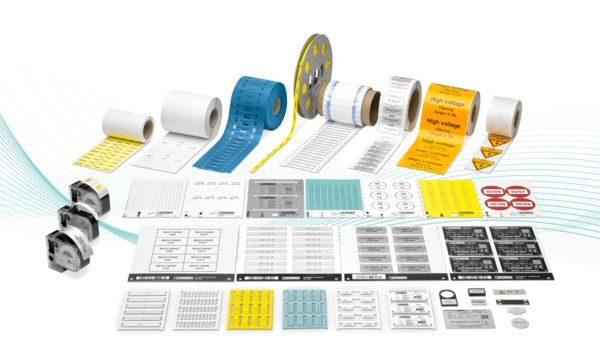

Label, Roll, yellow, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, THERMOMARK X1.2, mounting type: adhesive, Number of individual labels: 10000, text field height: 5 mm, text field width: 16.5 mm