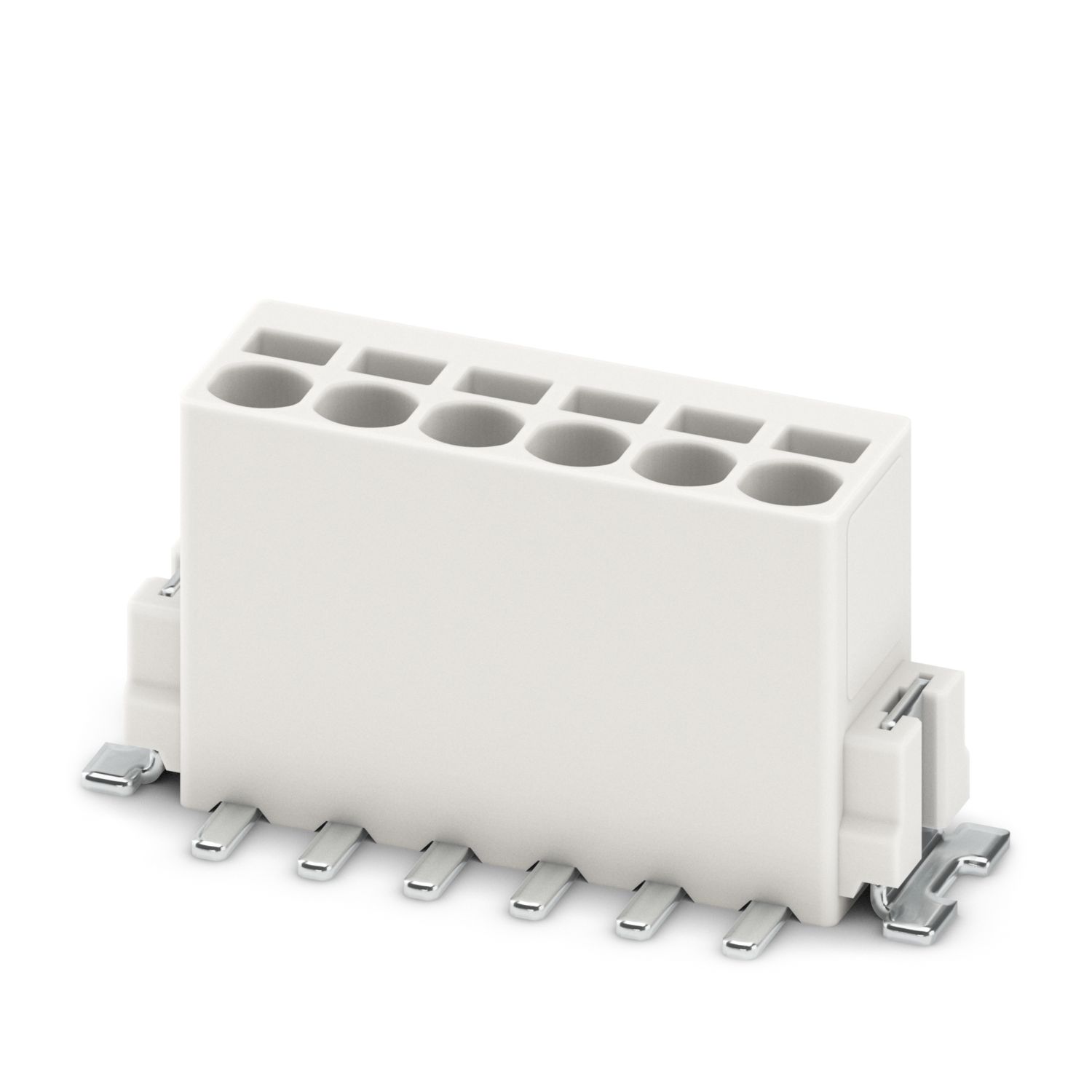

product line COMBICON Terminals XS

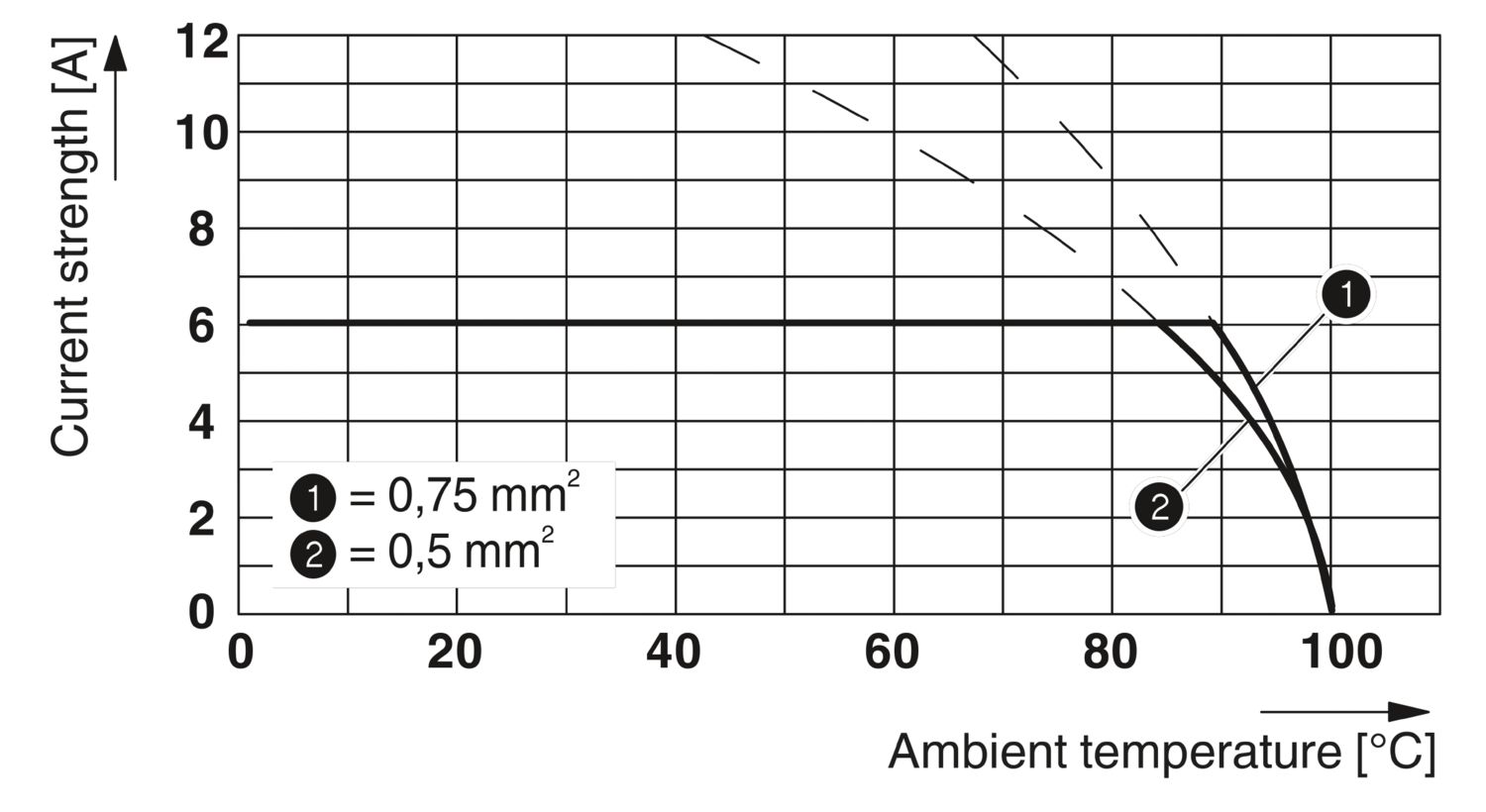

cross section 0.5 mm2

