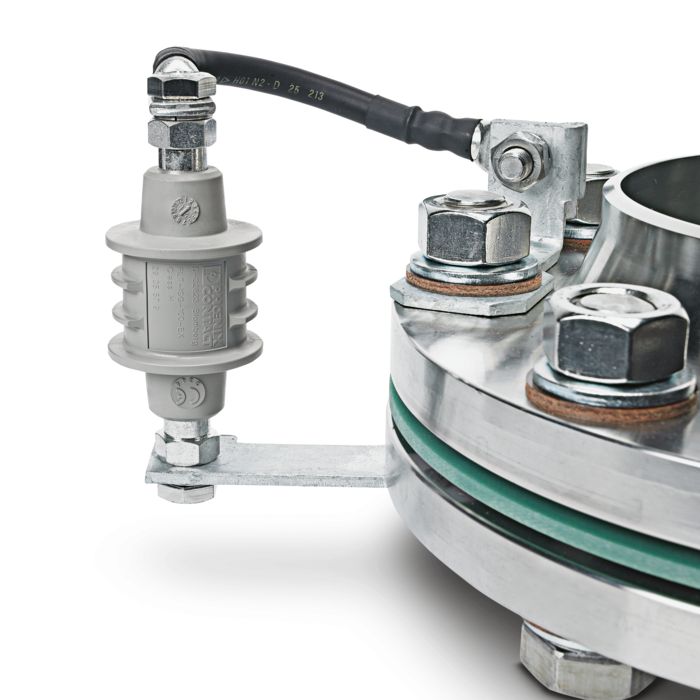

Isolating spark gap for the hazardous area with plastic sleeve and M10 connection thread screws. For indirect connection/grounding of operationally isolated system parts in the event of lightning.

Use our isolating spark gaps to protect your insulating flanges against damage caused by overvoltages. Avoid failures, downtimes, and even leaks on pipelines and protect sensitive insulating flanges against sparkover. The isolating spark gap ensures lightning protection equipotential bonding and safely discharges overvoltages. This in turn ensures smooth operation of the pipeline.

Isolating spark gap for the hazardous area with plastic sleeve and M10 connection thread screws. For indirect connection/grounding of operationally isolated system parts in the event of lightning.

Connecting cable for FLT-ISG-100-EX, length 300 mm.

Plate for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 18 mm.

Plate for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 11 mm.

Connecting cable for FLT-ISG-100-EX, length 100 mm.

Bracket for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 22 mm.

Plate for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 26 mm.

Bracket for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 36 mm.

Bracket for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 48 mm.

Plate for fixing the FLT-ISG-100-EX isolating spark gap to a flange, drill hole diameter of 42 mm.

Insulating flange with isolating spark gap

A long service life is vital for the cost-effective operation of pipelines. Active corrosion protection systems are used to protect against rust. When used in regular operation, these require the metal pipes to be insulated against ground potential.

In order to protect the pipe insulation and the insulating flanges against damage caused by overvoltages, isolating spark gaps are used. In the event of an overvoltage, the isolating spark gap becomes low impedance and discharges the voltage. Lightning protection equipotential bonding is thus ensured. Thanks to the highest possible lightning current carrying capacity class H (in accordance with IEC 52561-3), even large lightning currents are safely discharged to ground via a defined path.

Isolating spark gap with mounting material

Since very high currents are discharged via the material in the event of a lightning strike, the accessories must also be able to reliably cope with these loads.

All accessories for connecting the FLT-ISG… isolating spark gap from Phoenix Contact are therefore designed with the appropriate discharge capacity.

When installing the isolating spark gap, use tested accessories to avoid a spark hazard in potentially explosive areas.