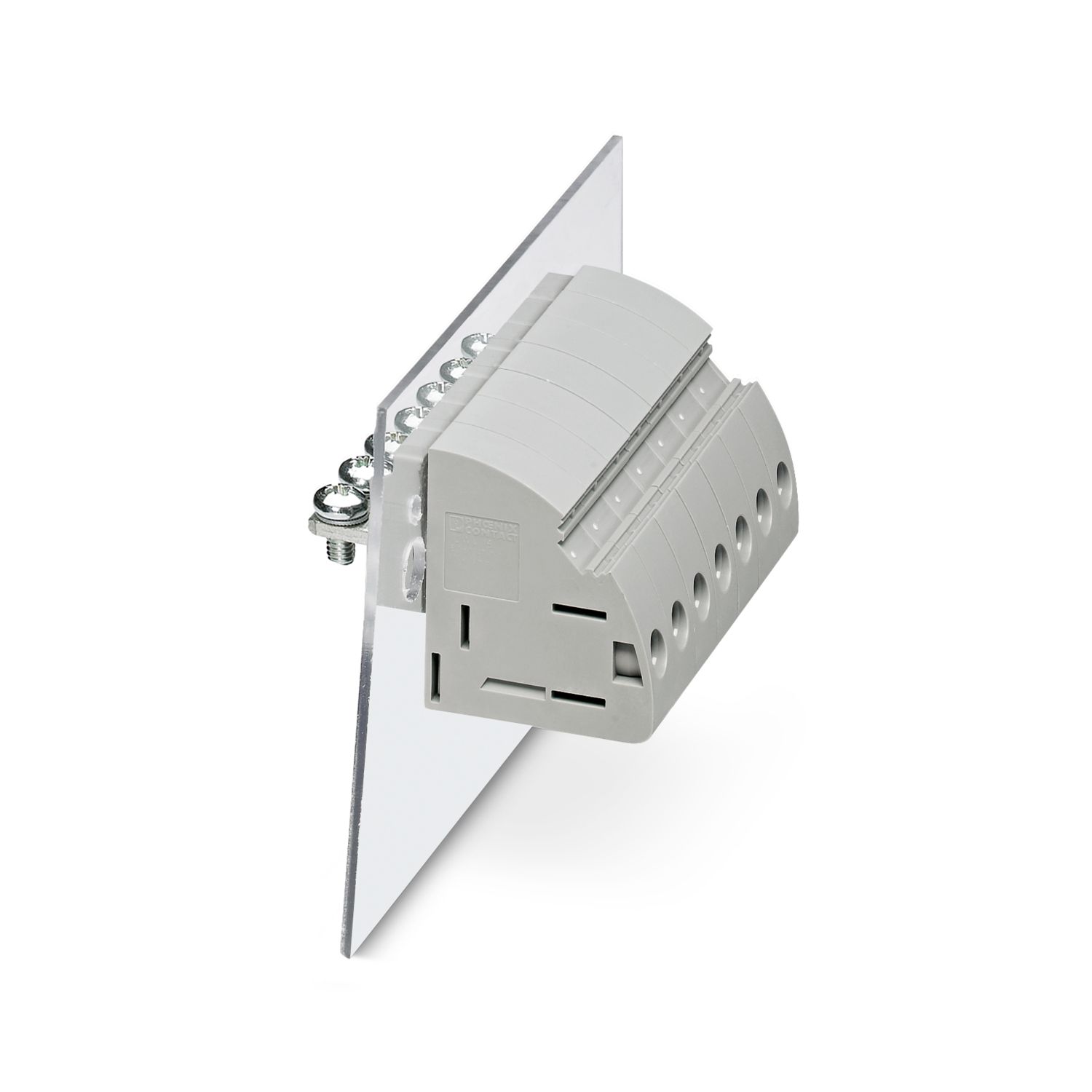

UWV 16/ 3-POT/S BK 2DP

-

Panel feed-through terminal block

1100661

Panel feed-through terminal block, connection method: Screw connection with tension sleeve, Cable lug connection, number of positions: 3, load current: 76 A, cross section: 6 mm2 - 25 mm2, connection direction of the conductor to plug-in direction: -90 °, width: 42 mm, color: black

