Optimum yield at the Falkenberg solar park Tracking the solar trackers ensures reliable system operation.

Customer profile

Each solar tracker has an output of 35 kW

Landshut-based Elektro Ecker GmbH &Co. KG set up a tracking park on the site of a former Bundeswehr military base in 2017 and has been operating it since then. 22 solar trackers have been installed on the bunkers that used to serve as ammunition storage. The installed overall output of the park is 770 kW.

The challenge

The 22 client controllers on the trackers are controlled via the server controller

Each tracker has 143 solar panels with a nominal power of 245 W each, which are aligned bi-axially based on the position of the sun. In total, one solar tracker has a weight of 55 metric tons and achieves an output of 35 kW.

In the beginning, the tracking system for the individual trackers was controlled with non-industry-standard Raspberry Pi minicomputers. But it soon became apparent that this solution was not working reliably. After a short time in operation, it failed entirely. To keep the loss of yield that resulted from the trackers not being aligned toward the sun as low as possible, a suitable alternative had to be found quickly. Elektro Ecker had already had good experiences with control technology from Phoenix Contact in the past for the feed-in control of photovoltaic parks. Josef Ecker therefore decided to also implement the tracking system for the solar trackers with the company’s industrial controllers.

The solution

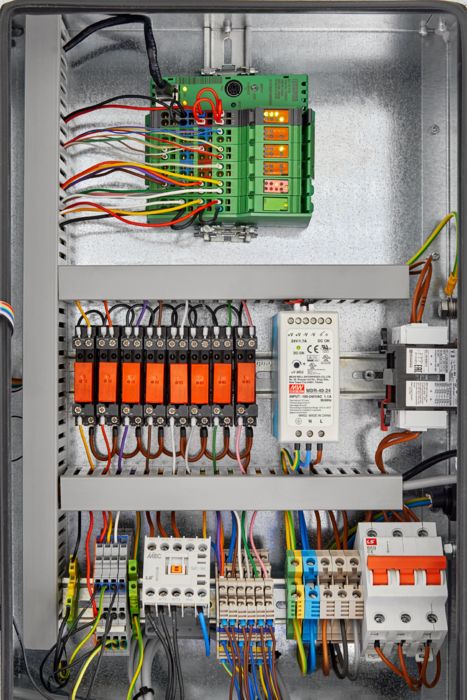

Elektro Ecker uses the ILC 131 ETH modular small-scale controller in the client control cabinet

Two inverters as well as the client control cabinet with the control technology needed for the tracking system are installed on each tracker. Elektro Ecker uses the ILC 131 ETH modular small-scale controller as the PLC, which allows the system to be automated easily. The ILC 131 ETH acts as a PROFINET device or Modbus/TCP client. It receives its commands from a higher-level server controller. This controller is an AXC 1050 Axioline controller, and its control cabinet is located centrally on the site. The controller is characterized by its robust design featuring a built-in uninterruptible power supply for controlled shutdown of the application as well as an electromagnetically compatible housing. Along with the high transmission speed, a USB port provides quick access for diagnostic purposes, for example.

With the comprehensive Solarworx library with function blocks to calculate the sun’s position and the tracking system for the photovoltaic trackers, Josef Ecker and his team were able to quickly program the photovoltaic application. The library, which also includes other drivers for data loggers and interfaces for inverters, is constantly being expanded. Since the preprogrammed function blocks are thoroughly tested, they not only ensure faster project implementation, but also reliable system operation. The server controller measures the current wind speed via a wind sensor. If the wind loads are too high, then the AXC 1050 issues the command to the subordinate client controllers to move the trackers out of the wind.

A transformer station is situated next to the control cabinet containing the server controller. Here, the alternating voltages are transformed from the low-voltage to the medium-voltage level. The generated solar power is fed into the grid at the grid connection point, which is located outside the tracking park. Elektro Ecker has installed a feed-in controller from Phoenix Contact to ensure that the local power grid is not overloaded. If the photovoltaic trackers produce too much electricity, the power generation plant controller ensures that the individual inverters are shut down. To do this, it forwards the necessary signals to the client controllers via the server controller.

Contact person

Tracking the trackers optimizes the yield at the Falkenberg solar park

Summary

As the builder and operator of the tracking park, Josef Ecker was impressed by Phoenix Contact‘s solution for the tracking system. It works reliably and does not need to be “paid for twice”. Therefore, the photovoltaic specialist can envision adding an energy storage facility to the park in the near future. Then the photovoltaic system won’t need to be held back any longer. Instead, the excess current would be stored short-term and then fed into the grid later when it is not overloaded.

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.