EAC

Approval ID: RU C-DE.BL08.B.00540cULus Recognized

Approval ID: E60425| Nominal voltage UN | Nominal current IN | Cross section AWG | Cross section mm2 | |

|---|---|---|---|---|

| B | ||||

| 600 V | 30 A | |||

| C | ||||

| 600 V | 30 A | |||

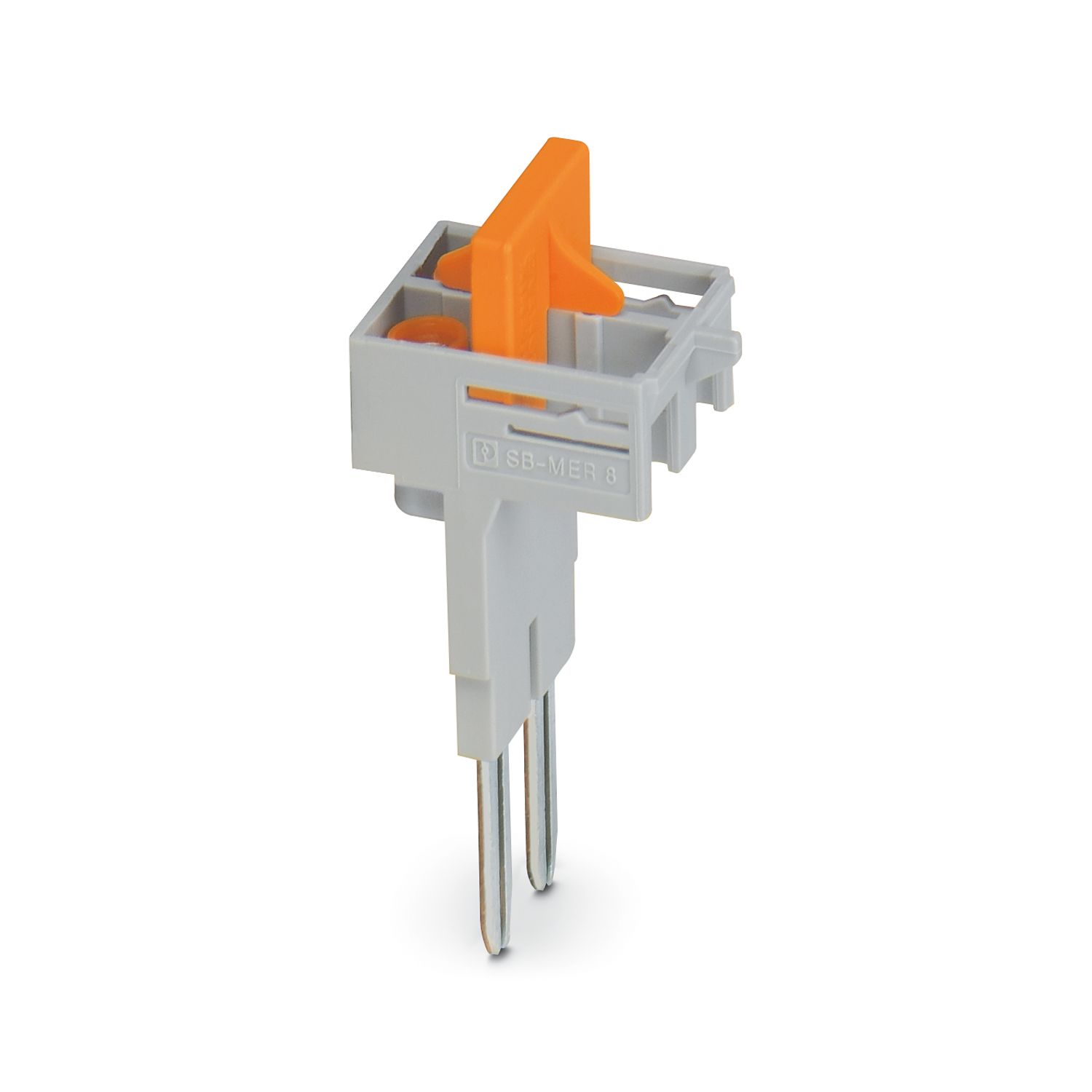

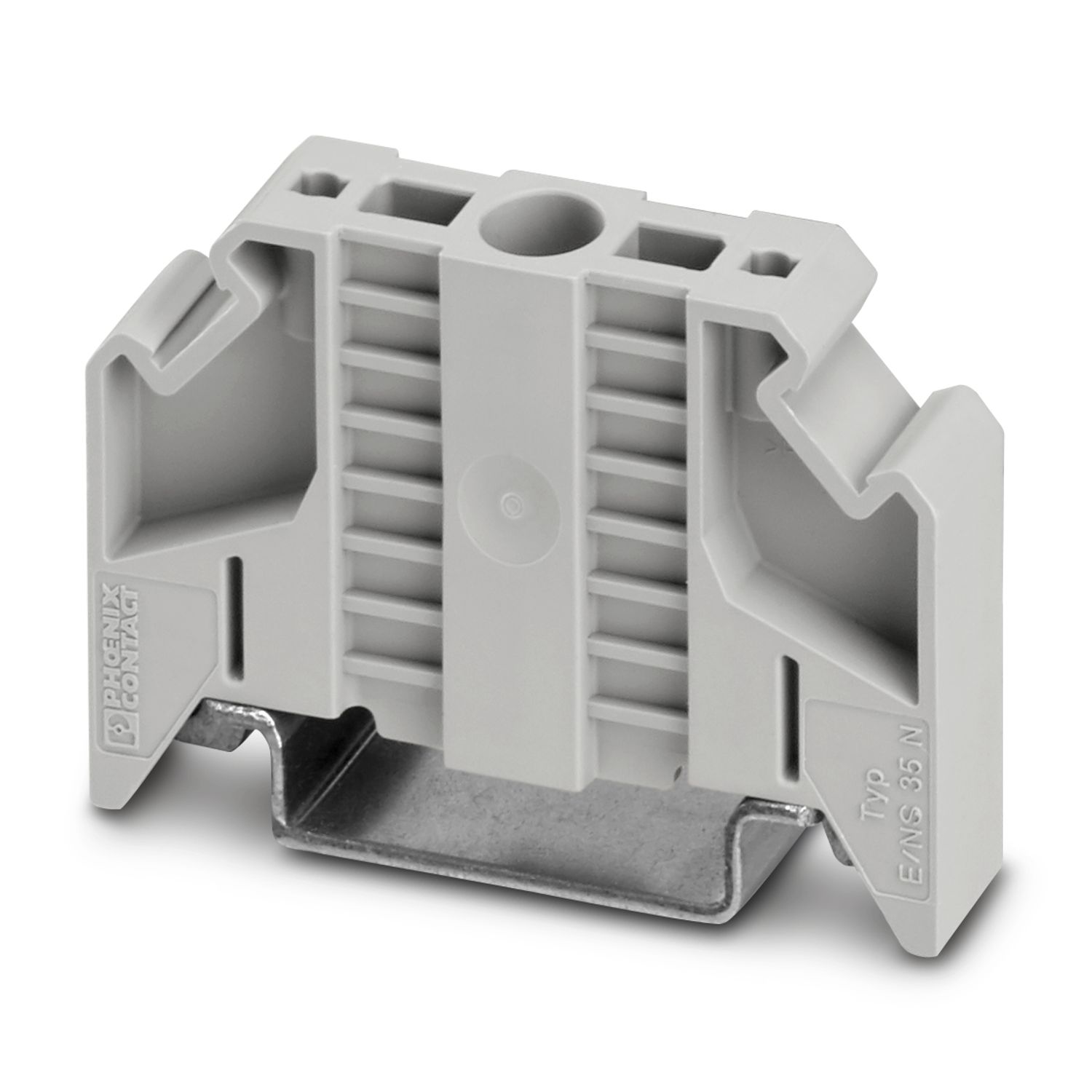

