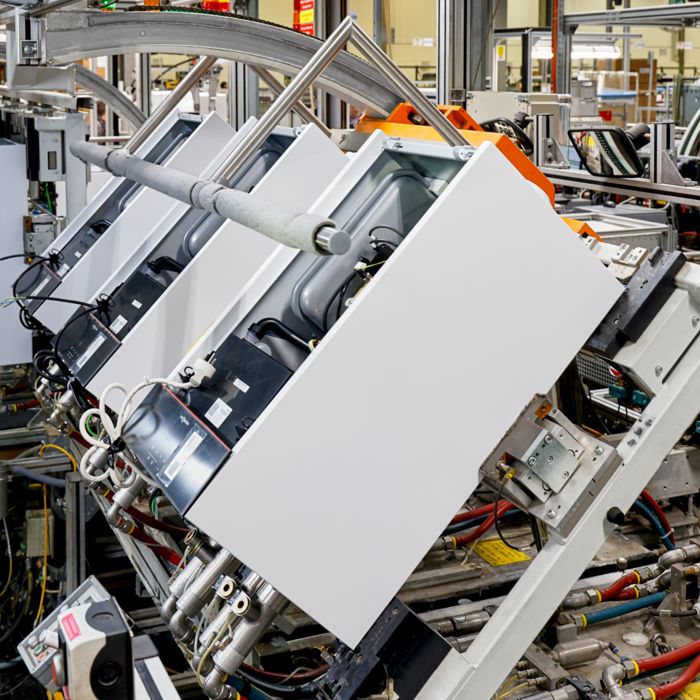

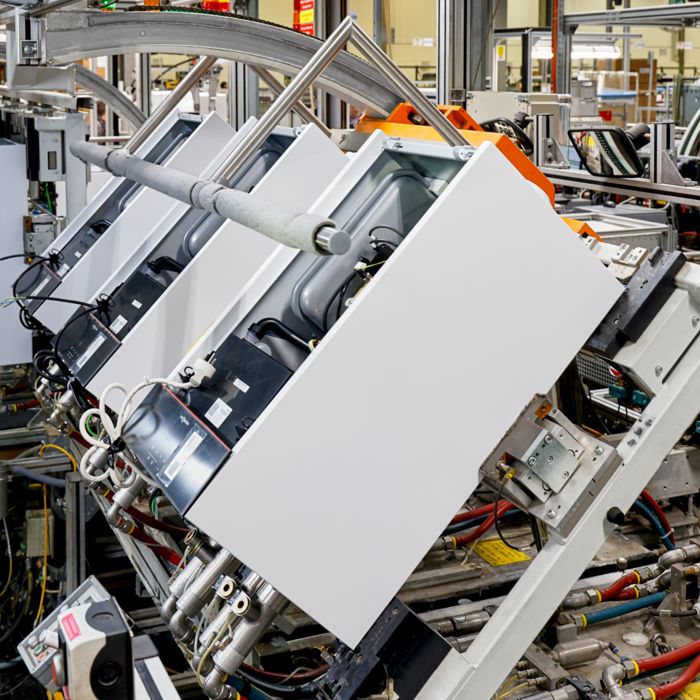

In maintenance-intensive applications, such as tool changes on robots, you can easily replace wear-prone and maintenance-intensive connections with NearFi couplers, thus minimizing downtime costs.

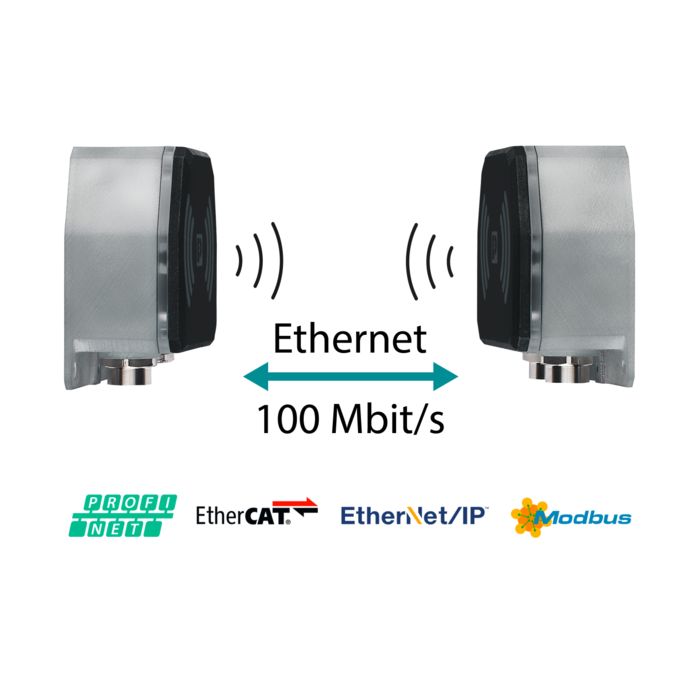

NearFi – communication in real time

Full duplex transmission, i.e., simultaneous transmission in both directions, is required in order to transmit real-time Ethernet protocols.

