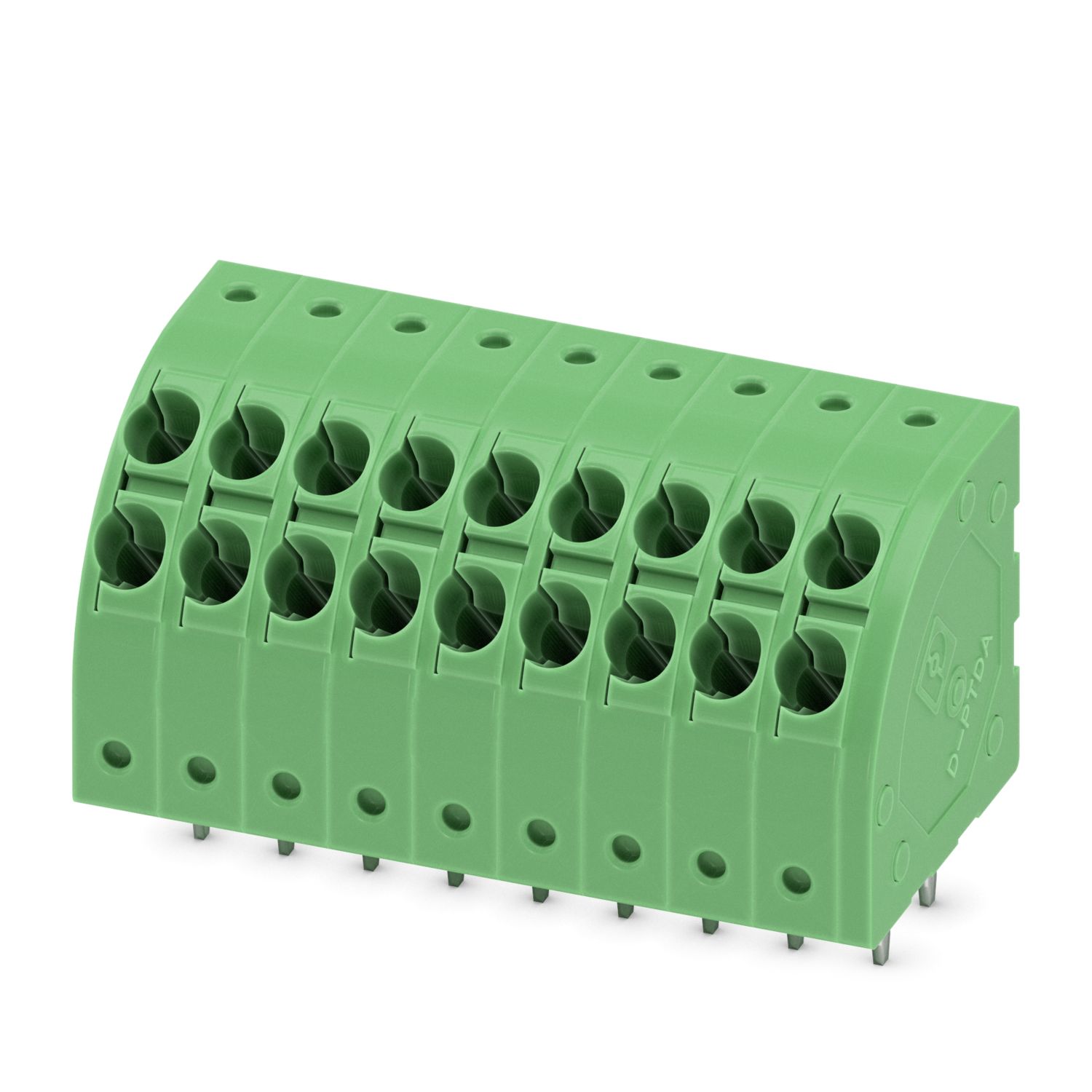

product line COMBICON Terminals S

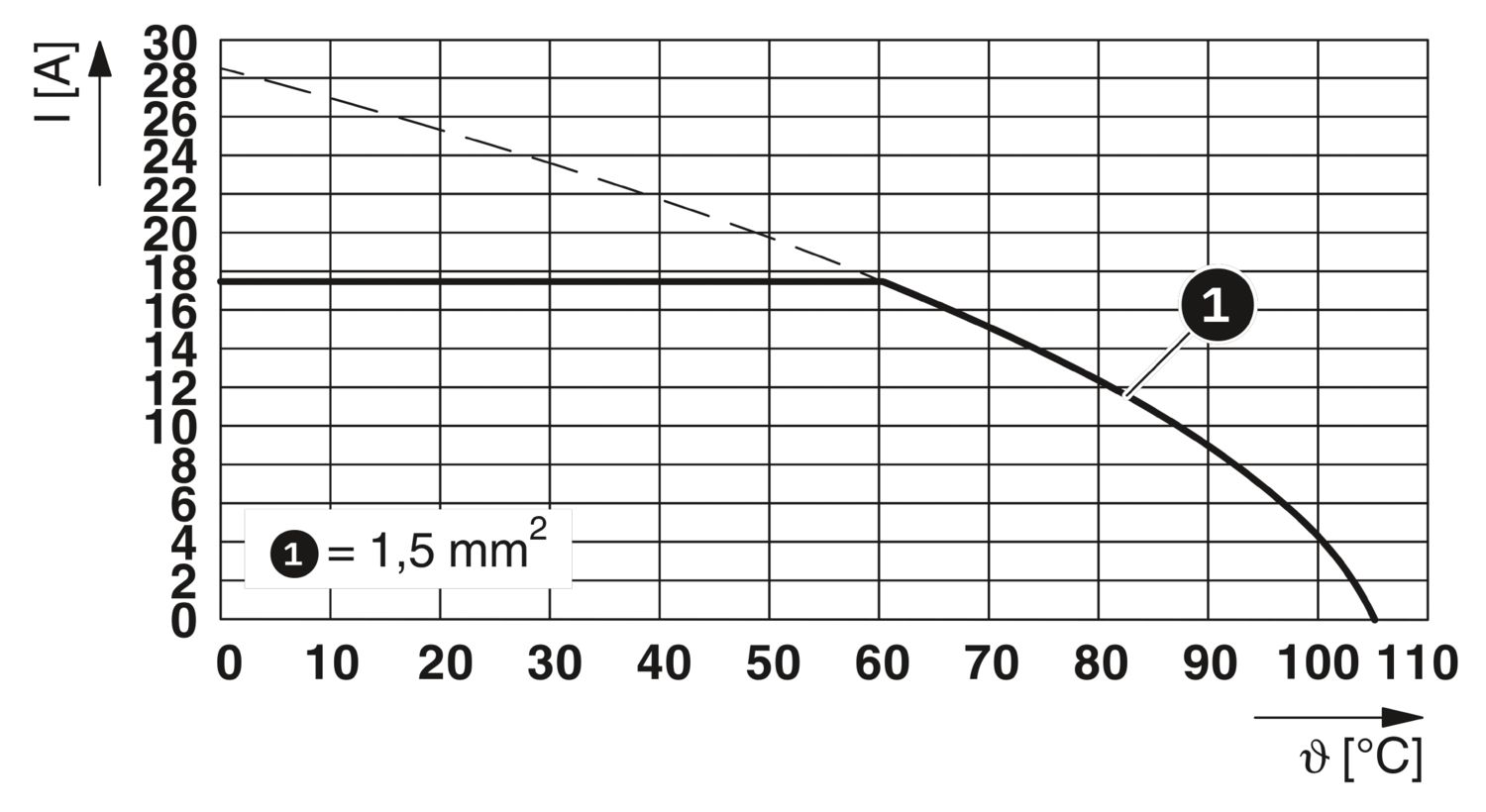

cross section 1.5 mm2