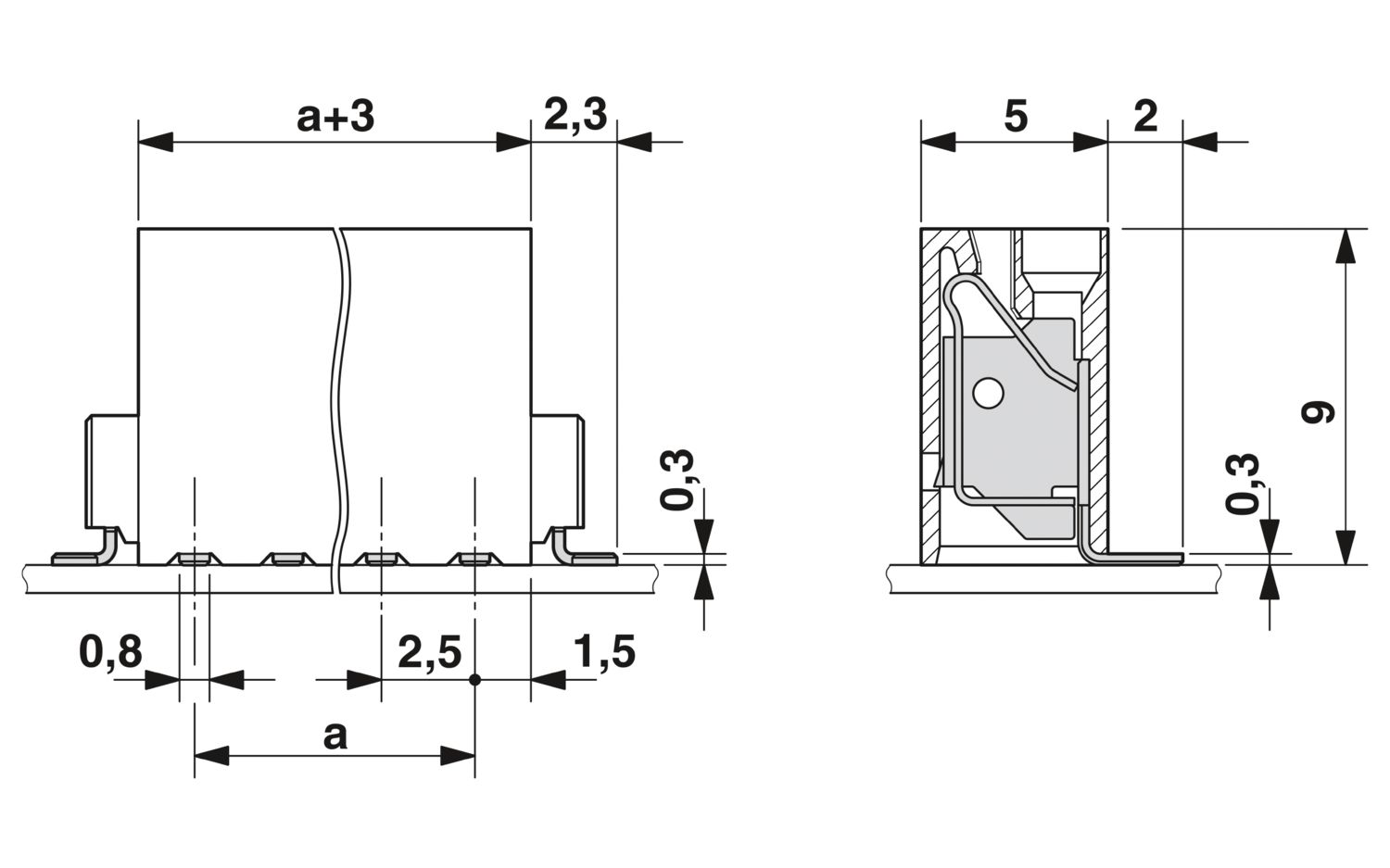

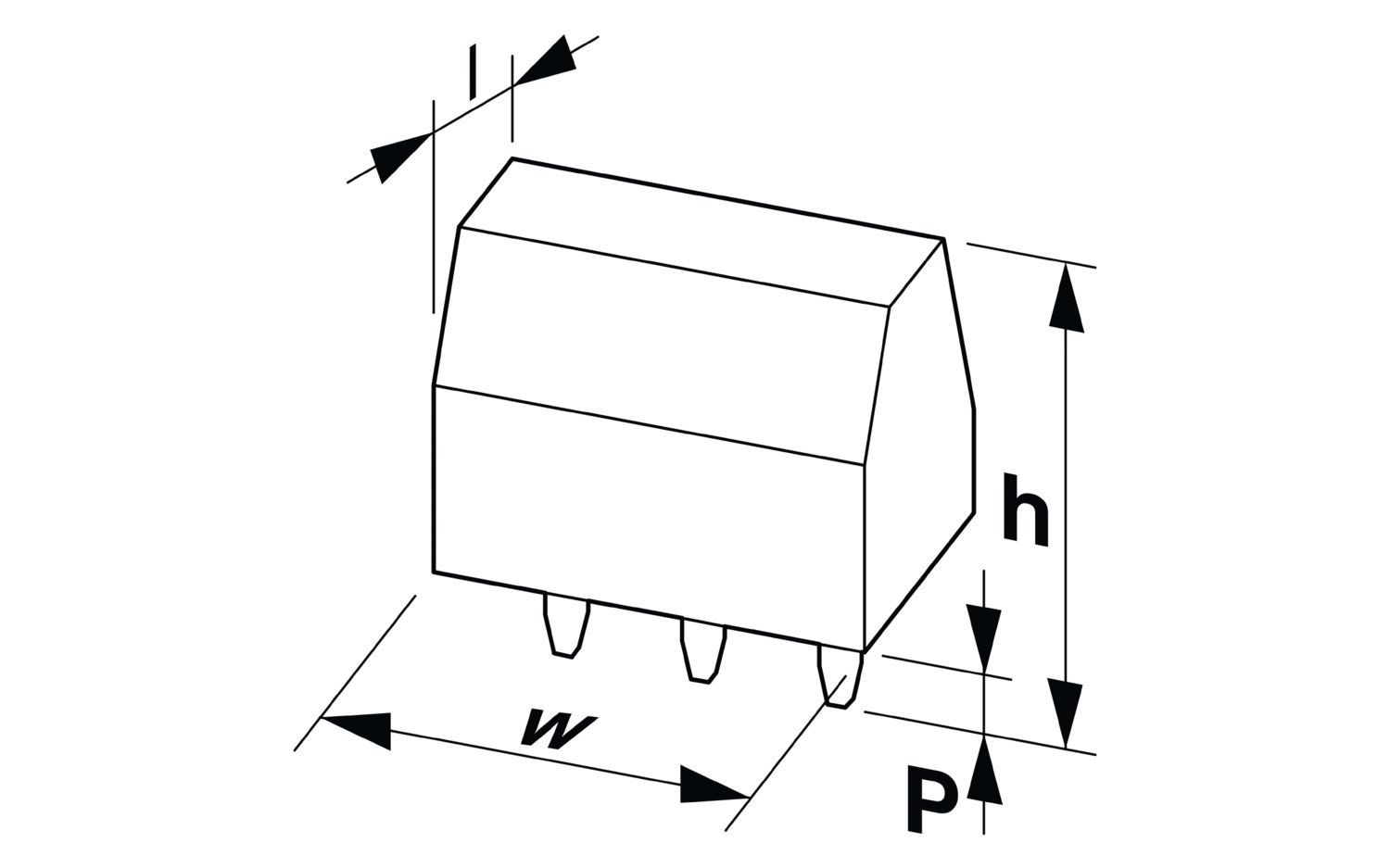

pitch 2.5 mm

connection method Push-in spring connection

