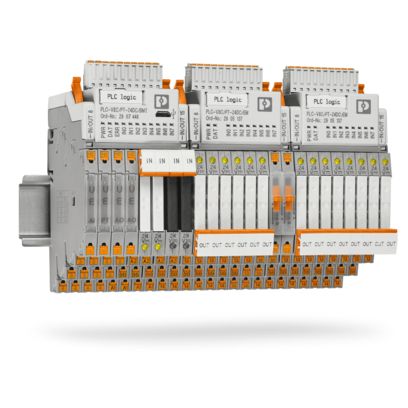

PLC-INTERFACE relays ensure that you always switch safely and reliably

The PLC-INTERFACE product range includes more than 700 different and fully automated items to meet the requirements of any application.

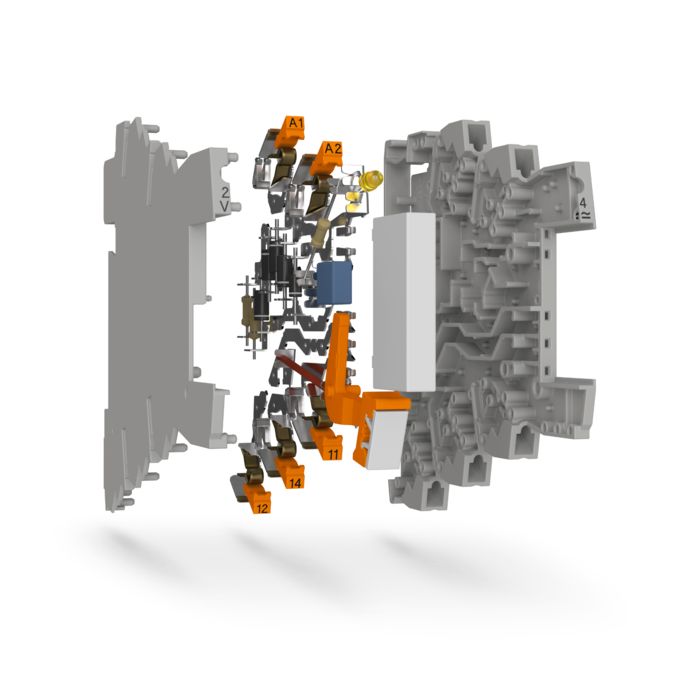

For maximum flexibility, the PLC-INTERFACE relays are available with either screw or Push-in connection technology. Choose between plug-in electromechanical and solid-state relays. In the selection process, both the external characteristics and the core of the products are decisive for the specific application:

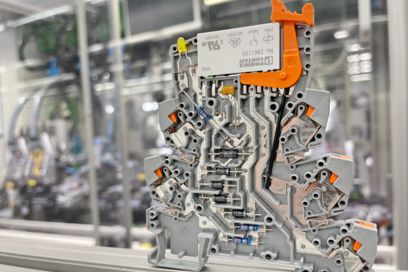

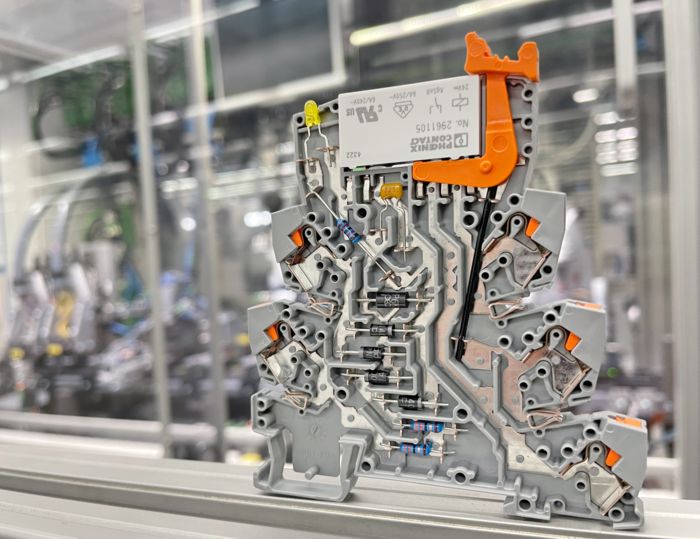

The core consists of a robust lead frame made of copper, which always ensures reliable connections and ideal heat distribution in the housing. Versions with a printed circuit board are also available.

With relays from Phoenix Contact, you are benefitting from the latest, innovative technology, for a wide product range of standard and special versions for every application.

How our relays are created – a look behind the scenes

Lead-frame technology

Switch signals reliably – in the tightest of spaces

The lead-frame technology in the PLC-INTERFACE relay series provides the solid foundation for reliably switching, isolating, and amplifying signals. In addition, electromechanical and solid-state relays are used. This combination proves itself day after day in millions of switching cycles. In 1997, Phoenix Contact set a milestone in relay technology: Lead-frame technology was integrated for the first time into relay modules with an overall width of 6.2 mm.

Your advantages

- Increased vibration resistance with press-fit electronic components

- Optimized thermal management reduces localized heating and extends the service life of electronics components

- Proven technology for highly compact relay modules

- Sustainable construction with easily separable construction elements and pluggable relays

- Easy wiring with Push-in and screw connection technology

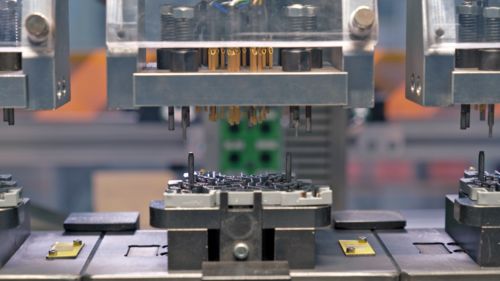

A look into the fully automated production system

Relays produced fully automatically with high-level manufacturing expertise support you reliably, efficiently, and sustainably in the operation of your systems and applications.

Plastic parts are made from granules, and conductors are formed and punched from raw metal plates. Printed circuit boards are laid out, assembled, and soldered. Electronic components are fed to the right points in the system process and then reach their defined destination.