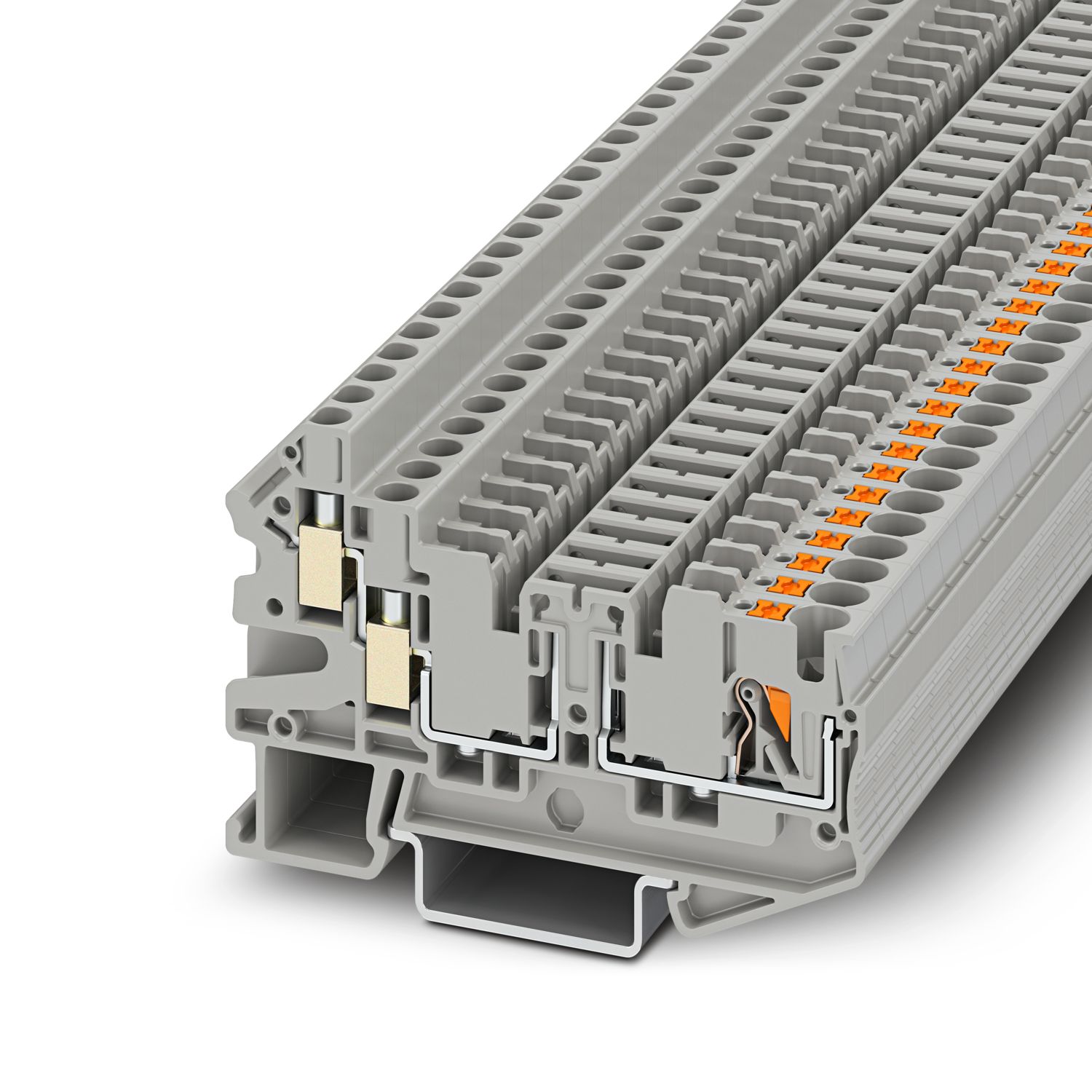

PTU 4-TWIN-TG-P

-

Disconnect terminal block

1157686

Disconnect terminal block, with test socket screws to accommodate 4 mm test plugs, nom. voltage: 500 V, nominal current: 20 A, connection method: Push-in connection, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 6 mm2, connection method: Screw connection, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 6 mm2, mounting: NS 35/7,5, NS 35/15, color: gray

Product details

| General | |

| Note | When establishing a connection on the open housing side of a feed-through modular terminal block of the same series and size, the block must be provided with a cover if the expected insulation voltage is >320 V. |

| The max. load current must not be exceeded by the total current of all connected conductors. | |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Number of connections per level | 2 |

| Nominal cross section | 4 mm² |

| Push-in connection | |

| Connection method | Push-in connection |

| Stripping length | 10 mm ... 12 mm |

| Internal cylindrical gage | A4 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.2 mm² ... 6 mm² |

| Cross section AWG | 24 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.2 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] | 24 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.25 mm² ... 4 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.25 mm² ... 4 mm² |

| Conductor cross-section flexible (2 conductors with the same cross-section, with TWIN ferrule and plastic sleeve) | 0.5 mm² ... 1 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1 mm² |

| Nominal current | 20 A |

| Maximum load current | 20 A |

| Nominal voltage | 500 V |

| Nominal cross section | 4 mm² |

| Screw connection | |

| Connection method | Screw connection |

| Screw thread | M3,5 |

| Tightening torque | 1 ... 1.2 Nm |

| Stripping length | 9 mm ... 12 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.2 mm² ... 6 mm² |

| Cross section AWG | 24 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.2 mm² ... 6 mm² |

| Conductor cross-section, flexible [AWG] | 24 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.25 mm² ... 4 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.25 mm² ... 4 mm² |

| Conductor cross-section flexible (2 conductors with the same cross-section, with TWIN ferrule and plastic sleeve) | 0.5 mm² ... 1 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.2 mm² ... 1.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1 mm² |

| Nominal current | 20 A |

| Maximum load current | 20 A |

| Nominal voltage | 500 V |

| Nominal cross section | 4 mm² |

| Push-in connection Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 0.5 mm² ... 6 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 4 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 4 mm² |

| Width | 6.2 mm |

| End cover width | 2.2 mm |

| Color | gray |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | Yes |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.2 mm² / 0.2 kg |

| 4 mm² / 0.9 kg | |

| 6 mm² / 1.4 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Pulse shape | Semi-sinusoidal |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/15 |

| Item number | 1157686 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Sales key | BE2231 |

| Product key | BE2231 |

| GTIN | 4063151162726 |

| Weight per piece (including packing) | 22.222 g |

| Weight per piece (excluding packing) | 22.222 g |

| Customs tariff number | 85369010 |

| Country of origin | Country of origin will be provided upon delivery. |

ETIM

| ETIM 8.0 | EC000902 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes |

| Exemption | 6(c) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | Lead (CAS: 7439-92-1) |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

