Control and monitoring of electric trace heating Increase your system availability by detecting failures early and avoiding system downtime.

The challenge

Monitoring trace heating systems

Older trace heating systems are often only connected to the grid by a fuse, which means that failures often go unnoticed. In the event of a failure, the entire operation usually comes to a standstill. For this reason, the individual trace heating systems are examined regularly during a special inspection round. Our customized and scalable monitoring solution for aging systems provides a remedy. Get up-to-date status information on your trace heating systems directly in the distributed control system so that you can initiate countermeasures at an early stage.

The solution

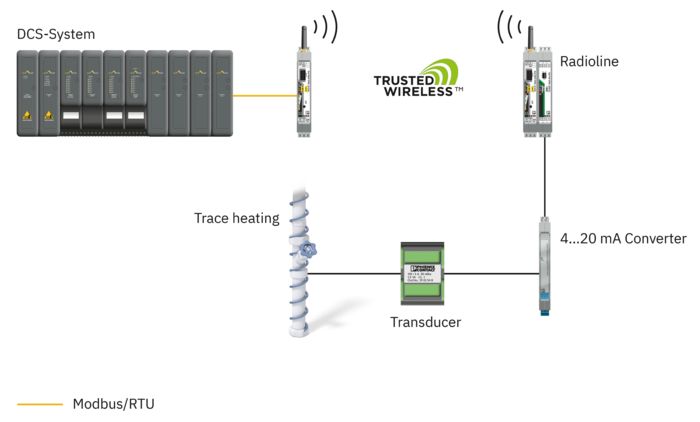

Simple assurance via current measurement

Our current transducers detect the current of the heating system. This method ensures that an open circuit, short circuit, or insulation fault in the trace heating system can be identified. Monitoring the current guarantees that the medium to be transported is transported safely.

These devices are combined with our Radioline wireless system to transmit the measuring signals to the control room without the need for complex cabling. The Radioline client polls up to 99 Radioline stations. You can connect several trace heaters to each station. This allows you to easily monitor any number of trace heating systems.

Ready-to-use control cabinet solution

Benefit from quick and easy installation with our pre-assembled, ready-to-use control box.

Whether for monitoring or controlling your trace heating, we offer you the right control cabinet solution for your individual requirements. Our SIL 2-capable connector solutions ensure that the temperature sensor always monitors the correct heating strip.

Reduced energy consumption

Control your trace heating as needed via the local PLC. Configuration is via an existing HMI or a laptop that you connect via WLAN. Alternatively, you can simply integrate the trace heating into your control system. Integration is via an interface that is compliant with Modular Type Package (MTP). By setting parameters via PROFIsafe in compliance with SIL 2, you define the switch-off parameters for your trace heating.

Use only as much energy as needed with our intelligent controller. A temperature sensor ensures that the heating is only turned on when required via a configurable limit switch. Using a small-scale controller allows targeted and precise power control. In this scenario, the heat output is adjusted by means of pulse width modulation.

Engineering software for control cabinet building

The clipx ENGINEER engineering software enables the efficient planning of terminal strips, the placement of industrial electronics, and the design of mounting plates.

Transfer the existing solution for trace heating systems as a template into our clipx ENGINEER tool. With just a few clicks, you can adapt our solutions perfectly to your needs. You can then order the solution with individual items or pre-assembled using our tool in the Phoenix Contact online store.

Your advantages

- Increased system availability due to continuous and SIL-2-compliant monitoring of the heating strips

- Optimization of your energy consumption with targeted and precise power control

- Low installation costs due to the preassembled, ready-to-use control box

- Easy integration of existing heat tracing in your control room

Contact person

Reference

Wireless-based trace heating monitoring at Sappi Stockstadt GmbH

- Sappi Limited is a leading global supplier of paper, paper pulp, and chemical pulp solutions.

- Find out more about how abnormal readings are immediately displayed in the operator control center so that countermeasures can be initiated at an early stage.

Products

Still haven’t found the right product?

Feel free to contact us. We will give you advice and work with you to find the ideal solution.