HSCP-SP 1,5-6 POWER-9005

-

PCB connector

1634000

PCB connector, nominal cross section: 1.5 mm2, color: black, nominal current: 8 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Socket, number of potentials: 6, number of rows: 2, number of positions: 6, number of connections: 6, pitch: 5.08 mm, connection method: Push-in spring connection, conductor/PCB connection direction: 0 °, locking clip: - Locking clip, plug-in system: HSC 1,5, locking: without, mounting method: without, type of packaging: packed in cardboard

This product needs further products for operation.

Mandatory accessories

Product details

| Product type | PCB connector |

| Product family | HSCH-SP 1,5-..POWER |

| Number of positions | 6 |

| Pitch | 5.08 mm |

| Number of connections | 6 |

| Number of rows | 2 |

| Number of potentials | 6 |

| Mounting flange | without |

| Properties | |

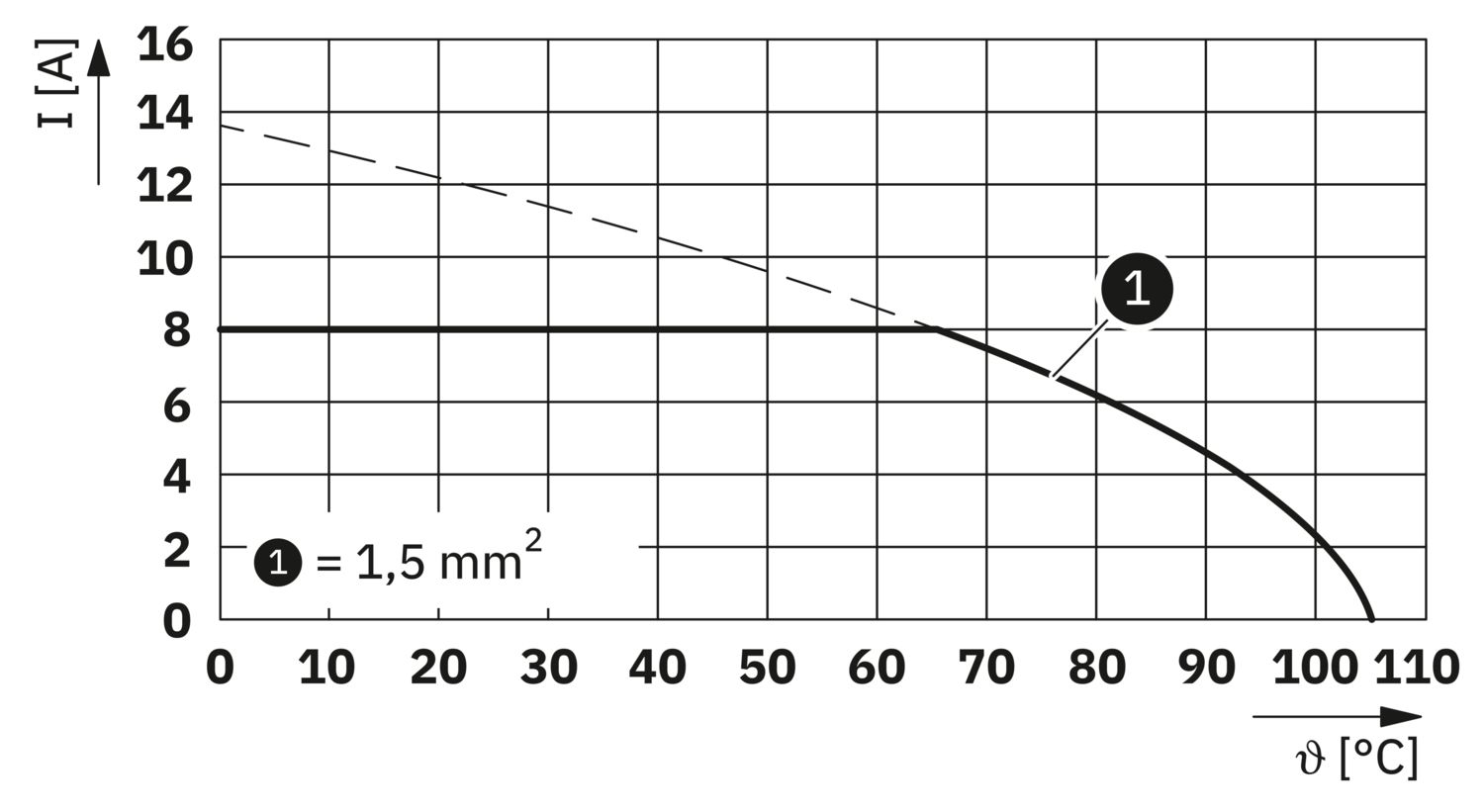

| Nominal current IN | 8 A |

| Nominal voltage UN | 300 V |

| Contact resistance | 2.39 mΩ |

| Rated voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| Rated voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| Rated voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| Connection technology | |

