Tunnel drainage With our monitoring and control solutions for pumping stations, you can realize a more energy-efficient and long-term system operation.

The challenge

Flood and contaminated wastewater

Extreme weather events, plus the proximity to the water table, call for complex drainage systems in tunnels. Not only must flooding be prevented, but flammable liquids such as fuel and contaminated extinguishing water also need to be transported out of the tunnel safely. The continuous monitoring of pump availability is essential for the protection of tunnel users and underground facilities.

Solution

Intelligent pump automation

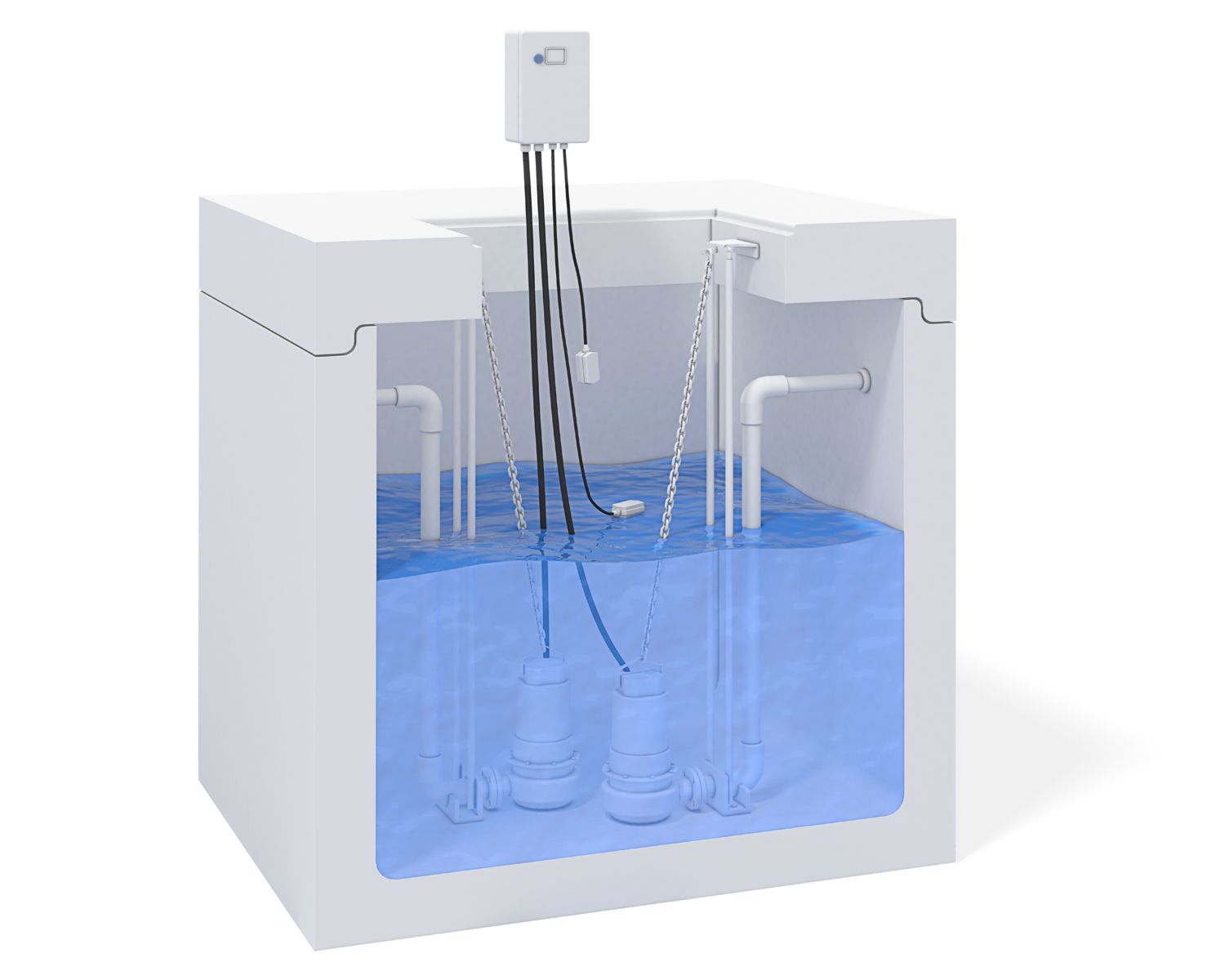

Drainage pumping stations prevent flooding of the tunnel during storms and provide drainage of contaminated extinguishing water in emergency situations. The water that enters the tunnel is first collected there, before being routed into the sewerage system. High-availability pumps are needed to move these quantities of water.

In addition to redundant network and control infrastructures, Phoenix Contact provides solutions for performance monitoring and reliable closed-loop control of the drainage pumps, even in the event of a communication failure.

Based on the changing water level, the PLC controls several pumps in accordance with their operating hours and number of motor starts. Together with detailed diagnostics, monitoring, and data logging features, the system guarantees reliable and energy efficient operation in tunnels. Every anomaly is transmitted to the higher-level control system for the purposes of predictive maintenance.

Protection against hazardous chemicals

Toxic or explosive fluids can enter the drainage system either through normal traffic or in the event of an accident or fire. The water is therefore continuously monitored for dangerous chemicals, such as fuel and contaminated extinguishing water, before it enters the pumping station. If the situation is hazardous, protective measures are introduced or the pump system is shut down completely.

Predictive maintenance

With our holistic monitoring and control solutions for pumping stations, you can realize a more energy-efficient and long-term operation. The collection of relevant measured variables, such as vibrations, temperatures, and seals enables predictive maintenance. This ensures optimum operation of your pumps and reliable drainage of your tunnel structure.

Your advantages

- Minimization of maintenance and repair work with predictive maintenance

- Reduced energy consumption through optimum pump operation

- Detailed recording of operating data, such as operating hours, temperature, and water levels

Contact

Products

Still haven’t found the right product?

Feel free to contact us. We will consult with you to find the ideal solution together.