Easy installation and integration: BlueBay Automation upgrades control system for taillight manufacturer

- Installing taillight shields in vehicles relied on manual force, which caused ergonomic issues and sometimes led to product damage

- BlueBay Automation designed and installed a solution with a variety of Phoenix Contact products, including PLCnext Technology and many components with Push-in Technology (PT)

- The new solution solved the original equipment manufacturer's (OEM's) torque requirements and will provide a blueprint for future projects

Customer profile

BlueBay Automation, in Nashville, Tennessee, is the Southeast's premier automation solutions provider. BlueBay's customers include system integrators, OEMs, end users, and beyond.

Robert Barnard, applications engineer at BlueBay Automation, explained the company's proactive approach to adopting the latest technology: "At BlueBay, as soon as we find out about a new technology, it seems like we already have a project that requires that technology." (Figure 1)

Application

One of BlueBay's end customers is an automotive OEM that designs and manufactures taillights for trucks. When installing these taillights, the installation force requirements are tight and extremely critical. The OEM previously used manual force for installation. This process was inconsistent and caused product damage when taillight shields fell out. The required force for the manual process also caused ergonomic issues with the installers' thumbs.

BlueBay wanted a flexible control solution that could be used in this project and others in the future. Robert explained, "The idea was to develop a solution that can be applied to multiple projects, to multiple customers and their needs. You need something to manage all of these different solutions coming together, and that solution needs to be open. You can't have limitations with communications, features, or functionality."

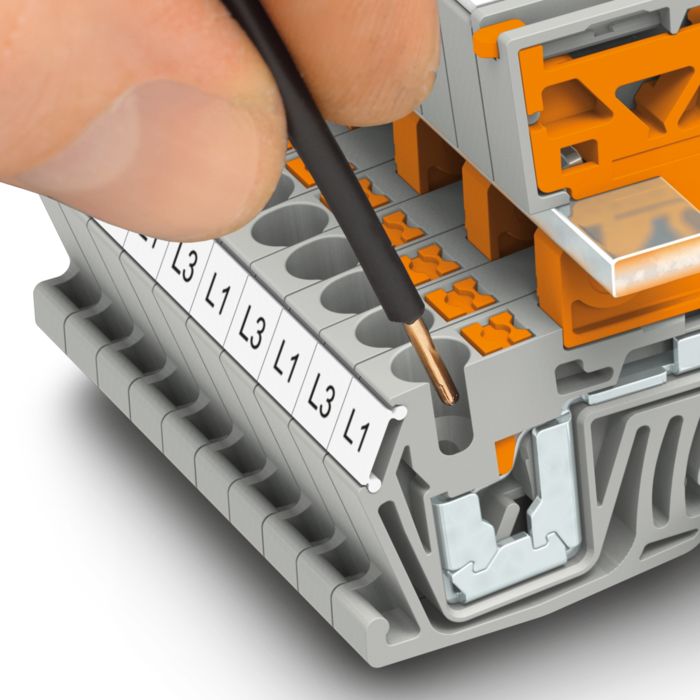

Figure 2: Push-in Technology (PT) from Phoenix Contact saves time and reduces manual labor. Phoenix Contact now offers more than 6,000 part numbers featuring this technology

Solution

Robert said, “In this application, we used a vast offering from Phoenix Contact, from breakers, terminal blocks, the Axioline (PLCnext) controller, signal conditioner, all of the DIN rails, panel ducts, and much more.”

Several of the components use Phoenix Contact’s PT Technology, which met the

OEM’s force and assembly requirements. The easy-to-use connection reduces installation time while reducing the manual strain. With the shorter timeframe, the project met the budget requirements. (Figure 2)

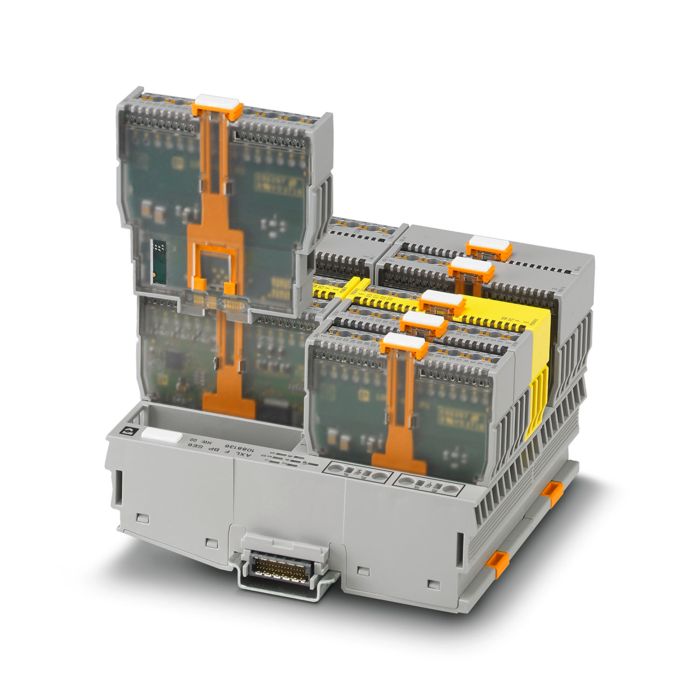

Figure 3: The Axioline SE, or Smart Elements, are extremely compact, easy, and economical

Results

The new system significantly improved the manufacturer’s ROI, and the customer will be able to deploy future projects much faster. The manufacturer’s quality, process, and visualization have also improved. Because the system uses open-source software through the PLCnext platform, it is protocol-agnostic and has nearly limitless adoption capability.

BlueBay had recently learned about Phoenix Contact's PLCnext Technology, an open control system. The controller had everything BlueBay needed in one platform: an open-source controller with a secure IIoT connection, and an integrated I/O bus.

"The controller has to be able to use all of the latest technologies that are available in the industrial sector, and with the PLCnext solution, we're finding all of those combined in one package," Robert said. "Because of the customer requirements, we found that using Node-RED as a plugin and an IIoT solution was going to be the most effective way to transmit data to their data lake."

BlueBay chose Smart Elements I/O for its small form factor and low cost. This gives them the flexibility to stock the bases and I/O modules and use them interchangeably. (Figure 3)

Figure 4: BlueBay Automation has standardized on numerous Phoenix Contact products, which are backed by a Limited Lifetime Warranty.

Summary

Because BlueBay protected the components with Phoenix Contact surge protection and power supplies, the Phoenix Contact Lifetime Limited Warranty (LLW) will cover the application – for both the integrator and the end-user.

Robert said, "The Limited Lifetime Warranty, which backs the Cabinet Confidence offering from Phoenix Contact, has really been one of the key selling points for a number of projects that we've worked on. We found solutions that really work well for our customers and us."

The use of PLCnext Technology future-proofs the project and ensures a secure IIoT solution. The customer was happy with the ease of integration for both the hardware and software. The upgraded control system will ensure higher repeatability, traceability, and efficiency.

Robert said BlueBay has "pretty much standardized with Phoenix Contact. The reason that we install multiple Phoenix Contact products in the panels is that we've had good success with their products." (Figure 4)