EML-EX (100X40)R

-

Label

0803258

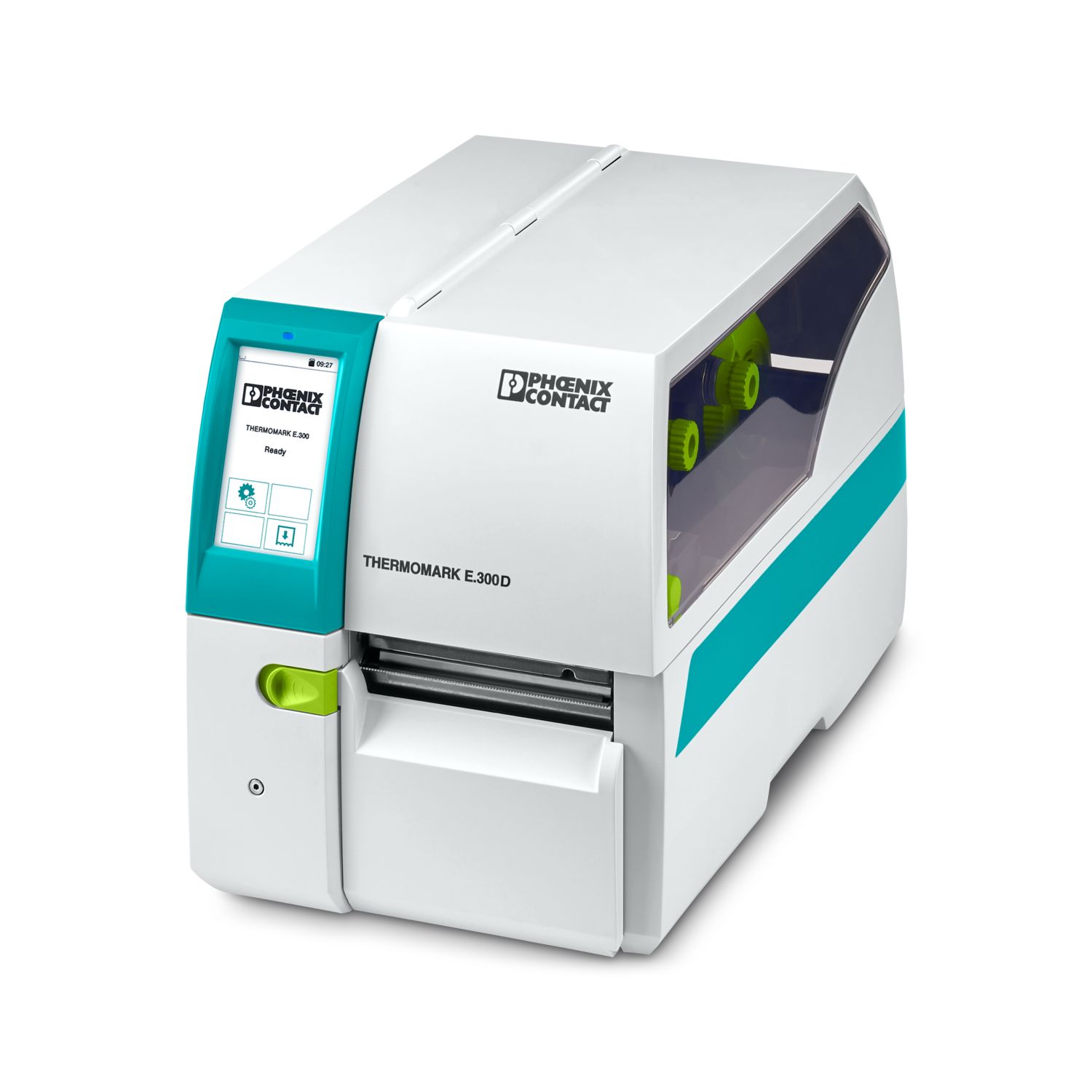

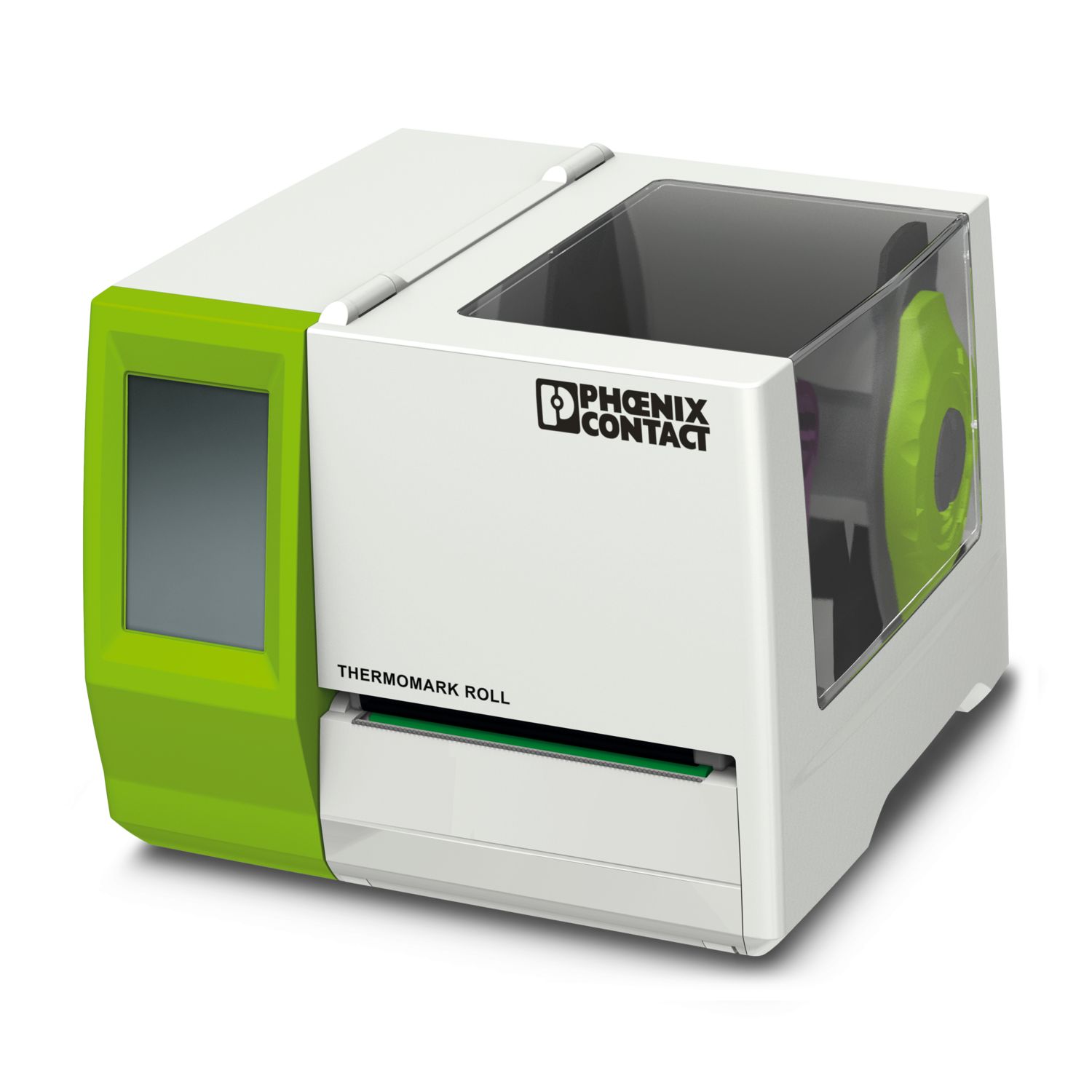

Label, Roll, white, unmarked, can be labeled with: THERMOMARK E.300 (D)/600 (D), THERMOMARK ROLL 2.0, THERMOMARK ROLL, THERMOMARK ROLL X1, THERMOMARK ROLLMASTER 300/600, THERMOMARK X1.2, mounting type: adhesive, Number of individual labels: 300, text field height: 40 mm, text field width: 100 mm

Product details

Compatible products

Your advantages

The EML...-EX self-adhesive device markers are designed for the identification of various types of equipment in areas where extreme resistance to chemicals is required

The marking meets the requirements regarding legibility, adhesion, and wipe resistance as stipulated in industries such as the process industry and process engineering due to the presence of extreme chemicals

These labels meet the requirements for wipe resistance in accordance with DIN EN 61010-1 against aggressive media such as acetone, ethanol, and MEK

Thanks to the special surface and adhesive, the marker meets the demanding requirements of process engineering

When high-quality ink ribbons are used, the marking is resistant to solvents and suitable for use even under harsh industrial conditions.

Precise printing quality and good adhesive properties