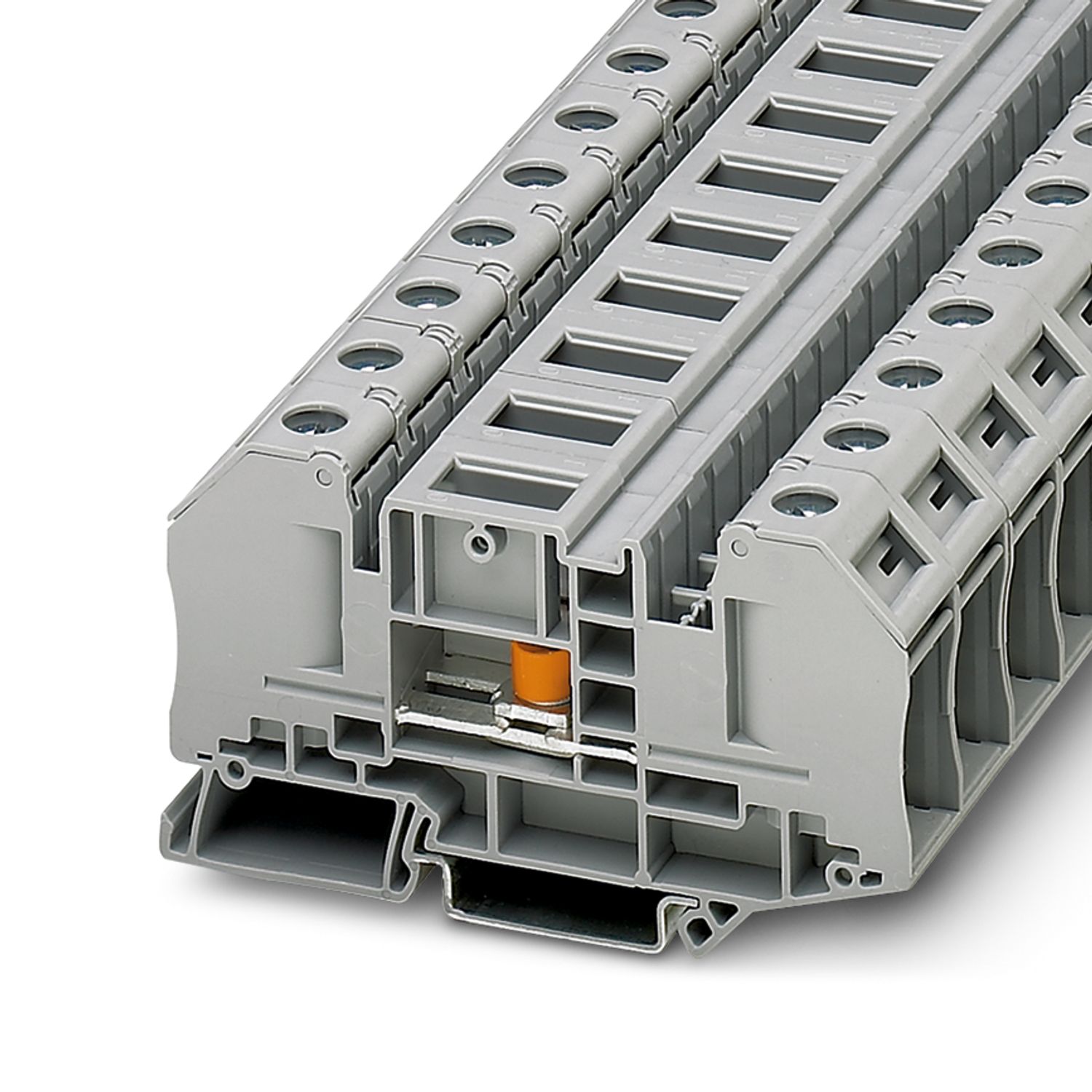

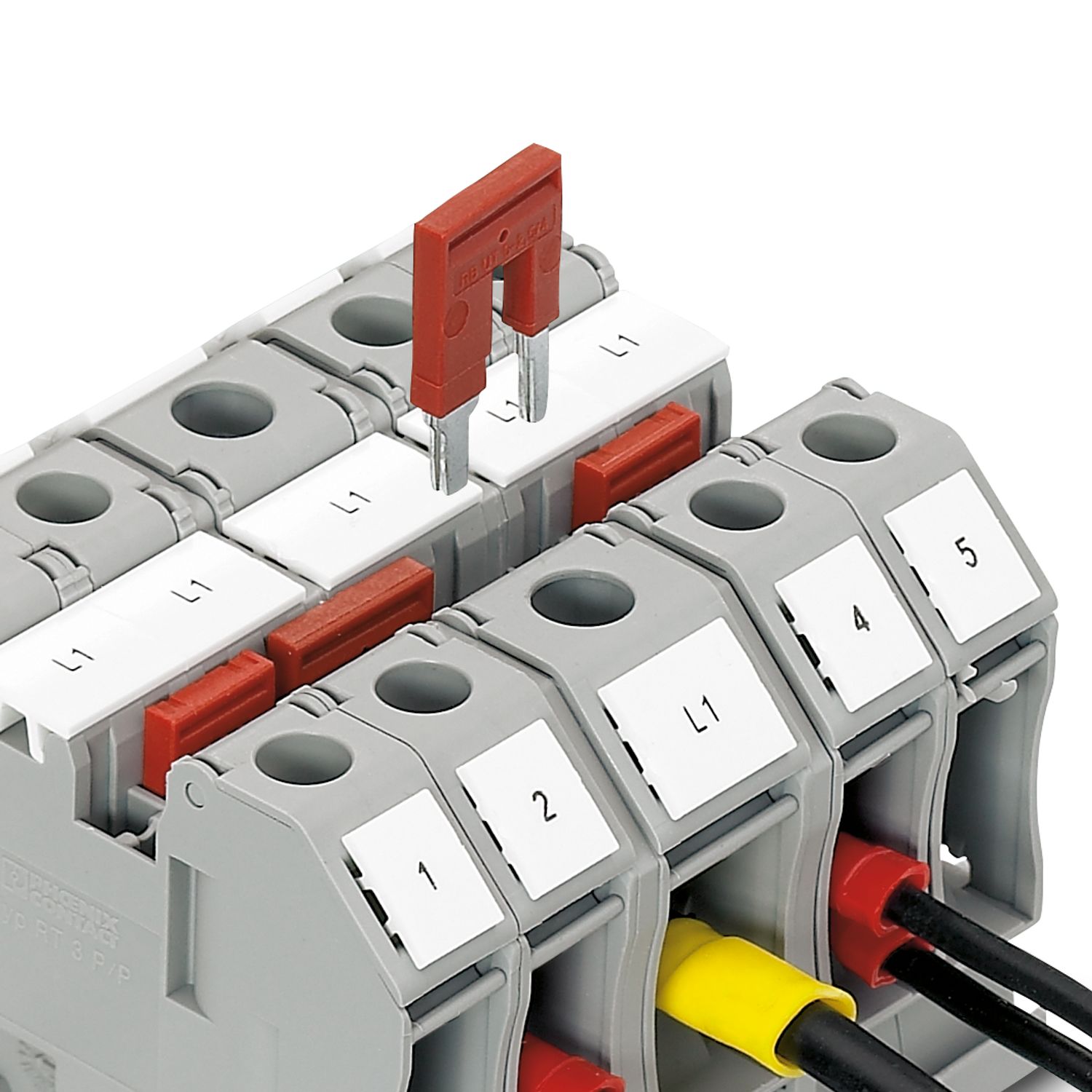

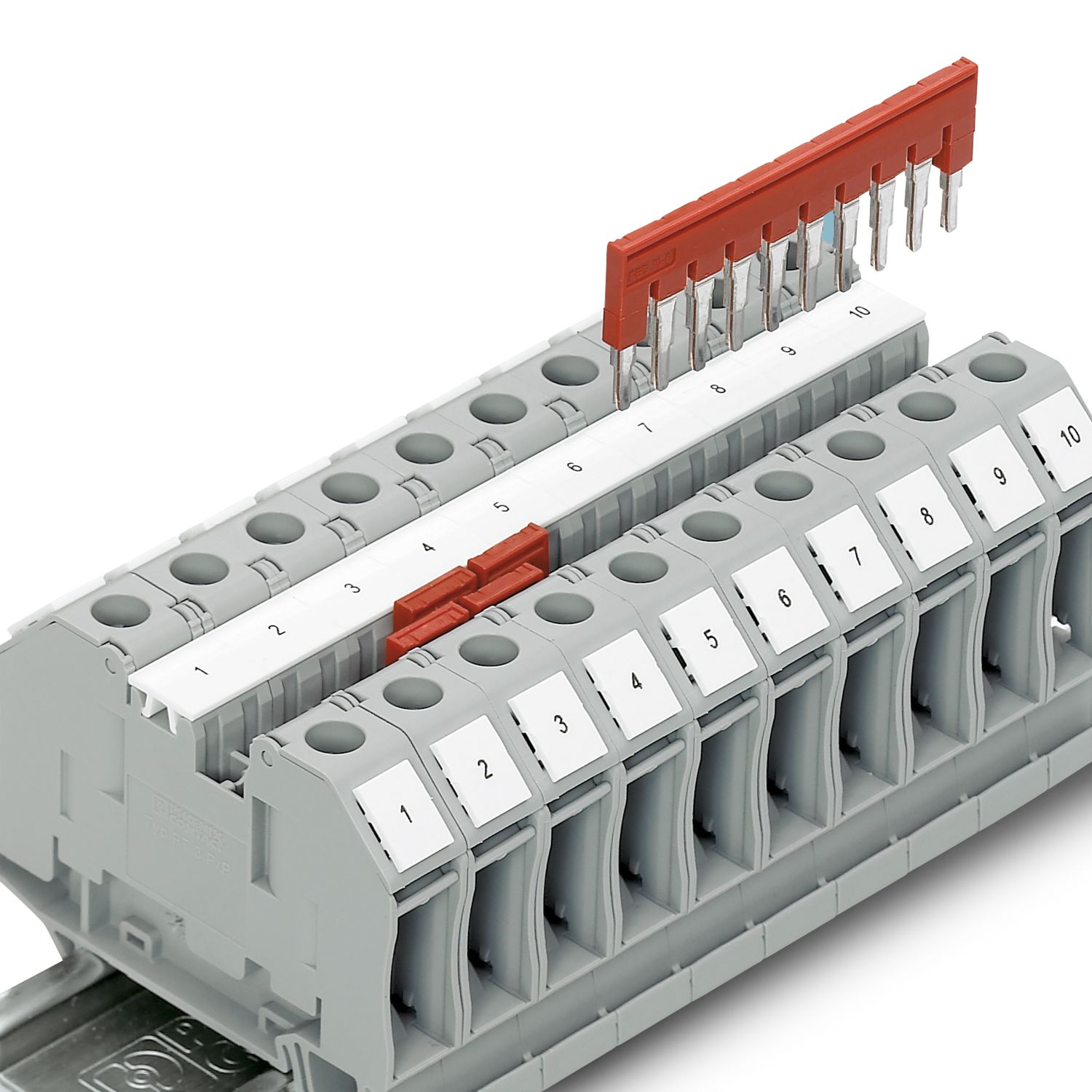

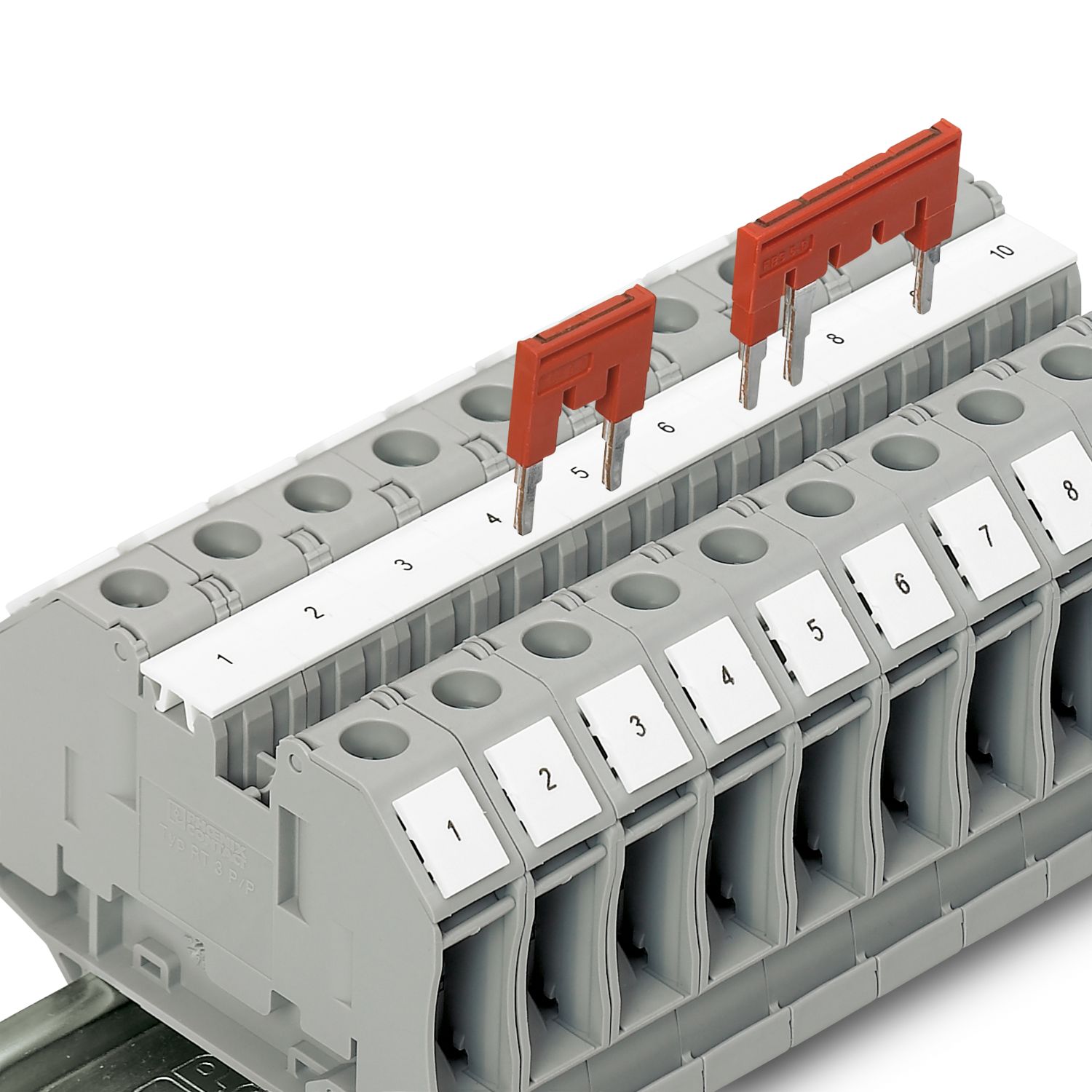

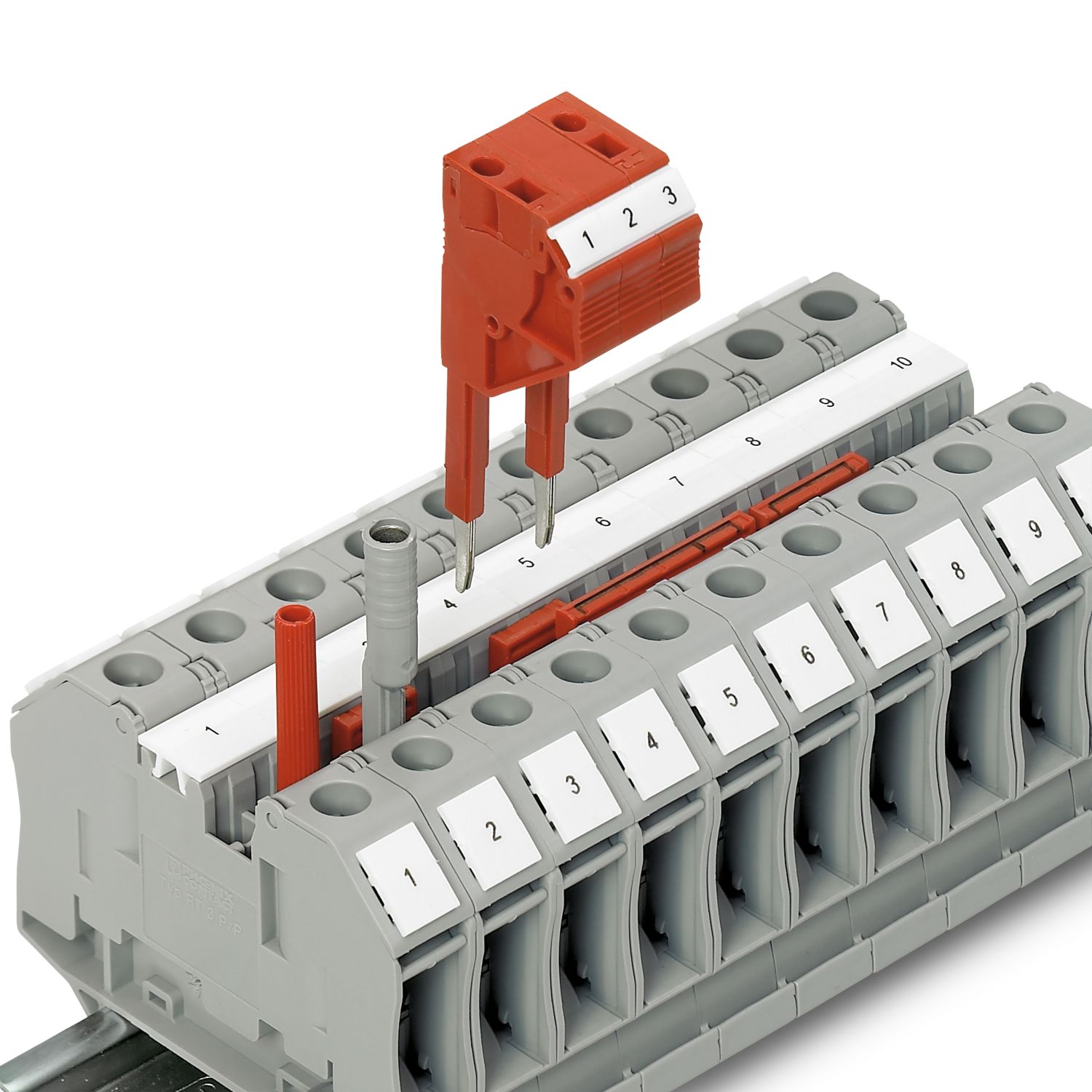

Test disconnect terminal block, Note: the BE-RT... path extension is to be used for non-insulated cable lugs (see accessories)., nom. voltage: 1000 V, nominal current: 41 A, 1 level, connection method: Bolt connection, Rated cross section: 6 mm2, mounting: NS 35/7,5, NS 35/15, color: gray

| General | Note: the BE-RT... path extension is to be used for non-insulated cable lugs (see accessories). |