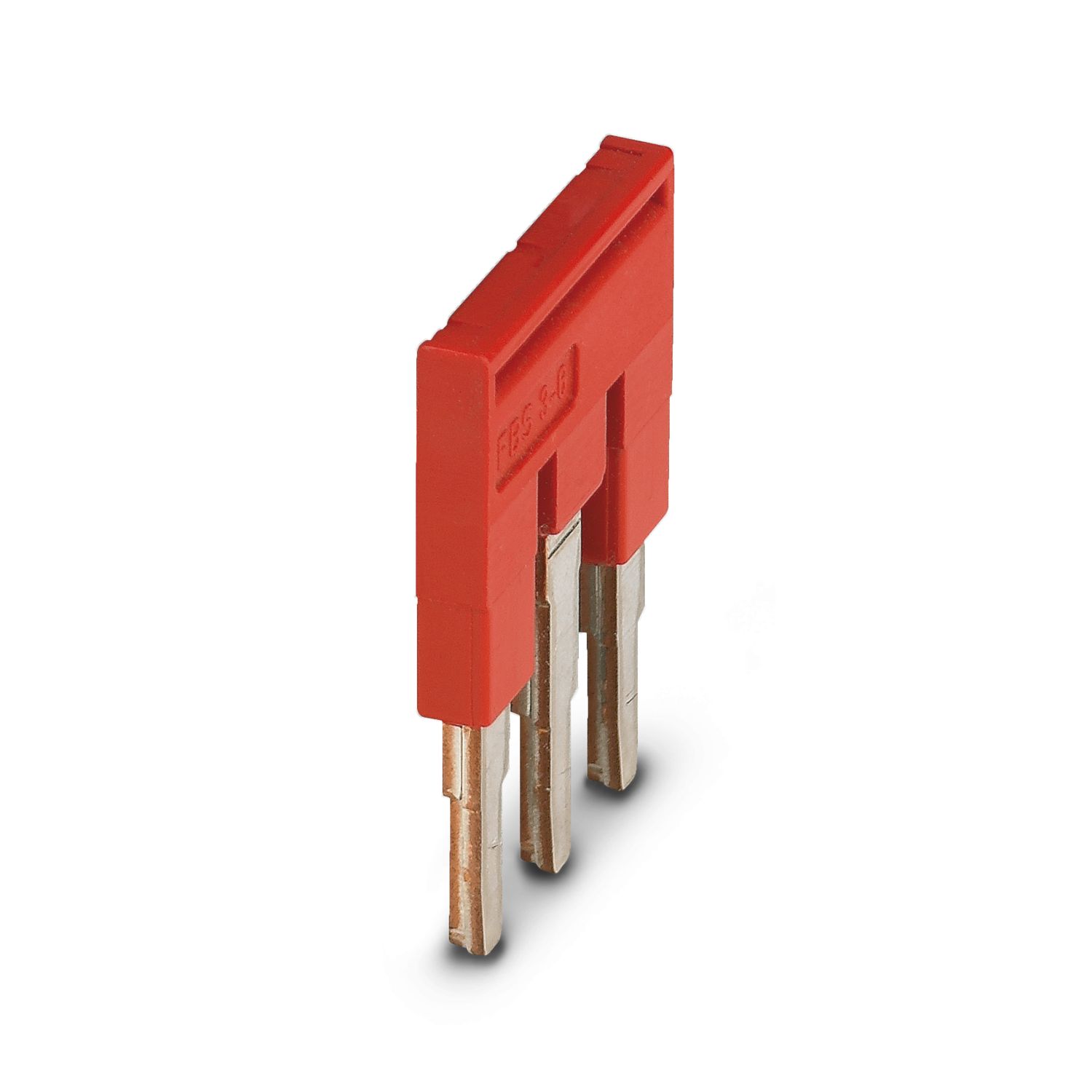

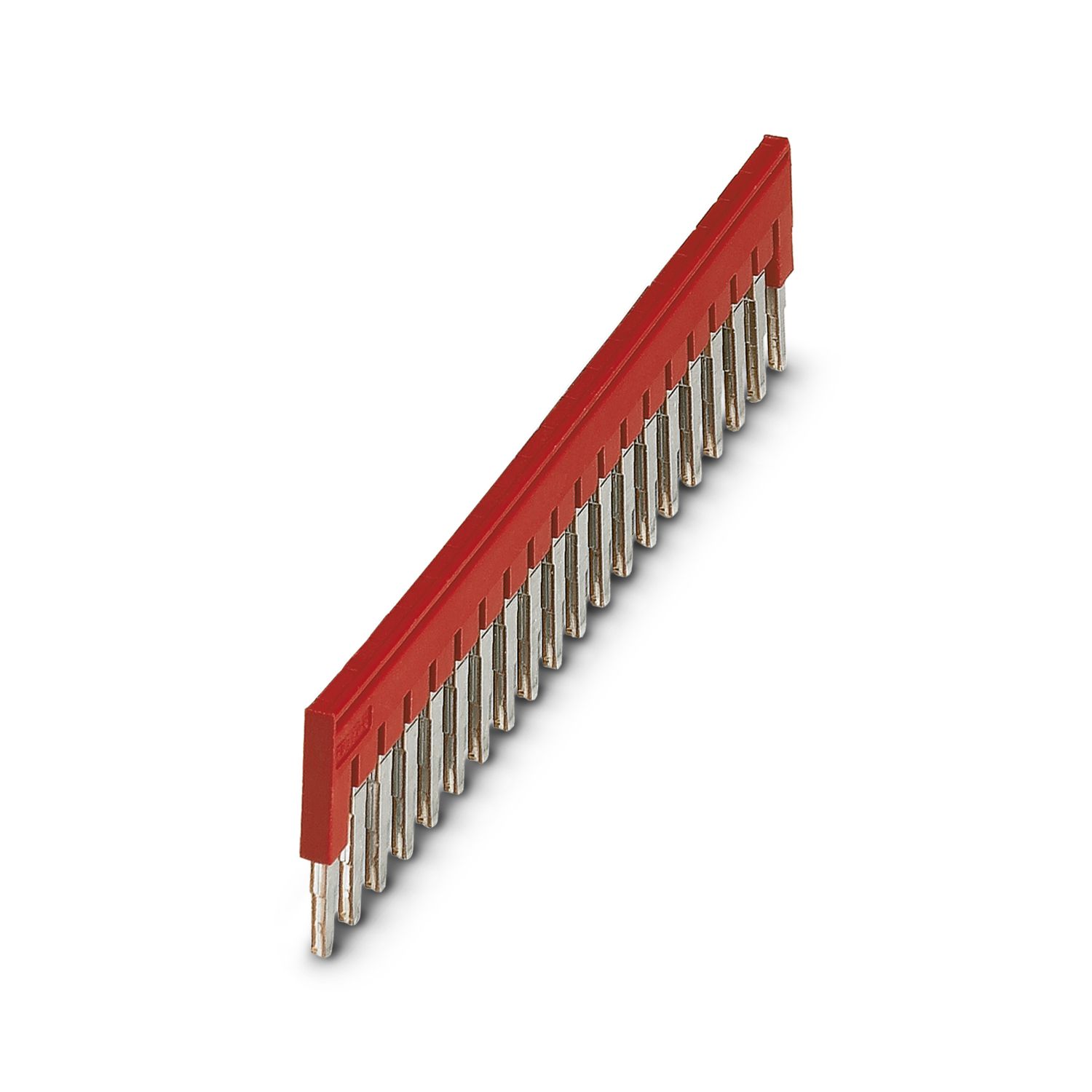

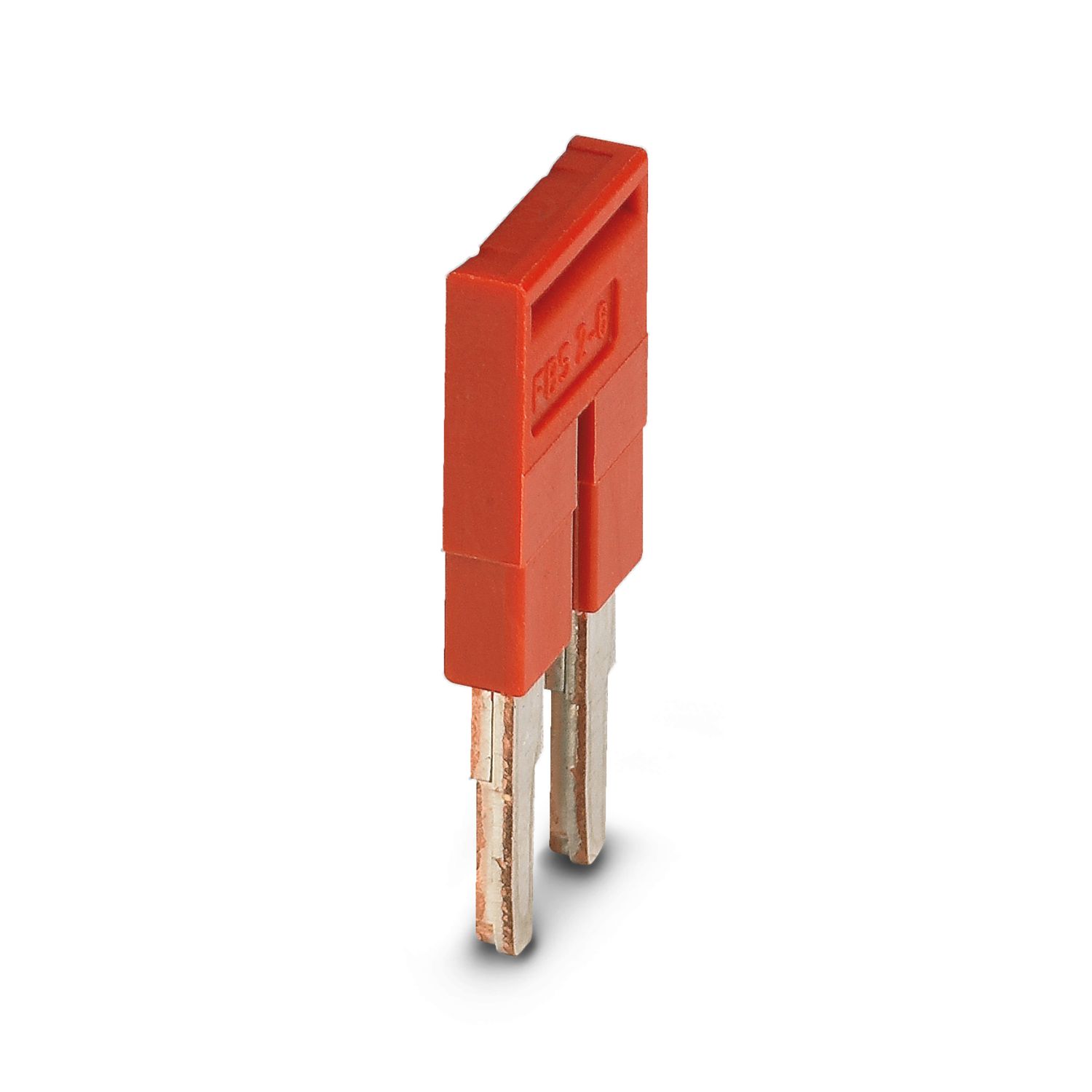

FBS 3-6 - Plug-in bridge 3030242

-

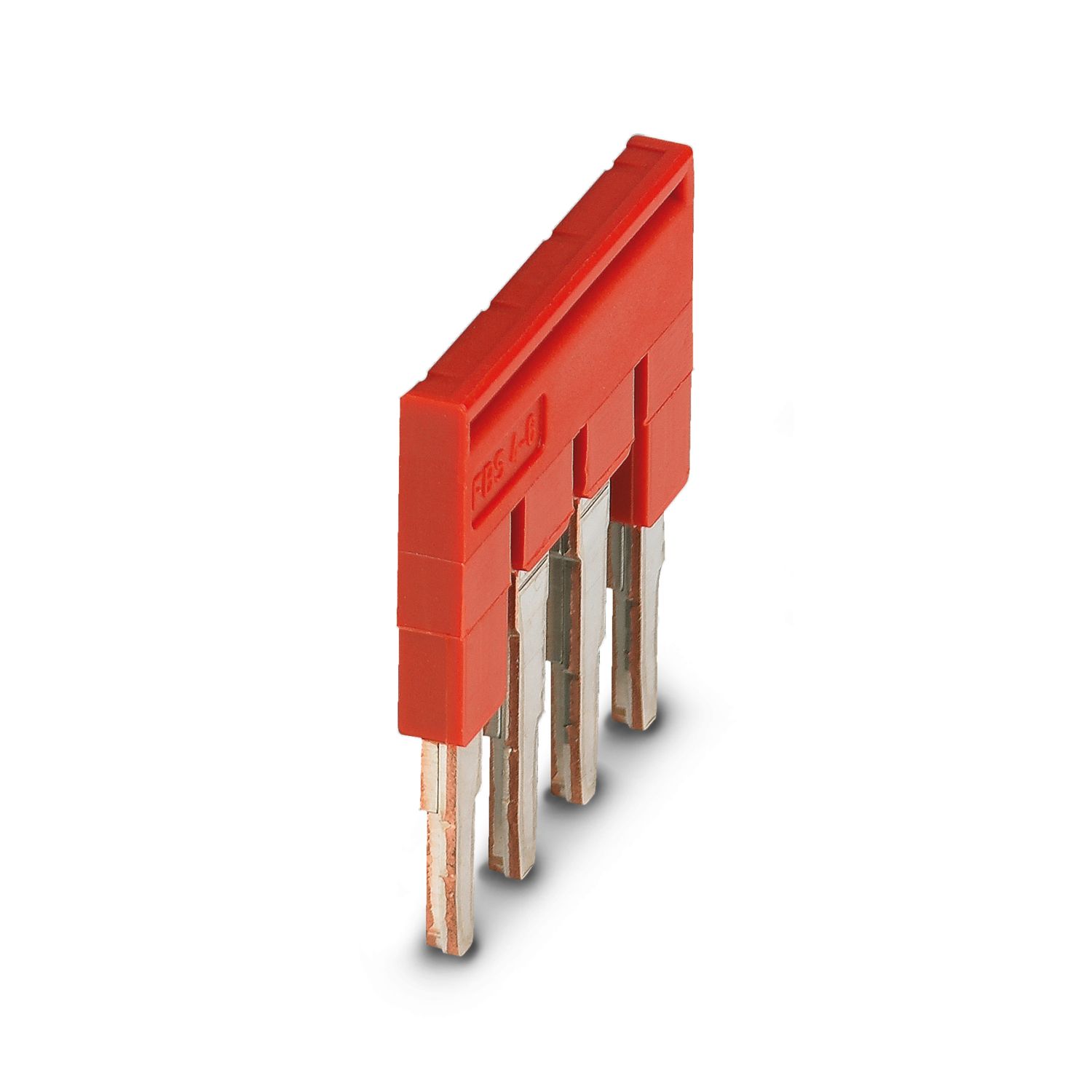

FBS 4-6 - Plug-in bridge 3030255

-

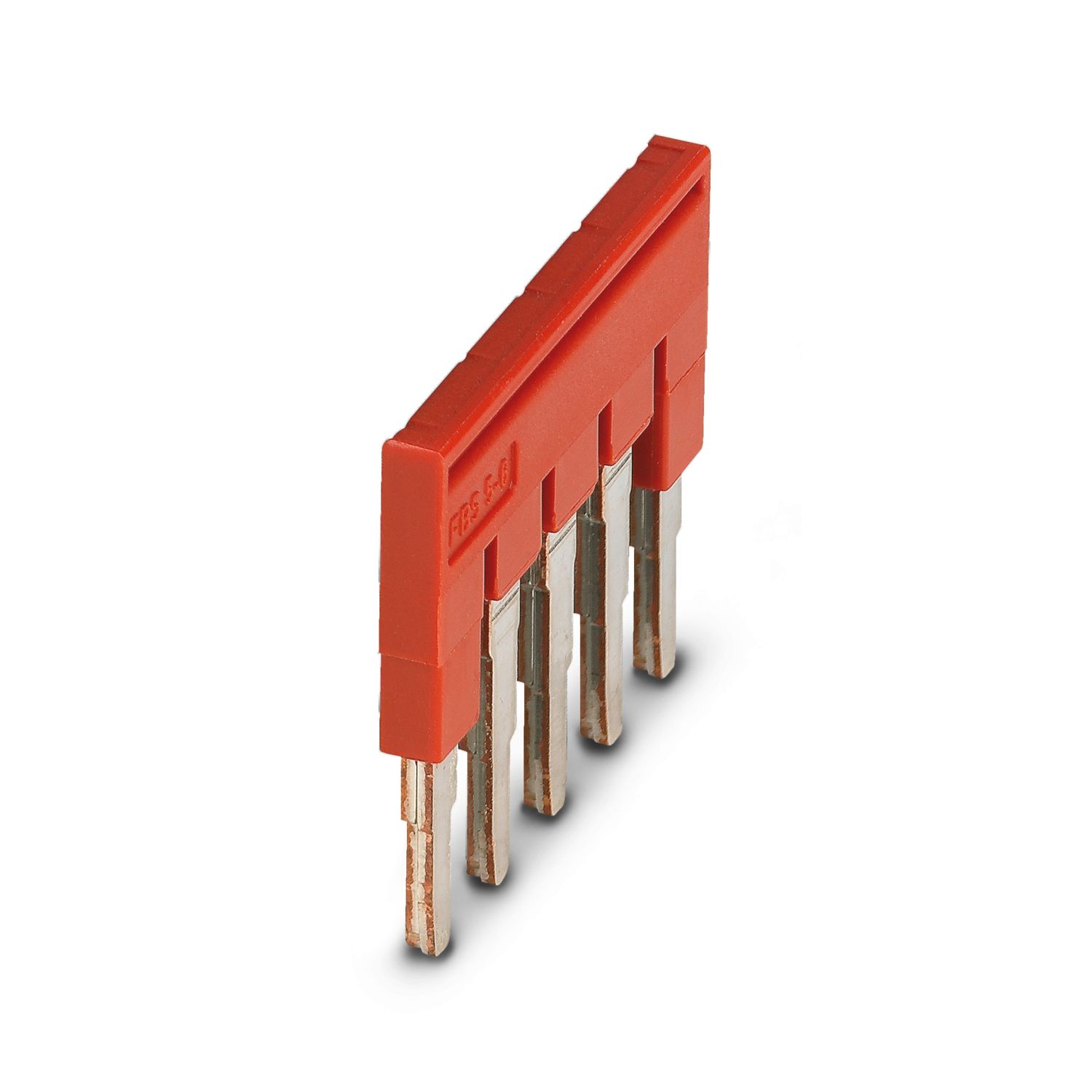

FBS 5-6 - Plug-in bridge 3030349

-

FBS 6-6 - Plug-in bridge 1008238

-

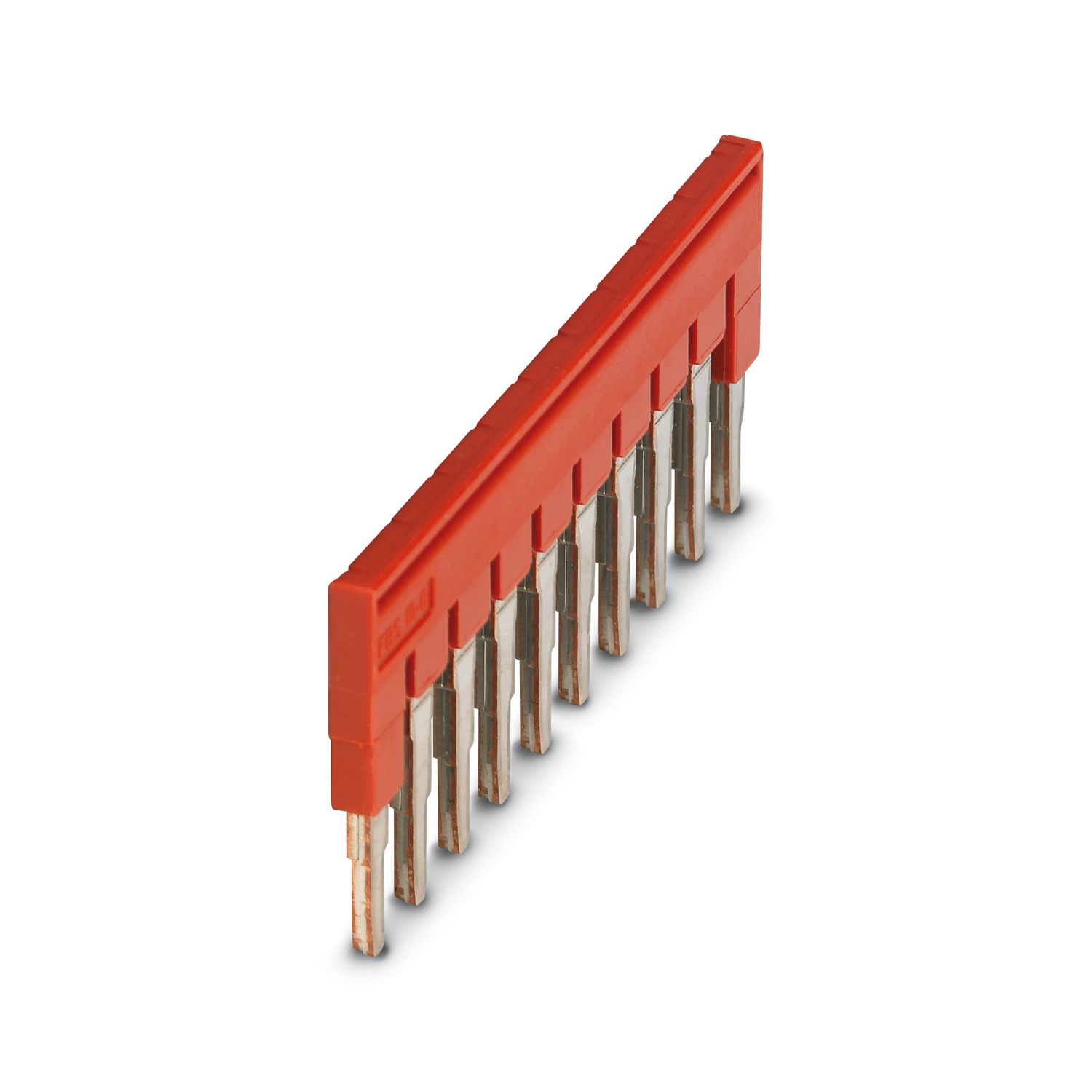

FBS 10-6 - Plug-in bridge 3030271

-

FBS 20-6 - Plug-in bridge 3030365

-

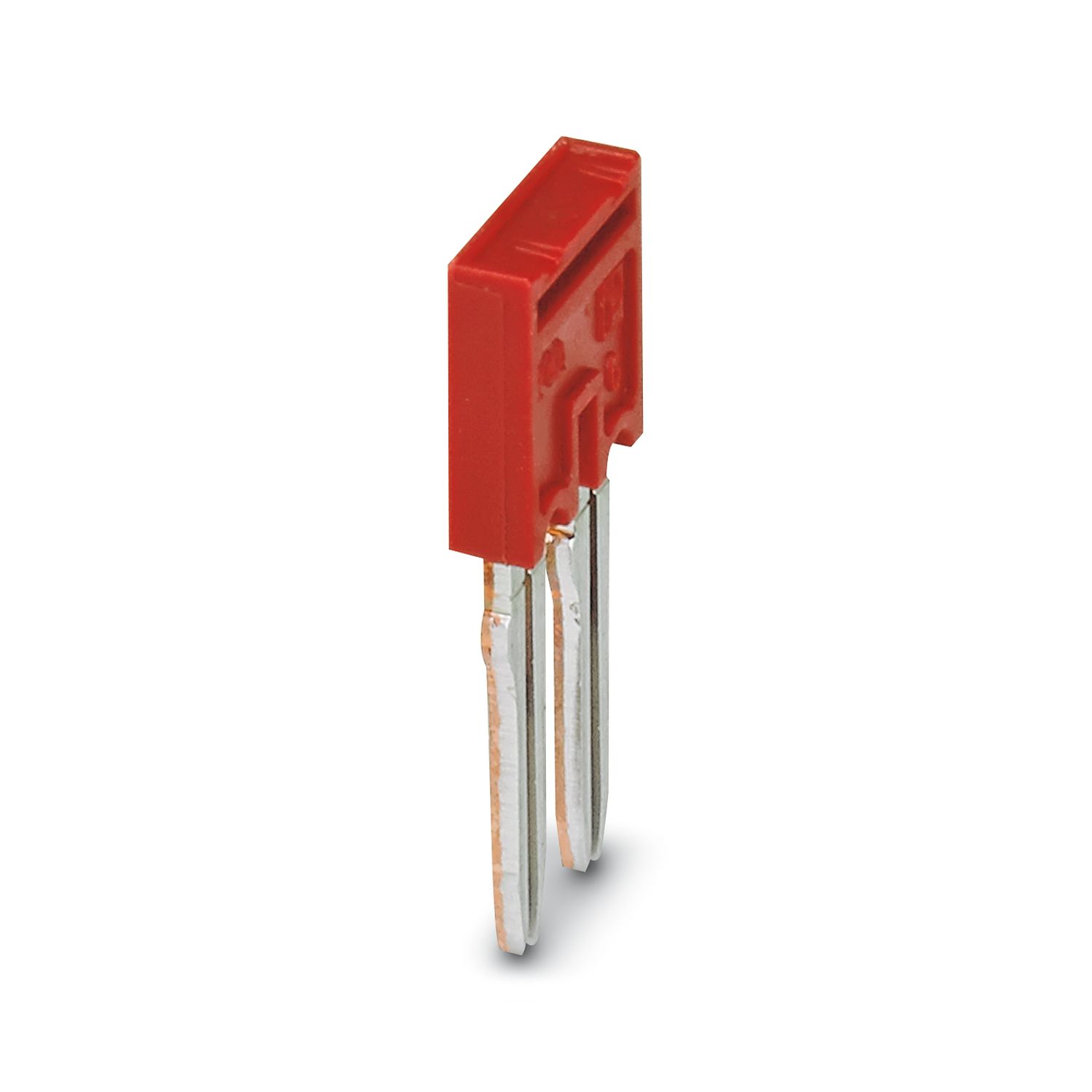

FBSR 2-6 - Plug-in bridge 3033715

-

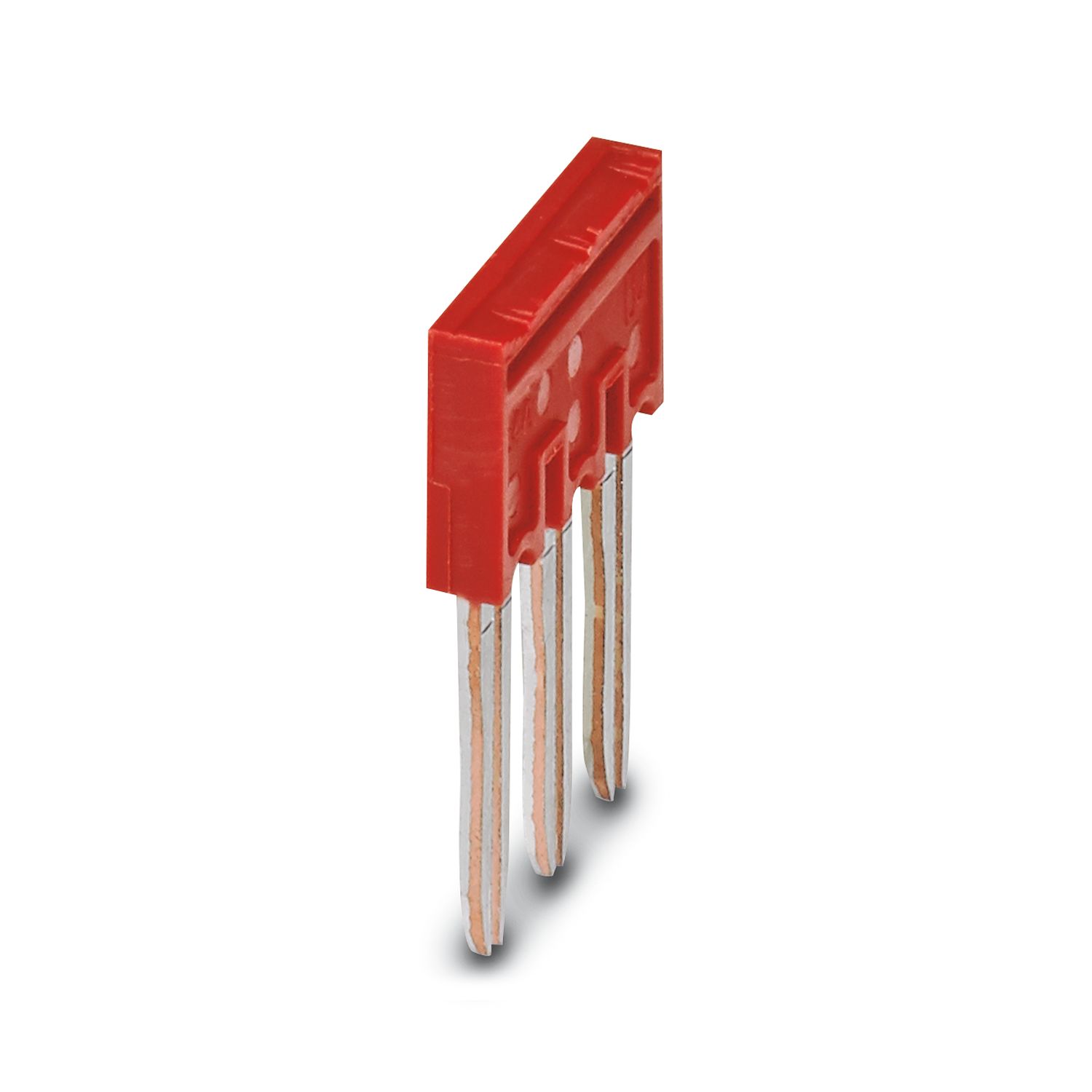

FBSR 3-6 - Plug-in bridge 3001594

-

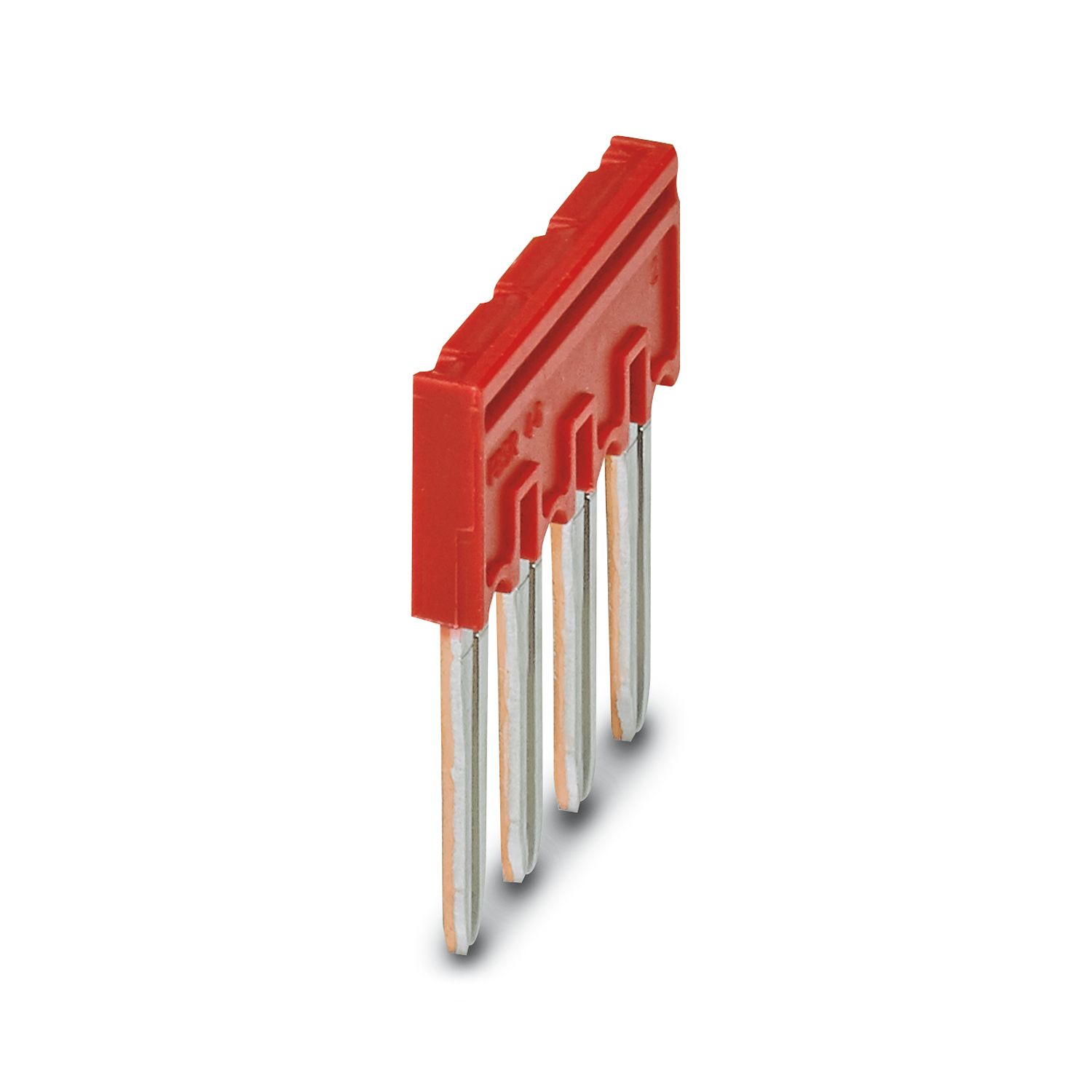

FBSR 4-6 - Plug-in bridge 3001595

-

FBSR 5-6 - Plug-in bridge 3001596

-

FBSR 10-6 - Plug-in bridge 3033716

-

FBSRH 2-6 - Short-circuit connector 3033812

-

FBS 2-6 BU - Plug-in bridge 3036932

-

FBS 3-6 BU - Plug-in bridge 3036945