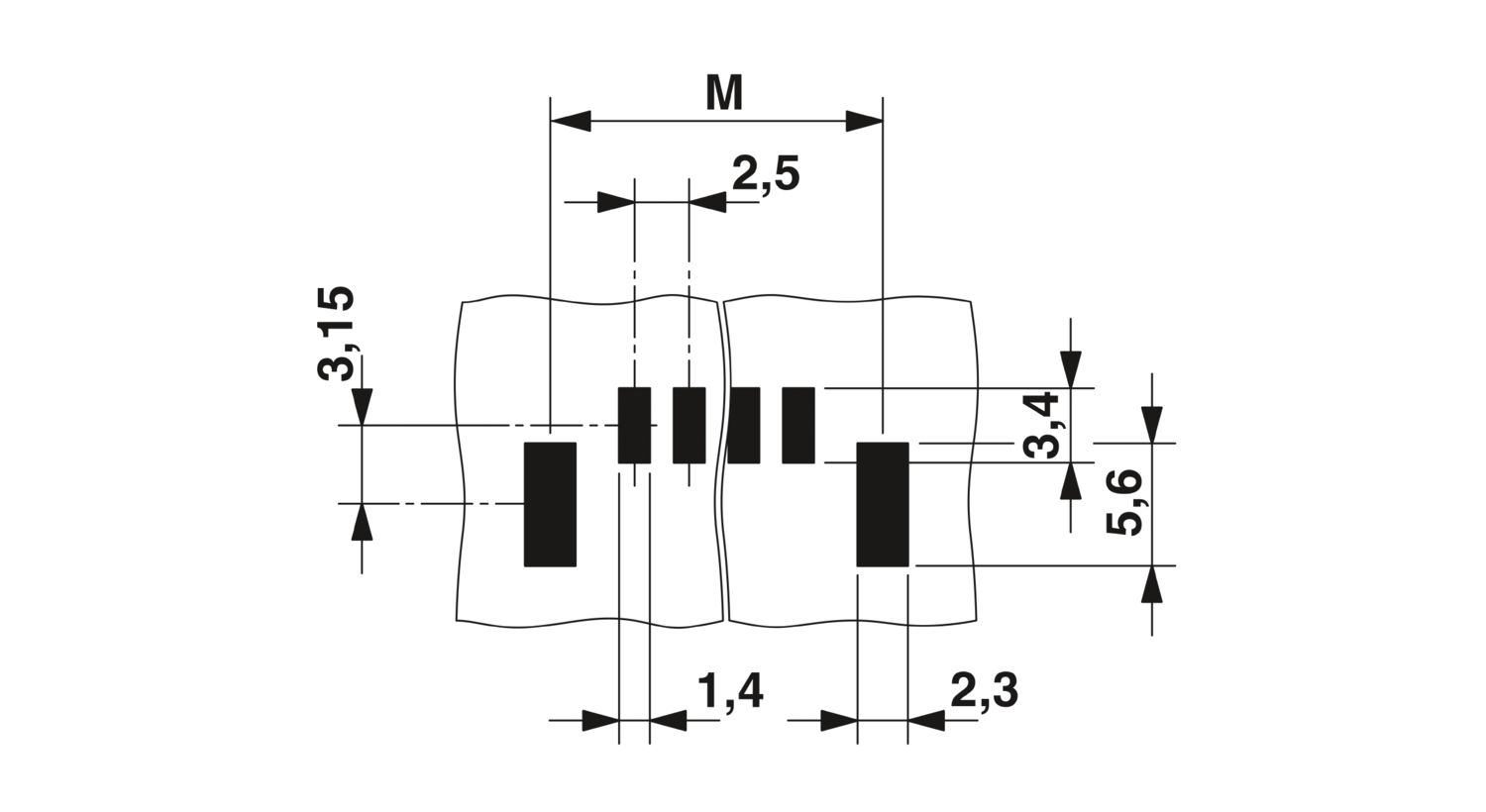

mounting type SMD soldering

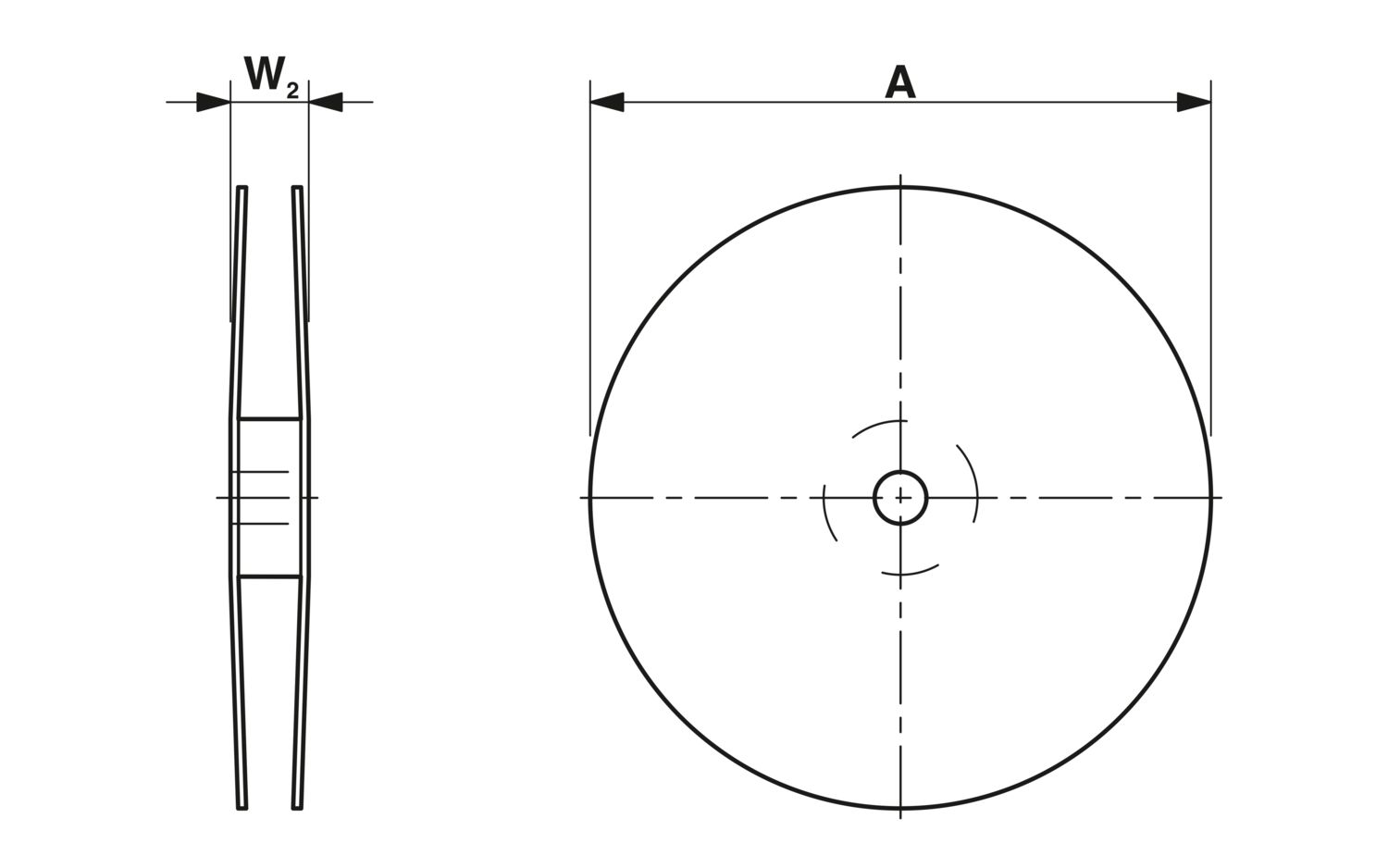

type of packaging 44 mm wide tape

Printed circuit board terminal, nominal current: 6 A, rated voltage (III/2): 160 V, nominal cross section: 0.5 mm2, number of potentials: 6, number of rows: 1, number of positions per row: 6, product range: PTSM 0,5/..-V-SMD WH, pitch: 2.5 mm, connection method: Push-in spring connection, mounting: SMD soldering, conductor/PCB connection direction: 90 °, color: signal white, Pin layout: Linear pad geometry, number of solder pins per potential: 1, type of packaging: 44 mm wide tape