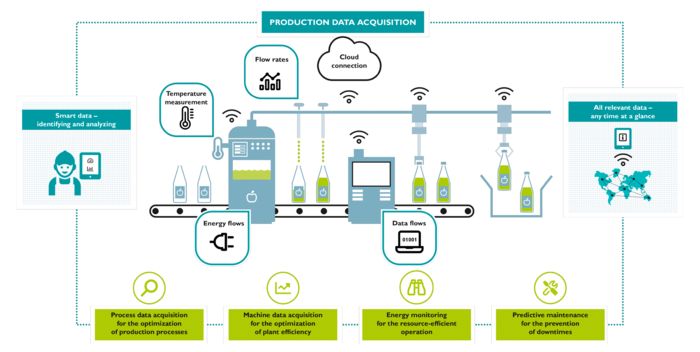

Acquire and visualize operating data Process data acquisition enables the optimization of production processes through the acquisition and evaluation of machine and system data. This data provides the basis for making decisions regarding the targeted improvement of machines and production processes. By precisely recording values such as flow rates, currents, and temperatures, bottlenecks can be identified and predictive maintenance can be performed. Process data acquisition helps to increase machine performance and reduce machine downtimes.

Overview of process data acquisition in machine building