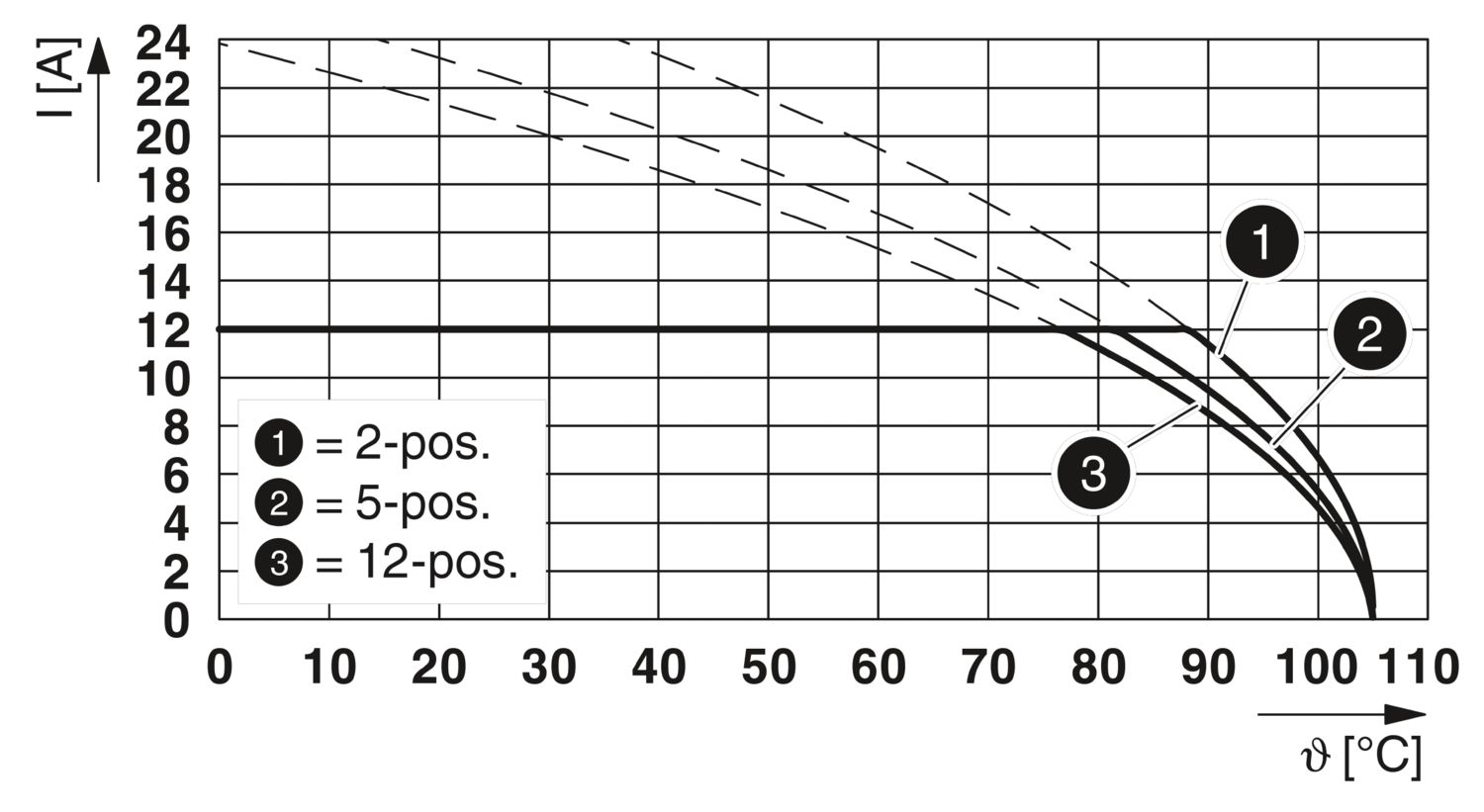

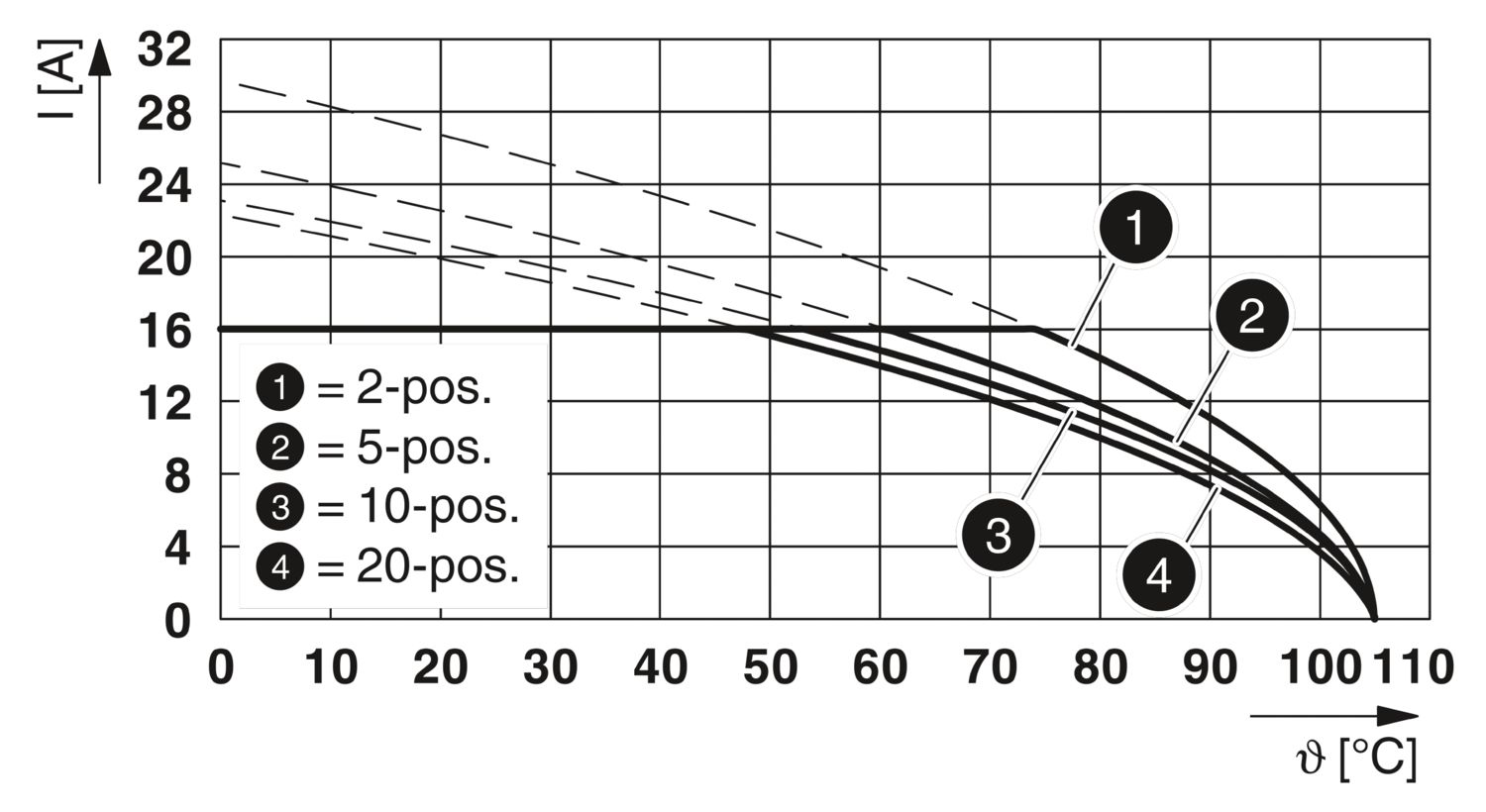

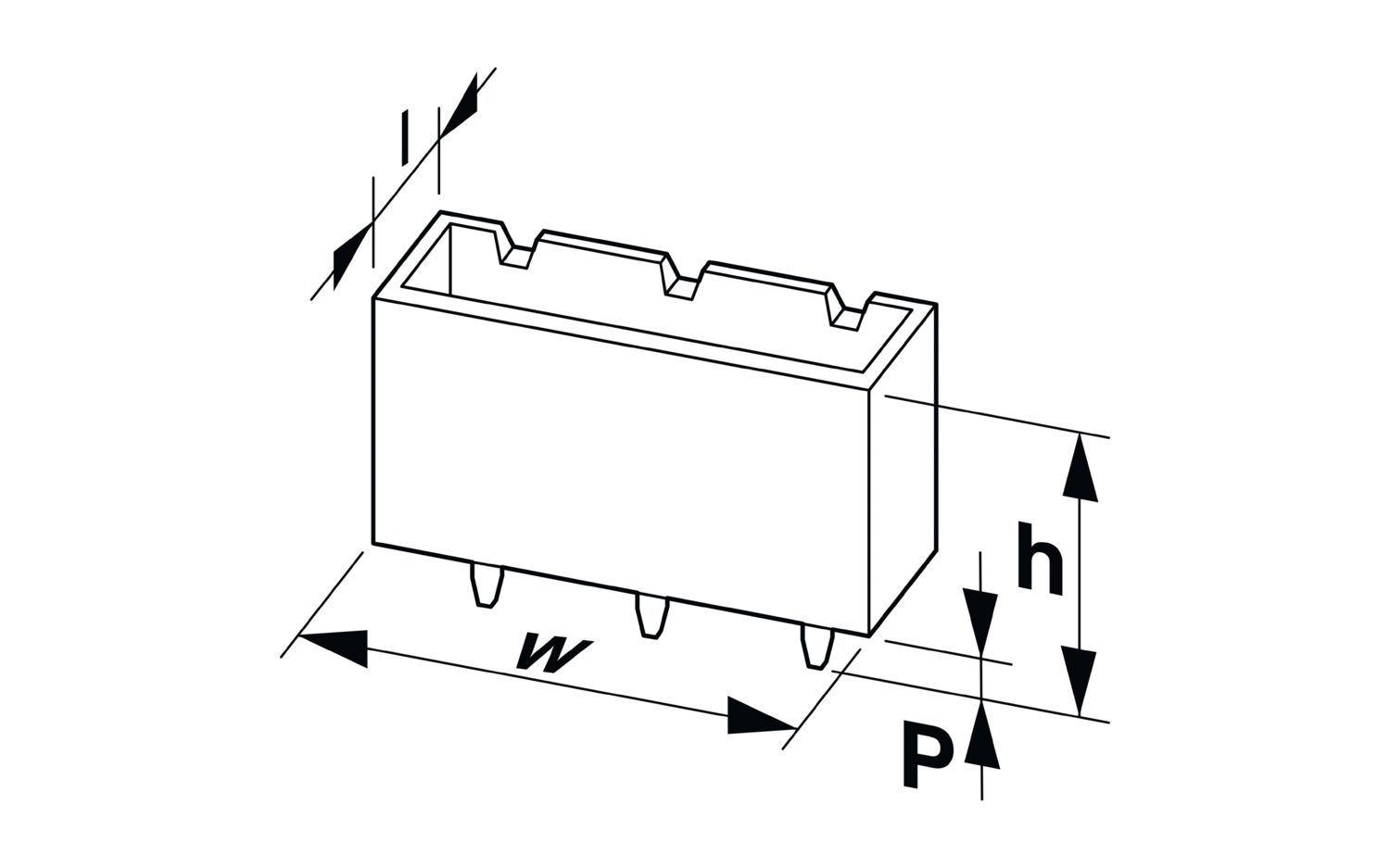

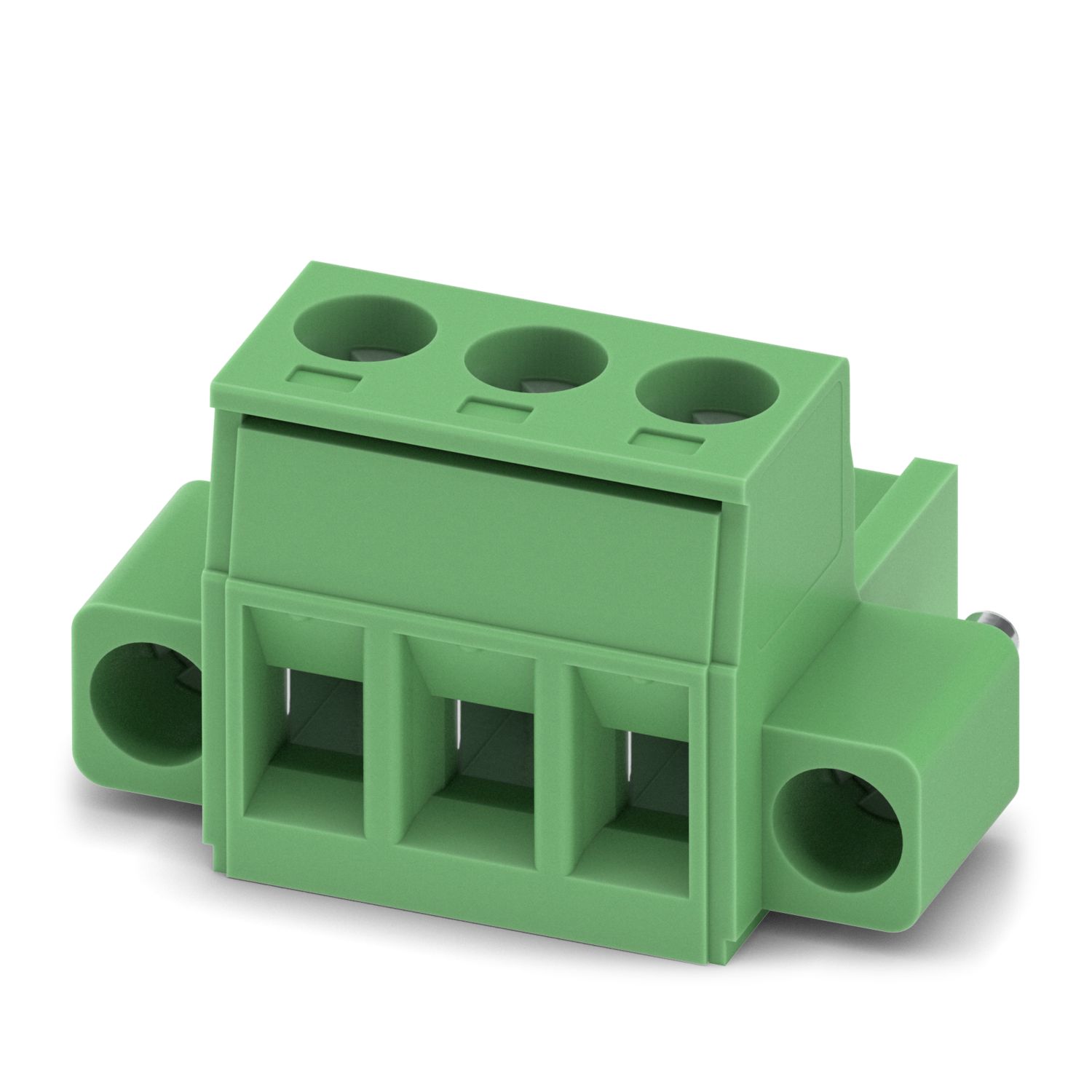