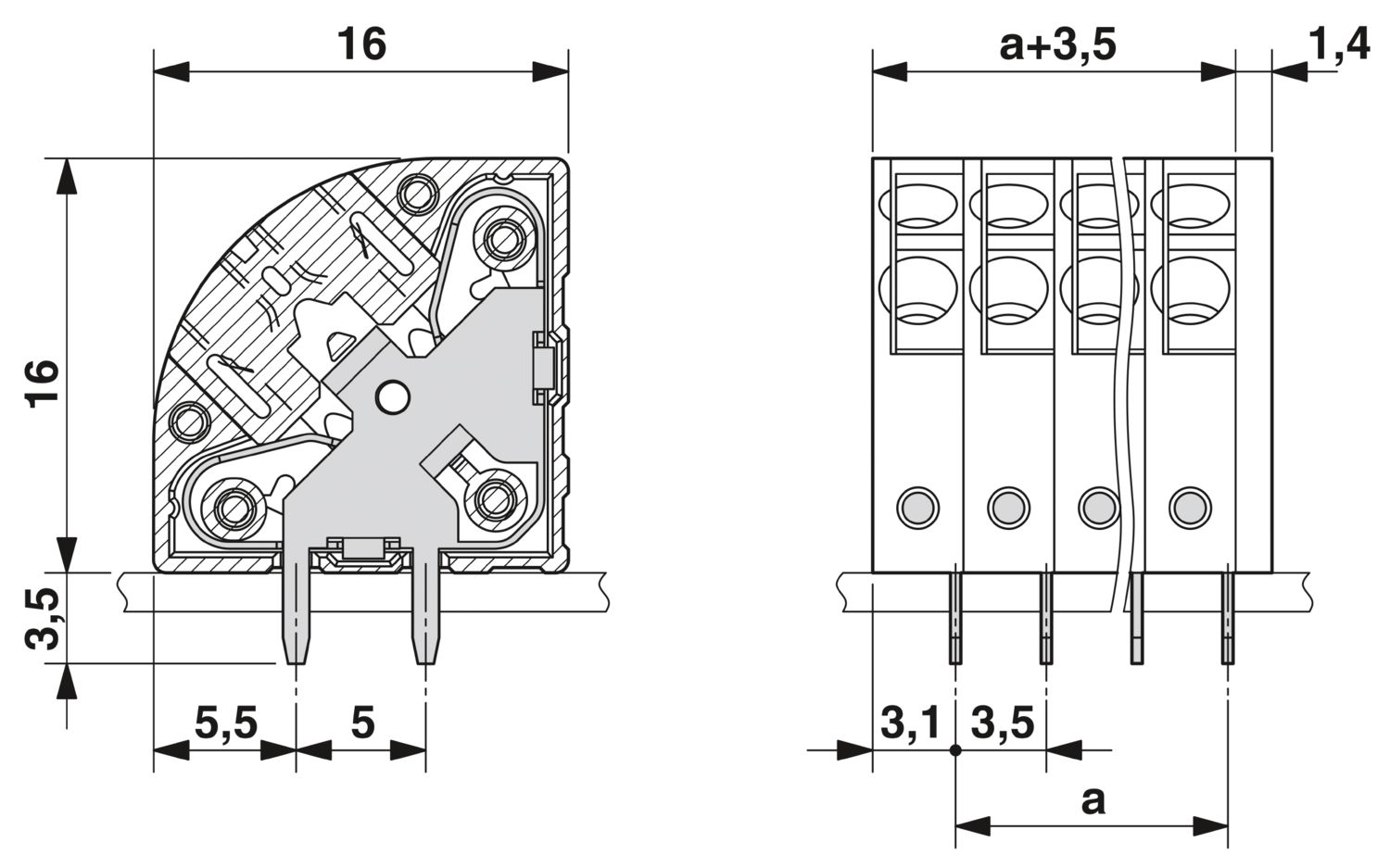

pitch 3.5 mm

connection method Push-in spring connection

mounting type Wave soldering

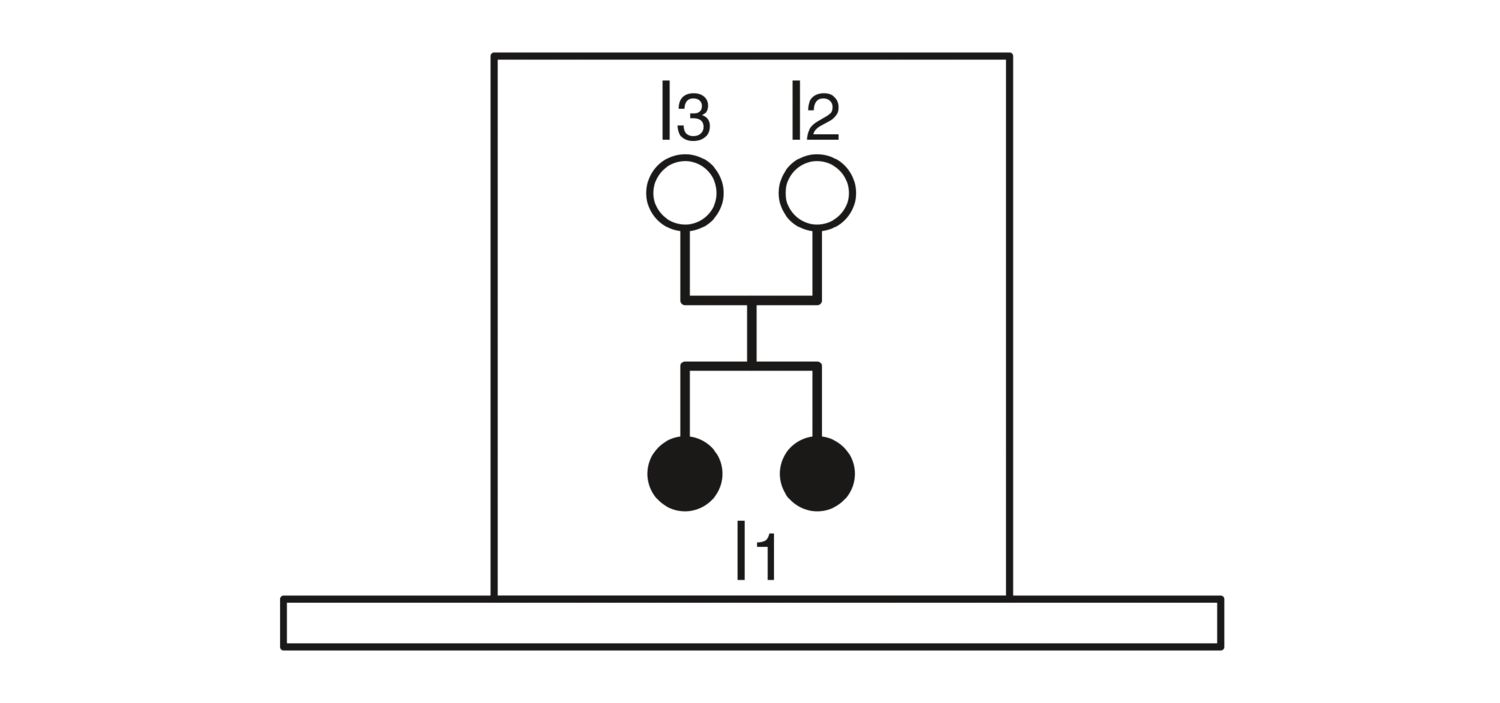

