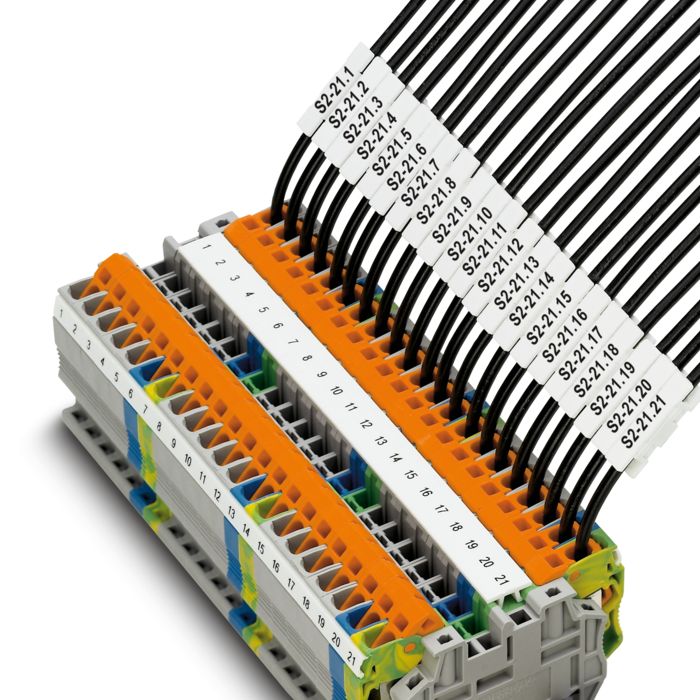

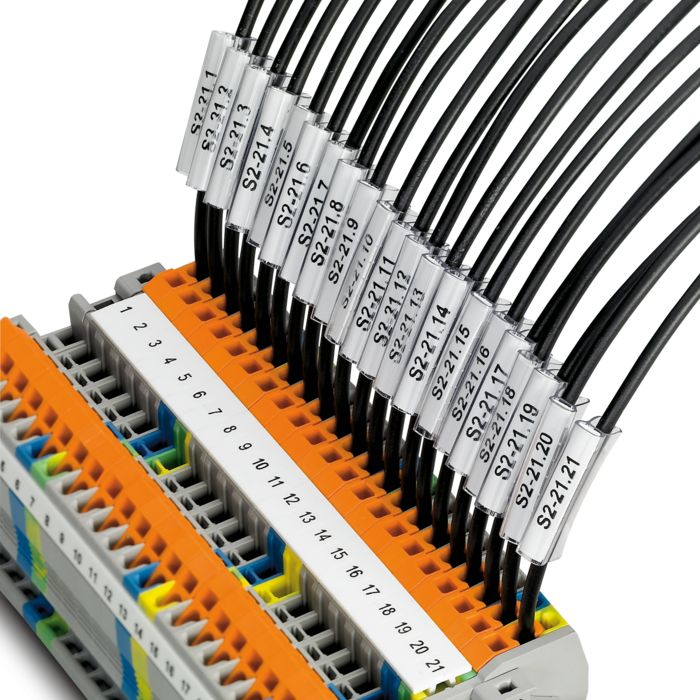

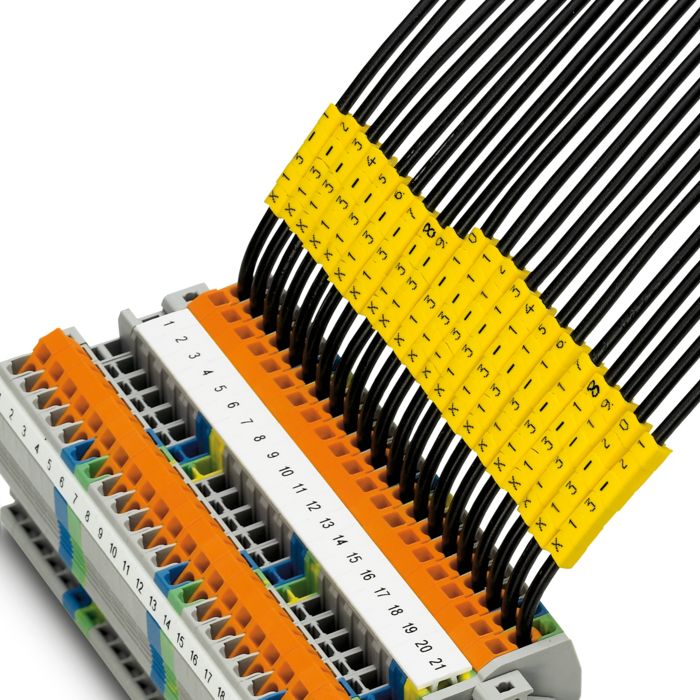

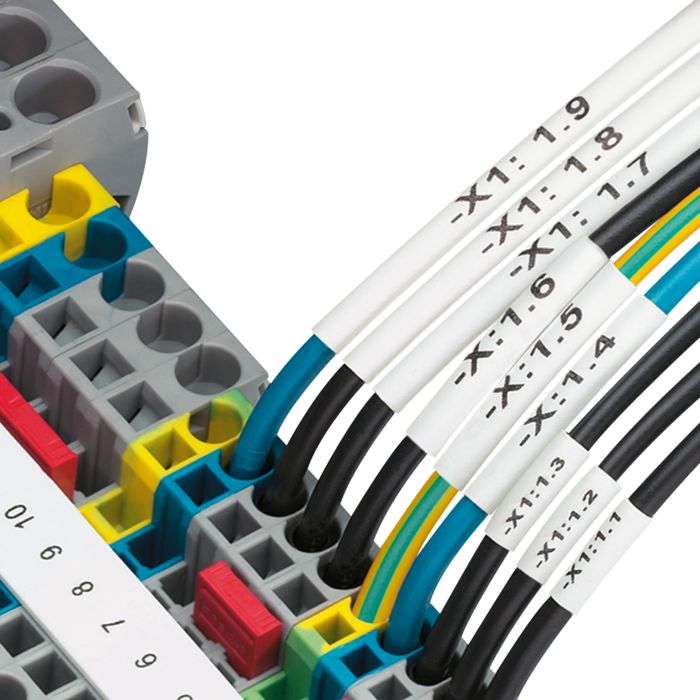

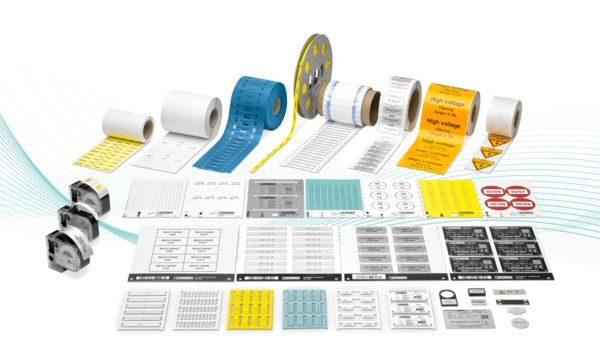

Shrink sleeve, Roll, white, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLLMASTER 300/600, THERMOMARK ROLL X1, THERMOMARK ROLL, THERMOMARK ROLL 2.0, THERMOMARK W, THERMOMARK X1.2, cable diameter range: 1.6 ... 4.8 mm, perforated, mounting type: slide-on, Number of individual labels: 5000, text field height: 9 mm, text field width: 30 mm