| Product family | RT |

| Area of application | Railway industry |

| Machine building | |

| Plant engineering | |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

| Number of connections per level | 2 |

| Nominal cross section | 6 mm² |

| Tightening torque disconnect slide | M4 1.5 ... 1.8 Nm |

| 1 level | |

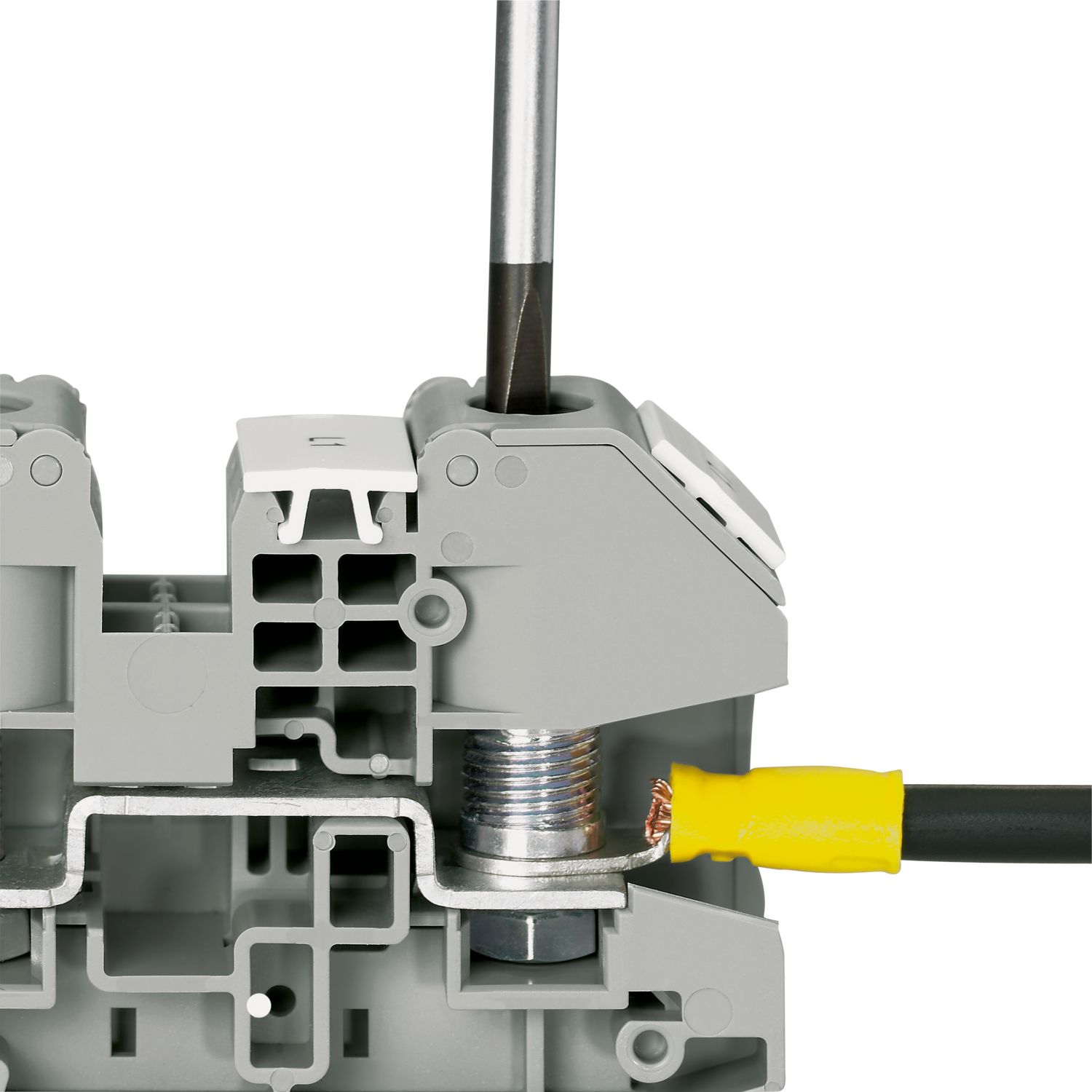

| Connection method | Bolt connection |

| Stripping length | The stripping length depends on the specification provided by the cable lug manufacturer. |

