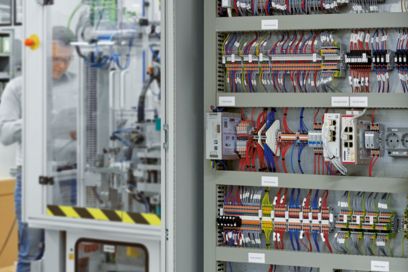

Control cabinet manufacturers are faced with particular challenges in terms of the cost-effectiveness of their processes. It is often very difficult or even impossible to influence external conditions, such as the delivery capability of suppliers, their pricing policies, and the shortage of skilled workers. This is different with in-house production. Here, significant increases in efficiency can often be achieved through process optimization, the use of end-to-end software and interface solutions, through to auxiliary and automatic tools, marking systems, and assistance solutions.