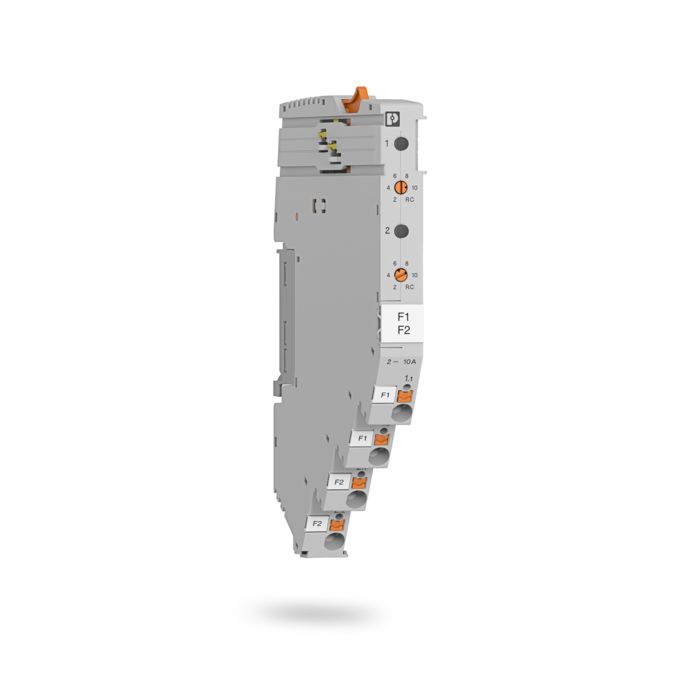

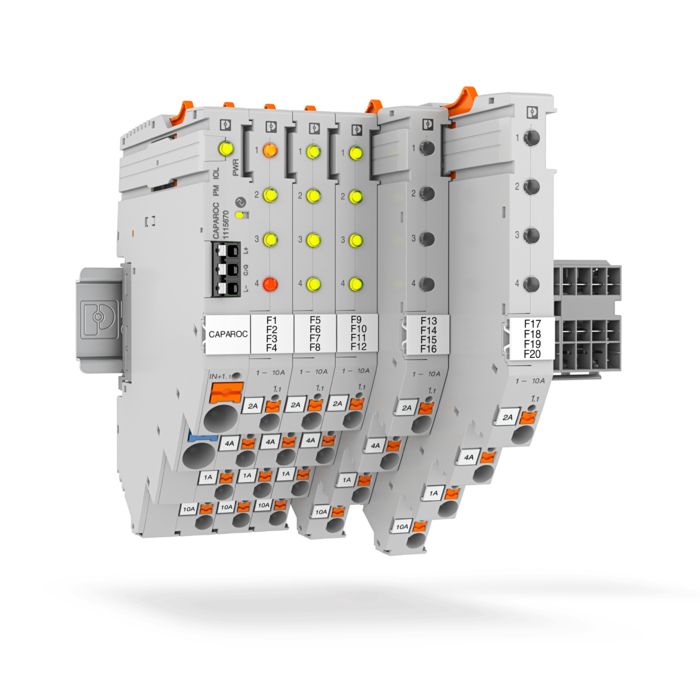

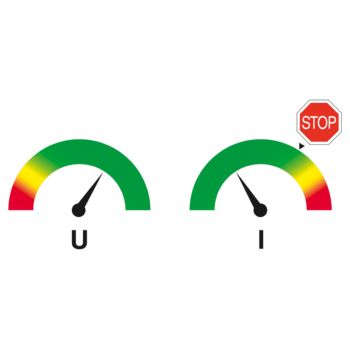

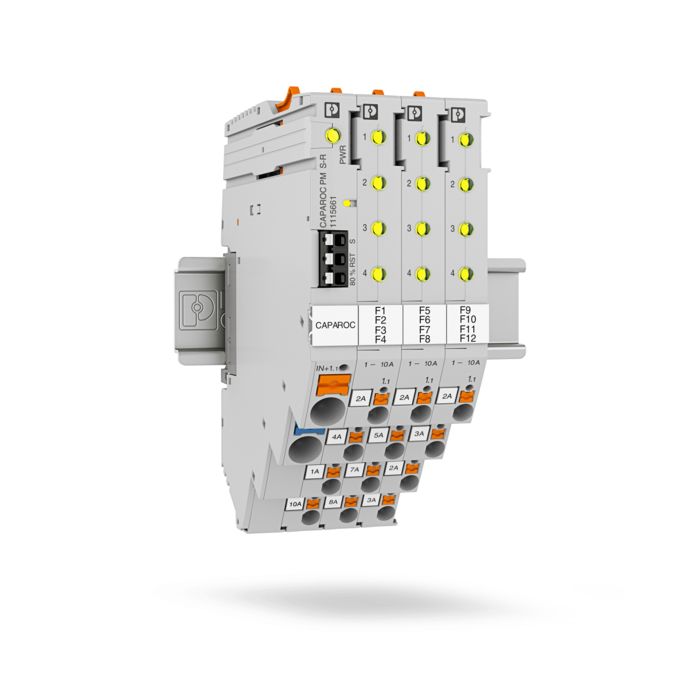

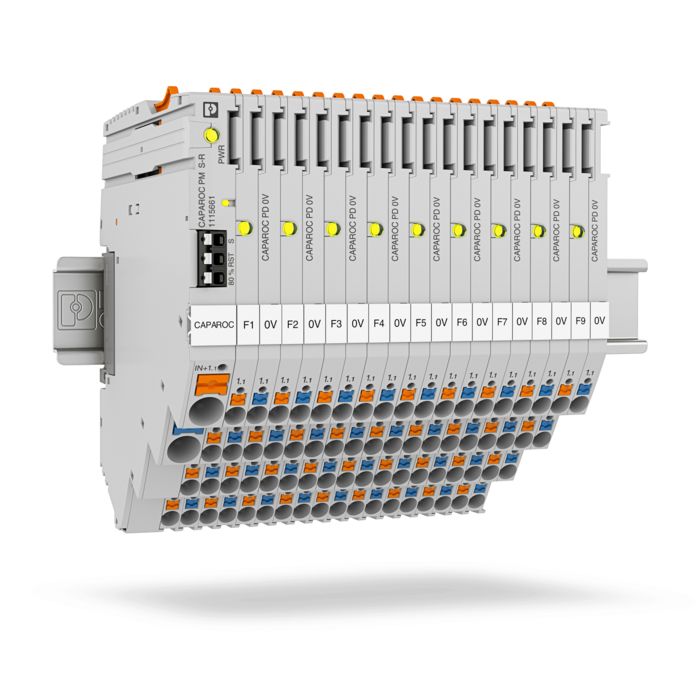

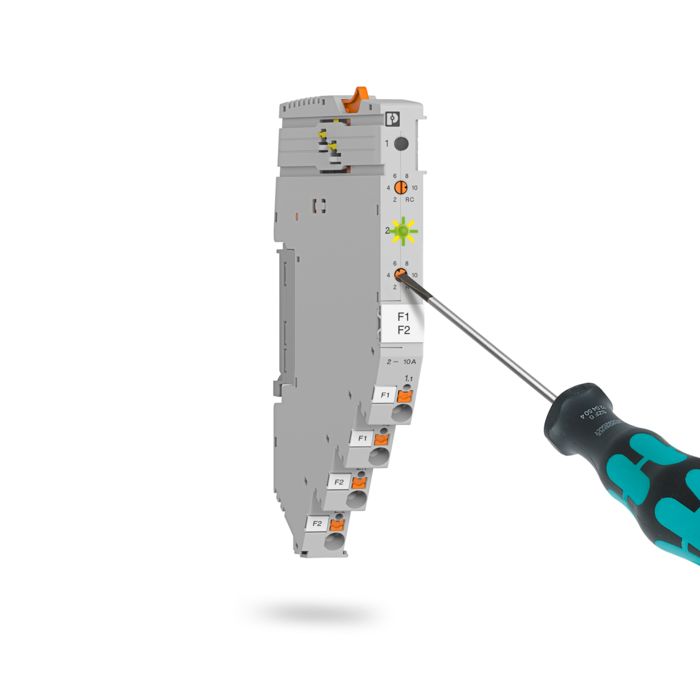

The orange nominal current assistant dials on the 2-channel modules allow load currents to be manually adjusted from 2 to 10A or 1 to 4A on the NEC Class 2 versions. The nominal current of the 1- and 4-channel modules are adjusted using single push-button operation.