| Connection in acc. with standard | IEC 60947-7-1 |

| Nominal cross section | 6 mm² |

| Nominal current | 41 A |

| Maximum load current | 41 A (with 6 mm² conductor cross-section) |

| Nominal voltage | 1000 V (Rated voltage for open disconnect point 500 V) |

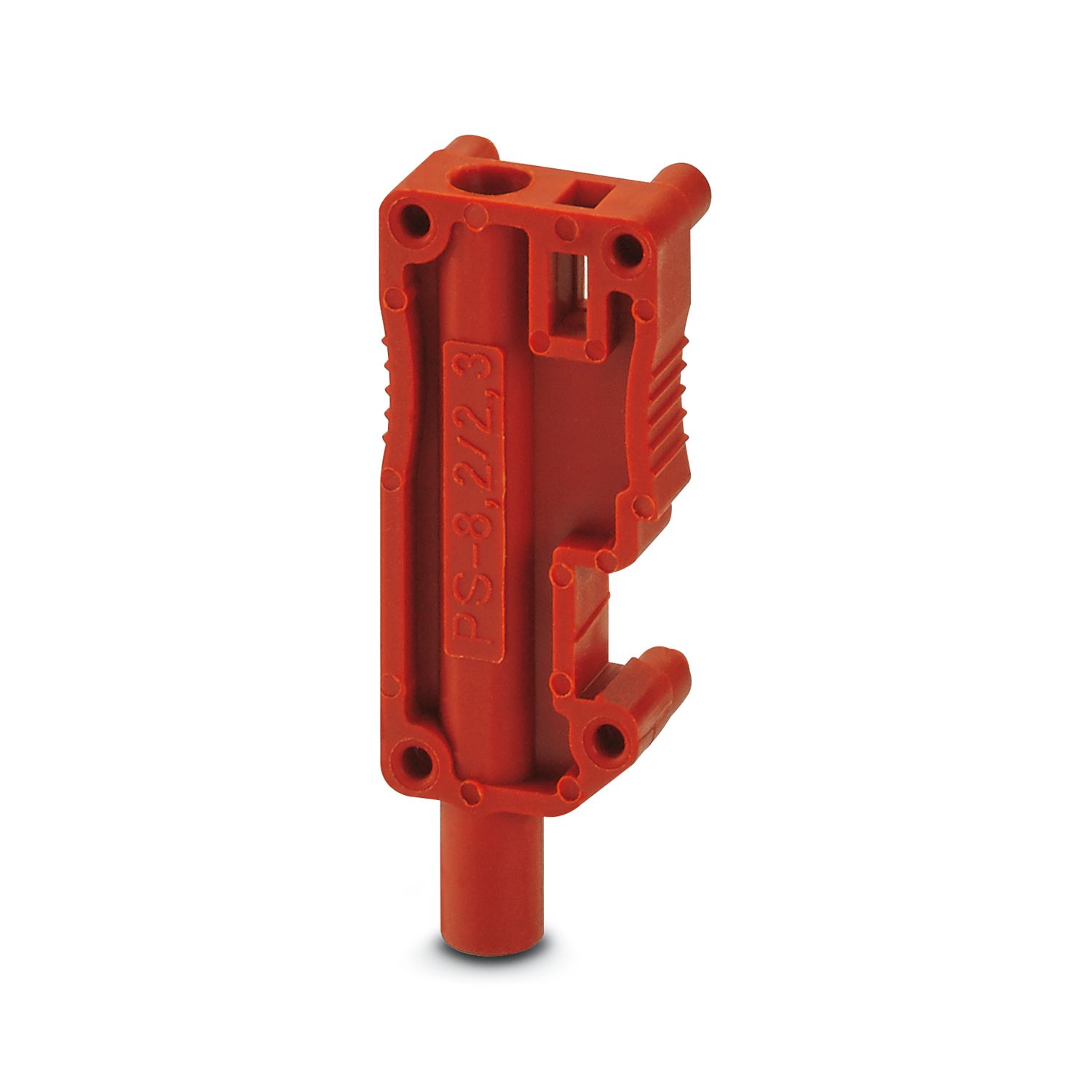

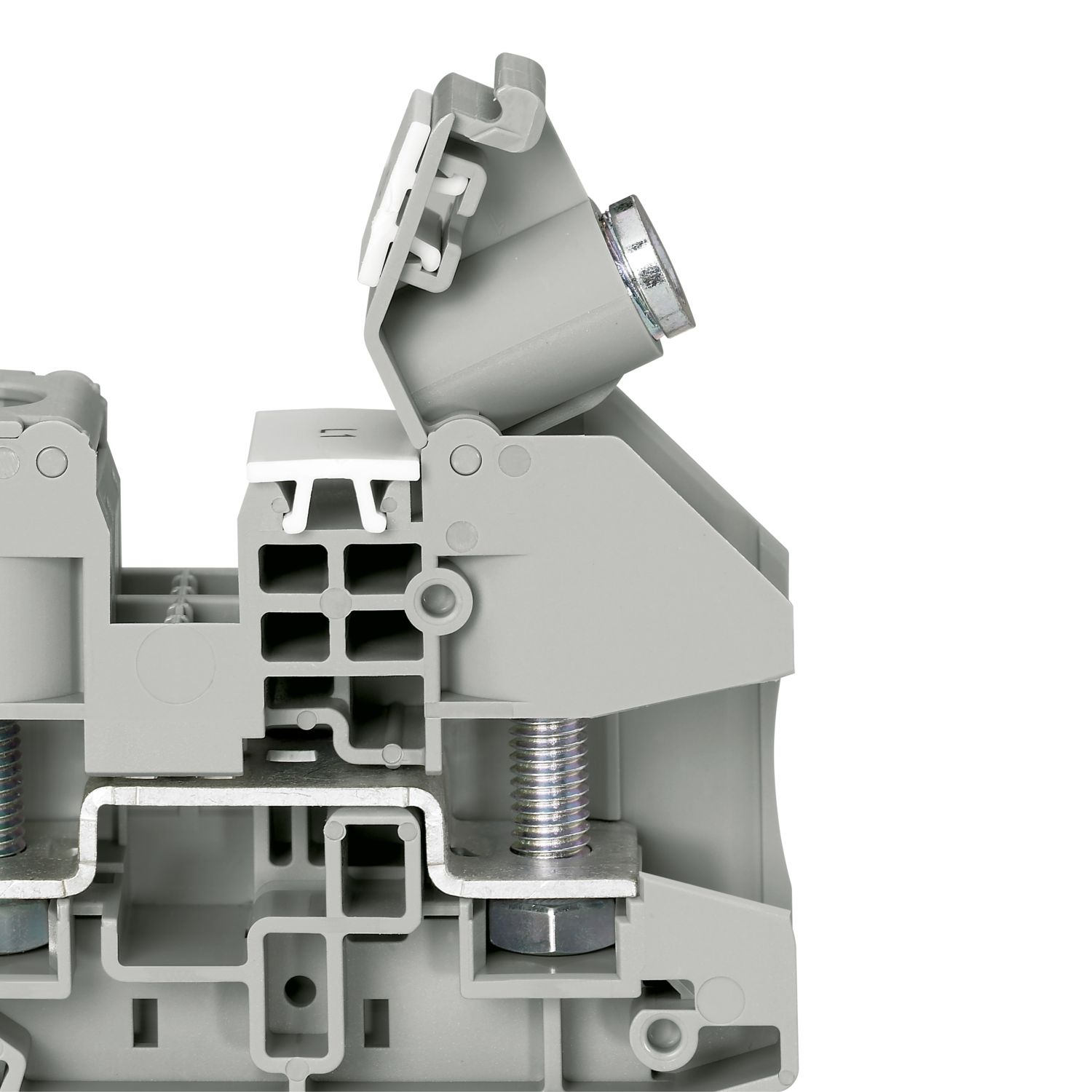

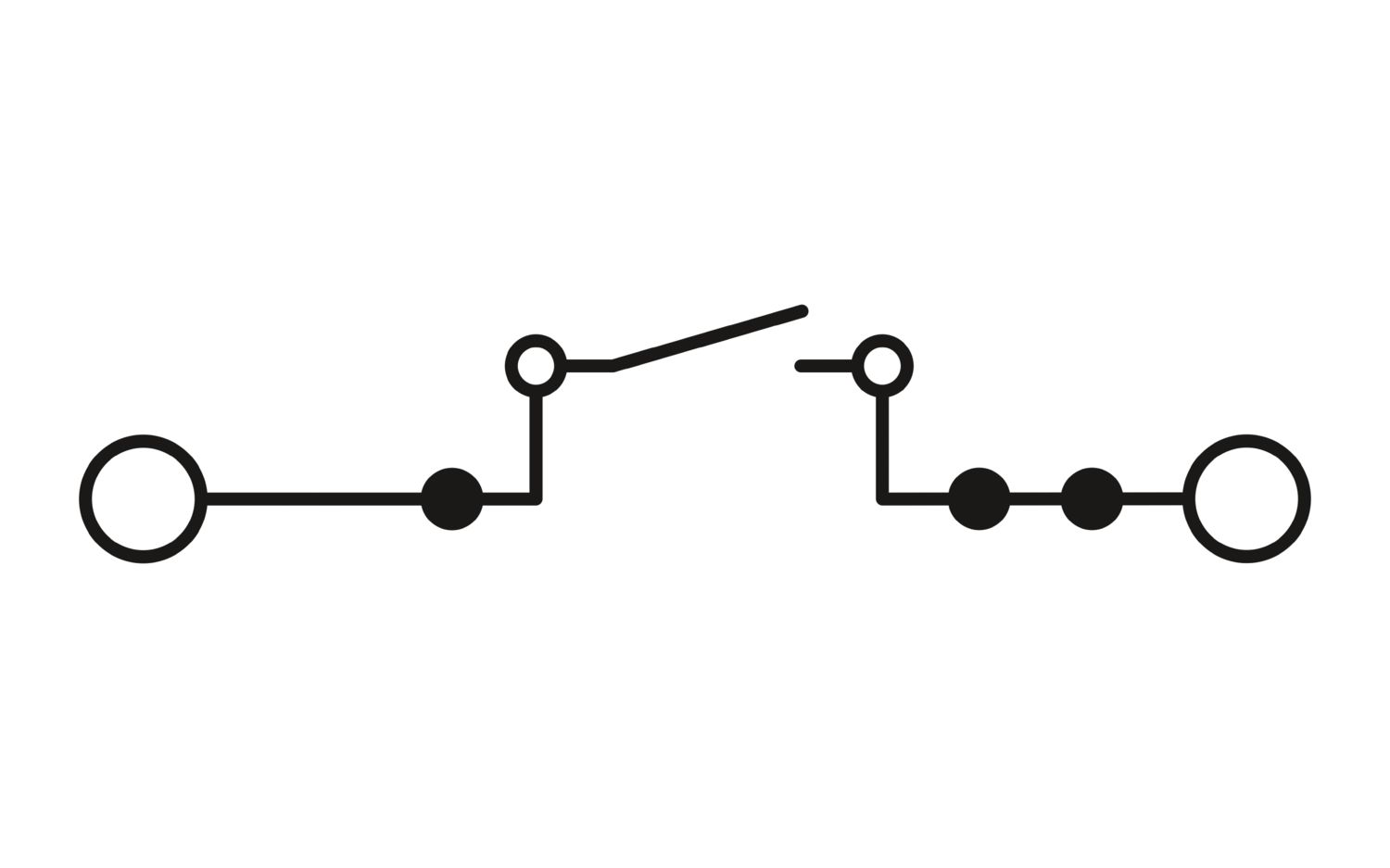

| Disconnect slide | |

| Screw thread | M4 |

| Tightening torque | 1.5 ... 1.8 Nm |

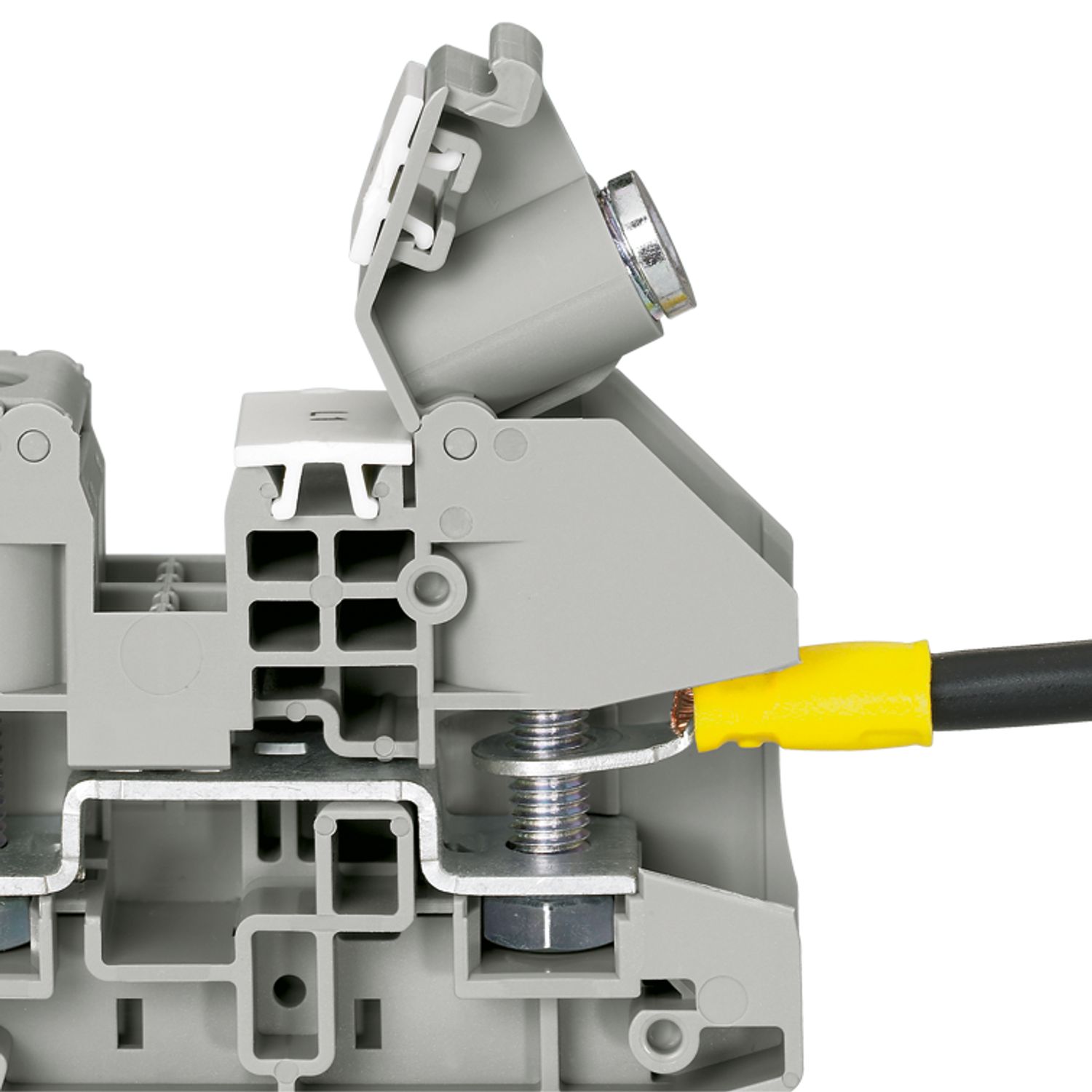

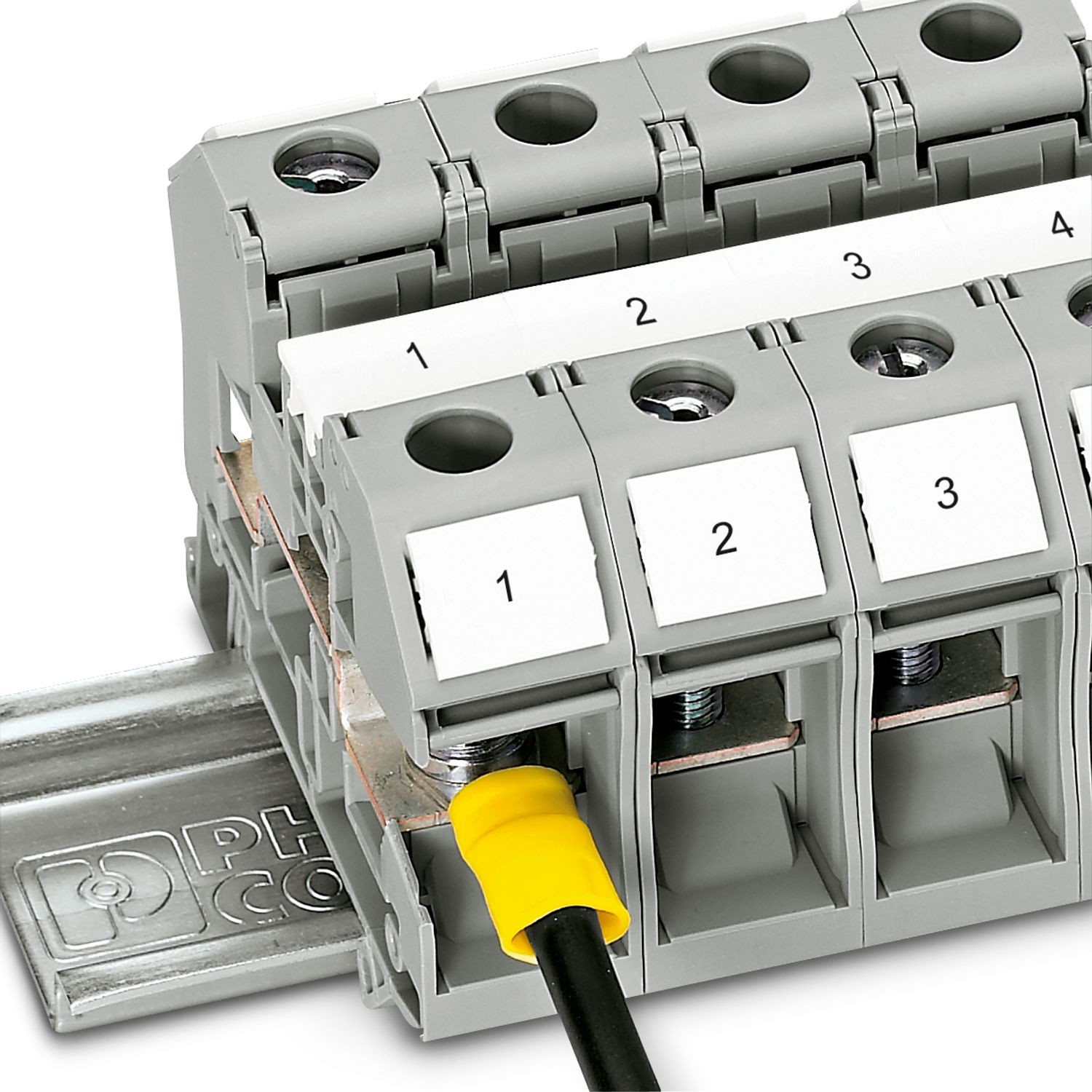

| Cable lug connection DIN 46234:1980-03 | |