-

FBS 4-6 BU - Plug-in bridge 3036958

-

FBS 5-6 BU - Plug-in bridge 3036961

-

FBS 10-6 BU - Plug-in bridge 3032198

-

FBS 20-6 BU - Plug-in bridge 3032208

-

FBS 50-6 BU - Plug-in bridge 3032211

-

RB ST 6-(2,5/4) - Reducing bridge 3030860

-

RB ST 10-(2,5/4) - Reducing bridge 3030873

-

RB ST 16-(2,5/4) - Reducing bridge 3030886

-

RB ST 35-(2,5/4) - Reducing bridge 3030899

-

RB ST (2,5/4)-1,5 - Reducing bridge 3038943

-

RB UT 6-ST(2,5/4) - Reducing bridge 3047264

-

RB UT 35-ST(2,5/4) - Reducing bridge 3047280

-

RB UT 10-ST(2,5/4) - Reducing bridge 3047086

-

RB UT 16-ST(2,5/4) - Reducing bridge 3047099

-

D-PTU 4-TWIN-MT - End cover 1157700

-

SZF 1-0,6X3,5 - Screwdriver 1204517

-

GBS 5-25X12 - Group marker label for terminal marking 0810588

-

GBS-ZB/26X6 - Group marker label for terminal marking 0809298

-

CARRIER-TM 300 - Marker carriers 0828282

-

