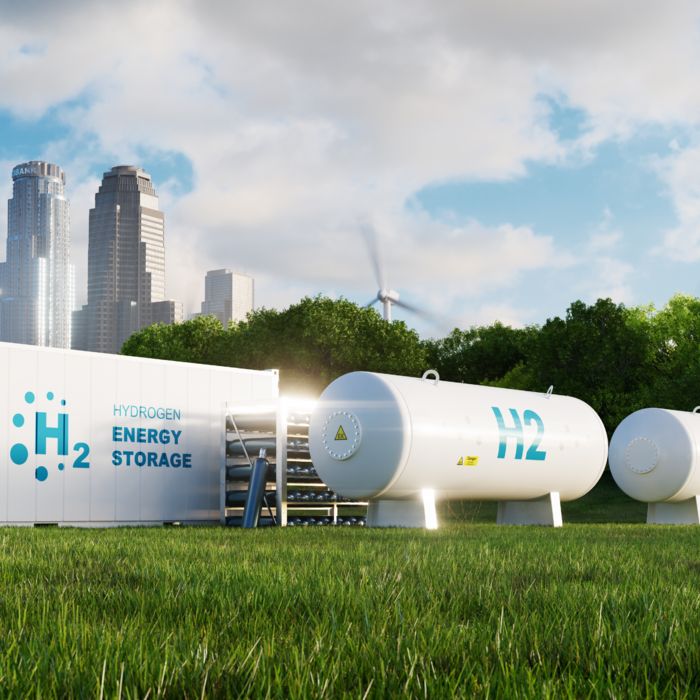

Power-to-X is a key technology for the sustainable energy transition. Surplus electrical energy from renewable sources, such as wind or solar power, is converted into other usable forms of energy. This is where electrolysis is used, a process in which water is split into hydrogen and oxygen. The hydrogen produced can be used directly or further processed into other fuels such as methane or methanol. Renewable energy is not only storable, but can also be used across sectors in various areas of daily life, such as heavy goods vehicles or industry.