| Connector system | HSC 1,5 |

| Nominal cross section | 1.5 mm² |

| Contact connection type | Socket |

| Interlock | |

| Locking type | without |

| Mounting flange | without |

| Conductor connection | |

| Connection method | Push-in spring connection |

| Conductor/PCB connection direction | 0 ° |

| Conductor cross section rigid | 0.5 mm² ... 1.5 mm² |

| Conductor cross section flexible | 0.5 mm² ... 1.5 mm² |

| Conductor cross section AWG | 24 ... 16 |

| Conductor cross section flexible, with ferrule without plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Conductor cross section, flexible, with ferrule, with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Cylindrical gauge a x b / diameter | 2.4 mm x 1.5 mm / 1.9 mm |

| Stripping length | 10 mm |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | Tin-plated |

| Metal surface terminal point (top layer) | Tin (Sn) |

| Metal surface contact area (top layer) | Tin (Sn) |

| Material data - housing | |

| Color (Housing) | black (9005) |

| Insulating material | PBT |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

| Material data – actuating element | |

| Color (Actuating element) | deep orange (2011) |

| Insulating material | POM |

| Flammability rating according to UL 94 | V0 |

| Pitch | 5.08 mm |

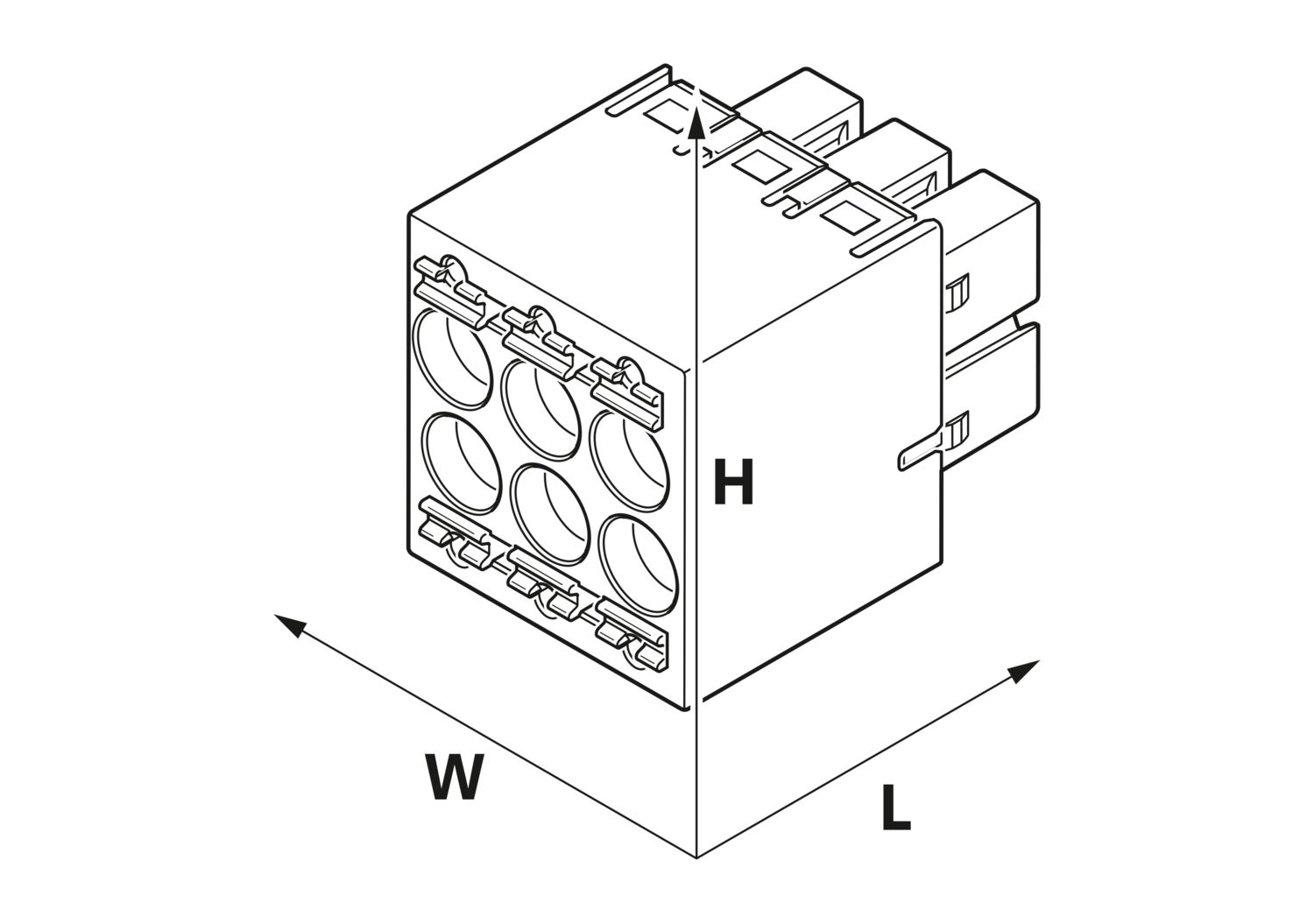

| Width [w] | 16.06 mm |

| Height [h] | 17.05 mm |

| Length [l] | 22.35 mm |

| Assembly note | Please observe the application note in the download area. |

| Safety note | |

| Safety note | WARNING: The connectors may not be plugged in or disconnected under load. Ignoring the warning or improper use may damage persons and/or property. |