PT-IL - Mounting material 3208090

-

ST-BW - Actuation tool 1207608

-

P-DI - Isolating plug 3036783

-

P-DI GY - Isolating plug 3047390

-

P-DI GN - Isolating plug 1071062

-

TPS 3/20/5 - Test plug strip 3246586

-

PSBJ 6-T GY - Test plug strip 3070316

-

PSBJ 6-T BN - Test plug strip 3070317

-

PSBJ 6-T BK - Test plug strip 3070318

-

PSBJ 6-T RD - Test plug strip 3070319

-

PSBJ 6-T OG - Test plug strip 3070320

-

PSBJ 6-T WH - Test plug strip 3070324

-

PSBJ 6-T YE - Test plug strip 3070326

-

PSBJ 6-T GN - Test plug strip 3070327

-

PSBJ 6-T VT - Test plug strip 3070328

-

PSBJ 6-T BU - Test plug strip 3070329

-

NS 35/ 7,5 PERF 2000MM - DIN rail perforated 0801733

-

NS 35/ 7,5 UNPERF 2000MM - DIN rail, unperforated 0801681

-

NS 35/ 7,5 WH PERF 2000MM - DIN rail perforated 1204119

-

NS 35/ 7,5 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204122

-

NS 35/ 7,5 AL UNPERF 2000MM - DIN rail, unperforated 0801704

-

NS 35/ 7,5 ZN PERF 2000MM - DIN rail perforated 1206421

-

NS 35/ 7,5 ZN UNPERF 2000MM - DIN rail, unperforated 1206434

-

NS 35/ 7,5 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 0801762

-

NS 35/ 7,5 CAP - End cap 1206560

-

NS 35/15 PERF 2000MM - DIN rail perforated 1201730

-

NS 35/15 UNPERF 2000MM - DIN rail, unperforated 1201714

-

NS 35/15 WH PERF 2000MM - DIN rail perforated 0806602

-

NS 35/15 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204135

-

NS 35/15 AL UNPERF 2000MM - DIN rail, unperforated 1201756

-

NS 35/15 ZN PERF 2000MM - DIN rail perforated 1206599

-

NS 35/15 ZN UNPERF 2000MM - DIN rail, unperforated 1206586

-

NS 35/15 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201895

-

NS 35/15 CAP - End cap 1206573

-

NS 35/15-2,3 UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201798

-

