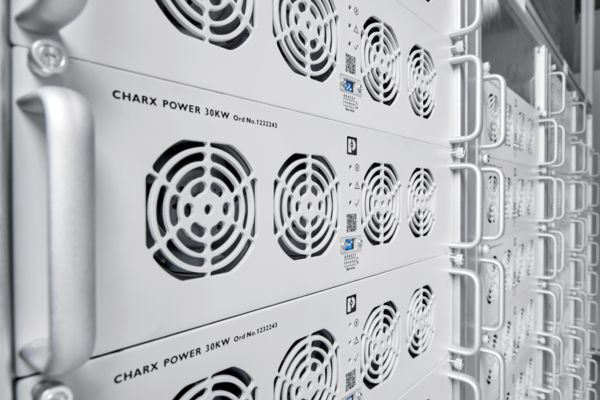

CHARX AC/DC converters based on IGBT or SiC technology are used for the DC power supply. With an efficiency of up to 97 percent, it is significantly superior to monolithic converters. With a controllable DC output voltage range of 30 to 1000 V, they can be adapted to the operating voltage of different electrolysis stacks. Both the operating voltage and the output current can be ramped up slowly via a ramp function. The converters have an internal electrical isolation between the AC and DC grids. This is vitally important for the design of the power supply of many electrolyzers.