Machinery Directive Safety of machinery in the European Economic Area

Are your machines intended to be placed on the internal European market? Then you have to observe the requirements on the safety of machinery. You will find all you need to take into account in order to comply with the Machinery Directive 2006/42/EC here.

What is the Machinery Directive?

The European Machinery Directive 2006/42/EC aims to reduce the number of accidents that occur through the use of machinery. To this end, the Directive of the European Parliament and of the Council of May 17, 2006, requires that the aspect of safety be incorporated into the design and construction of machinery.

The Machinery Directive is intended to ensure uniform safety standards for machines in the European Economic Area. In order to achieve legal conformity and market access, manufacturers must ensure that their machines comply with the directives and harmonized standards. These standards enable products to be sold throughout the European Economic Area without additional testing.

As a manufacturer, you must ensure that the technical documentation required by the Machinery Directive is drawn up. The technical documentation for a machine must make it possible to assess whether the machine complies with the requirements of the Machinery Directive. The manufacturer of a machine or their authorized representative is responsible for creating the technical documents as well as adhering to all requirements. It is only when these requirements are met in full that machines are allowed to bear the CE marking. This marking is required in the European Economic Area so that the machine can be placed on the market and operated without restrictions.

Key contents of the Machinery Directive

The latest EU Machinery Directive contains essential health and safety requirements for machines. It also considers harmonized standards, conformity assessment procedures, and the requirements for CE marking.

1. Essential health and safety requirements

The essential health and safety requirements for the design and construction of machinery in accordance with the Machinery Directive 2006/42/EC are described in detail in Annex I of the directive. Machines must be designed and constructed such that they are safe and do not pose any hazards to persons. In addition to mechanical and electrical safety, ergonomics, protection against noise and vibration, and the avoidance of risks from moving parts must also be taken into consideration.

Emergency stop in machine building

2. Scope

The Machinery Directive applies to complete and partly-completed machines that are placed on the market or put into operation. This also includes replaceable equipment, safety components, load lifting devices, chains, ropes, and belts, as well as removable mechanical gearboxes.

-

Complete machines: Machines that perform all functions and are ready for operation. They must meet all the essential health and safety requirements of the Machinery Directive and be subjected to a conformity assessment procedure.

-

Partly-completed machine: Not all functions have yet been fulfilled and are only ready for operation once they have been installed in another machine or after addition. These must have a declaration of incorporation and technical documentation that demonstrates compliance with the relevant requirements.

3. Placing on the market and putting into service

Only machines that meet the essential health and safety requirements and bear the CE marking may be placed on the market. A machine is considered to be “placed on the market” if it was made available on the European market for the first time. The manufacturer must ensure that the machine meets the safety requirements. The technical documentation must be drawn up.

For startup, machines must be safely installed and maintained and comply with the requirements of the Machinery Directive. If the machine is used for the first time by the end user in accordance with its specification, the machine is considered to be started up. The operator is obliged to safely install, operate, and maintain the machine in accordance with the operating instructions.

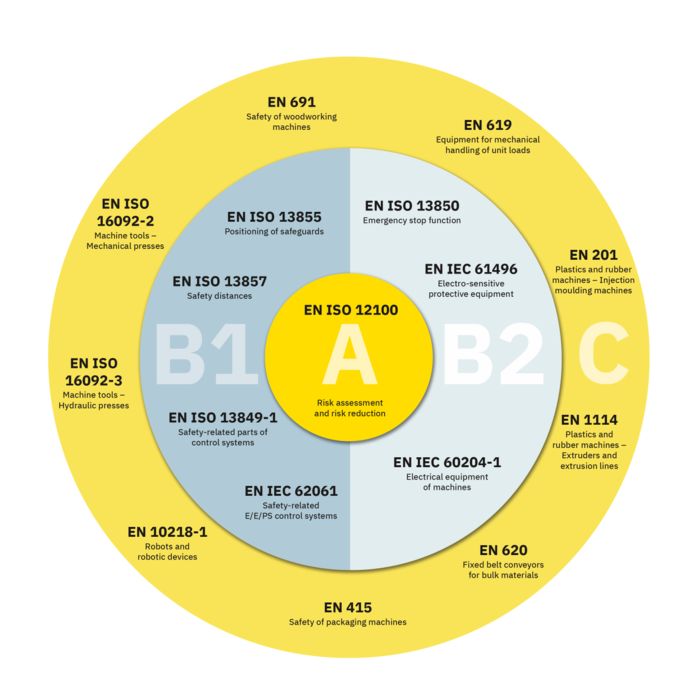

Differences between type A, type B, and type C standards

Harmonized standards

Harmonized standards are technical specifications created by European standardization organizations. They are published in the Official Journal of the EU. The harmonized standards are designed to facilitate compliance with the essential requirements of the Machinery Directive. The application of these standards is voluntary, but they come with a presumption of conformity.

Example: A machine manufactured in accordance with the specified harmonized standards is presumed to meet the essential health and safety requirements of the Machinery Directive.

The EN IEC 62061 and EN ISO 13849-1 standards were derived from the EN 61508 standard especially for the machine building industry:

- EN 61508: Standard regarding the functional safety of electrical, electronic, and programmable electronic safety-related systems.

- EN ISO 13849-1: Describes the design of the safety-related parts of control systems. An important parameter for the reliability of safety-related functions is the performance level (PL).

- EN IEC 62061: Describes the functional safety aspects of safety-related electrical, electronic, and programmable control systems. An important parameter for the reliability of safety-related functions is the safety integrity level (SIL).

Risk assessment

A risk assessment is a crucial element of the Machinery Directive that must be carried out systematically and comprehensively. It is essential that all potential hazards that can be associated with the operation of the machine are identified.

Procedure for performing the risk assessment for machinery:

- Identification of hazards: Identification of potential hazards

- Assessment of risks: Analysis of the probability and severity of possible injuries

- Definition of protective measures: Implementation of measures for risk reduction

The risk assessment developed in this way must be documented, checked regularly, and updated. This ensures that all new safety standards are observed and that the machines meet the latest technological developments.

Cobot risk assessment

Combination of several machines or components

When several machines or components are interlinked, mutual dependencies and potential hazards must be re-examined. This requires a comprehensive risk analysis that assesses the safety of all of the machines working together.

Conformity assessment procedures

As part of the conformity assessment procedure, the manufacturer must check whether all requirements on the applicable directives have been met. With the declaration of conformity, the manufacturer confirms conformity with the respective EU directives and regulations.

The conformity assessment procedure includes:

- Risk assessment: Identification and evaluation of potential hazards.

- Technical documentation: Creation and provision of technical documentation.

- CE marking: affixing the CE marking after successful evaluation.

For partly-completed machinery Declaration of incorporation is required. This confirms that the machine satisfies the relevant requirements. In order to demonstrate conformity, technical documentation must also be provided.

Press brake as a high-risk machine

Involvement of external bodies for high-risk machines

All machines that are considered to be particularly dangerous are listed in Annex IV of the Machinery Directive 2006/42/EC. Examples of these machines include:

- Sawing machines

- Milling machines

- Presses

- Injection molding and compression molding machines

- Lifting platforms

Strict procedures for assessing conformity apply to these machines. If the machine under consideration falls into one of the categories in Annex IV of the Machinery Directive and a harmonized standard is not applied or adhered to, an external body must be consulted for evaluation. This body then either performs a type test or evaluates the manufacturer’s quality assurance system.

Technical documentation

The technical documentation must contain all the information necessary to assess the conformity of the machine, including:

- Technical drawings and circuit diagrams

- Calculations and test results

- Operating instructions

- Risk assessment

- EC declaration of conformity

In which language must the technical documentation be created?

In principle, there are no specifications regarding the language when creating the technical documentation. In individual cases, market surveillance authorities may require translation into the official language of the EU member state in which the machine is to be placed on the market.

Who must keep the technical documentation?

The manufacturer must keep the technical documentation for at least ten years after the machine has been placed on the market.

CE marking

The CE marking indicates that a machine meets the basic requirements of the relevant European directives and has successfully passed the conformity assessment procedure.

Machines with CE marking

Alteration of CE marked machines

CE marked machines may be altered. However, if the alteration represents a significant change in the sense of the Machinery Directive, the machine must go through the conformity assessment procedure again after it has been altered.

Significant changes may be due to:

- Changes to functions

- Increases in performance

- Retrofitting of accessories or attachment parts

- Modernization or replacement of safety equipment

- Use of new operating materials

Further information on significant changes is provided in §72 of the Guide to the Machinery Directive of the European Commission as well as the “Blue Guide” of the European Commission.

Other directives

In addition to the EU Machinery Directive 2006/42/EC, there are other directives relevant for machinery that must be taken into account at the same time.

These include, for example:

- Low Voltage Directive 2014/35/EU (LVD)

- Electromagnetic Compatibility 2014/30/EU (EMC)

- Radio Equipment Directive 2024/53/EU

- RoHS Directive 2011/65/EU

- ATEX directive 2014/34/EU

Products for functional safety

Discover our comprehensive portfolio of products and solutions for functional safety. From our safety switches right through to our safety controllers, all of our safety products are SIL-certified. Phoenix Contact will provide the products, training courses, and TÜV-certified experts to help you meet the safety requirements of the Machinery Directive. We make you fit for protecting people and machines.