PLCnext Technology - Open, IIoT-ready, Revolutionary

PLCnext is a new technology that expands the use of a PLC in ways that will change the future of automation. This state-of-the-art digital ecosystem offers an open Linux environment for edge computing with access to more data via IoT systems and more flexibility with open source code. PLCnext presents a revolutionary new development environment offering HTML5 visualization and seamless integration of high-level languages.

Your Advantages:

- It’s Linux. PLCnext Technology is completely open, allowing Linux-minded users to directly access the core of the controller for virtually limitless creative freedom.

- It’s IIoT-ready. PLCnext Technology is IIoT-ready with simple connection to common platforms including AWS, Azure, Google IoT, and more.

- It’s Revolutionary. PLCnext Technology provides a completely reimagined programming environment for standard PLC operations and integration with high-level languages.

Linux

Open access provides a means for Linux-minded users to develop new applications or migrate existing ones into the proven PLCnext Control hardware platform. This reduces lifecycle management for control hardware, while IEC 62443-4-1 standardization ensures a secure product development lifecycle.

Users can explore and take advantage of pre-developed resources and concepts, giving ideas a competitive boost. Adapt existing projects and modify features to fit your needs. Open-source, community-driven development is proven to be more efficient, reduces cost, enables cross-functional collaboration, and provides an opportunity to leverage new programming techniques for innovative applications.

IIoT-ready

IoT, IIoT, and edge computing are all buzz words in the industry. In a nutshell, users want to collect data about a system or process. PLCnext has integrated IIoT capability with direct connection to the Phoenix Contact PROFICLOUD, which is ideal for simple data dashboarding. You can also connect to 3rd party clouds including AWS, Microsoft Azure, and Google IoT for virtually endless options to access data.

PLCnext is not only a control platform, but also a gateway. A gateway to the future of data in the cloud. PLCnext can be used alone or in conjunction with an existing control system to collect data from a network or via I/O and push it to the cloud.

This means any PLC user can keep their current system and PLCnext can be used alongside it, collecting control system data via EtherNet/IP, PROFINET, or MODBUS, where it can push this information to a cloud instance. Machine builders, system integrators, and end users can quickly make their systems and processes IIoT-enabled by adding PLCnext as a gateway on the network.

Revolutionary

PLCnext Engineer enables PLC programming like never before. Users are no longer confined to a single development environment; they can utilize popular programming environments such as Microsoft Visual Studio, Eclipse, MATLAB Simulink, and more, together with PLCnext Engineer to have real-time control with advanced computation.

PLCnext Engineer also offers modern visualization using HTML5 and Adaptive Response. For simple machines or dedicated applications, the integrated visualization tools of PLCnext Engineer make it quick and easy to visualize the application on any modern device including IPCs and HMIs, smartphones, tablets, and laptops.

PLCnext ECOSYSTEM

PLCnext Technology offers something for everyone. The core message of PLCnext is “Linux, IIoT-ready, and Revolutionary”. But, if you want to know more about the complete PLCnext ecosystem, the following information will explore the PLCnext Engineer, PLCnext Store, PLCnext Control, and PROFICLOUD.

PLCnext Engineer provides an intuitive development environment with IEC 61131, HTML5 visualization, integration with high-level languages, and direct connection to PROFICLOUD for a complete IIoT-ready solution.

PLCnext Store is a new repository for libraries, applications, and solutions for PLCnext control. Users can access free applications and libraries and create their own to share. It is our goal for the PLCnext Store to become a comprehensive online marketplace for users and suppliers around the world.

PLCnext Control is the hardware that makes PLCnext Technology a reality. The Axioline F 2152 leverages the proven technology of the Axioline family which incorporates I/O modules for almost every sensor type.

PROFICLOUD is our simple, secure, easy-to-use dashboarding service designed to connect data directly from PLCnext Control to "the cloud". This service can be used today with limited functionality during its beta period.

White papers and case studies

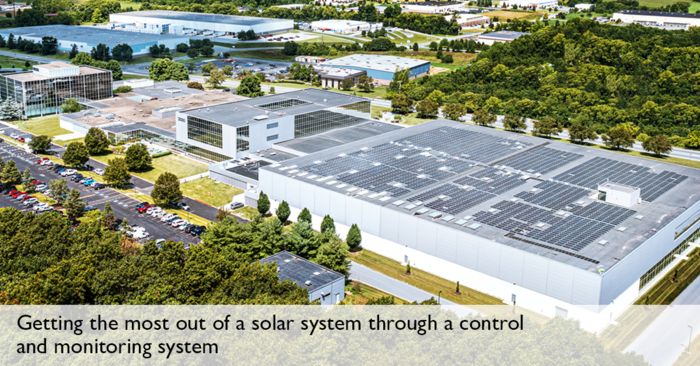

Getting the most out of a solar system through a control and monitoring system

When installing a rooftop photovoltaic system at its U.S. headquarters, the Phoenix Contact facilities team wanted to improve efficiency and plan for predictive maintenance. The control and monitoring system, built with Phoenix Contact components, provides real-time data about operations and measures progress toward long-term sustainability goals.

Auto supplier looks to implement net-zero greenhouse-gas emissions standards for its manufacturing plants around the globe

To achieve net zero emissions in its plants, an auto manufacturer integrated energy monitoring into its "Smart Factory global standard."

Automation maximizes court time and profits for gymnasiums

Litania worked with Springfield Electric to develop the Powr-Touch 6, an intuitive system that lets a gym employee control multiple systems at one time. Thanks to reliable Phoenix Contact products, such as PLCnext Technology, the Powr-Touch 6 helps gym operators maximize court usage.

Making OPC UA solutions easy to use: Efficient engineering with a hands-on approach

This paper explains the three pillars of OPC UA. While OPC UA is large in scope, this paper gives some simple steps to get started with the technology. It also explains how an automation system with a comprehensive OPC UA portfolio can help users implement OPC UA efficiently.

Creating organic fertilizer with cutting-edge plasma technology

Radom Corporation has found a unique way to create nitric acid by utilizing a microwave plasma process using only electricity,water, and air. Radom selected PLCnext Technology, which offers programming in high-level languages and can communicate with all the required industrial protocols.