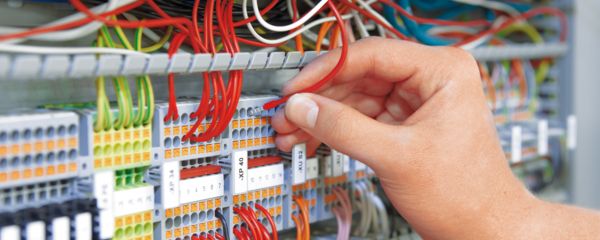

Reduce wiring time and prevent installation fatigue

Push-in connection technology from Phoenix Contact revolutionizes terminal block assembly. Easy handling reduces wiring time and the ergonomic design prevents fatigue at work – two important factors for daily operations. Push-in design technology requires 50 percent less insertion force on the leg spring block as compared to our competitor.

Easiest spring termination

Solid, stranded or ferruled wire can be used, requiring no specialized tools. Solid and ferruled wires can be simply pushed in the termination area. For stranded wires, open the termination area by pushing on the orange actuator with basic screwdriver. This leads to faster wiring time and simple direct termination. It also decreases error rates thanks to reducing operator strain during the installation and assembly process.

One system

Push-in terminal blocks form a fundamental component of Phoenix Contact’s CLIPLINE complete terminal block system. The same complete line of accessories used for our screw, spring-cage, insulation displacement and bolt connection series are used here; plug-in bridges, testing equipment and labeling. This reduces your cost of part storage significantly.

Push-in terminal blocks feature:

- Leg spring block design with 50 percent less push-in force than other similar products

- Faster terminations and reduced operator strain

- Ideal for vibration applications: pullout force five times the IEC requirement

- Shorter operating stroke creates 35 percent faster operation than spring based products

- Clear visual identification between termination area and touch-proof orange activation button

- Universal jumpers create various bridging options and multiple marking options with top dual channel