| Connection in acc. with standard | DIN 46234:1980-03 |

| Cross section | 0.5 mm² ... 6 mm² |

| Cross section range AWG | 20 ... 10 (converted acc. to IEC) |

| Hole diameter | 5.3 mm |

| Width | 10 mm |

| Bolt diameter | 5 mm |

| Screw thread | M5 |

| Tightening torque | 2.5 ... 3 Nm |

| Connection in acc. with standard | DIN 46237:1970-07 |

| Cross section | 1 mm² ... 6 mm² |

| Cross section range AWG | 18 ... 10 (converted acc. to IEC) |

| Hole diameter | 5.3 mm |

| Width | 10 mm |

| Bolt diameter | 5 mm |

| Screw thread | M5 |

| Tightening torque | 2.5 ... 3 Nm |

| Identification color of ring cable lugs : red | 1 mm² |

| Identification color of ring cable lugs : blue | 2.5 mm² |

| Identification color of ring cable lugs : yellow | 6 mm² |

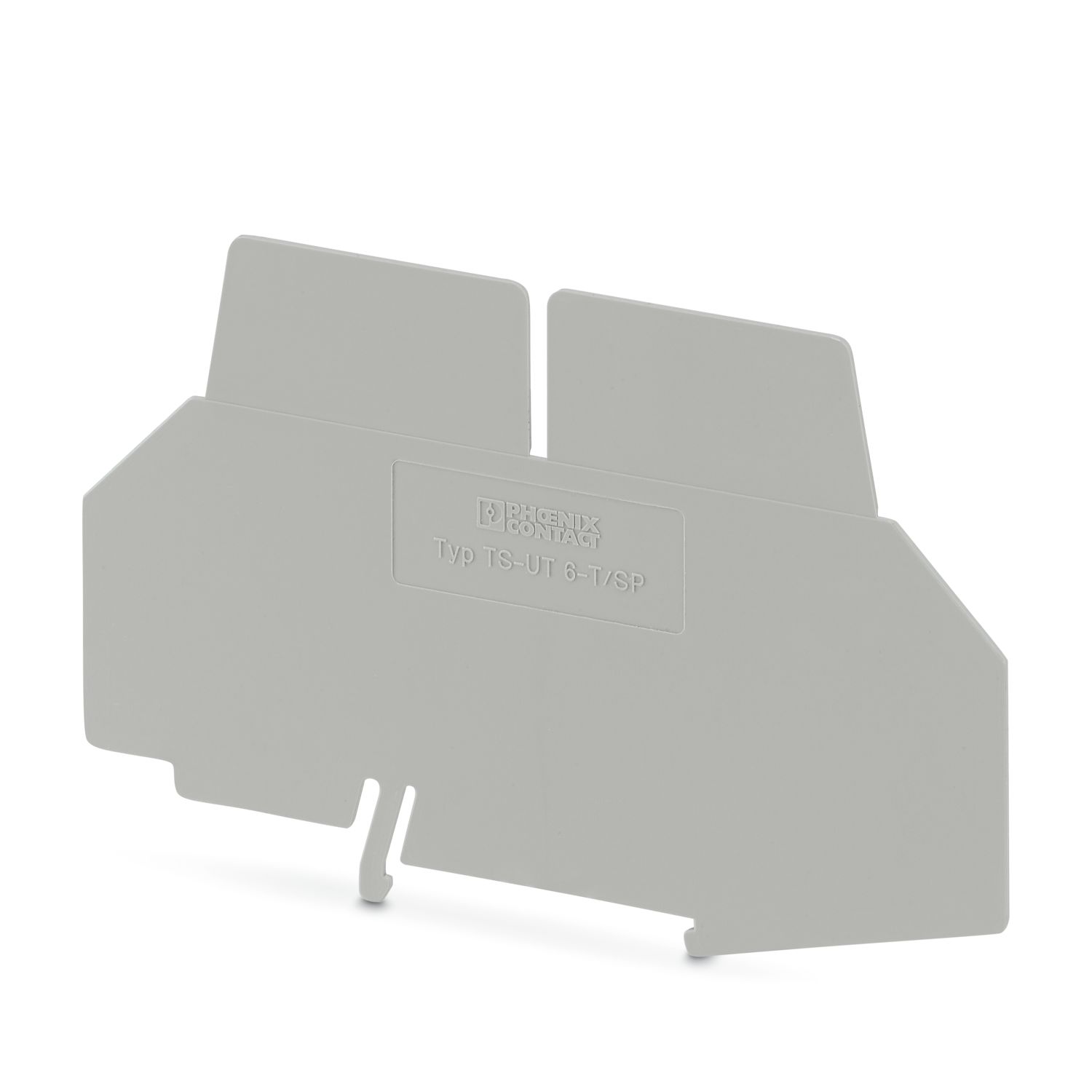

| Width | 16.3 mm |

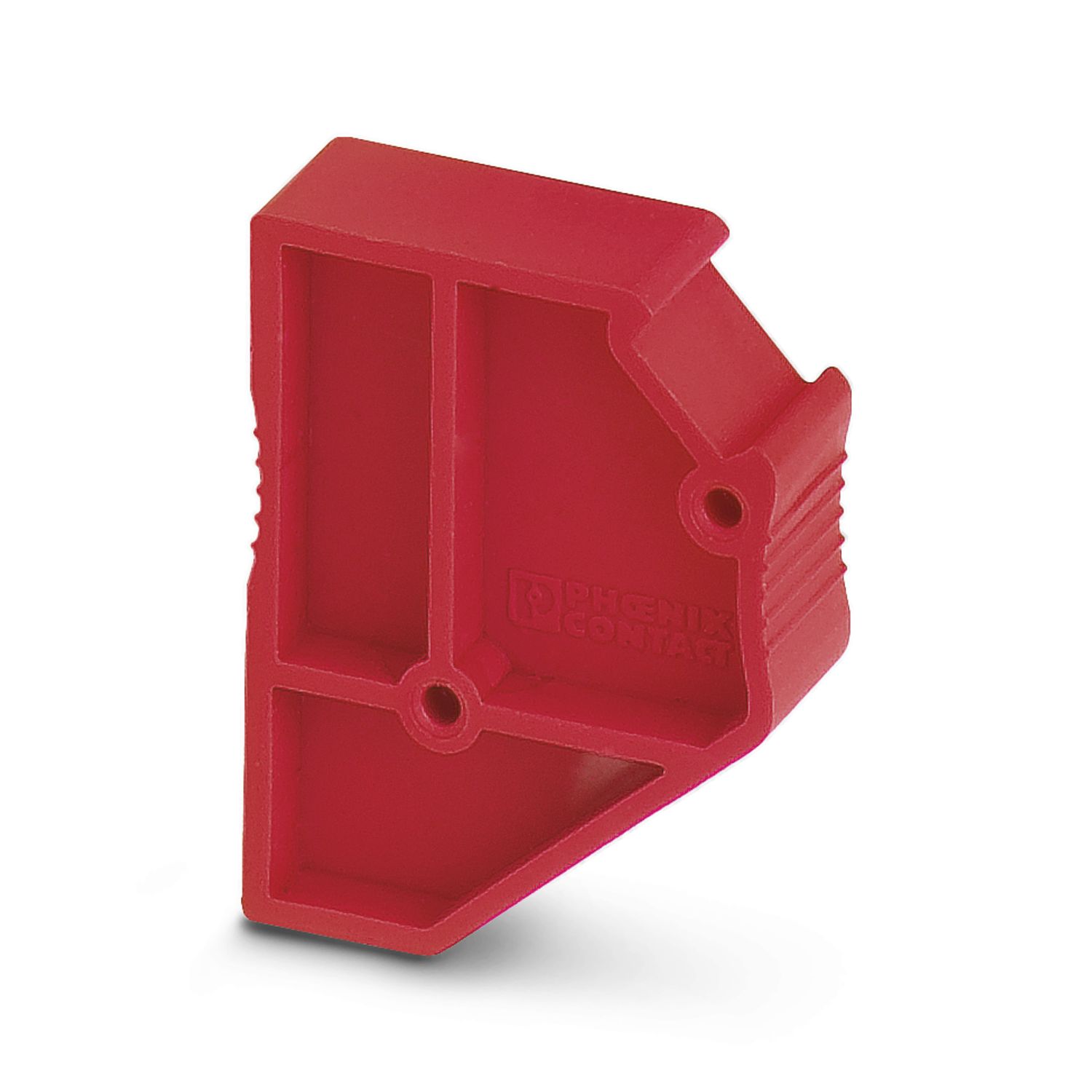

| End cover width | 2.2 mm |

| Height | 91.4 mm |

| Depth on NS 35/7,5 | 51 mm |

| Depth on NS 35/15 | 58.5 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 130 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 28 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 6 mm² | 0.72 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | Yes |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