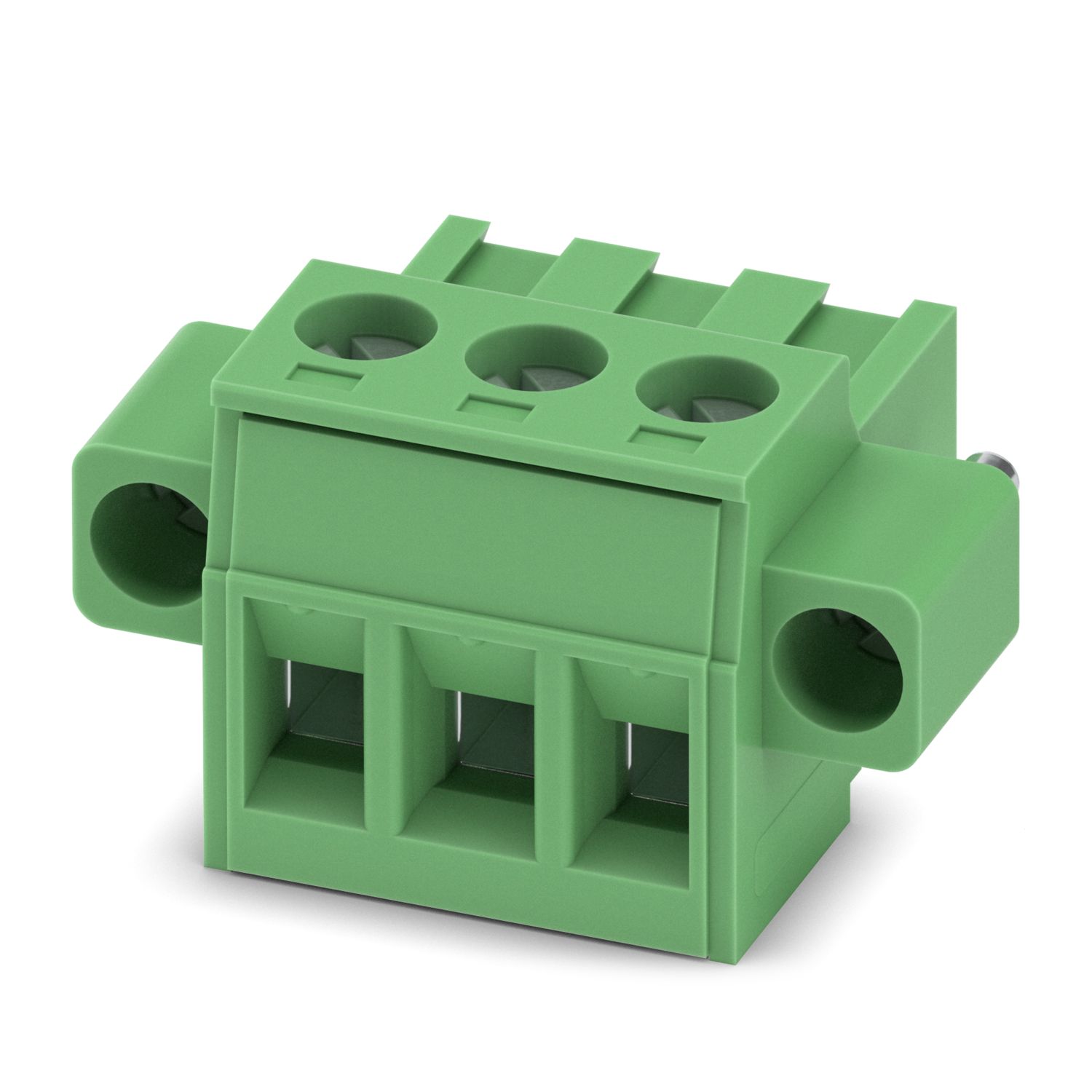

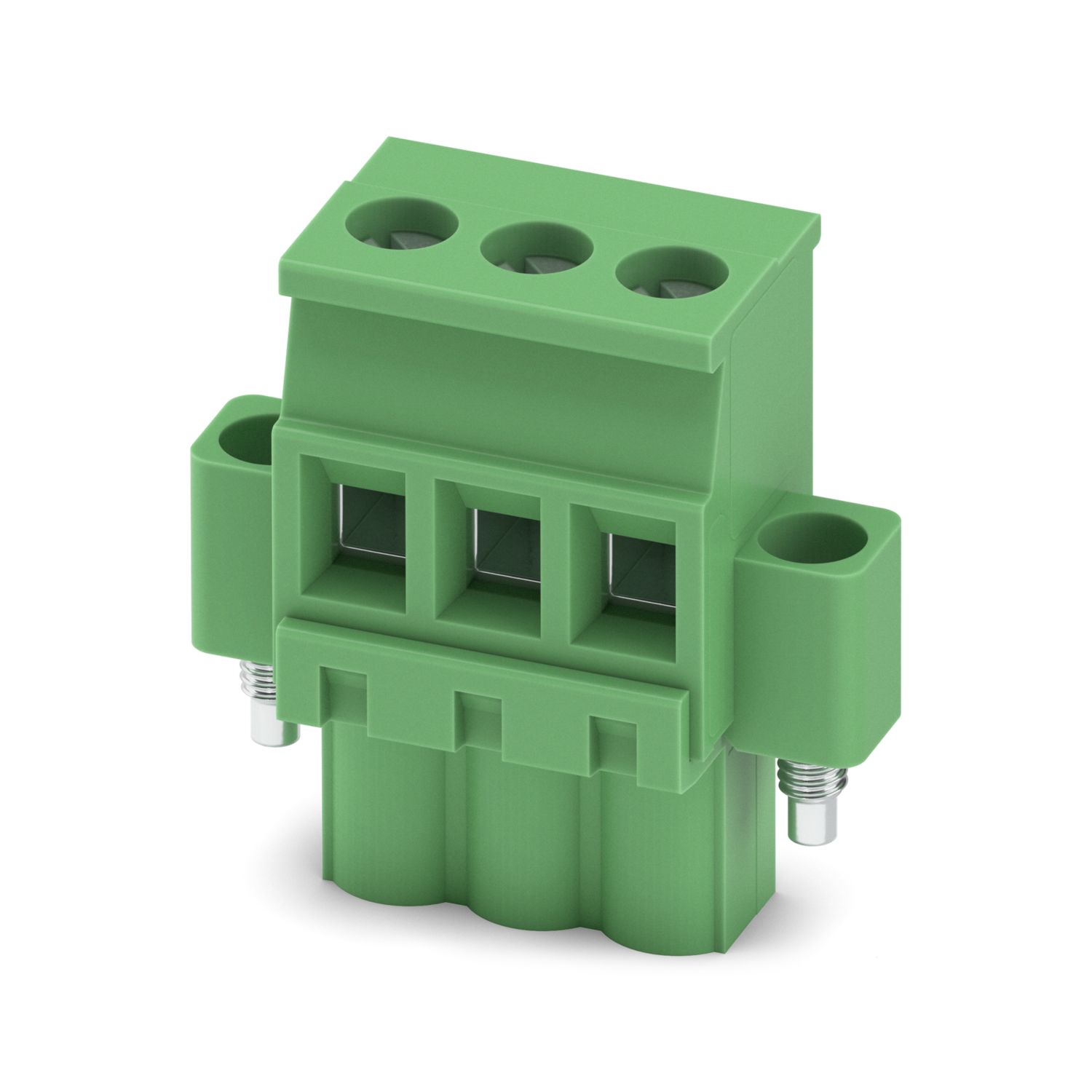

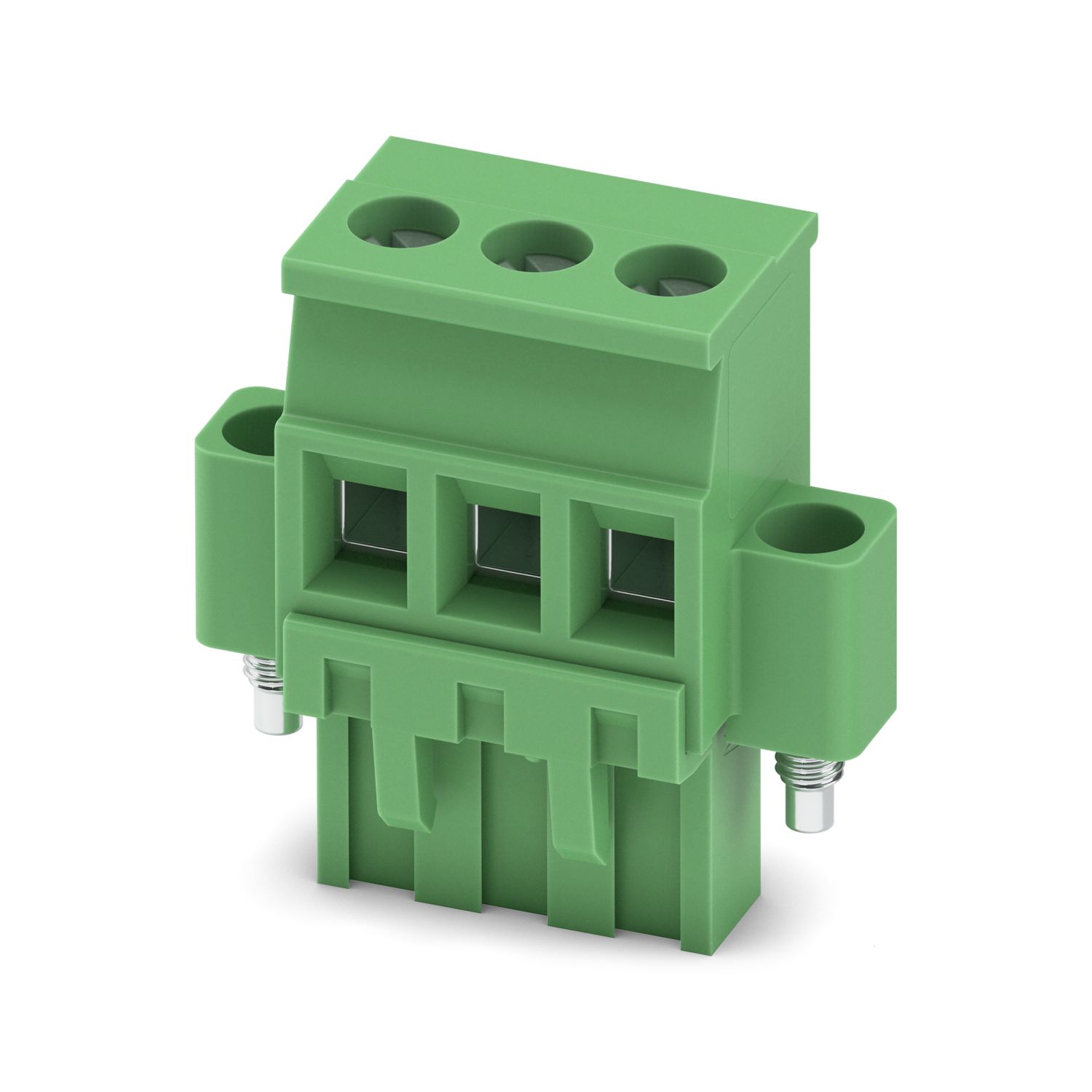

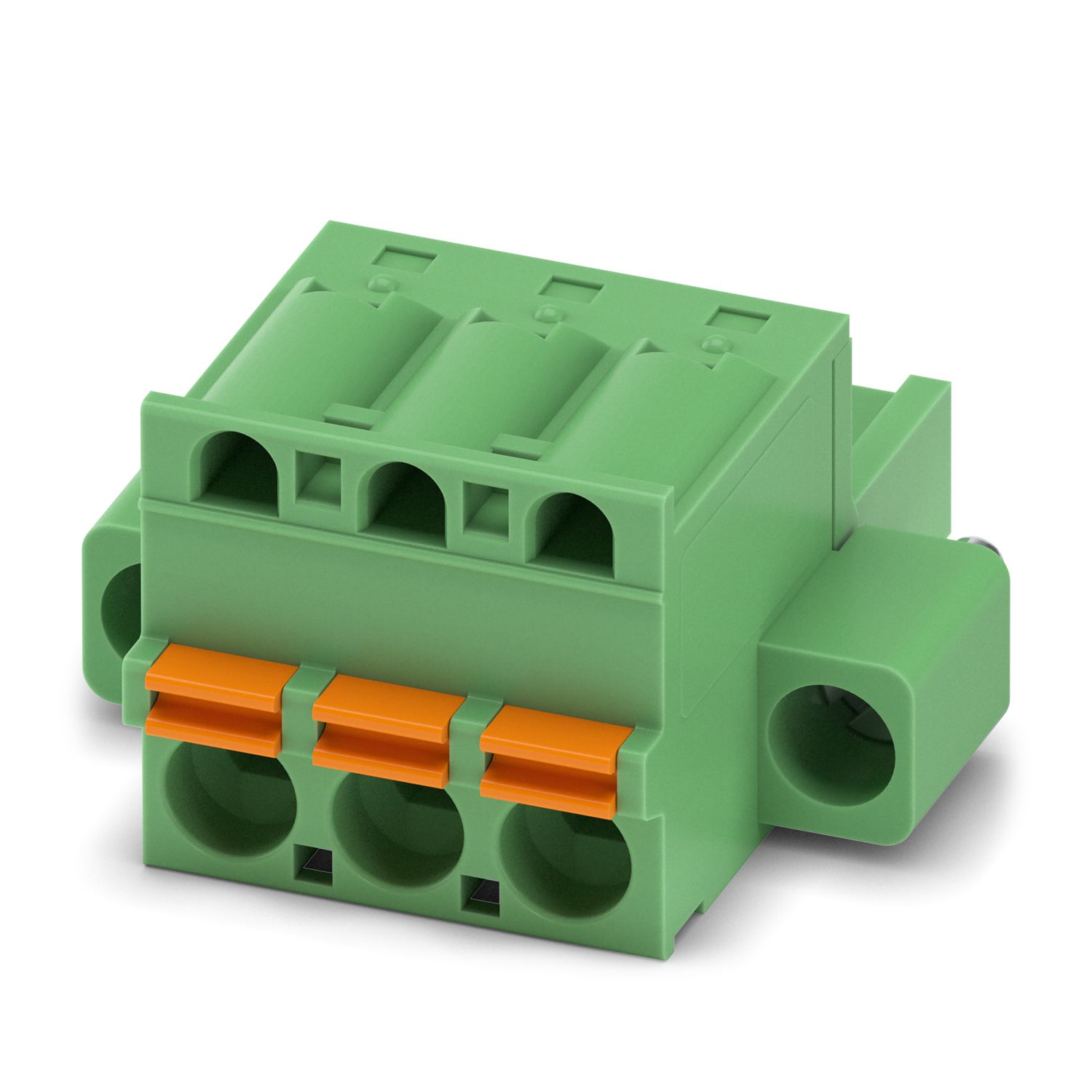

