Norms and standards for industrial identification Secure and durable identifications – Depending on the area of application, marking materials and their markings are exposed to various environmental influences and mechanical effects. To ensure clear and durable identification, the materials and marking must be particularly resilient. Phoenix Contact strictly uses tested materials to meet the requirements set by various standards in every respect.

Testing the UV light resistance of plastics

Weathering and radiation in accordance with DIN EN ISO 4892-2

UV B components restrict mechanical properties in plastics. As a consequence, markings can be damaged to a greater or lesser extent depending on the type of plastic. To simulate several years of use outdoors, the marking materials are exposed to cyclical stresses through UV radiation and humidity. In this way, artificial weathering can be created, which provides an insight into the mechanical properties and the appearance of a material. Marking materials from Phoenix Contact can be stored in dry as well as humid atmospheres under UV radiation and are tested in accordance with standard DIN EN ISO 4892-2.

Testing chemical resistance

Resistance to oil and chemicals in accordance with DIN EN ISO 175

Liquid oils and chemicals can trigger physical or chemical reactions that have a negative impact on the base material. Both the mechanical properties of a plastic and the durability of the marking can be affected. To avoid this, Phoenix Contact only uses plastics and marking materials that have been tested in accordance with DIN EN ISO 175.

Abrasion and wipe resistance testing

Wipe resistance in accordance with DIN EN ISO 61010-1 and DIN EN 62208

Strong cleaning agents are used in industrial environments, e.g., in the food industry. Therefore, marking must be very durable, depending on the area of application. To ensure the wipe resistance of markings, the markings undergo a test with isopropanol, n-hexane, and petroleum ether. A cloth is soaked in the respective chemical and wiped over the marking material with a defined force for 30 s. After the test, the marking must still be clearly legible. Phoenix Contact marking materials satisfy the stringent requirements for abrasion and wipe resistance and can be used in all applications.

Testing corrosion resistance with the help of a climate cabinet

Corrosion test in accordance with DIN 50018

Corrosion is the reaction of a material with its environment that causes the material to change or deteriorate. This includes rust damage, for example, which can cause marking materials to become illegible or lost. To test the resistance of the materials against corrosion damage, they are exposed to a condensation changing climate with an atmosphere containing sulfur dioxide at +40°C for eight hours. An acidic atmosphere forms during the test. Finally, a microscopic visual inspection of the materials is performed. All marking materials used by Phoenix Contact conform to the standard and are resistant to aggressive substances.

Testing resistance to corrosive atmospheres containing salt

Salt spray in accordance with IEC 60068-2-11/-52

Particularly in shipbuilding and in offshore applications, the markings must withstand corrosive atmospheres containing salt. To ensure this can be achieved, the resistance of the materials is tested through salt spray in a corrosive atmosphere. The materials are placed in a test chamber and subjected to a finely dosed spray of five percent sodium chloride solution, at a temperature of +35°C for a period of 96 hours. A visual inspection is performed after the test. Phoenix Contact marking materials satisfy these stringent requirements and can be used even in extreme climatic conditions.

Testing scratch resistance

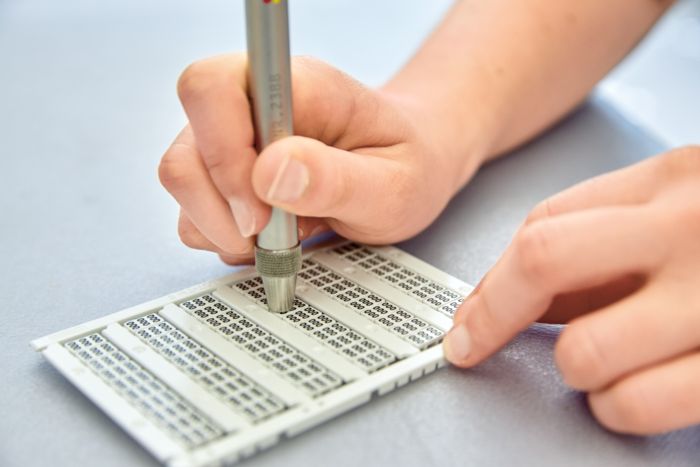

Scratch resistance in accordance with DIN EN ISO 1518

Depending on the area of application, marking materials are subject to mechanical effects. Using an Erichsen hardness test pencil, the scratch resistance of markings is tested by exposing them to intermittent or linear stress. A defined force is applied to an engraving needle via spring tension. This is followed by a visual and microscopic inspection of the test object. The spring tension under which the Erichsen hardness test pencil leaves a barely visible trace is the deciding factor. Phoenix Contact marking materials satisfy these high mechanical requirements.

