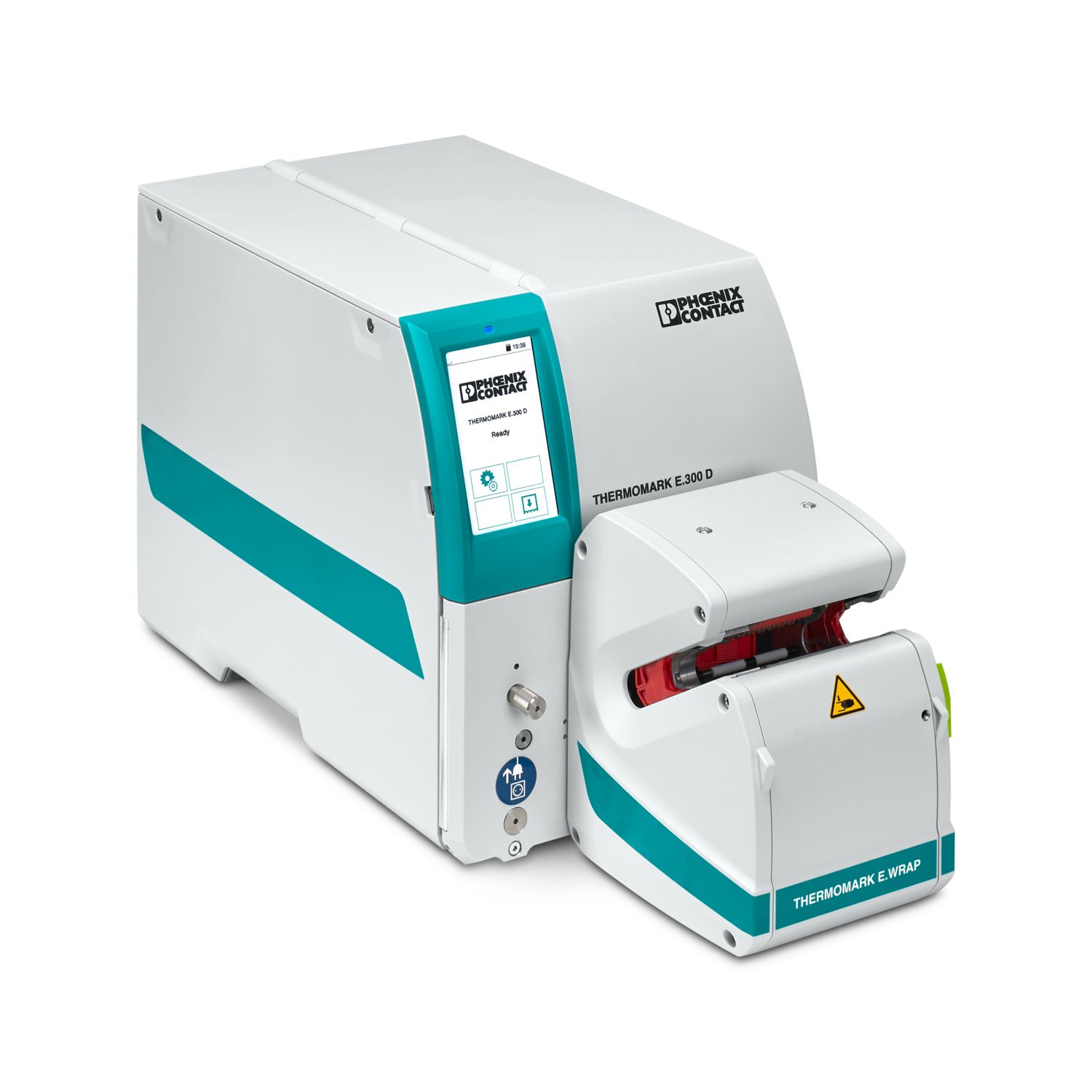

The THERMOMARK E.WRAP set is taking productivity in wire and cable marking to the next level. The combination of the THERMOMARK E.300 BASIC roll printer and the THERMOMARK E.WRAP applicator offers maximum efficiency for wire and cable identification processes. This provides you with an automated printing and application system that enables you to achieve time savings of up to 60% compared to manual identification processes.

The THERMOMARK E.WRAP automatically applies wire-wrap labels to cylindrical objects, while also ensuring a consistently high level of quality. This is essential in the case of wire-wrap labels, as they have an additional protective laminate to protect the printed surface. The end result is an extremely resilient identification solution that can even be used outdoors, for example. To make handling as easy as possible, the device features an adjustable scale, ensuring that the marking is always attached at the desired distance from the cable end. This efficient system enables the automated identification of all objects that have a diameter of between 2 mm/0.08" and 16 mm/0.63".