Product details

| Product family | UWV 16-POT |

| Number of positions | 3 |

| Pitch | 12.1 mm |

| Number of connections | 6 |

| Number of potentials | 3 |

| Properties | |

| Nominal current IN | 76 A |

| Nominal voltage UN | 500 V |

| Rated voltage (III/3) | 500 V |

| Rated surge voltage (III/3) | 6 kV |

| Connection technology | |

| Connector system | UW 16 / PW 16 |

| Nominal cross section | 16 mm² |

| Conductor connection exterior | |

| Connection method | Screw connection with tension sleeve |

| Connection direction of the conductor to plug-in direction | -90 ° |

| Conductor cross-section rigid | 6 mm² ... 25 mm² |

| Conductor cross-section flexible | 6 mm² ... 16 mm² |

| Conductor cross-section, flexible, with ferrule, without plastic sleeve | 6 mm² ... 16 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 6 mm² ... 16 mm² |

| 2 conductors with same cross section, rigid | 2.5 mm² ... 10 mm² |

| 2 conductors with same cross section, flexible | 2.5 mm² ... 6 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 4 mm² ... 6 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 4 mm² ... 6 mm² |

| Internal cylindrical gage | B7 |

| Stripping length | 16 mm |

| Tightening torque | 2.5 Nm ... 3 Nm |

| Conductor connection interior | |

| Connection method | Cable lug connection |

| Connection direction of the conductor to plug-in direction | 0 ° |

| Panel thickness | 1 mm...6 mm |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | tin-plated |

| Material data - housing | |

| Color (Housing) | black (9005) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

| Safety note | |

| Safety note | • Only electrically qualified personnel may install and operate the product. To recognize and prevent danger, the qualified personnel must be familiar with the basics of electrical engineering. |

| • Observe the technical data provided here and refer to the documents listed under “Downloads”. The download area contains important information, such as installation notes, technical drawings, and 3D data. | |

| • The cable entry funnel is not safe to touch. Never connect or disconnect the terminal when it is energized. Take appropriate steps to ensure touch protection. | |

| • To maintain the nominal voltage, align the cable lugs straight and centered, and cast the terminals on the inside. | |

