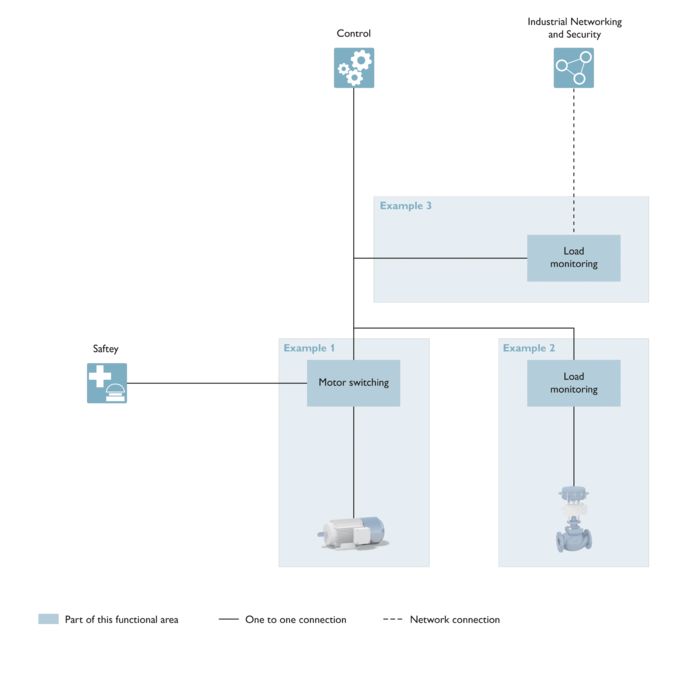

Load switching in machine building

Electric motors are used in a variety of industrial applications for controlling movements. Motors are often started and reversed using classic, mechanical protective circuits. However, these require a great deal of space as well as a lot of wiring effort, and have a limited service life. Complex sensor technology is often required to collect important motor and process data.

Load switching

The COMPLETE line system provides high-quality solutions for switching and monitoring loads.

Example 1

Compact and practically wear-free motor starters can switch loads over a much longer service life than electromechanical versions. Moreover, they can be integrated into safety concepts and communication networks. They switch motors and other loads reliably and safely.

Example 2

This advanced technology also enables the acquisition of performance data. Here, the ability to detect over- and underload states enables preventive maintenance and the avoidance of mechanical damage to the loads.

Example 3

The machine manager also reliably monitors powerful loads and transmits key parameters to higher-level networks.