Scope of supply:

THERMOMARK E.WRAP (1203216), TM E.WRAP-PR pressure roller (1259200), TM E.300/E.600-DISPENSING EDGE/L (1263116), THERMOMARK E.300 BASIC, power cable (pin connector pattern: type F), USB cable, and multilingual packing slip.

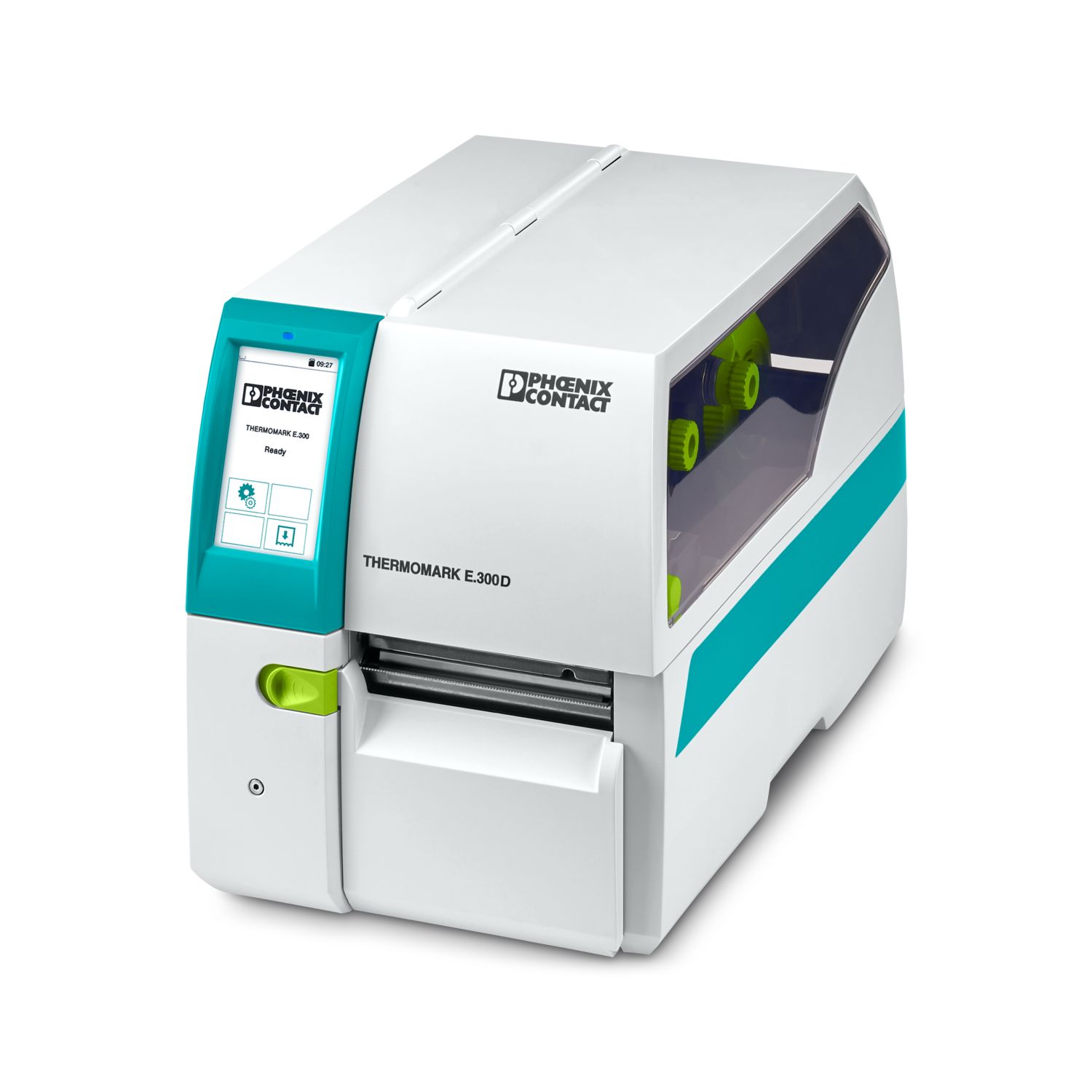

Note:

The THERMOMARK E.300 (D) BASIC printing system is equipped for immediate use in combination with the corresponding applicator. Unlike with the THERMOMARK E.300 (D)/E.600 (D) standard printer, the following items are not included in the delivery: TM E.300/E.600-FRONT COVER (1285305), TM E.300/E.600-TEAR OFF PLATE (1263118), TRM-PRESSURE ROLLER STANDARD (0804655), EML (20X8)R/TL (0802999) label roll, and THERMOMARK-RIBBON 110/50 ink ribbon (0800687).