NearFi uses two 60 GHz connections (one uplink and one downlink) in parallel on separate frequency bands in order to enable full duplex mode.

This means that the technology is also suitable for future developments, such as TSN, OPC UA, etc.

Bit-oriented transmission is latency-free

NearFi uses a synchronous, bit-oriented transmission method. This allows contactless communication in real time, meaning that every Ethernet protocol is transmitted immediately.

All other radio transmission technologies to date rely on packet-oriented transmission. This always leads to considerable latency, as packets are first received, then repackaged and sent wirelessly. The wireless packet must be received at the receiver end, unpackaged, and output again. This process involves many asynchronous and latency-causing operations, which are completely eliminated by the innovative transmission technology from Phoenix Contact.

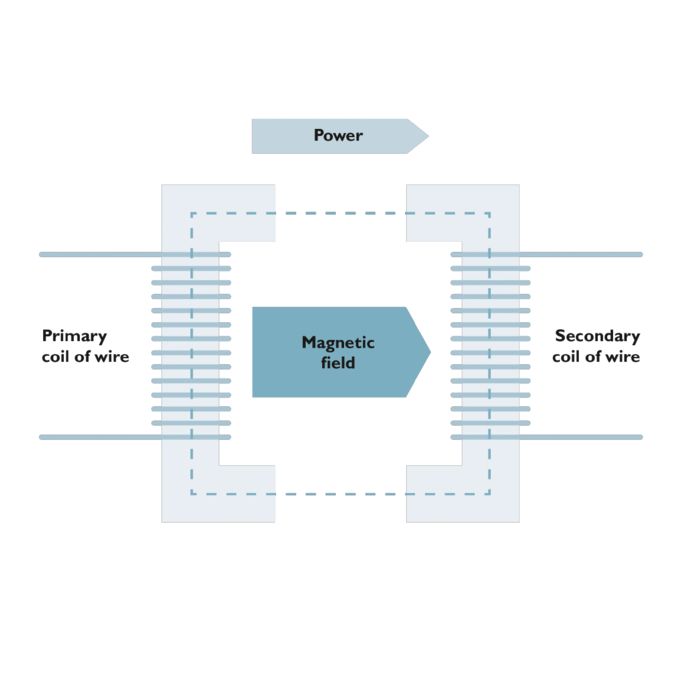

Inductive power transmission via magnetic field

Power transmission up to 50 W (with parallel connection up to 100 W) is inductive. The base coupler generates a magnetic field via a coil, which is induced in the coil of the remote coupler.The active control system always selects the optimum parameters for transmission and enables constant power transmission over the entire working range.

By combining two NearFi coupler paths, the power can be increased to 100 W with automatic current equalization, or two electrically isolated voltages (US/UA) with 50 W each can be transmitted.

Wireless technologies for every requirement

NearFi is a contactless real-time transmission technology from Phoenix Contact and is based on wireless 60 GHz communication in the near-field range with a range of a few centimeters.

Wireless communication in the near-field range does not create a spectrum of interference in the vicinity of the devices, which means that numerous NearFi systems can be used in parallel. Coexistence with existing wireless technologies such as WLAN or Bluetooth is ensured at all times. Industrial interference spectrums likewise cannot influence the NearFi technology.

No frequency planning and therefore no expertise is required.

In maintenance-intensive applications, such as tool changes on robots, you can easily replace wear-prone and maintenance-intensive connections with NearFi couplers, thus minimizing downtime costs.

Communicate contactlessly with movable or rotating system parts using NearFi couplers and avoid production downtimes due to defective connectors or slip rings that are susceptible to interference.

Use NearFi couplers for contactless transmission between the workpiece carrier and the production station and replace wear-prone and maintenance-intensive connectors.

Install NearFi couplers quickly and easily on your automated guided vehicle system (AGVS) and transmit safety-related data contactlessly between the AGVS and production station.