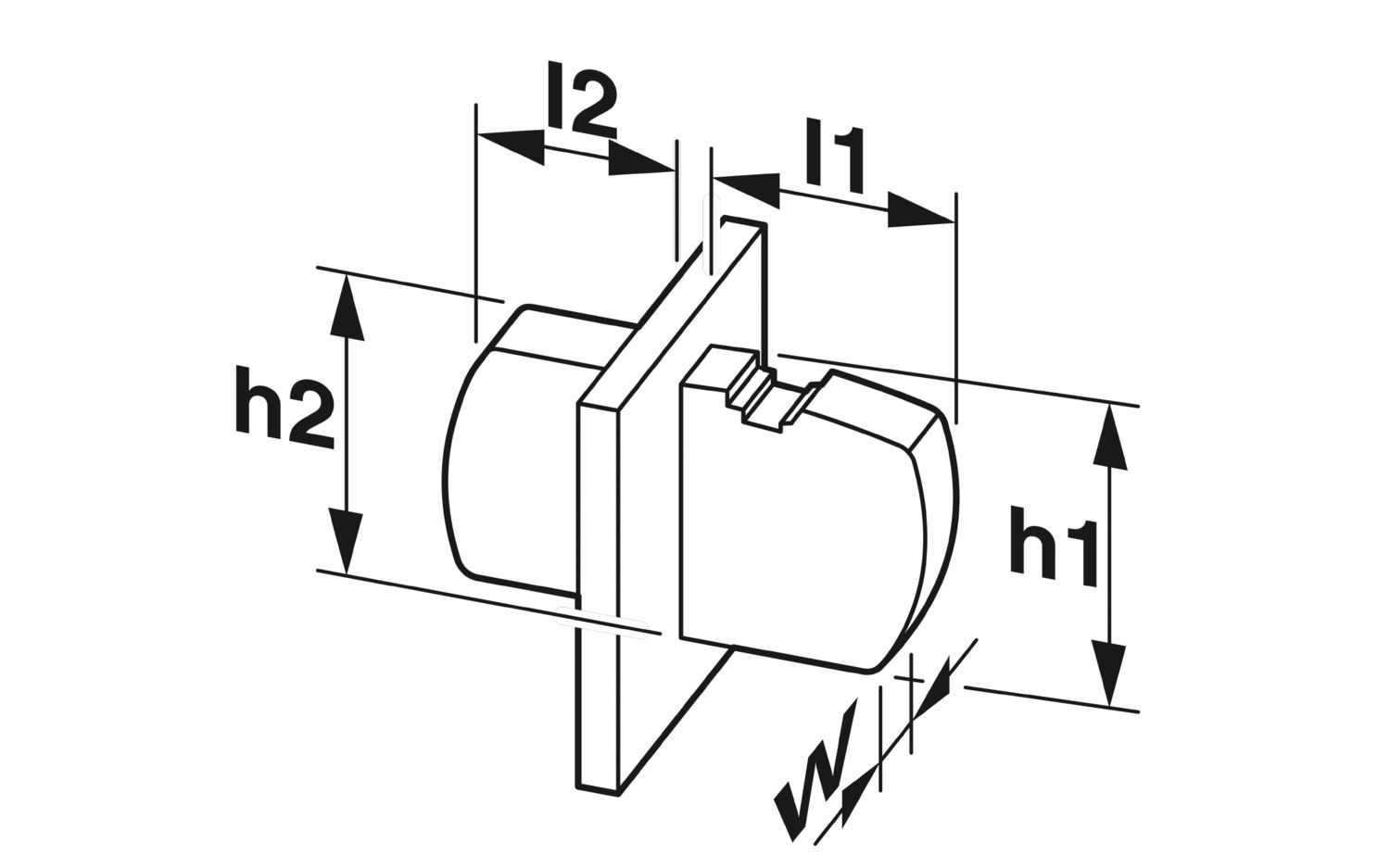

| Dimensional drawing |

|

| Pitch | 12.1 mm |

| 12.1 mm | |

| Width [w] | 42 mm |

| External dimensions | |

| Width [w] | 42 mm |

| Height [h1] | 43.2 mm |

| Length [l1] | 39.1 mm |

| Internal dimensions | |

| Width [w] | 42 mm |

| Height [h2] | 26 mm |

| Length [l2] | 23.65 mm |

| Test for conductor damage and slackening | |

| Specification | IEC 60947-7-1:2009-04 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60947-7-1:2009-04 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 6 mm² / solid / > 80 N |

| 6 mm² / flexible / > 80 N | |

| 25 mm² / stranded / > 135 N | |

| 16 mm² / flexible / > 100 N | |

| Temperature-rise test | |

| Specification | IEC 60947-7-1:2009-04 |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Short-time withstand current | |

| Specification | IEC 60947-7-1:2009-04 |

| Air clearances and creepage distances | 1. Insulation coordination | |

| Application | without spacer plate |

| Specification | IEC 60947-7-1:2009-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 500 V |

| Rated surge voltage (III/3) | 6 kV |

| minimum clearance value - non-homogenous field (III/3) | 5.5 mm |

| minimum creepage distance (III/3) | 6.3 mm |

| Air clearances and creepage distances | 2. Insulation coordination | |

| Application | with spacer plate |

| Specification | IEC 60947-7-1:2009-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 800 V |

| Rated surge voltage (III/3) | 8 kV |

| minimum clearance value - non-homogenous field (III/3) | 8 mm |

| minimum creepage distance (III/3) | 10 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Glow-wire test | |

| Specification | IEC 60695-2-11:2014-02 |

| Temperature | 960 °C |

| Time of exposure | 30 s |

| Shocks | |

| Specification | IEC 60068-2-27:2008-02 |

| Pulse shape | Semi-sinusoidal |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 105 °C (Depending on the current carrying capacity/derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Type of packaging | packed in cardboard |

| Item number | 1100661 |

| Packing unit | 25 pc |

| Minimum order quantity | 25 pc |

| Note | Made to order (non-returnable) |

| Product key | AA1DDD |

| GTIN | 4055626955162 |

| Weight per piece (including packing) | 90.896 g |

| Weight per piece (excluding packing) | 80 g |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27141134 |

| ECLASS-15.0 | 27141134 |

ETIM

| ETIM 10.0 | EC001283 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

Well-known connection principle allows worldwide use

Low temperature rise, thanks to maximum contact force

Tool-free snap-in principle enables easy mounting on the device panel

Automatic panel thickness compensation enables universal use

Reliable seal even with low-viscosity molding compounds

PHOENIX CONTACT

586 Fulling Mill Road, Middletown, PA 17057