Grid test with adhesive film test

Grid test in accordance with DIN EN ISO 2409

The adhesive film test is used to test the adhesion of printing. A transparent self-adhesive tape with an adhesive strength of 10 ±1 N is applied to the marking to be tested. It is then removed from the surface at an angle of 60° to the pull-off direction at a speed of approx. 1 cm/s. There should be no marks from the printing on the adhesive tape after the test. Phoenix Contact marking materials conform to this standard. They are tough and resistant to peeling.

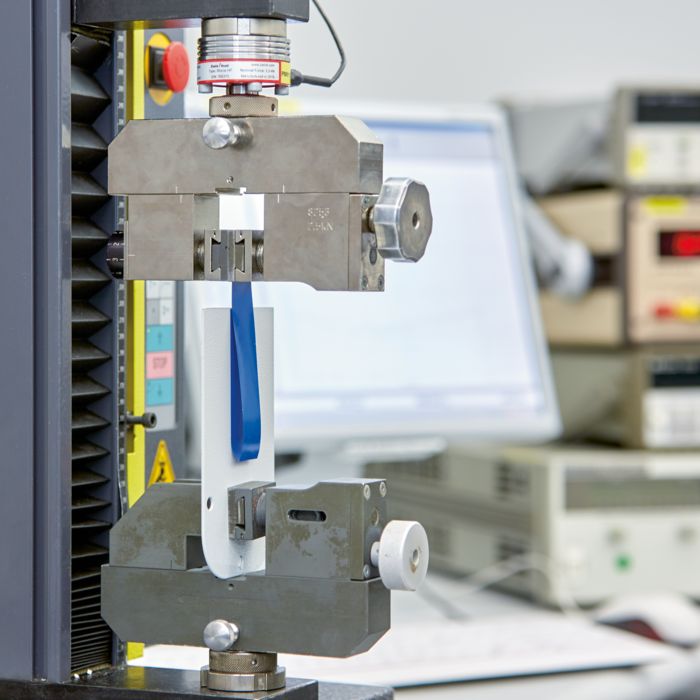

Adhesive strength test with FINAT test method 9

Adhesive strength test in accordance with FINAT test method 1, 2, and 9

The purpose of the FINAT test is to compare the adhesive strength of labels on various base materials. To determine the adhesive strength of a label, a strip of labels (25 mm x 175 mm) is applied to a base material with a defined force. The test sample is then removed after a wait time of 20 min and 24 h, at a predefined angle, at 300 mm/min. The adhesive strength is specified in N/25 mm. The tests enable the most suitable label to be selected for the application.

- FINAT 1: angle of 180° and at a speed of 300 mm/min

- FINAT 2: angle of 90° and at a speed of 300 mm/min

- FINAT 9: this test method tests the initial adhesion (loop tack) of a label. The force with which a material loop is separated from a standard test surface at a specified speed is measured.

Testing the requirements for IP degrees of protection

Degrees of protection in accordance with DIN EN 60529/ISO 20653

Differing ambient conditions and requirements necessitate a clear classification of markings in IP degrees of protection. These are indicated by a code consisting of two numbers following the IP abbreviation. The first number describes the scope of protection against the ingress of foreign bodies, and the second the tightness of seal against moisture. The marking material is tested with the help of water jets.

Testing vibration resistance

Vibration test in accordance with DIN EN 50155

In many applications and especially in transportation technology, marking materials are subjected to vibrations and shocks. To simulate vibration stress that occurs in practice (e.g., in the railway industry), the marking materials are exposed to increasing and decreasing frequencies and amplitudes. They are tested in the three axes (x, y, z) for five hours each, and must not be damaged and their secure positioning must not have been impacted. All Phoenix Contact marking materials satisfy these stringent vibration requirements.