ZB 6:UNBEDRUCKT - Zack marker strip 1051003

-

ZB 6 CUS - Zack marker strip 0824992

-

ZB 6,LGS:L1-N,PE - Marker for terminal blocks 1051414

-

ZB 6,LGS:U-N - Marker for terminal blocks 1051430

-

UC-TM 6 - Marker for terminal blocks 0818085

-

UC-TM 6 CUS - Marker for terminal blocks 0824589

-

UCT-TM 6 - Marker for terminal blocks 0828736

-

UCT-TM 6 CUS - Marker for terminal blocks 0829602

-

ZBF 6:UNBEDRUCKT - Zack Marker strip, flat 0808710

-

ZBF 6 CUS - Zack Marker strip, flat 0825027

-

UC-TMF 6 - Marker for terminal blocks 0818140

-

UC-TMF 6 CUS - Marker for terminal blocks 0824646

-

UCT-TMF 6 - Marker for terminal blocks 0828746

-

UCT-TMF 6 CUS - Marker for terminal blocks 0829665

-

MPS-MT - Test plug 0201744

-

MPS-IH WH - Insulating sleeve 0201663

-

MPS-IH RD - Insulating sleeve 0201676

-

MPS-IH BU - Insulating sleeve 0201689

-

MPS-IH YE - Insulating sleeve 0201692

-