| • WARNING: Commission properly functioning products only. The products must be regularly inspected for damage. Decommission defective products immediately. Replace damaged products. Repairs are not possible. | |

| • WARNING: Only electrically qualified personnel may install and operate the product. They must observe the following safety notes. The qualified personnel must be familiar with the basics of electrical engineering. They must be able to recognize and prevent danger. The relevant symbol on the packaging indicates that only personnel familiar with electrical engineering are allowed to install and operate the product. | |

| • The item is intended to be an unencapsulated plug for installation in a housing. | |

| • Operate the connector only when it is fully plugged in. | |

| Conductor connection | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Repeated connection and disconnection | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60999-1:1999-11 |

| Conductor cross section/conductor type/tractive force setpoint/actual value | 0.5 mm² / solid / > 10 N |

| 0.5 mm² / flexible / > 10 N | |

| 1.5 mm² / solid / > 40 N | |

| 1.5 mm² / flexible / > 40 N | |

| Insertion and withdrawal forces | |

| Specification | IEC 60512-13-2:2006-02 |

| Result | Test passed |

| No. of cycles | 25 |

| Insertion strength per pos. approx. | 6 N |

| Withdraw strength per pos. approx. | 3 N |

| Polarization and coding | |

| Specification | IEC 60512-13-5:2006-02 |

| Result | Test passed |

| Visual inspection | |

| Specification | IEC 60512-1-1:2002-02 |

| Result | Test passed |

| Dimension check | |

| Specification | IEC 60512-1-2:2002-02 |

| Result | Test passed |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Durability test | |

| Specification | IEC 60512-9-1:2010-03 |

| Impulse withstand voltage at sea level | 4.8 kV |

| Contact resistance R1 | 2.39 mΩ |

| Contact resistance R2 | 2.43 mΩ |

| Insertion/withdrawal cycles | 25 |

| Climatic test | |

| Specification | EN ISO 22479:2022-06 |

| Corrosive stress | 0.2 dm3 SO2 on 300 dm3/40 °C/1 cycle |

| Thermal stress | 105 °C/168 h |

| Power-frequency withstand voltage | 2.21 kV |

| Glow-wire test | |

| Specification | IEC 60695-2-11:2021-10 |

| Temperature | 650 °C |

| Time of exposure | 30 s |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 70 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Thermal test | Test group C | |

| Specification | IEC 60512-5-1:2002-02 |

| Tested number of positions | 6 |

| Insulation resistance | |

| Specification | IEC 61984:2008-10 |

| Insulation resistance, neighboring positions | >1 GΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| minimum clearance value - non-homogenous field (III/3) | 3 mm |

| minimum creepage distance (III/3) | 3.2 mm |

| Rated insulation voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| minimum clearance value - non-homogenous field (III/2) | 3 mm |

| minimum creepage distance (III/2) | 3 mm |

| Rated insulation voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| minimum clearance value - non-homogenous field (II/2) | 3 mm |

| minimum creepage distance (II/2) | 3.2 mm |

| Type of packaging | packed in cardboard |

| Outer packaging type | Carton |

| Item number | 1634000 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Product key | ACHEBF |

| GTIN | 4067923154278 |

| Weight per piece (including packing) | 6.112 g |

| Weight per piece (excluding packing) | 6.112 g |

| Country of origin | CN |

ECLASS

| ECLASS-13.0 | 27460202 |

| ECLASS-15.0 | 27460202 |

ETIM

| ETIM 9.0 | EC002638 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

-

ME-IO-S 24 COUPLER 100 7035 - Electronics housing 1569887

-

ME-IO-S 55 CPU 100 7035 - Electronics housing 1632614

-

ME-IO-S 12 IO 100 7035 - Electronics housing 1569889

-

HSCP-SP 1,5-18-IO-7035 - PCB connector 1569965

-

ME-IO-S COVER 100 7035 - Lateral element 1569961

-

ME-IO-S BUS8-9005 - Bus connector 1569885

-

ME-IO-S FE CONTACT SMT - Functional ground contact 1569960

-

CUC-USB3.1-J1ST-AH/UCF-SMD/THR - USB PCB connectors 1332643

-

CUC-SP-J1ST-A/R4LB-LED - RJ45 PCB connector 1149866

-

SZS 0,4X2,0 - Screwdriver 1205202

-

SZS 0,4X2,5 VDE - Screwdriver 1205037

Your advantages

Time saving push-in connection, tools not required

Defined contact force ensures that contact remains stable over the long term

Intuitive operation due to color-coded actuating push button

Operation and conductor connection from one direction enable integration into front of device

Quick and convenient testing using integrated test option

User-friendly front connection plug for high contact densities

PHOENIX CONTACT

586 Fulling Mill Road, Middletown, PA 17057