage at sea level | 2.95 kV |

| Contact resistance R1 | 1.4 mΩ |

| Contact resistance R2 | 1.5 mΩ |

| Insertion/withdrawal cycles | 25 |

| Climatic test | |

| Specification | ISO 6988:1985-02 |

| Corrosive stress | 0.2 dm3 SO2 on 300 dm3/40 °C/1 cycle |

| Thermal stress | 100 °C/168 h |

| Power-frequency withstand voltage | 1.39 kV |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 100 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

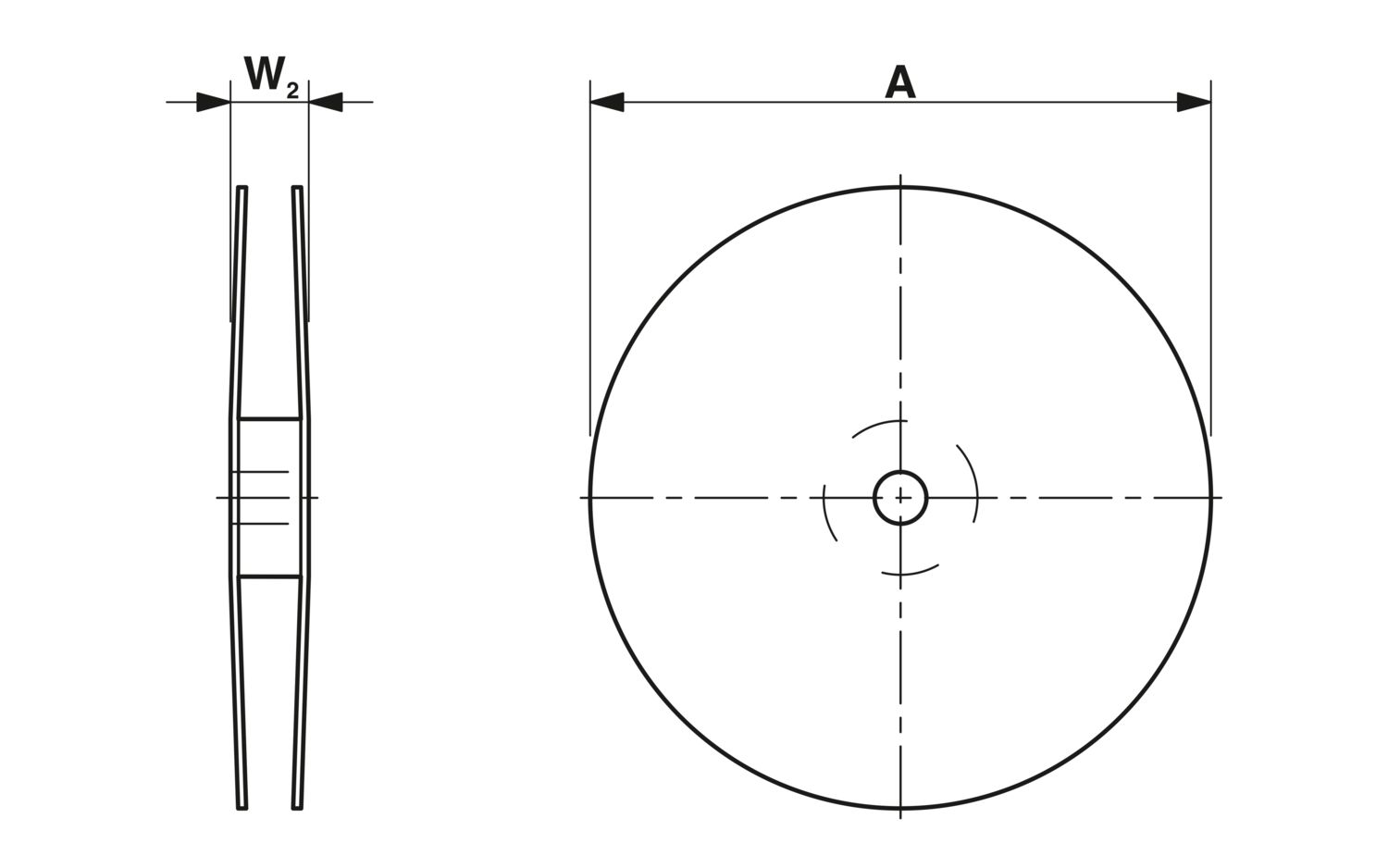

| Dimensional drawing |

|

| Type of packaging | 24 mm wide tape |

| [W] tape width | 24 mm |

| [W2] coil overall dimension | ≤ 30.4 mm |

| [A] coil diameter | ≤ 330 mm |

| Outer packaging type | Transparent-Bag |

| Item number | 1103274 |

| Packing unit | 400 pc |

| Minimum order quantity | 400 pc |

| Sales key | AA02 |

| Product key | AABTBB |

| GTIN | 4055626965833 |

| Weight per piece (including packing) | 1.645 g |

| Weight per piece (excluding packing) | 1.592 g |

| Customs tariff number | 85366930 |

| Country of origin | DE |

ECLASS

| ECLASS-13.0 | 27460201 |

| ECLASS-15.0 | 27460201 |

ETIM

| ETIM 9.0 | EC002637 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

Designed for integration into the SMT soldering process

Maximum flexibility when it comes to device design – one header for connectors with different connection technologies

Frequently searched

PHOENIX CONTACT

586 Fulling Mill Road, Middletown, PA 17057