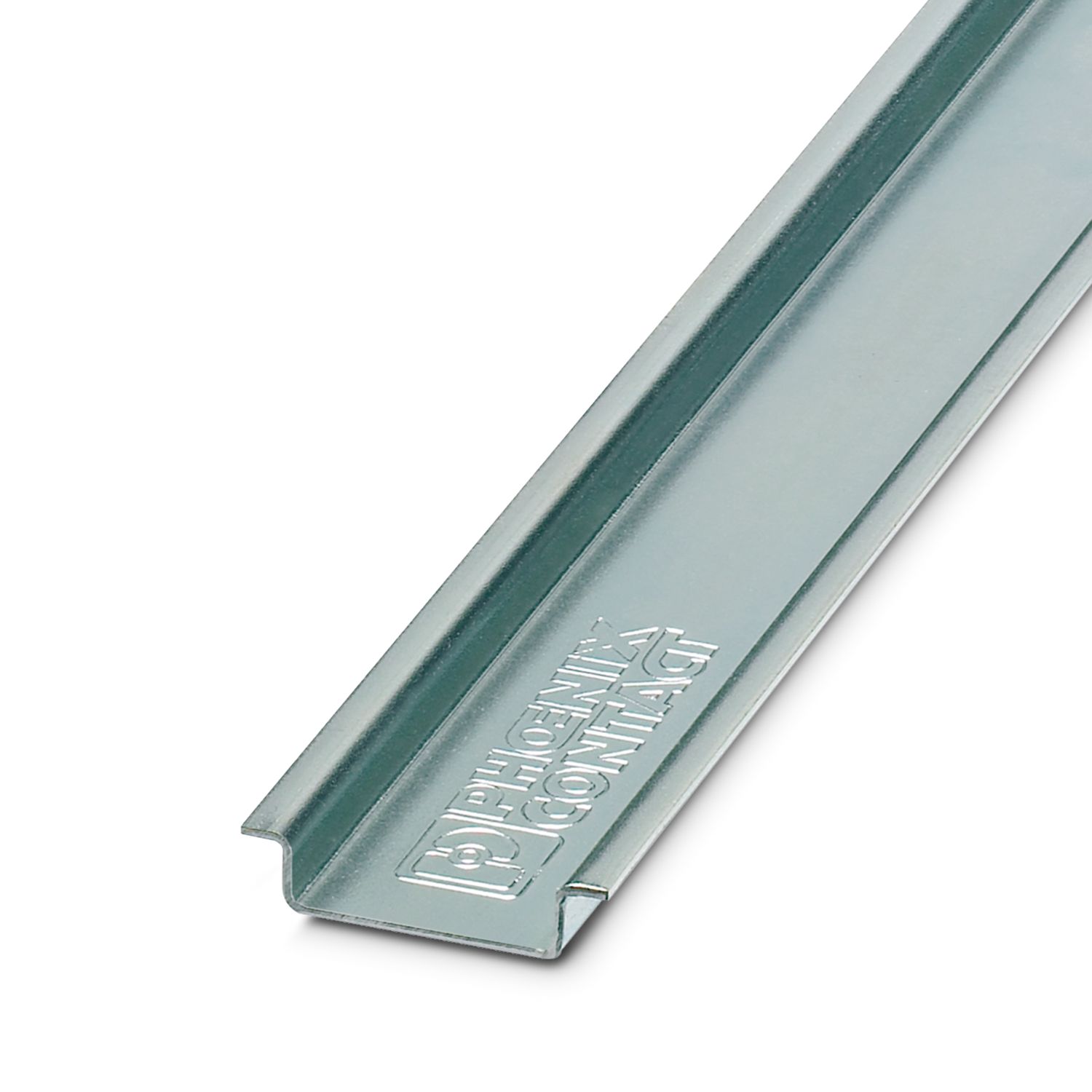

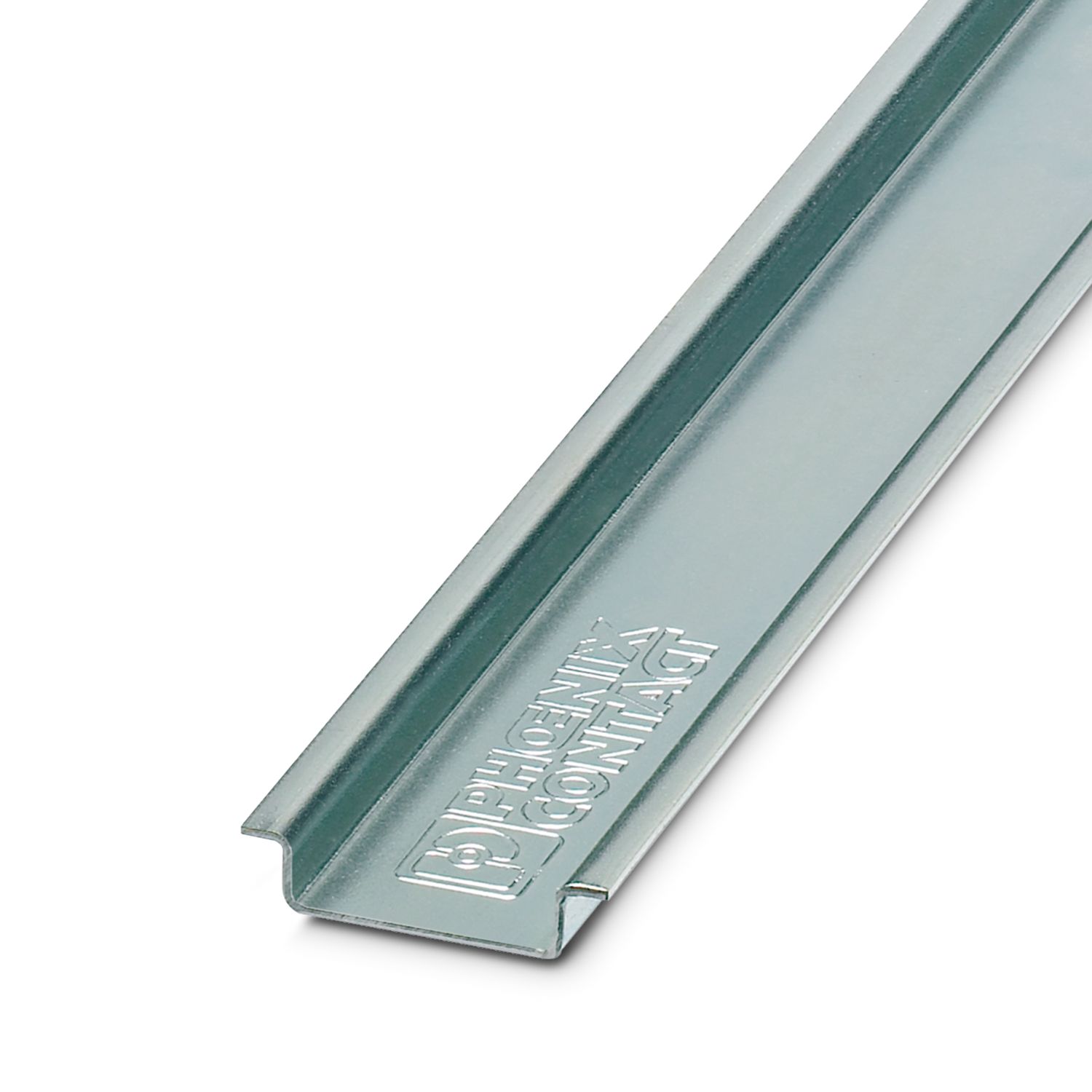

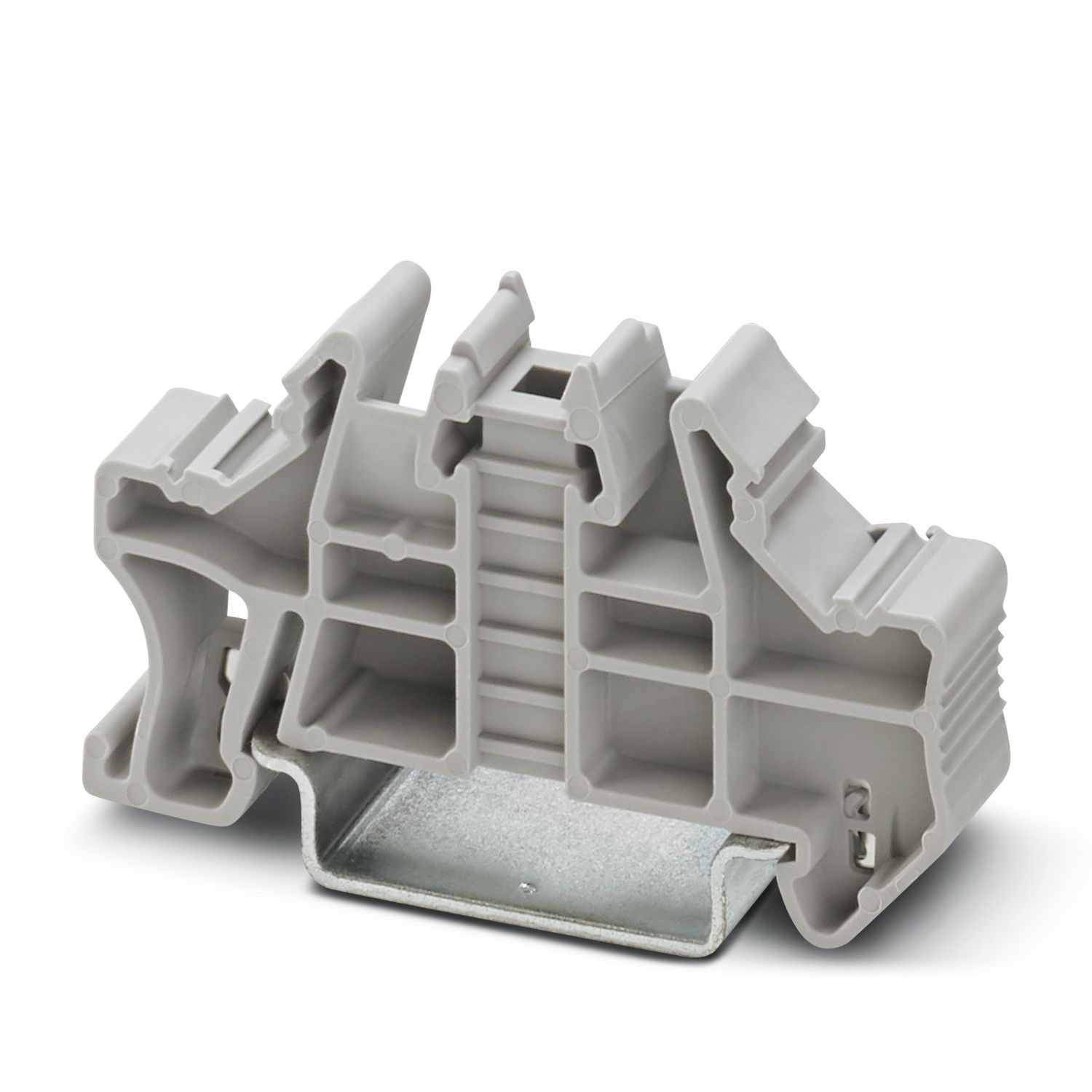

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 5 N |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 1.857 (m/s²)²/Hz |

| Acceleration | 0.8g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

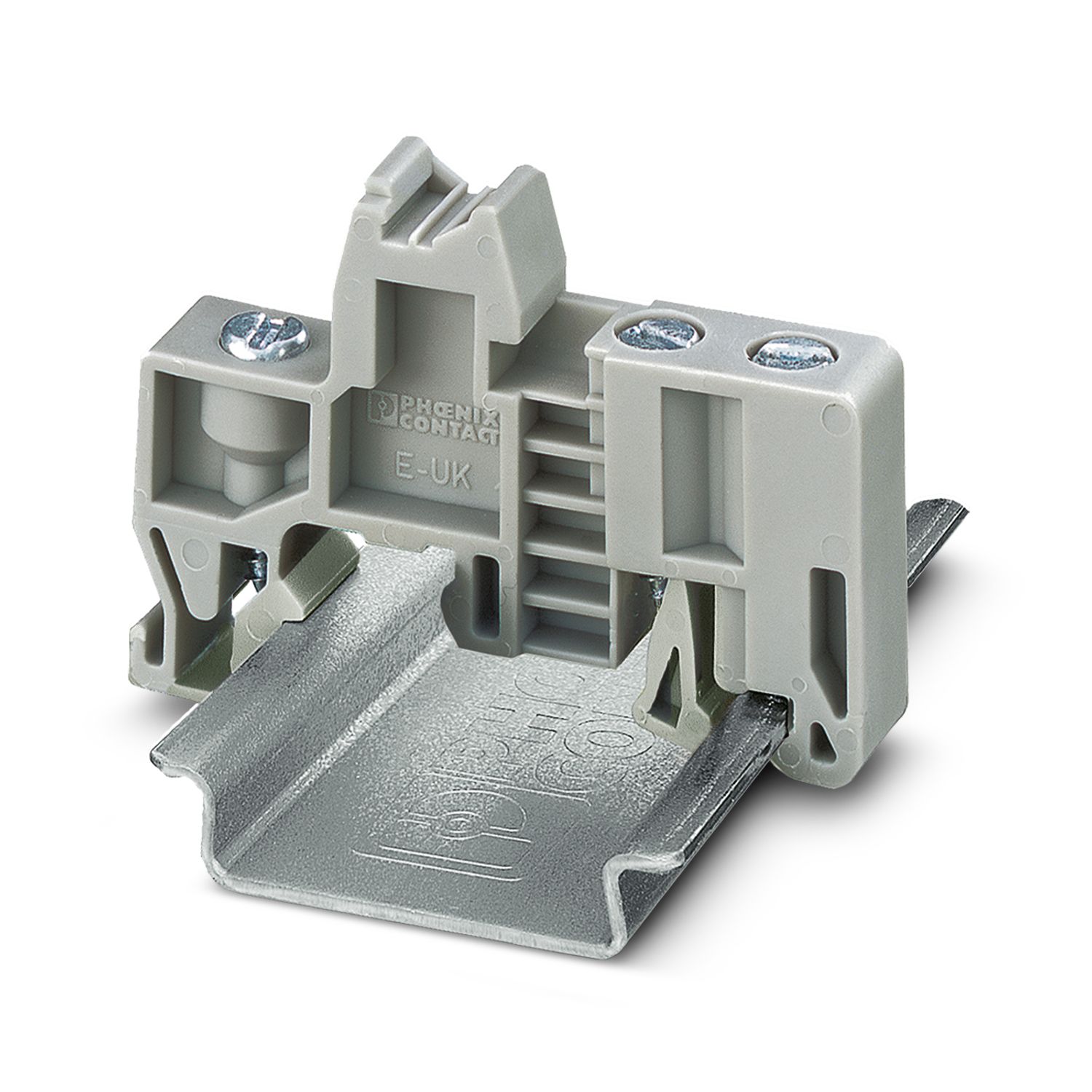

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/15 | |

| Screw thread | M4 |

| Item number | 3049039 |

| Packing unit | 25 pc |

| Minimum order quantity | 25 pc |

| Sales key | BE43 |

| Product key | BE4333 |

| GTIN | 4046356139991 |

| Weight per piece (including packing) | 50.774 g |

| Weight per piece (excluding packing) | 46.88 g |

| Customs tariff number | 85369010 |

| Country of origin | CN |

| ECLASS-15.0 | 27250101 |

| ECLASS-13.0 | 27250101 |

| ETIM 10.0 | EC000897 |

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |