Automation solutions for CCUS and DAC systems Increase the efficiency and safety of your systems for capturing, utilizing, and storing carbon with our open control and monitoring solutions.

The challenge

Optimization of safety and efficiency

CCUS (Carbon Capture, Utilization and Storage) and DAC (Direct Air Capture) are promising technologies for reducing carbon emissions. To achieve the net zero targets, more and more companies are investing in CCUS and DAC systems. The systems generate large amounts of data. To optimize operation and identify potential failures at an early stage, this data must be collected, stored, and analyzed efficiently. In addition, seamless integration of the different systems important, which requires scalable and open automation solutions. To ensure that your systems operate safely, reliably and economically, we offer you modular and open-technology concepts for networking and automation.

The solution

Consistent digitalization of systems and processes

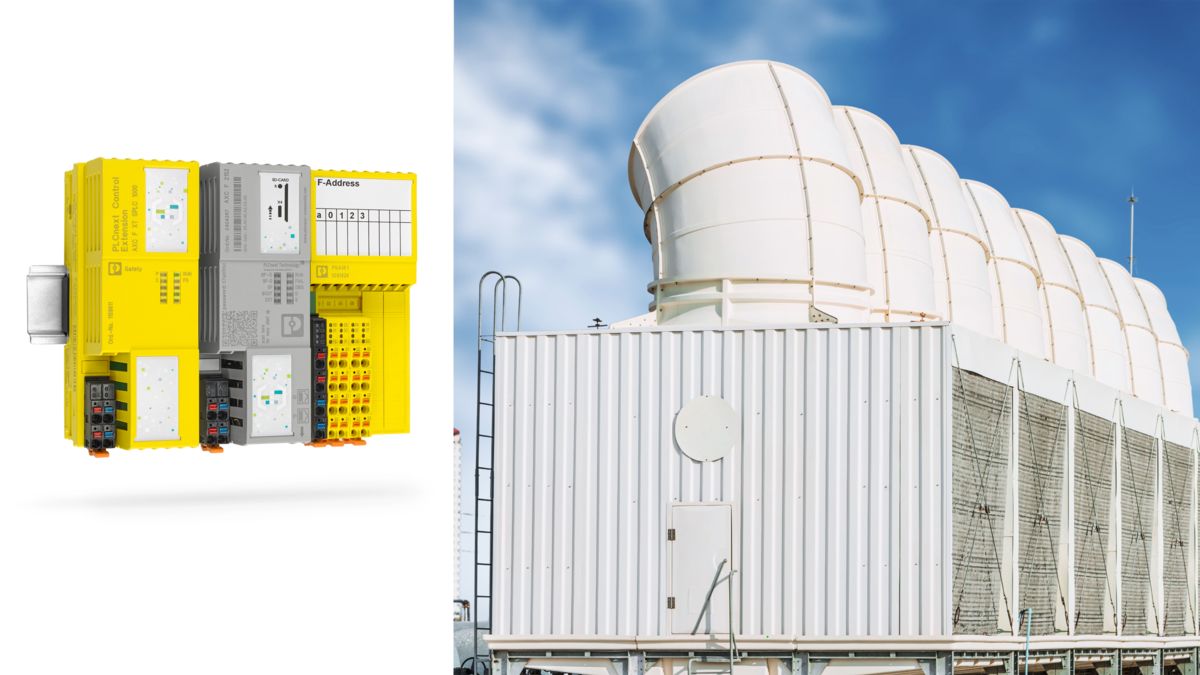

Our open ecosystem PLCnext Technology allows you to control and monitor the entire carbon capture system. This includes, for example, control systems for processes with liquid and solid adsorption materials. The boiler control required for specific processes and the associated safety systems can also be implemented. The system architecture of PLCnext Technology is optimized for the distributed setup of large-scale carbon capture systems.

AI-based data utilization

Our solution supports maintenance concepts based on diagnostic signals. PLCnext Technology records the sensor data synchronously and evaluates it in the appropriate format. This streamlines the planning and decision-making processes, thereby increasing the efficiency of carbon capture by using the data intelligently. AI-supported evaluations can detect deviations from the standard behavior of the system. It is possible to link to external databases as well as model and scenario calculations via Matlab Simulink or PLCnext Technology.

Access to distributed systems

We offer a range of options for secure remote access to your carbon capture systems. This means that you can perform maintenance and service jobs quickly and efficiently, as well as significantly reduce costly and time-consuming on-site service calls. For data transmission, we offer our mGuard Secure Cloud solution. This turnkey remote maintenance solution connects service personnel and systems over the Internet securely and reliably. The mGuard Secure Cloud uses highly secure VPN tunnels and ensures the confidentiality, authenticity, and integrity of data transmitted between the devices.

Contact person

Products

Still haven’t found the right product?

Feel free to contact us. Together, we can find an ideal solution for equipping your control cabinets with more than 100,000 products from the fields of connection, communication, and automation technology.