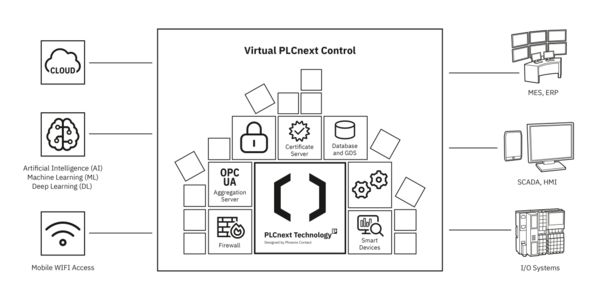

Controller; application: Virtual control; Type of software: On-premises; Subscription; License duration: 12 Months; Basic functions: Virtual control, The VPLCNEXT CONTROL is a powerful, real-time-capable virtual control based on PLCnext Technology.

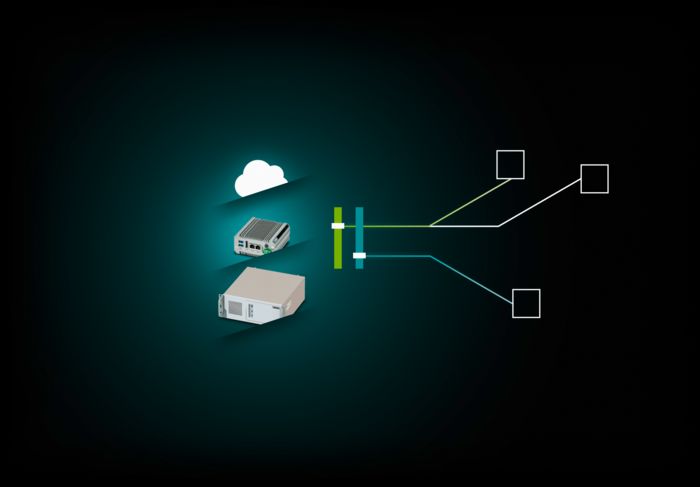

It is provided as an OCI-compliant container (Open Container Initiative) and can be instantiated flexibly..