MPS-IH GN - Insulating sleeve 0201702

-

MPS-IH GY - Insulating sleeve 0201728

-

MPS-IH BK - Insulating sleeve 0201731

-

ISH 4/0,5 - Insulating sleeve 3002885

-

ISH 4/1,0 - Insulating sleeve 3002898

-

PAI-4-FIX-5/6 BU - Test adapter 3035975

-

PAI-4-FIX-5/6 OG - Test adapter 3035974

-

PAI-4-FIX-5/6 YE - Test adapter 3035977

-

PAI-4-FIX-5/6 RD - Test adapter 3035976

-

PAI-4-FIX-5/6 GN - Test adapter 3035978

-

PAI-4-FIX-5/6 BK - Test adapter 3035980

-

PAI-4-FIX-5/6 GY - Test adapter 3035982

-

PAI-4-FIX-5/6 VT - Test adapter 3035979

-

PAI-4-FIX-5/6 BN - Test adapter 3035981

-

PAI-4-FIX-5/6 WH - Test adapter 3035983

-

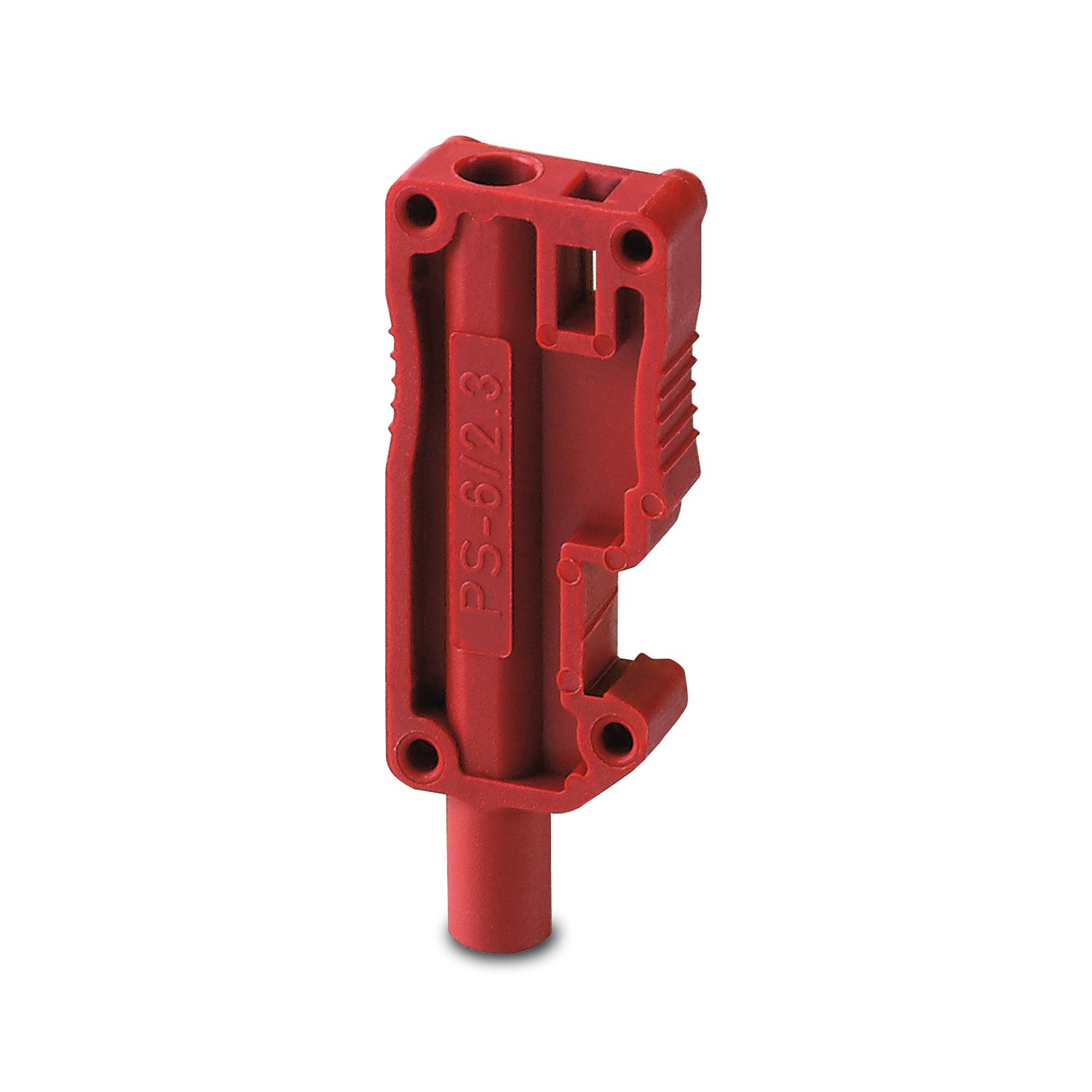

PS-6 - Test plug 3030996

-

PS-6/2,3MM RD - Test plug 3038736

-

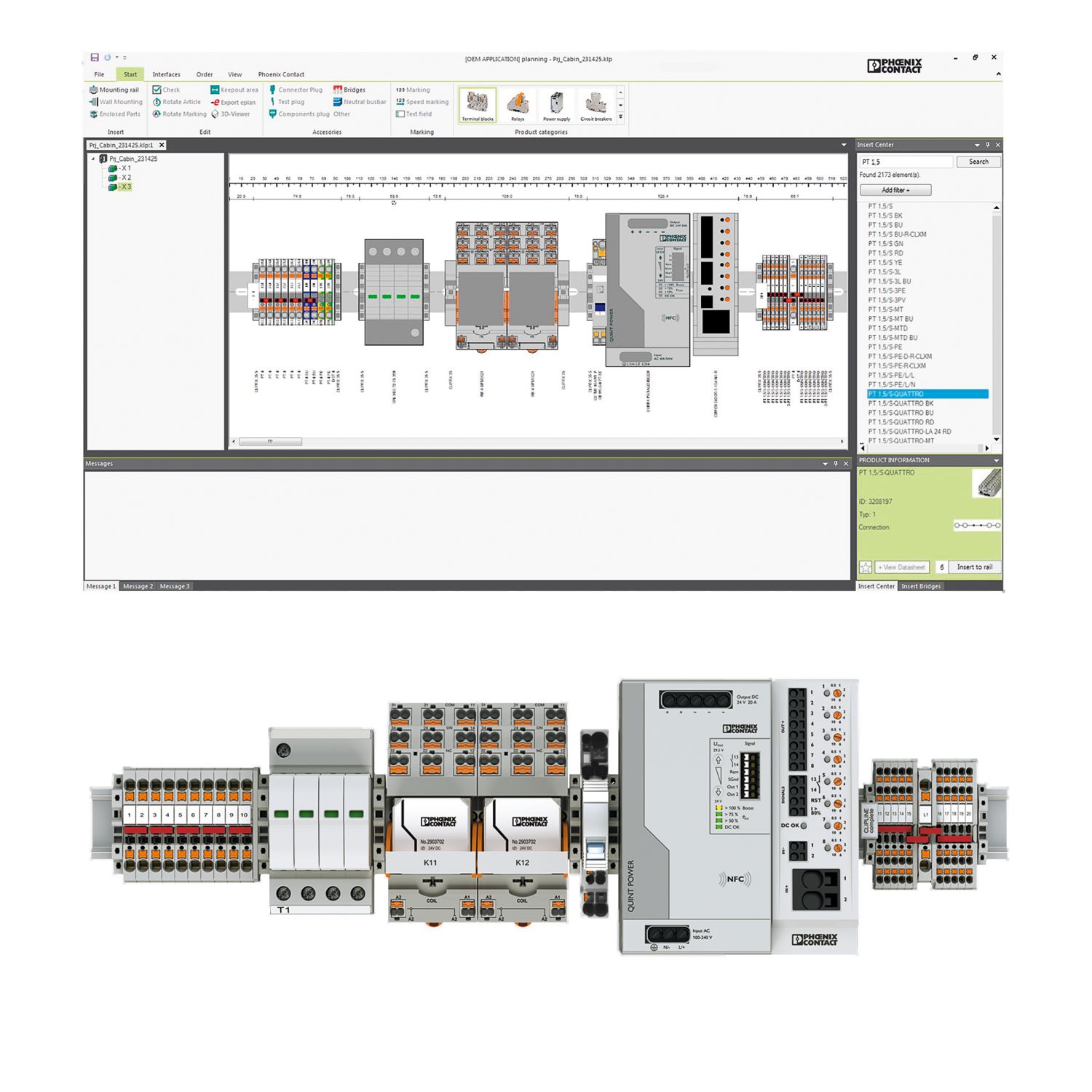

PROJECT COMPLETE - Software 1050453

-

TMT 6 R - Marker for terminal blocks 0816498

-

TMT 6 R CUS - Marker for terminal blocks 0824488

-

TMT (EX9,5)R - Marker for terminal blocks 0828295

-

US-TM 100 - Marker for terminal blocks 0829255

-

CLIPFIX 35 - End bracket 3022218

-

CLIPFIX 35-5 - End bracket 3022276

-

E/NS 35 N - End bracket 0800886

-

P-DI - Isolating plug 3036783

-

P-FIX - Feed-through connector 3038956

Your advantages

The compact design and front connection enable wiring in a confined space

The Push-in connection terminal blocks are characterized by the system features of the CLIPLINE complete system and by easy and tool-free wiring of conductors with ferrules or solid conductors

In addition to the testing option in the double function shaft, all terminal blocks provide an additional test pick-off

The push-in connection is used inside the control cabinet and the universal screw connection is used on the end customer side

PHOENIX CONTACT Ltd

Halesfield 13, Telford, Shropshire, TF7 4PG