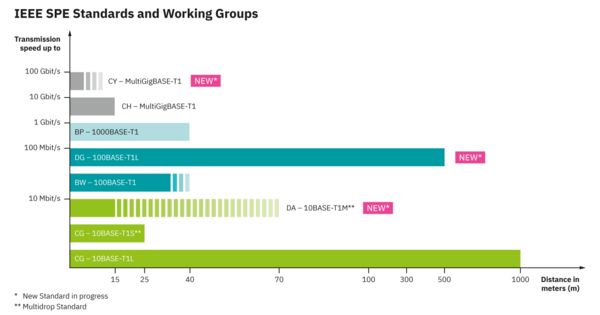

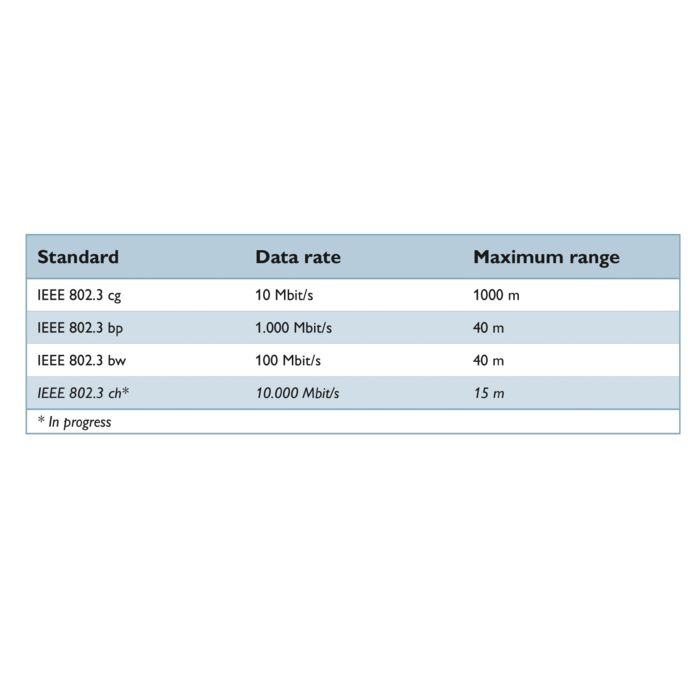

This space-saving technology is perfect for applications in the automotive industry. With transmission rates from 10 Mbps to 1 Gbps over just one twisted wire pair and a maximum cable length of 15 meters (unshielded) or 40 meters (shielded), it is ideally designed for use in vehicle cable harnesses. In addition, there are a number of new SPE standards under development that are expected to make data transfer rates up to 10 Gbps and even higher possible. In new generations of vehicles, SPE will therefore replace CAN, MOST, FlexRay, and other bus systems. Safety functions, control, and communications run uniformly via Ethernet. This is an essential prerequisite for connected or autonomous driving.