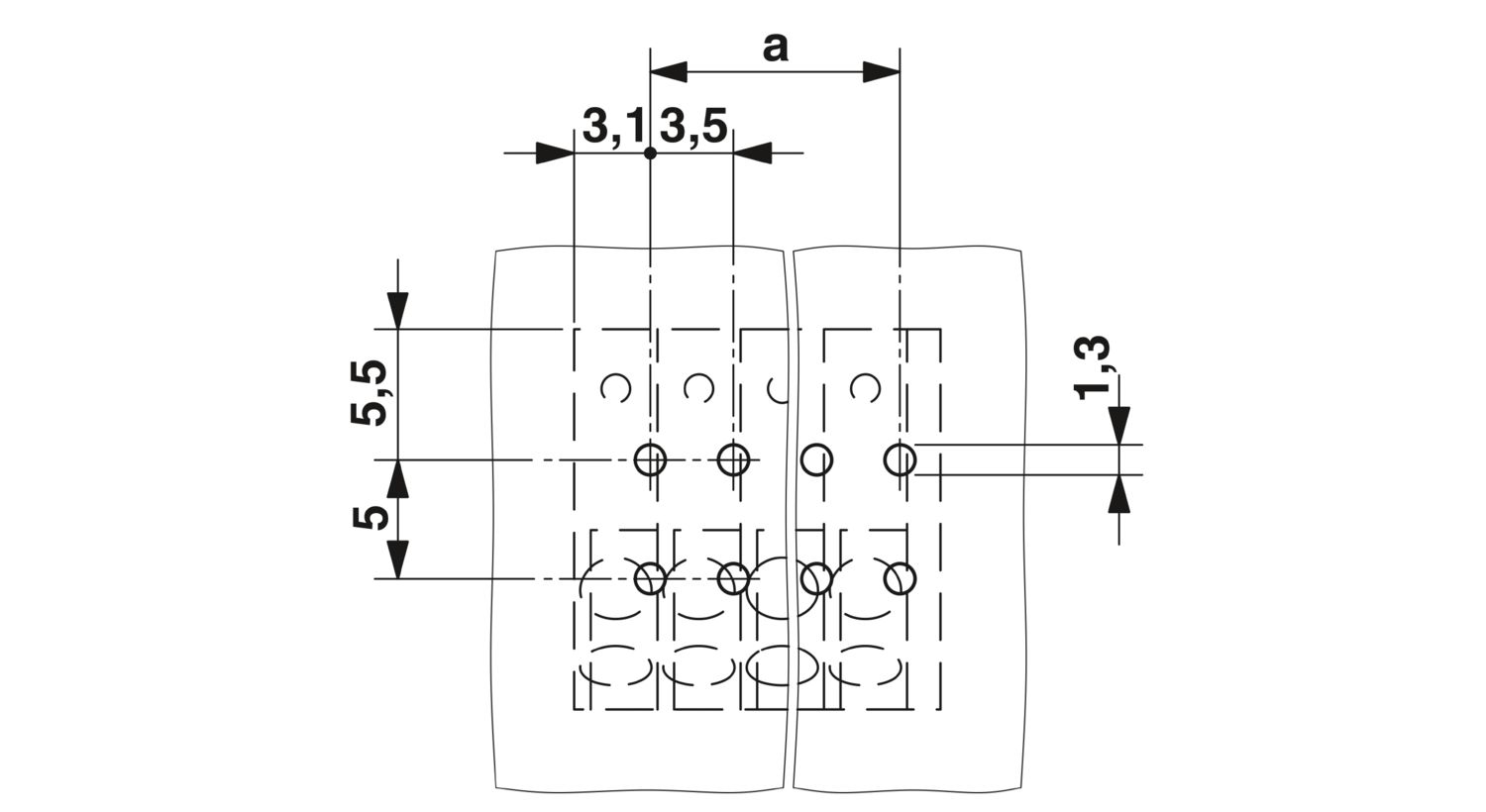

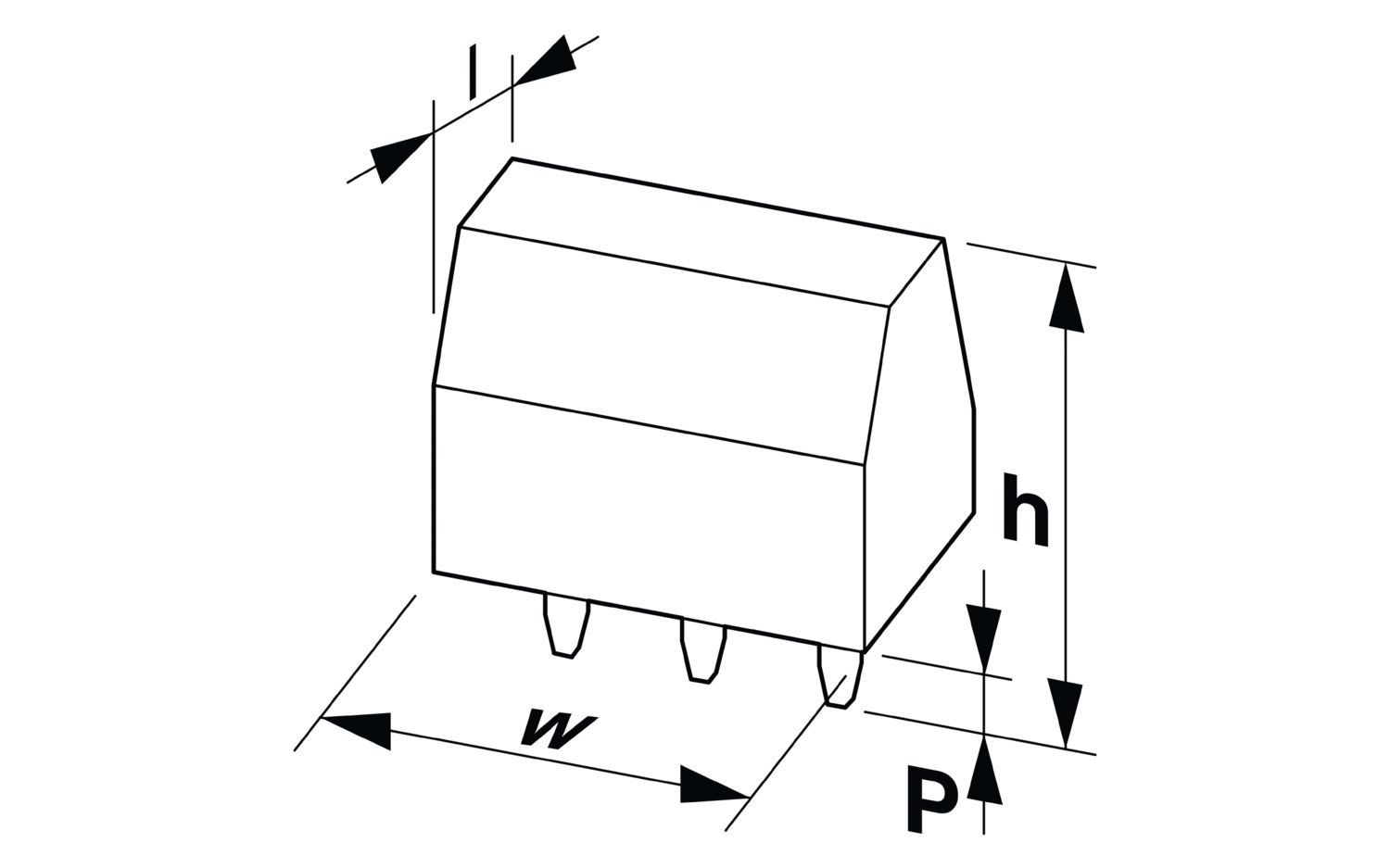

Printed circuit board terminal, nominal current: 17.5 A, rated voltage (III/2): 240 V, nominal cross section: 1.5 mm2, number of potentials: 9, number of rows: 1, number of positions per row: 9, product range: PTDA 1,5/, pitch: 3.5 mm, connection method: Push-in spring connection, mounting: Wave soldering, conductor/PCB connection direction: 45 °, color: green, Pin layout: Linear pinning, Solder pin [P]: 3.5 mm, number of solder pins per potential: 2, type of packaging: packed in cardboard