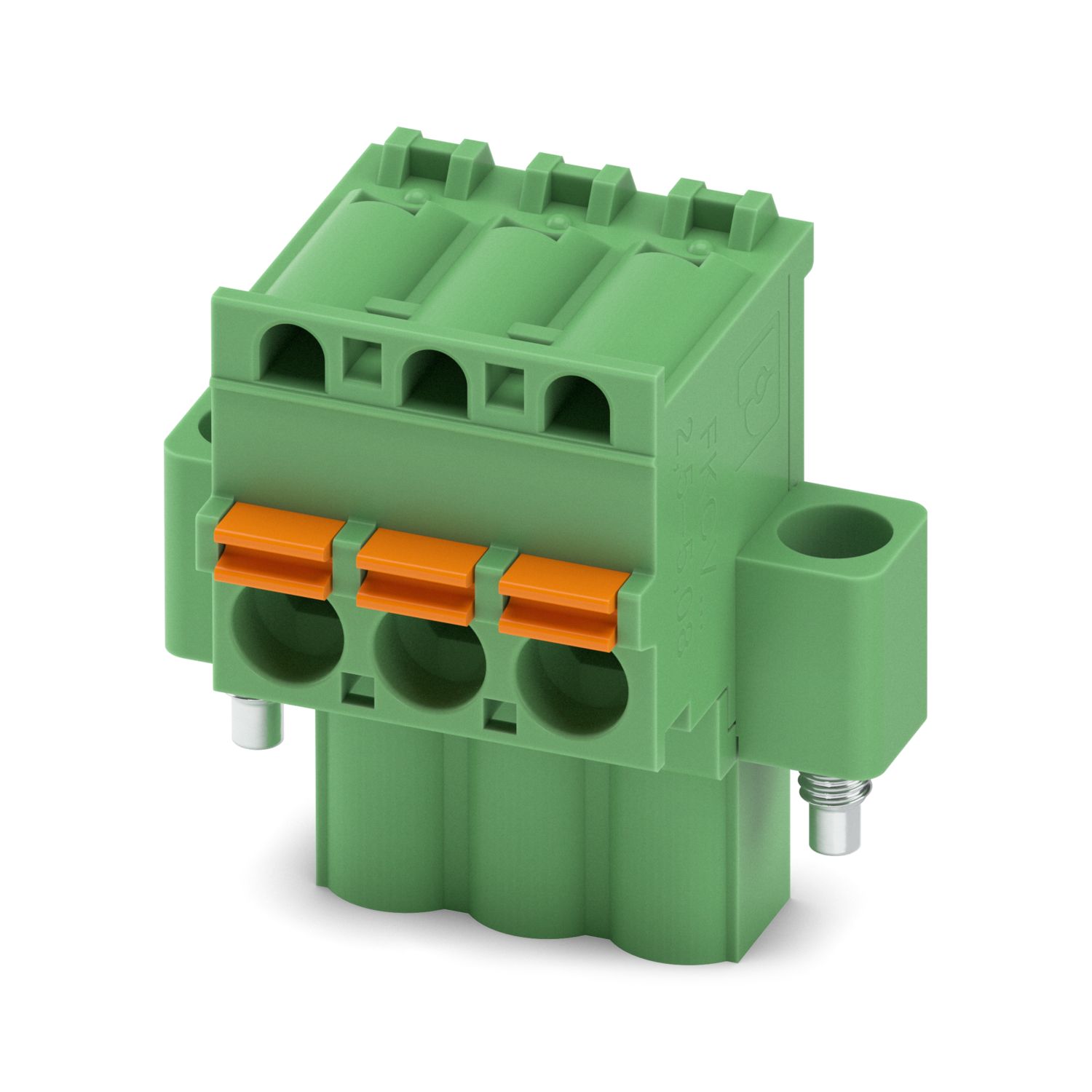

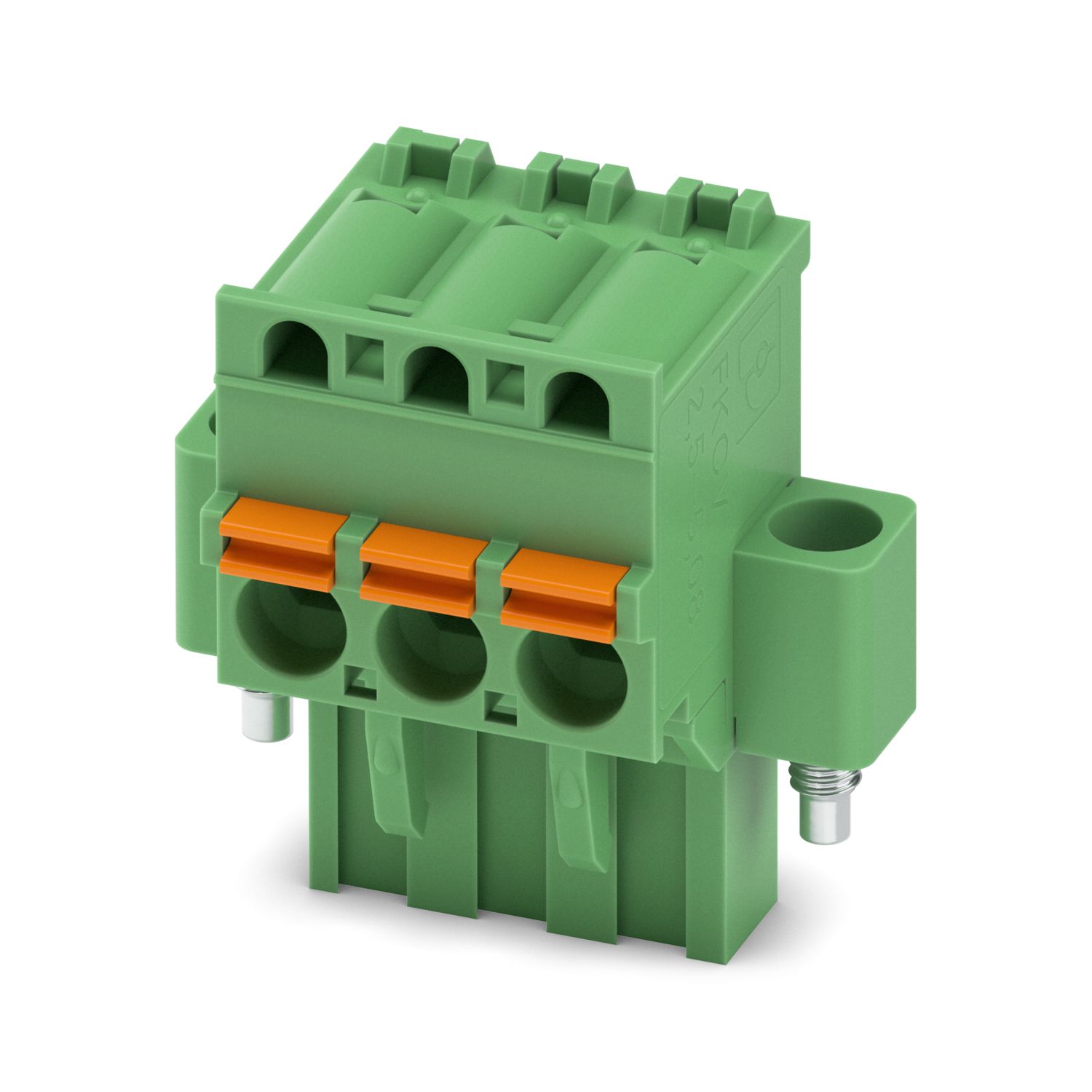

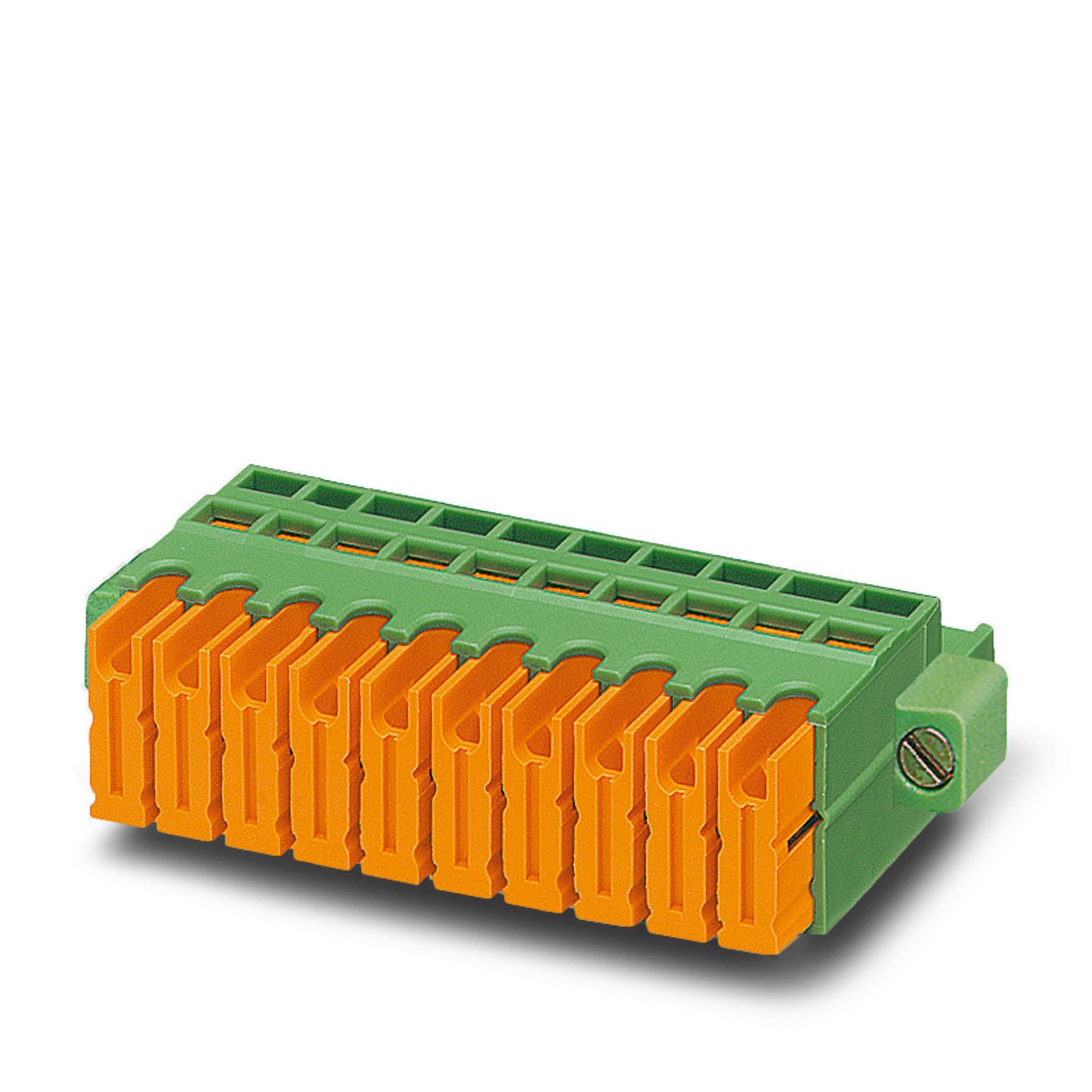

