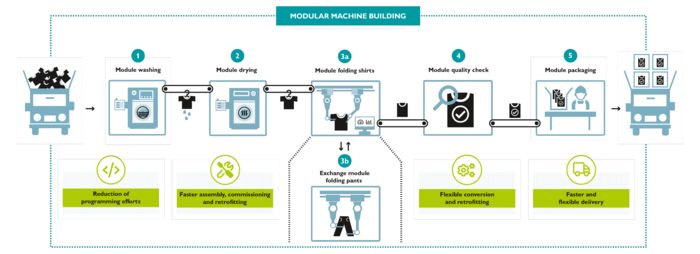

Modular and flexible machine building Nowadays, machines must provide the option to quickly adapt to changes on the market. Modular machine concepts provide the ideal solution here, because they provide your customers with the greatest possible flexibility. The modular machine design also brings the advantage that transporting large and extensive machines to the customer’s premises and installing then easier.

Overview of modular machine building Modular machines and switching devices can be set up in parallel and assembled quickly, easily, and safely at the destination. If required, you can convert your machine quickly and thus increase its efficiency.