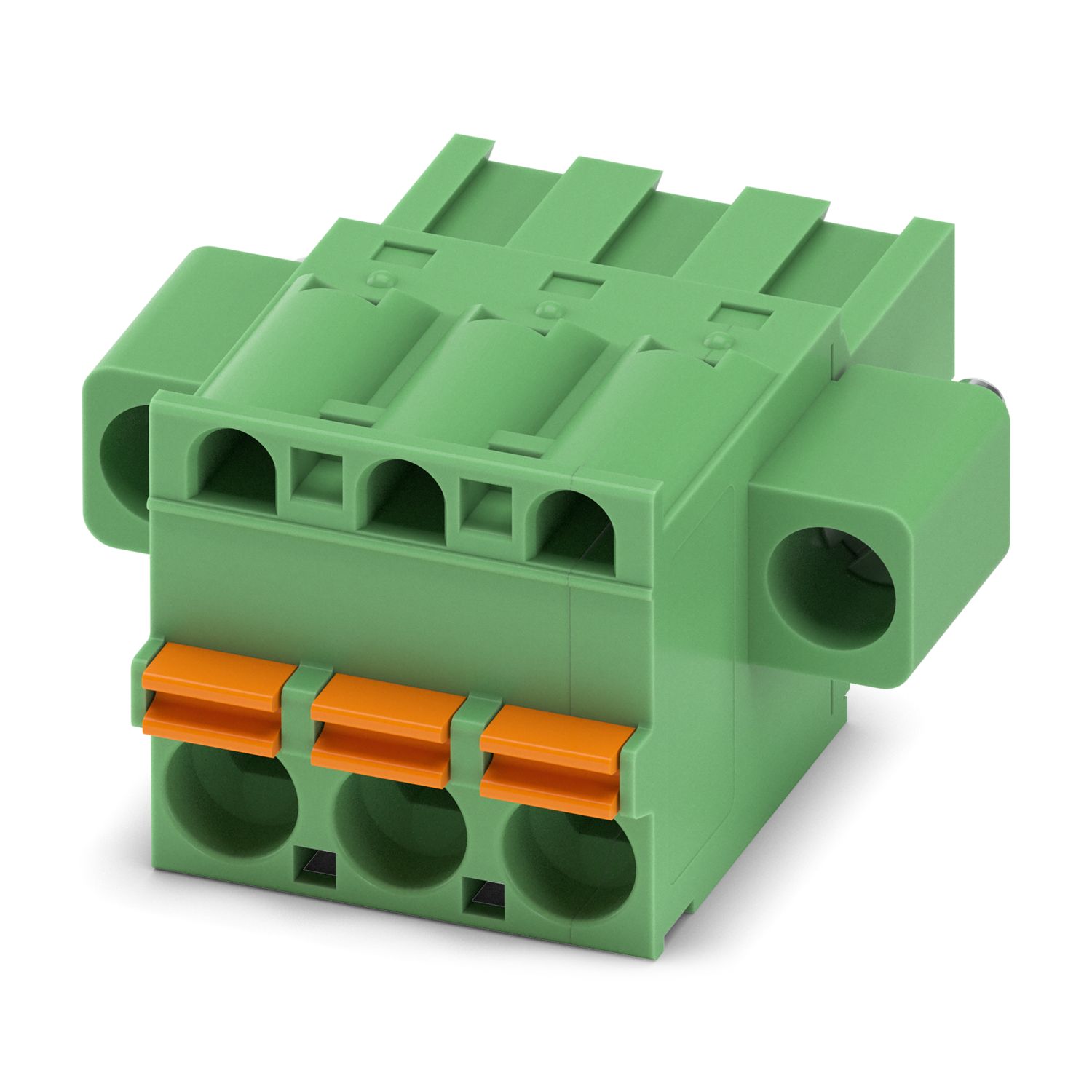

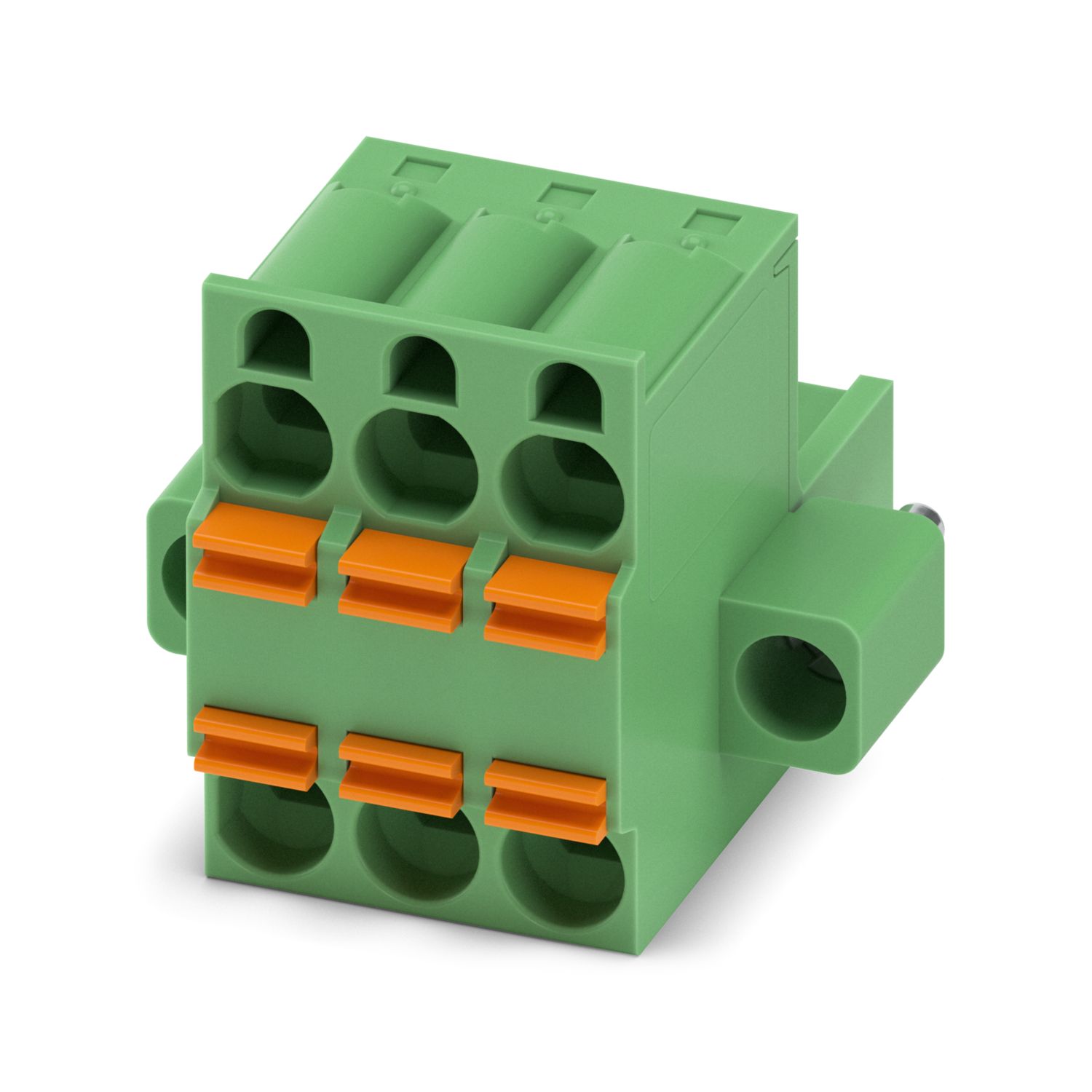

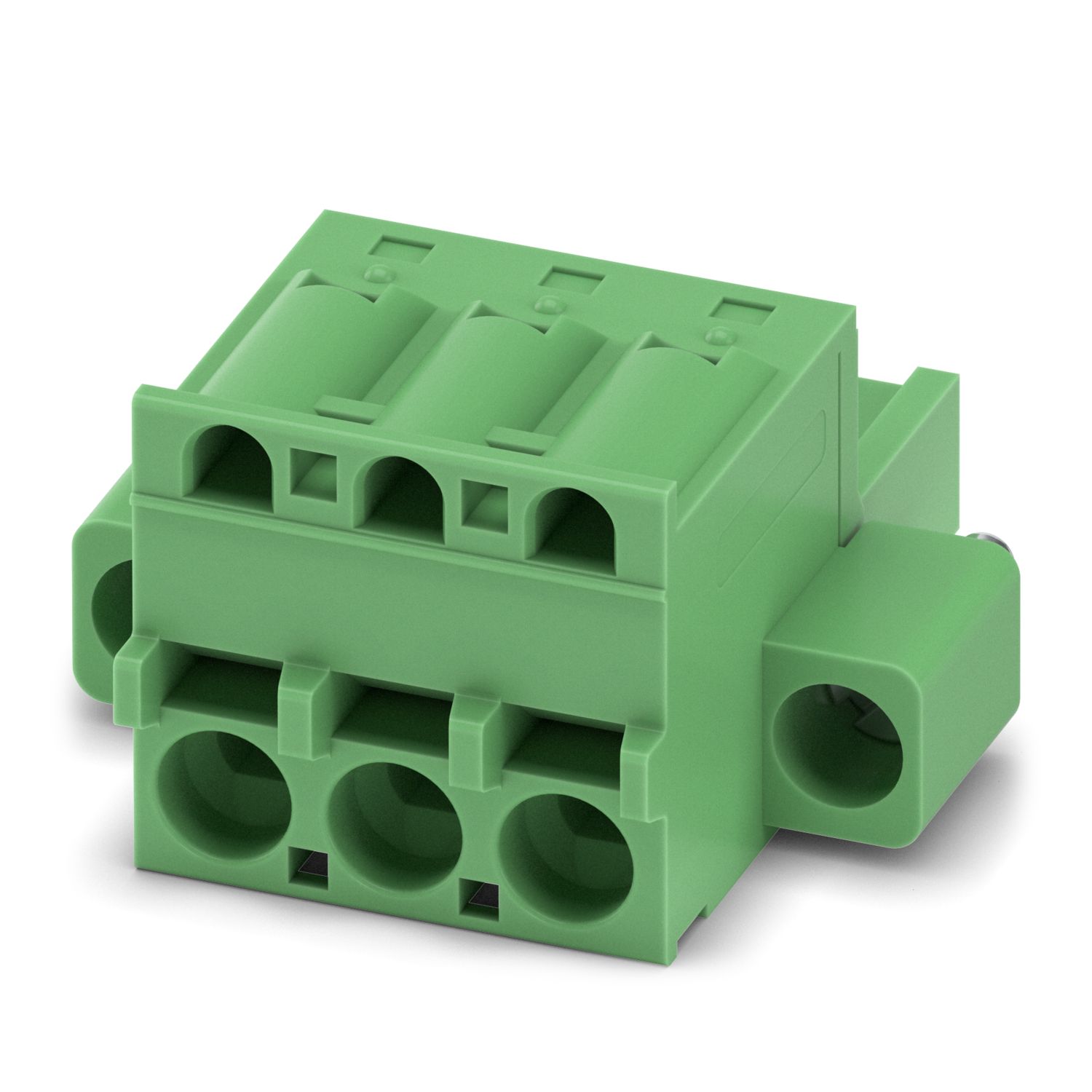

PCB headers, nominal cross section: 2.5 mm2, color: black, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Pin, number of potentials: 3, number of rows: 1, number of positions: 3, number of connections: 3, product range: CCV 2,5/..-GF, pitch: 5.08 mm, mounting: THR soldering / wave soldering, pin layout: Linear pinning, solder pin [P]: 2.6 mm, number of solder pins per potential: 1, plug-in system: COMBICON MSTB 2,5, Pin connector pattern alignment: Standard, locking: Screw locking mechanism, mounting method: Threaded flange, type of packaging: packed in cardboard, For user information and design recommendations for through-hole reflow technology, go to: Downloads